Hebben uw productielijnen in de auto-industrie te kampen met ruimtebeperkingen en uitdagingen op het gebied van precisie? Veel ingenieurs in de automobielsector vinden dat traditionele pneumatische cilinders niet de compacte, hoogwaardige oplossingen kunnen leveren die nodig zijn voor moderne productieprocessen. Dit is waar staafloze cilinders het spel veranderen.

Pneumatische cilinders zonder stangen transformeren de autoproductie door ruimtebesparende ontwerpen voor lastoepassingen te leveren, zeer nauwkeurige positionering voor assemblagelijnen mogelijk te maken en te voldoen aan de strenge eisen van contaminatiebeheersing in cleanroomomgevingen. Dit resulteert in een tot 50% kleiner machineoppervlak en een verbetering van de positioneringsnauwkeurigheid met 30-40%.

Ik werk al meer dan tien jaar rechtstreeks met toonaangevende automobielfabrikanten en ik heb uit de eerste hand gezien hoe de staafloze cilindertechnologie enkele van hun meest hardnekkige automatiseringsuitdagingen heeft opgelost. Ik zal u de belangrijkste toepassingen laten zien waar deze innovatieve componenten de grootste impact hebben.

Inhoudsopgave

- Hoe verbeteren staafloze cilinders de integratie van laspistolen?

- Wat maakt stangloze cilinders essentieel voor assemblagelijnpositionering?

- Wat maakt stangloze cilinders ideaal voor cleanroomomgevingen in de auto-industrie?

- Conclusie

- Veelgestelde vragen over staafloze cilinders in autotoepassingen

Hoe verbeteren staafloze cilinders de integratie van laspistolen?

Lasstraten in de auto-industrie zijn drukke, snelle omgevingen waar elke millimeter ruimte telt. Traditionele pneumatische oplossingen creëren vaak meer problemen dan ze oplossen.

Staafloze cilinders verbeteren de integratie van laspistolen door een compacte, krachtige oplossing te bieden voor het positioneren van zware puntlaspistolen in robotwerkcellen met beperkte ruimte. Het ontwerp elimineert de externe zuigerstang, waardoor de benodigde installatielengte met bijna 50% wordt verminderd in vergelijking met conventionele cilinders en flexibelere machine-lay-outs mogelijk worden.

Na tientallen laspistoolpositioneringssystemen te hebben geïmplementeerd, heb ik gezien hoe de juiste cilinder zonder stang zowel de prestaties als de onderhoudbaarheid drastisch kan verbeteren.

Ruimte-efficiëntie in robotlascellen

Ruimte is schaars in moderne autofabrieken. Dit is hoe cilinders zonder stang waarde creëren:

Voetafdrukreductieanalyse

| Parameter | Traditionele cilinder (100 mm boring, 500 mm slag) | Cilinder zonder stangen (100 mm boring, 500 mm slag) | Voordeel |

|---|---|---|---|

| Totale lengte | ~1200mm (slag + lichaam + stang) | ~650mm (slag + slede) | 46% reductie |

| Storingszone | Groot (bewegende staaf) | Minimaal (ingeperkte beweging) | Maakt kleinere machineafstanden mogelijk |

| Gewicht | Hoog | Matig | Vermindert de belasting op robotarmen |

Belastbaarheid en stijfheid

Laspistolen zijn zwaar en moeten nauwkeurig gepositioneerd worden. Staafloze cilinders zijn bij uitstek geschikt voor deze uitdaging:

- Ondersteuning voor hoge belasting: Geïntegreerde geleidingssystemen verwerken zware vrijdragende lasten.

- Moment Weerstand: Brede lagerscheiding weerstaat torsiekrachten tijdens beweging.

- Stijve constructie: Geëxtrudeerde aluminium behuizing biedt uitstekende stijfheid.

