Een slechte smering betekent vaak een slechte werking van de machine. Toch begrijpen de meeste mensen nauwelijks wat een smeermiddel echt onder stress laat werken.

Geavanceerde smering vertrouwt op de vorming van vloeistoffilms, chemische bescherming en real-time bewaking om wrijving te verminderen en slijtage te voorkomen.

Ik heb met talloze industriële ingenieurs gewerkt die dachten "olie is olie" - totdat hun apparatuur het begaf onder zware belasting. Laten we ons verdiepen in de wetenschap die uw machines in leven houdt.

[Inhoudsopgave].

- Wat is een hydrodynamisch smeringsmodel?

- Hoe beschermen EP-additieven eigenlijk onder extreme druk?

- Wat zijn de moderne manieren om de dikte van de oliefilm te meten?

- Conclusie

- Veelgestelde vragen over geavanceerde smeerprincipes

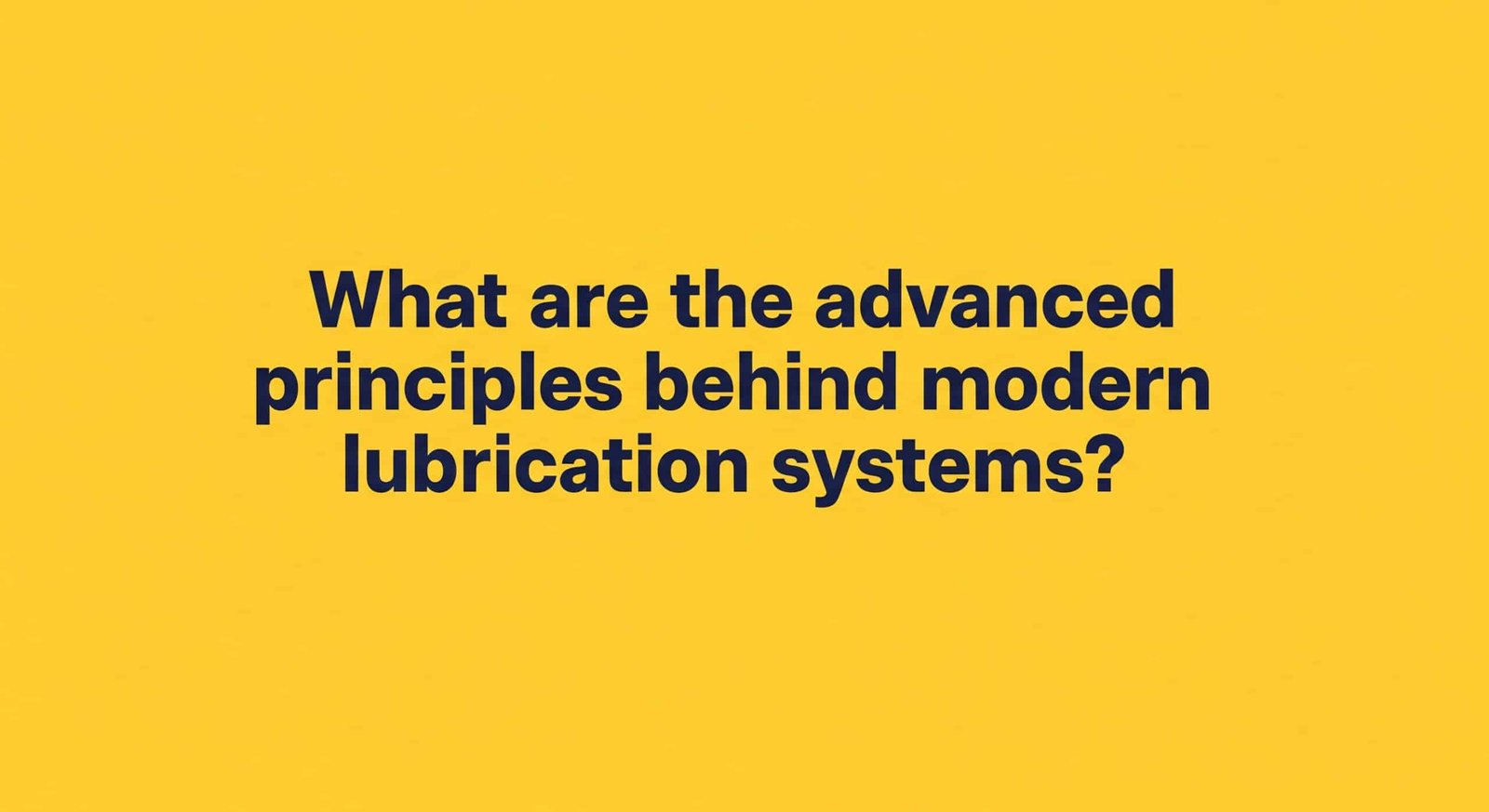

Wat is een hydrodynamisch smeringsmodel?

