Incorrect piston area calculations cause 40% of pneumatic system underperformance issues, leading to insufficient force output, slow cycle times, and costly oversized equipment purchases. A área efectiva do pistão em cilindros de efeito duplo é igual à área total do furo durante a extensão e à área do furo menos a área da haste durante a retração, com cálculos que requerem medições precisas do diâmetro e consideração dos diferenciais de pressão para previsões precisas da força. Yesterday, I helped David, an engineer from California, whose automated assembly line was running 30% slower than designed because he miscalculated piston areas and undersized his air supply system. 📐

Índice

- What Is Effective Piston Area and Why Does It Matter for Cylinder Performance?

- How Do You Calculate Piston Areas for Extension and Retraction Strokes?

- Which Factors Affect Piston Area Calculations in Real Applications?

What Is Effective Piston Area and Why Does It Matter for Cylinder Performance?

Understanding effective piston area is fundamental to proper pneumatic system design and performance optimization.

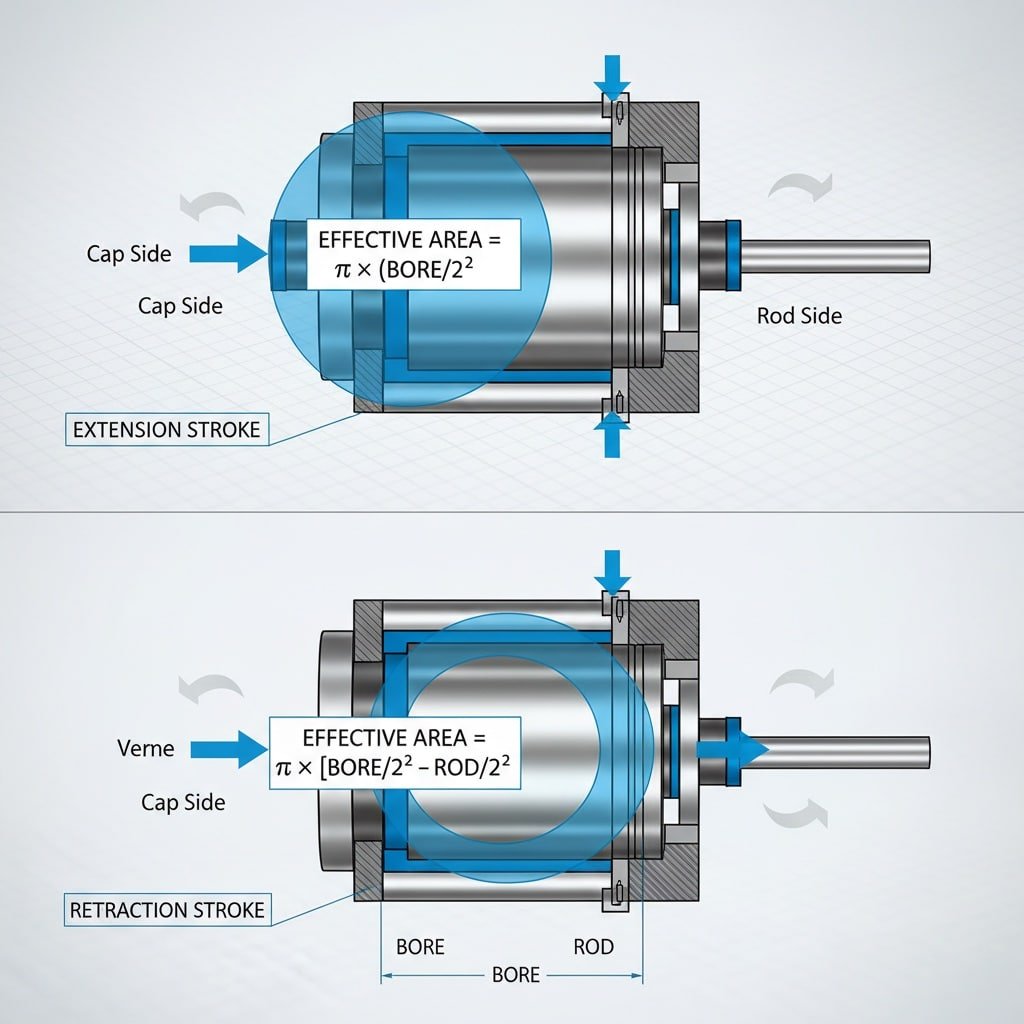

Effective piston area is the actual surface area of the piston that air pressure acts upon to generate force, which differs between extension and retraction strokes due to the rod occupying space on one side of the piston.