Praktijkstudie: Body-in-White laslijn

Een grote Europese autofabrikant worstelde met een body-in-white lasstation. Hun bestaande systeem met traditionele cilinders was:

- Groot en moeilijk toegankelijk voor onderhoud

- Vatbaar voor doorbuiging van de staaf, waardoor een inconsistente laskwaliteit ontstaat

- Beperkt in snelheid door hoge bewegende massa

We hebben een oplossing geïmplementeerd met behulp van onze mechanisch gekoppelde cilinders zonder stangen:

- 35% minder voetafdruk van de machine, waardoor de toegang voor onderhoud wordt verbeterd

- Geïntegreerde zware geleiderlagers om doorbuiging te voorkomen

- Bereikte 20% snellere cyclustijden dankzij een lagere bewegende massa

Het resultaat was een aanzienlijke verbetering van zowel de laskwaliteit als de productiedoorvoer. De sleutel was het benutten van de inherente ruimte-efficiëntie en stijfheid van het ontwerp van de cilinder zonder stang.

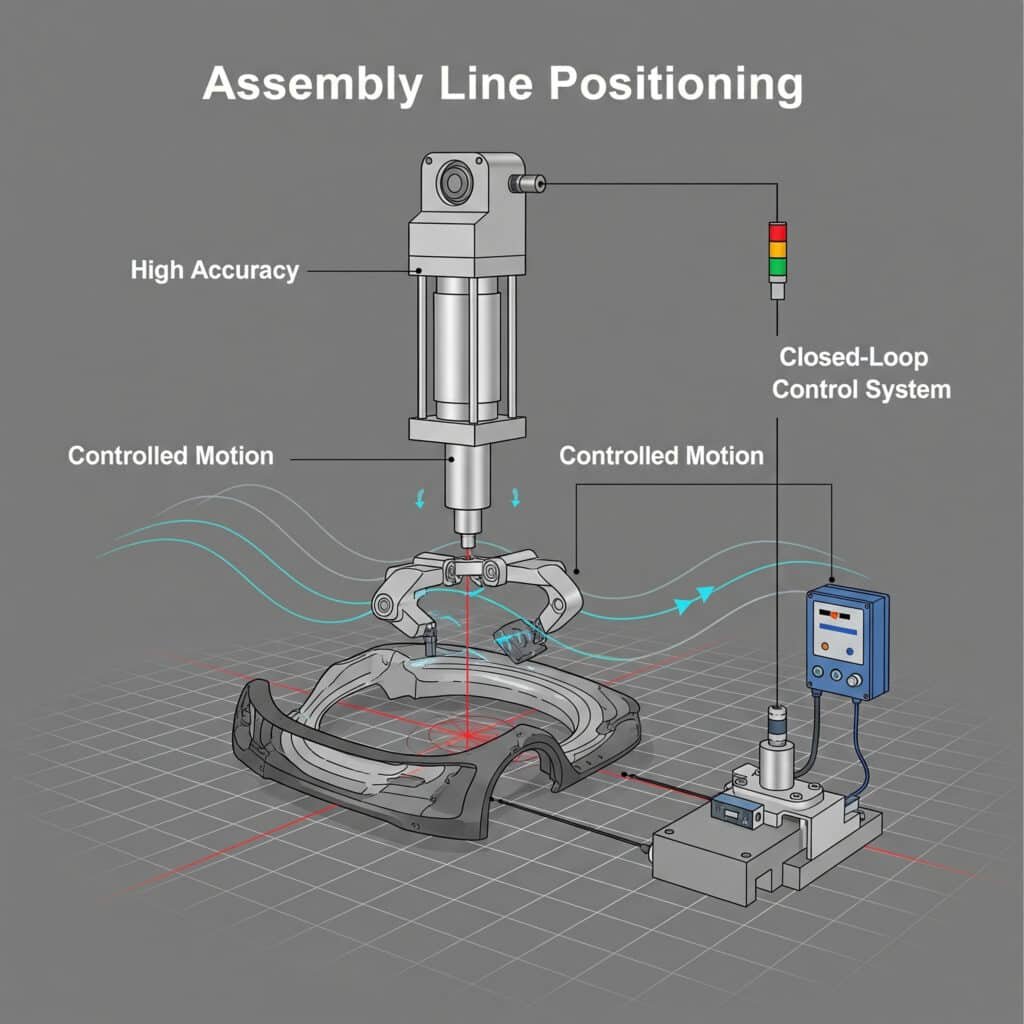

Wat maakt stangloze cilinders essentieel voor assemblagelijnpositionering?