Wanneer twee metalen oppervlakken snel bewegen met een smeermiddel ertussen, gebeurt er iets opmerkelijks: er vormt zich een volledige oliefilm die de oppervlakken uit elkaar houdt.

De hydrodynamisch smeermodel1 beschrijft hoe vloeistofdruk bewegende oppervlakken ondersteunt, waarbij direct metaal-op-metaalcontact wordt vermeden.

Duik dieper

In een hydrodynamisch smeermodelHet bewegende oppervlak sleept smeermiddel in een wigvormige spleet. Naarmate de snelheid toeneemt, neemt ook de druk toe. Deze zichzelf onderhoudende druk bouwt een oliefilm op die de hele lading draagt.

Dit model wordt veel gebruikt in:

- Lagerontwerp

- Versnellingsbakken

- Pneumatische cilinders zonder stangen

| Parameter | Effect op filmdikte |

|---|---|

| Viscositeit smeermiddel | Dikkere film |

| Oppervlaktesnelheid | Dikkere film |

| Belasting | Dunnere film |

| Temperatuur | Dunnere film (lagere viscositeit) |

Als je onderdelen ontwerpt of vervangt, zoals een pneumatisch staafloze pneumatische cilinderDe toepassing van dit model zorgt voor een stabiele werking bij wisselende belastingen.