Basic Piston Area Concepts

Extension Stroke (Rod Extending):

- Full bore area receives air pressure

- Maximum force generation capability

- Rod side vents to atmosphere or return port

- Area = π × (bore diameter/2)²1

Retraction Stroke (Rod Retracting):

- Reduced effective area due to rod displacement

- Lower force output compared to extension

- Cap side vents while rod side receives pressure

- Area = π × [(bore diameter/2)² – (rod diameter/2)²]

Impacto no desempenho

| Tamanho do cilindro | Extension Area | Retraction Area | Rácio de força |

|---|---|---|---|

| 2″ bore, 1″ rod | 3.14 in² | 2.36 in² | 1.33:1 |

| 4″ bore, 1.5″ rod | 12.57 in² | 10.81 in² | 1.16:1 |

| 6″ bore, 2″ rod | 28.27 in² | 25.13 in² | 1.12:1 |

Why Accurate Calculations Matter

Implicações para a conceção do sistema:

- Force output directly proportional to effective area

- Air consumption varies with piston area

- Cycle time depends on area-to-volume ratios

- Pressure requirements scale with area differences

Cost Considerations:

- Oversized systems waste energy and increase costs

- Undersized systems fail to meet performance requirements

- Proper sizing optimizes equipment investment

- Accurate calculations prevent expensive redesigns

David’s assembly line illustrates this perfectly. His initial calculations used full bore area for both strokes, leading to a 25% overestimate of retraction force. This caused him to undersize the air supply, resulting in slow retraction speeds that bottlenecked his entire production line. We recalculated using proper effective areas and upgraded his air system accordingly, restoring full design performance. 🎯

How Do You Calculate Piston Areas for Extension and Retraction Strokes?

Precise mathematical formulas ensure accurate force and performance predictions for double-acting pneumatic cylinders.