Moderne assemblage in de auto-industrie vereist een nauwkeurigheidsniveau dat tien jaar geleden nog ondenkbaar was. Stangloze cilinders bieden de nauwkeurigheid en flexibiliteit die nodig zijn voor deze veeleisende taken.

Cilinders zonder stang zijn essentieel voor het positioneren aan de assemblagelijn omdat ze een superieure nauwkeurigheid bieden over lange slagen, soepele en gecontroleerde bewegingsprofielen bieden die cruciaal zijn voor het hanteren van kwetsbare componenten, en gemakkelijk geïntegreerd kunnen worden met geavanceerde sensor- en besturingssystemen voor feedback in gesloten regelkringen.

Van de assemblage van de aandrijflijn tot de installatie van het dashboard, de precisie die wordt geboden door cilinders zonder stang is essentieel voor de moderne assemblage van voertuigen.

Precisie en regelmogelijkheden

Het ontwerp van cilinders zonder stang maakt verschillende geavanceerde besturingsfuncties mogelijk:

- Continue positiebepaling: Magnetische encoders geven real-time positieterugkoppeling.

- Stoppen met meerdere posities: Eenvoudig te implementeren zonder complexe externe mechanismen.

- Soepele versnelling/vertraging: Proportionele kleppen maken een nauwkeurige snelheidsregeling mogelijk.

- Wrijvingsarme ontwerpen: Minimaliseert de stick-slip voor consistente bewegingen bij lage snelheden.

Toepassingsspecifieke precisievereisten

| Toepassing | Vereiste positionele nauwkeurigheid | Cilinder zonder sleutel | Reden voor keuze |

|---|---|---|---|

| Puntlassen1 Pistolen | ±1,0 mm | Robuust geleid staafloos | Hoog draagvermogen |

| Installatie dashboard | ±0,5mm | Geleide staafloze lange slag | Stabiliteit over afstand |

| Koppeling aandrijflijn | ±0,1 mm | Zeer nauwkeurige geleide staafloze | Stijfheid onder belasting |

| Installatie van glas | ±0,3 mm | Magnetisch gekoppelde staafloze | Vloeiend bewegingsprofiel |

Implementatiestrategie in de praktijk

Toen ik een grote Amerikaanse autofabrikant hielp met het upgraden van hun deurmontagestation, concentreerden we ons op deze belangrijke elementen:

Kritische positioneringspunten identificeren

- Locaties deurscharnieren vereist ±0,15 mm nauwkeurigheid

- Presentatorbewegingen hadden soepele versnellingsprofielen nodig

- Meerdere positiestops binnen één slag waren vereist

Geschikte technologie selecteren

- Geïmplementeerde geleide cilinders zonder stangen met magnetische positiebepaling

- Proportionele debietregeling toegevoegd voor snelheidsbeheer

- Geïntegreerde feedback voor positieverificatie

Validatiemethode

- Vastgestelde meetprotocollen bij installatie

- Lopende verificatieprocedures geïmplementeerd

- Preventieve onderhoudsschema's gemaakt

Het resultaat was een reductie van 67% in deurgerelateerde kwaliteitsproblemen en een verbetering van 40% in de doorvoer van het station. De belangrijkste succesfactor was het inzicht dat positionering niet alleen te maken heeft met de cilinder zelf, maar met het hele besturingssysteem eromheen.