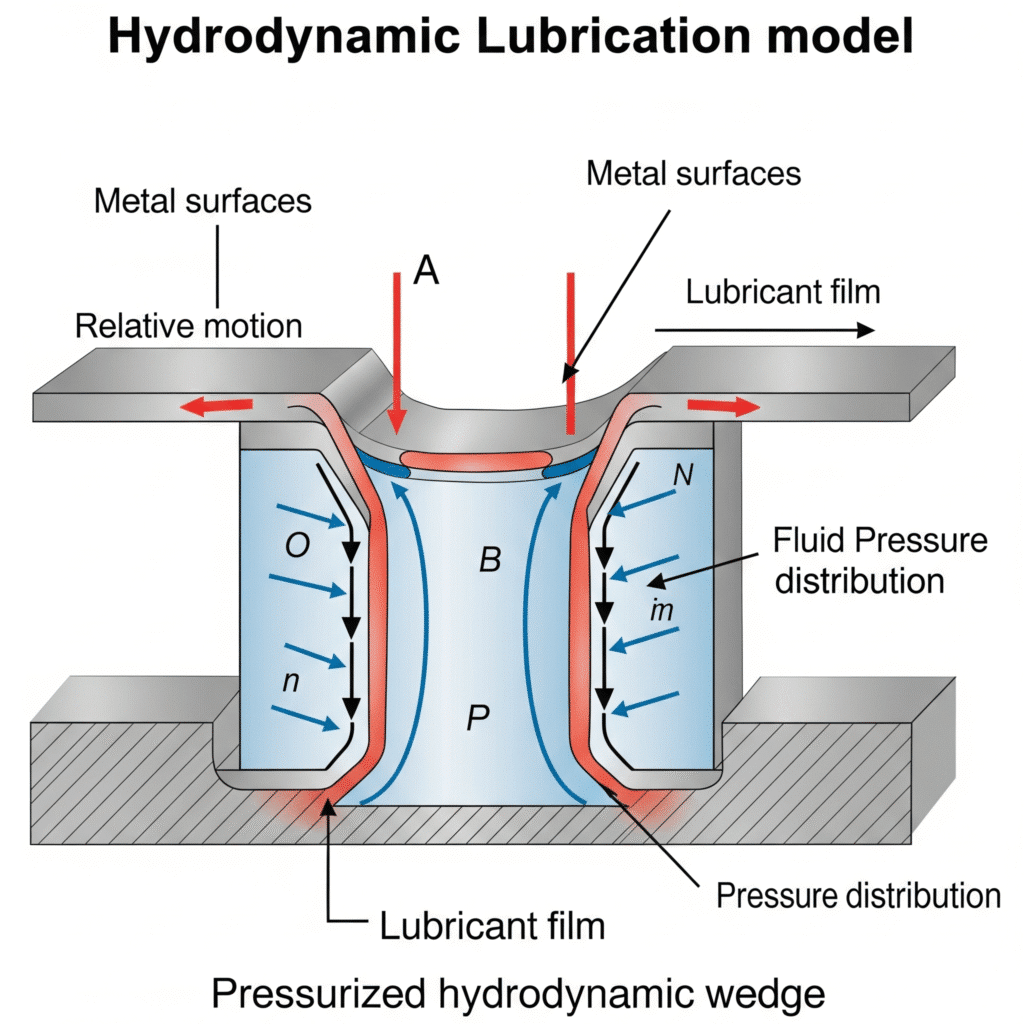

Hoe beschermen EP-additieven eigenlijk onder extreme druk?

Wanneer de druk en hitte hoger worden dan wat normale olie aankan, komen additieven in actie.

EP-additieven2 vormen beschermende lagen tijdens contact met metaal onder hoge druk, waardoor slijtage en vastlopen worden verminderd.

Duik dieper

Extreme druk (EP) additieven reageren chemisch met metalen oppervlakken. Onder hoge belastingen en temperaturen vormen ze sulfide- of fosfaatfilms die lassen tussen contactoppervlakken voorkomen.

Gebruikelijke soorten EP-additieven:

- Gezwavelde alkenen

- Gechloreerde paraffines

- Zinkdialkyldithiofosfaten (ZDDP's)3

Deze zijn cruciaal voor:

- Tandwieloliën

- Hydraulische vloeistoffen

- Pneumatisch gereedschap met hoge belasting

In onze industrie denken veel gebruikers van staafloze luchtcilinders dat zichtbare smering voldoende bescherming biedt. Maar EP-bescherming gebeurt onzichtbaar, op moleculair niveau-Vooral bij plotselinge schokken of zware cycli.