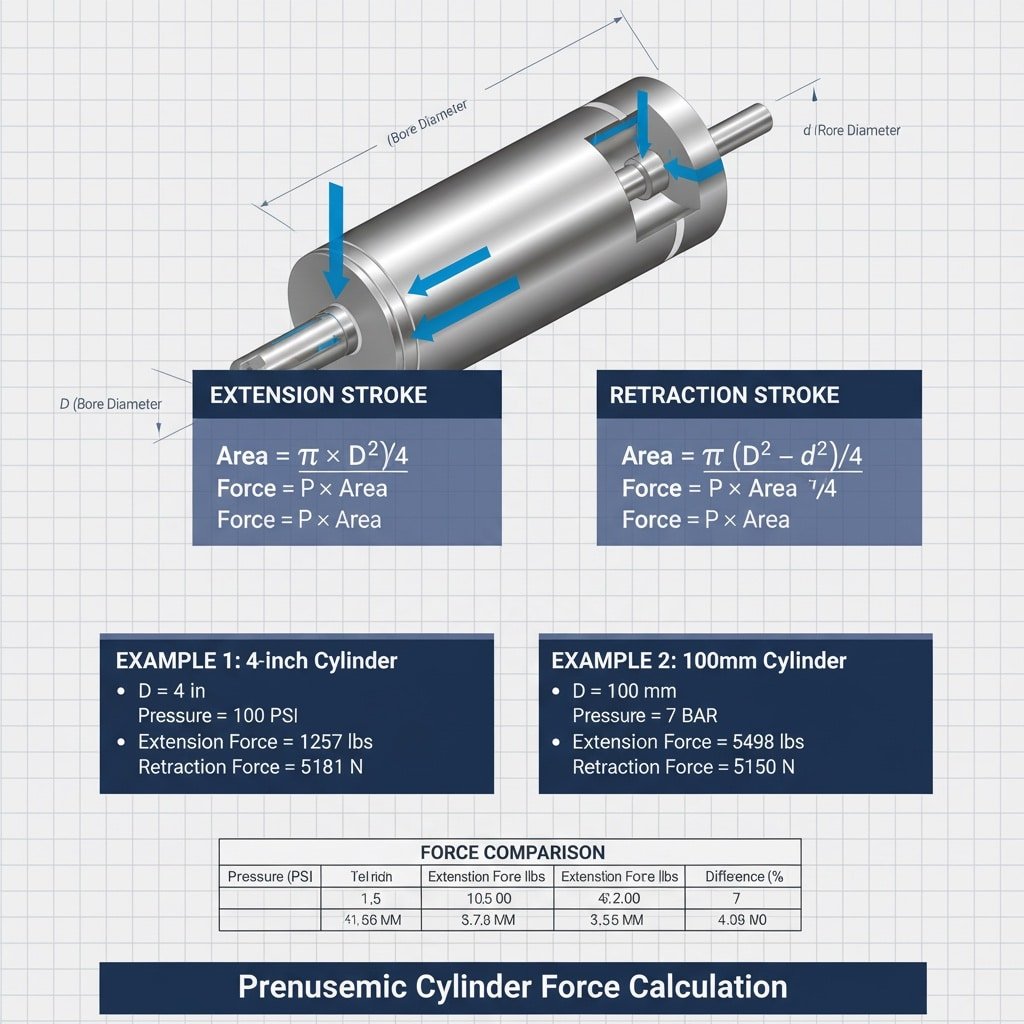

Extension area equals π × (D/2)² where D is bore diameter, while retraction area equals π × [(D/2)² – (d/2)²] where d is rod diameter, with all measurements in consistent units for accurate results.

Processo de cálculo passo a passo

Required Measurements:

- Cylinder bore diameter (D)

- Rod diameter (d)

- Operating pressure (P)

- Fator de segurança2 requisitos

Extension Area Formula:

- A_extension = π × (D/2)²

- A_extensão = π × D²/4

- A_extensão = 0,7854 × D²

Fórmula da área de retração:

- A_retracção = π × [(D/2)² - (d/2)²]

- A_retracção = π × (D² - d²)/4

- A_retracção = 0,7854 × (D² - d²)

Exemplos práticos de cálculo

Exemplo 1: Cilindro standard de 4 polegadas

- Diâmetro do furo: 4,0 polegadas

- Diâmetro da haste: 1,5 polegadas

- Área de extensão: 0,7854 × 4² = 12,57 in²

- Área de retração: 0,7854 × (4² - 1,5²) = 10,81 in²

Exemplo 2: Cilindro métrico de 100 mm

- Diâmetro do furo: 100 mm

- Diâmetro da haste: 25 mm

- Área de extensão: 0,7854 × 100² = 7.854 mm²

- Área de retração: 0,7854 × (100² - 25²) = 7,363 mm²

Aplicações de cálculo de forças

| Pressão (PSI) | Força de extensão (lbs) | Força de retração (lbs) | Diferença de forças |

|---|---|---|---|

| 60 PSI | 754 lbs | 649 lbs | Redução 14% |

| 80 PSI | 1.006 lbs | 865 lbs | Redução 14% |

| 100 PSI | 1.257 lbs | 1.081 lbs | Redução 14% |

Considerações avançadas

Queda de pressão3 Efeitos:

- As perdas de linha reduzem a pressão efectiva

- As restrições de fluxo afectam o desempenho dinâmico

- As quedas de pressão da válvula afectam a força real

- As variações de temperatura afectam o fornecimento de pressão

Integração do fator de segurança:

- Aplicar factores de segurança de 1,5-2,0 às forças calculadas

- Considerar condições de carga dinâmicas

- Ter em conta o desgaste e a degradação do desempenho

- Incluir ajustamentos de factores ambientais

Maria, uma designer de máquinas do Oregon, estava a sentir forças de aperto inconsistentes no seu equipamento de embalagem. Os seus cálculos pareciam corretos, mas ela não tinha tido em conta a queda de pressão de 15 PSI através do coletor da válvula. Ajudámo-la a recalcular as pressões efectivas e a redimensionar os cilindros em conformidade, obtendo uma repetibilidade de força consistente de ±2% em toda a sua linha de produção. 💪

Which Factors Affect Piston Area Calculations in Real Applications?

As aplicações do mundo real introduzem variáveis que afectam significativamente o desempenho efetivo da área do pistão e devem ser consideradas para uma conceção precisa do sistema.