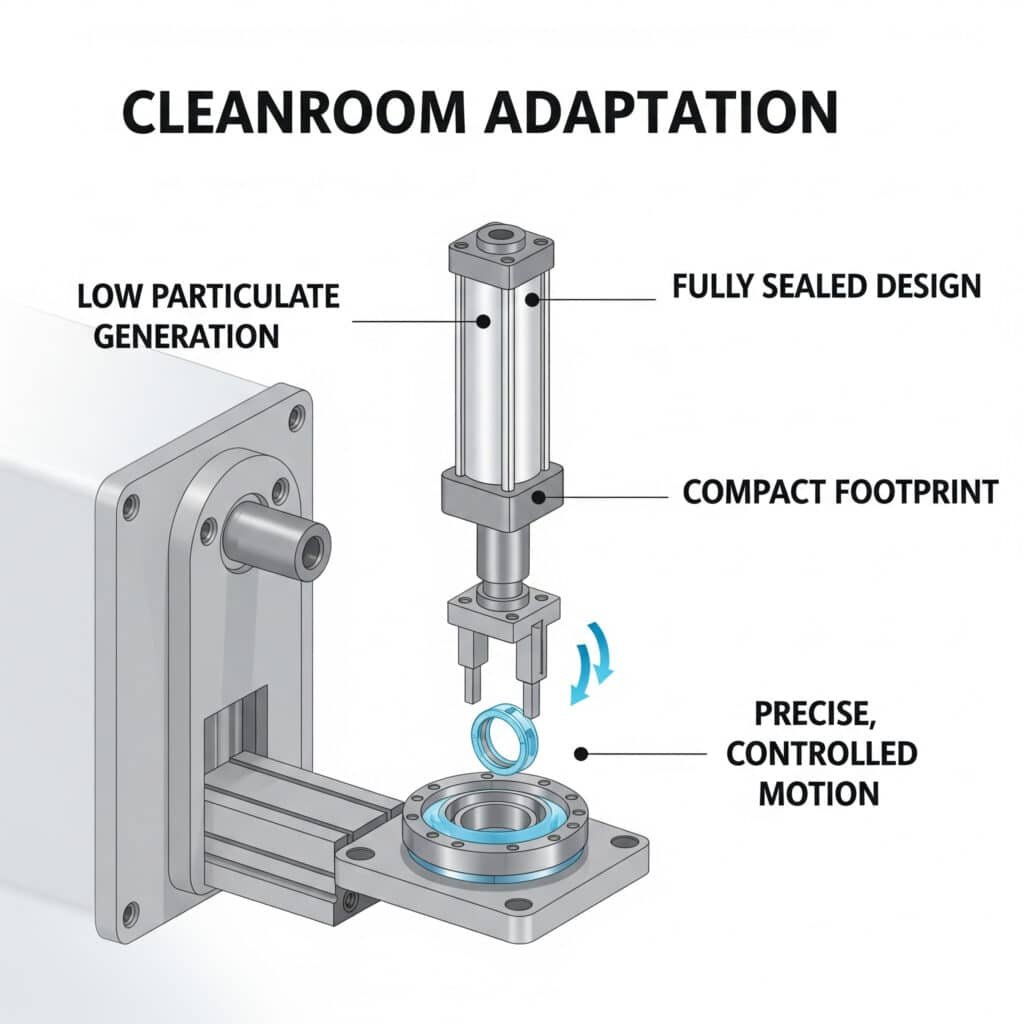

Wat maakt stangloze cilinders ideaal voor cleanroomomgevingen in de auto-industrie?

Cleanroom-omgevingen2 in de autofabricage vormen unieke uitdagingen waar conventionele pneumatische oplossingen niet goed op inspelen.

Staafloze cilinders zijn ideaal voor cleanroomomgevingen in de auto-industrie omdat ze minimale deeltjesemissies genereren, een afgedicht ontwerp bieden dat verontreiniging voorkomt, een compacte voetafdruk bieden voor cleanrooms met beperkte ruimte en de nauwkeurige besturing bieden die nodig is voor het hanteren van gevoelige onderdelen.