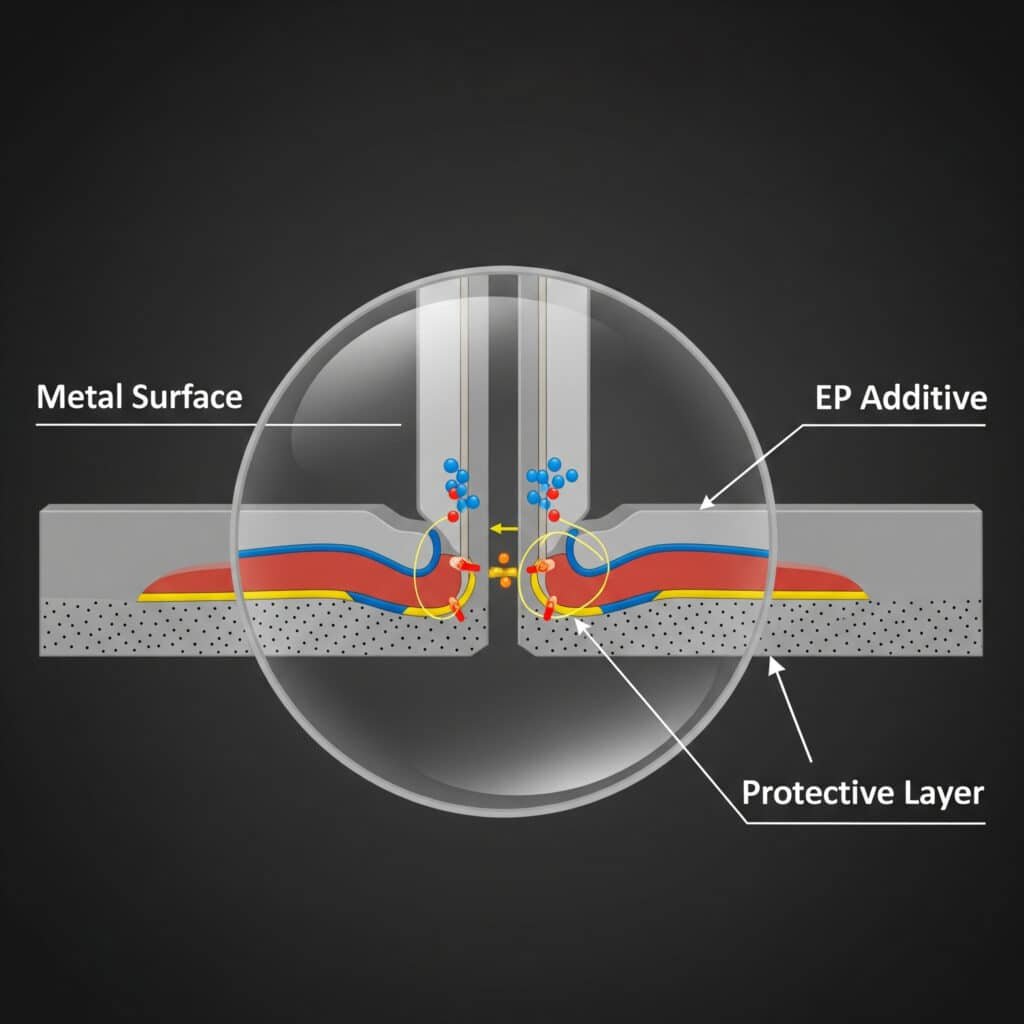

Wat zijn de moderne manieren om de dikte van de oliefilm te meten?

Je kunt niet verbeteren wat je niet meet. En bij smering zijn microns van belang.

Moderne meettechnieken voor oliefilm omvatten ultrageluid, capaciteit en optische interferometrie4.

Duik dieper

In het verleden werd de dikte van de oliefilm vaak geraden. Nu hebben we precisiegereedschap:

| Methode | Principe | Toepassingsvoorbeeld |

|---|---|---|

| Ultrageluid sensoren | Reflectie van geluidsgolven | Lagers, compressoren |

| Capaciteitssensoren | Elektrische weerstand op basis van spleet | Dunne-filmmeting in tandwielen |

| Optische interferometrie | Interferentie van lichtgolven | R&D-laboratoria, oppervlaktetests |

Voor bedrijven zoals het onze die zich bezighouden met staafloze pneumatische cilindersDeze technologie helpt ons om betere glijafdichtingen en magnetische koppelingen te ontwerpen, zodat de oliefilm behouden blijft bij lineaire bewegingen met hoge snelheid.

Conclusie

Geavanceerde smering is een mix van fysica, chemie en nauwkeurige detectie.

Veelgestelde vragen over geavanceerde smeerprincipes

Wat is hydrodynamische smering?

Het is een vloeistofdrukmechanisme dat bewegende oppervlakken scheidt om metaalcontact te voorkomen.

Waarom zijn EP-additieven belangrijk in smering?

Ze beschermen metalen onderdelen chemisch wanneer de oliefilm onder extreme druk breekt.

Hoe wordt de dikte van de oliefilm tegenwoordig gemeten?

Met ultrasone, capacitieve en optische sensoren voor nauwkeurige real-time feedback.

Biedt Bepto smeermiddelvriendelijke cilinders zonder stang?

Ja. Onze ontwerpen minimaliseren slijtage en ondersteunen langdurige smeerprestaties.

Kan smering de stilstandtijd van industriële machines verminderen?

Absoluut. Een goede smering voorkomt slijtage, verlengt de levensduur en voorkomt dure stops.

-

Geeft een gedetailleerde uitleg van het hydrodynamische smeringsregime, inclusief de vorming van de vloeistoffilm en de principes van de vergelijking van Reynolds die dit regelt. ↩

-

Legt de chemische mechanismen uit waarmee EP-additieven reageren met metalen oppervlakken onder hoge belasting en temperatuur om een beschermende, opofferende laag te vormen. ↩

-

Biedt diepgaande informatie over zinkdialkyldithiofosfaten (ZDDP's), een cruciaal antislijtage-additief, met details over de chemische functie, toepassingen en geschiedenis in smering. ↩

-

Legt de wetenschappelijke principes uit van het gebruik van interferentie van lichtgolven om zeer nauwkeurige, niet-invasieve metingen van de dikte van de smeermiddelfilm uit te voeren in onderzoek en ontwikkeling. ↩