As tolerâncias de fabrico, o atrito do vedante, as perdas de pressão, os efeitos da temperatura e as condições de carga dinâmica influenciam o desempenho real da área efectiva do pistão, exigindo ajustes de engenharia aos cálculos teóricos para um funcionamento fiável do sistema.

Impacto da tolerância de fabrico

Variações dimensionais:

- Tolerância do diâmetro do furo: tipicamente ±0,002″

- Tolerância do diâmetro da haste: tipicamente ±0,001″

- Efeitos do acabamento da superfície na vedação

- Requisitos de folga para a montagem

Análise do efeito de tolerância:

- 0,002″ variação do furo = ±0,6% variação da área

- As tolerâncias combinadas podem criar uma variação de força de ±1,2%

- O controlo de qualidade garante um desempenho consistente

- O Bepto mantém padrões de tolerância de ±0,001″.

Factores ambientais

Efeitos da temperatura:

- Expansão térmica4 changes dimensions

- Seal material temperature coefficients

- Air density variations with temperature

- Lubrication viscosity changes

Pressure System Variables:

- Supply pressure regulation accuracy

- Line pressure drops during operation

- Valve flow characteristics

- Air treatment system performance

Dynamic Performance Considerations

| Condição de funcionamento | Area Effectiveness | Impacto no desempenho |

|---|---|---|

| Static holding | 100% | Força nominal total |

| Slow movement | 95-98% | Seal friction losses |

| Funcionamento a alta velocidade | 85-92% | Restrições de fluxo |

| Dirty conditions | 80-90% | Aumento da fricção |

Bepto Engineering Advantages

Fabrico de precisão:

- Tighter tolerances than industry standards

- Enhanced surface finishes reduce friction

- Premium seal materials minimize losses

- Comprehensive quality testing protocols

Performance Optimization:

- Custom area calculations for specific applications

- Environmental factor analysis and compensation

- Dynamic performance modeling and validation

- Ongoing support for system optimization

Validação no mundo real:

- Field testing confirms theoretical calculations

- Performance monitoring identifies optimization opportunities

- Continuous improvement based on application feedback

- Technical support for troubleshooting and upgrades

Our precision manufacturing and engineering support help customers achieve 98%+ of theoretical performance in real applications, compared to 85-90% typical with standard components. We provide complete calculation services, application analysis, and performance validation to ensure your pneumatic systems deliver exactly the performance you need. 🔧

Conclusão

Accurate effective piston area calculations are essential for proper pneumatic system design, ensuring optimal performance, efficiency, and cost-effectiveness in double-acting cylinder applications.

FAQs About Effective Piston Area Calculations

Q: Why is retraction force always lower than extension force in double-acting cylinders?

Retraction force is lower because the rod occupies space on the pressure side, reducing effective piston area by the rod’s cross-sectional area. This typically results in 10-30% less force depending on rod-to-bore ratio.

Q: How do manufacturing tolerances affect piston area calculations?

Manufacturing tolerances can create ±1-2% variation in actual piston area, affecting force output proportionally. Bepto maintains tighter tolerances (±0.001″) compared to standard components (±0.002-0.005″) for more consistent performance.

Q: What safety factors should be applied to calculated piston areas?

Apply 1.5-2.0 safety factors to account for pressure losses, seal friction, and performance degradation over time. Critical applications may require higher safety factors based on risk assessment and regulatory requirements.

Q: How do pressure drops affect effective piston area performance?

Pressure drops don’t change physical piston area but reduce effective pressure, proportionally decreasing force output. A 10 PSI drop at 80 PSI operating pressure reduces force by 12.5%, requiring larger cylinders or higher supply pressure.

Q: Can Bepto provide custom piston area calculations for my specific application?

Yes, our engineering team provides free piston area calculations, force analysis, and system sizing recommendations for any application. We consider all real-world factors to ensure optimal performance and reliability.

-

Review the fundamental formula for calculating the area of a circle. ↩

-

Learn about the role of safety factors in mechanical engineering design and why they are critical. ↩

-

Understand the causes of pressure drop in pneumatic systems and how it impacts performance. ↩

-

Explore the principle of thermal expansion and its effects on mechanical components. ↩