Door de toenemende complexiteit van de productie van auto-elektronica en batterijen zijn de cleanroomvereisten in de industrie drastisch toegenomen. Op basis van mijn ervaring met het implementeren van oplossingen in deze omgevingen, bieden cilinders zonder stang duidelijke voordelen.

Vereisten voor cleanroomclassificatie

Cleanroomtoepassingen voor auto's vallen meestal in deze categorieën:

ISO-klasse 7-83 (Federale norm 209E Klasse 10.000-100.000)

- Batterijcelassemblage

- Productie van sensoren

- Productie van elektronische besturingseenheden

ISO klasse 6-7 (Federal Standard 209E klasse 1.000-10.000)

- Camera en LIDAR4 assemblage van onderdelen

- Integratie van microchips

- Geavanceerde ondersteuningssystemen voor de bestuurder (ADAS)

Beheersing van vervuiling in staafloze cilinders

Moderne cilinderontwerpen zonder stang hebben verschillende kenmerken die specifiek nuttig zijn in cleanroomomgevingen:

Ingesloten bewegingsmechanismen

- Afdichtingsbanden voorkomen het ontstaan van deeltjes

- Interne smeersystemen verminderen onderhoud

- Geen externe bewegende delen voor minimale verontreiniging

Materiaal compatibiliteit

- Niet-uitgassende afdichtingen en onderdelen

- Chemisch bestendige oppervlakken

- Elektrostatische ontlading (ESD)5 volgzame opties

Gespecialiseerde Cleanroom-aanpassingen

- Externe vacuümpoorten voor deeltjesafzuiging

- Smeermiddelen die weinig deeltjes genereren

- Gespecialiseerde reinigingsprotocollen

Vergelijking van cleanroomimplementaties

| Functie | Standaard Pneumatisch | Staafloze cilinders voor cleanrooms | Voordeel |

|---|---|---|---|

| Deeltjesgeneratie | Matig tot hoog | Zeer laag | Zorgt voor een schone classificatie |

| Externe smering | Periodiek vereist | Verzegelde systemen beschikbaar | Vermindert besmettingsrisico |

| Reinigingscompatibiliteit | Beperkt | Verbeterde chemische weerstand | Ondersteunt ontsmettingsprotocollen |

| Ruimte-efficiëntie | Slecht | Uitstekend | Maximaliseert het gebruik van schone ruimtes |

Elektrische vs. pneumatische staafloze opties voor cleanrooms

Hoewel elektrische staafloze actuators vaak worden overwogen voor gebruik in cleanrooms, bieden pneumatische staafloze cilinders duidelijke voordelen in bepaalde toepassingen:

- Minder warmteontwikkeling (essentieel voor temperatuurgevoelige processen)

- Geen elektromagnetische interferentie met gevoelige elektronica

- Vereenvoudigde explosieveilige implementatie voor batterijproductie

- Over het algemeen lagere kosten voor gelijkwaardige prestaties

Onlangs heb ik een batterijfabrikant in Oostenrijk geholpen bij het implementeren van een cleanroom-compatibel staafloos cilindersysteem voor hun elektrodenstapelproces. Door magnetisch gekoppelde staafloze cilinders met speciale afdichtingen en interne smering te selecteren, bereikten we het volgende:

- Consistente naleving van ISO-klasse 7

- 30% snellere cyclustijden dan hun vorige elektrische actuatoroplossing

- Aanzienlijke kostenbesparingen op zowel de initiële investering als het energieverbruik

De sleutel was het begrijpen van de specifieke cleanroomvereisten en het selecteren van de juiste cilindervariant zonder stang met de juiste afdichtings- en smeringstechnologie.

Conclusie

Staafloze cilinders zijn essentiële onderdelen geworden in de moderne autofabricage en bieden de ruimte-efficiëntie, precisie en betrouwbaarheid die nodig zijn voor lasintegratie, positionering aan de lopende band en cleanroomtoepassingen. Door voor elke toepassing de juiste staafloze oplossing te kiezen, kunnen fabrikanten aanzienlijke verbeteringen bereiken in kwaliteit, efficiëntie en kosteneffectiviteit.

FAQ

Wat zijn de belangrijkste typen cilinders zonder stang die worden gebruikt in de autoproductie?

De belangrijkste types zijn magnetische cilinders zonder stang (met een magnetische koppeling tussen de interne zuiger en de externe meenemer), mechanische cilinders zonder stang (met mechanische verbindingen zoals gegroefde banden) en geleide cilinders zonder stang (met extra geleiderails voor het hanteren van zijdelingse belastingen). Elk type dient verschillende automobieltoepassingen op basis van de vereisten voor belasting en precisie.

Hoe verhouden staafloze cilinders zich tot traditionele cilinders in autotoepassingen?

Wat zijn de belangrijkste typen cilinders zonder stang die worden gebruikt in de autoproductie?

De belangrijkste types zijn magnetische cilinders zonder stang (met een magnetische koppeling tussen de interne zuiger en de externe meenemer), mechanische cilinders zonder stang (met mechanische verbindingen zoals gegroefde banden) en geleide cilinders zonder stang (met extra geleiderails voor het hanteren van zijdelingse belastingen). Elk type dient verschillende automobieltoepassingen op basis van de vereisten voor belasting en precisie.

Welk onderhoud is vereist voor cilinders zonder stang in lasomgevingen?

Staafloze cilinders in lasomgevingen vereisen regelmatige inspectie van afdichtingsbanden op spatten, periodieke reiniging van externe oppervlakken, controle van de werking van de magneetkoppeling en af en toe smering volgens de specificaties van de fabrikant. Goed onderhouden eenheden hebben meestal slechts om de 10-15 miljoen cycli een grote onderhoudsbeurt nodig.

Kunnen cilinders zonder stang de zware belastingen in de assemblage van auto's aan?

Ja, moderne staafloze cilinders kunnen aanzienlijke belastingen aan, met modellen voor zwaar gebruik die tot 200 kg dragen in horizontale toepassingen. Voor extreme belastingen kunnen geleide cilinders zonder stangen met extra lagersteun nog grotere krachten aan, terwijl de positioneringsnauwkeurigheid binnen ±0,1 mm blijft.

Wat is het typische rendement op investering voor het upgraden naar cilinders zonder stang?

De meeste autofabrikanten zien de ROI binnen 8-18 maanden na het upgraden naar cilinders zonder stang. Het rendement komt van lagere onderhoudskosten (30-40% lager), betere kwaliteit (meestal 25-50% minder defecten), ruimtebesparing (40-60% kleiner vloeroppervlak) en een hogere doorvoer (15-30% hoger) dankzij geoptimaliseerde bewegingsprofielen en betrouwbaarheid.

-

Geeft een gedetailleerde uitleg over weerstandspotlassen, een veelvoorkomend proces in de autoproductie dat wordt gebruikt om plaatmetalen onderdelen te verbinden door druk en elektrische stroom toe te passen. ↩

-

Legt het concept van een cleanroom uit, een gecontroleerde omgeving met een laag niveau van verontreinigende stoffen zoals stof, in de lucht zwevende microben en chemische dampen, wat essentieel is voor gevoelige productie. ↩

-

Gaat in op de ISO 14644-1 norm, die de luchtzuiverheid van cleanrooms en gecontroleerde omgevingen classificeert op basis van de concentratie zwevende deeltjes. ↩

-

Beschrijft de principes van LiDAR (Light Detection and Ranging), een teledetectiemethode die gepulseerd laserlicht gebruikt om variabele afstanden tot de aarde te meten, wat een belangrijk onderdeel is van autonome voertuigen. ↩

-

Biedt uitleg over elektrostatische ontlading (ESD), de plotselinge stroom van elektriciteit tussen twee elektrisch geladen voorwerpen, die aanzienlijke schade kan veroorzaken aan gevoelige elektronische onderdelen. ↩