Engineers designing systems for high-temperature environments face critical decisions about pneumatic cylinder selection, knowing that standard components will fail catastrophically in extreme heat, causing costly downtime, safety hazards, and project delays that can destroy budgets and reputations.

High-temperature pneumatic cylinders require specialized seal materials, heat-resistant housings, thermal expansion1 compensation, and enhanced lubrication systems to operate reliably above 150°C, with proper selection and application enabling continuous operation up to 350°C in demanding industrial processes.

Two months ago, I worked with Robert, a process engineer at a steel processing facility in Pennsylvania, whose standard cylinders kept failing in their 280°C annealing line. After switching to our Bepto high-temperature rodless cylinders with PTFE seals and ceramic coatings, his system has operated continuously for over 90 days without a single failure. 🔥

Table of Contents

- What Temperature Ranges Define High-Temperature Pneumatic Applications?

- How Do Material Selections Impact High-Temperature Performance?

- Which Design Features Enable Reliable High-Temperature Operation?

- What Installation Considerations Ensure Long-Term Success?

What Temperature Ranges Define High-Temperature Pneumatic Applications?

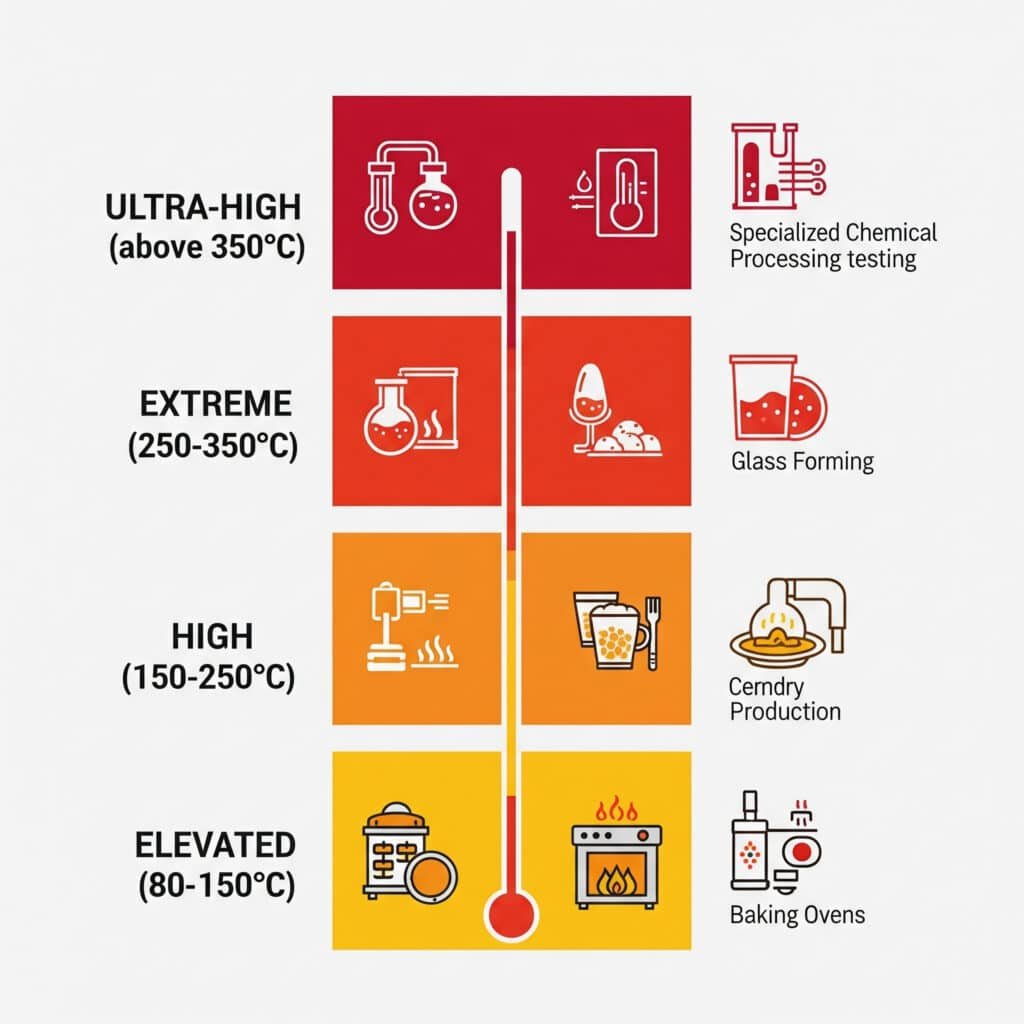

Understanding temperature classifications helps engineers select appropriate cylinder technologies for their applications.

High-temperature pneumatic applications are classified as elevated (80-150°C), high (150-250°C), extreme (250-350°C), and ultra-high (above 350°C), with each range requiring progressively specialized materials, sealing systems, and thermal management strategies for reliable operation.

Temperature Classification System

Standard vs. High-Temperature Ranges

| Temperature Range | Classification | Typical Applications | Special Requirements |

|---|---|---|---|

| -10°C to 80°C | Standard | General manufacturing | Standard seals/materials |

| 80°C to 150°C | Elevated | Food processing, drying | Enhanced seals |

| 150°C to 250°C | High | Plastics, glass forming | Specialized materials |

| 250°C to 350°C | Extreme | Steel, ceramics | Advanced engineering |

| Above 350°C | Ultra-high | Aerospace, research | Custom solutions |

Industry-Specific Temperature Demands

- Steel processing – Up to 300°C for rolling and forming operations

- Glass manufacturing – 200-280°C for shaping and annealing processes

- Plastic injection molding – 150-220°C for heating and cooling cycles

- Ceramic production – 250-350°C for firing and glazing operations

- Food processing – 80-150°C for sterilization and cooking applications

Thermal Cycling Considerations

Temperature Variation Challenges

High-temperature applications often involve:

- Rapid heating from ambient to operating temperature

- Thermal shock2 from sudden temperature changes

- Cycling fatigue from repeated expansion/contraction

- Gradient effects across cylinder length

- Ambient cooling during shutdown periods

Performance Impact Factors

- Seal degradation accelerates exponentially with temperature

- Lubrication breakdown occurs at elevated temperatures

- Material expansion affects tolerances and alignment

- Pressure variations due to gas law effects

- Component stress from thermal cycling

How Do Material Selections Impact High-Temperature Performance?

Strategic material choices determine cylinder reliability and service life in extreme temperatures.

High-temperature cylinder performance depends on selecting heat-resistant seals like PTFE or PEEK, corrosion-resistant housings such as stainless steel or ceramic-coated aluminum, specialized lubricants rated for temperature extremes, and thermal barrier coatings that protect critical components from heat damage.

Seal Material Technologies

Advanced Seal Options

- PTFE (Polytetrafluoroethylene) – Excellent for 200-260°C applications

- PEEK (Polyetheretherketone) – Superior performance up to 300°C

- Perfluoroelastomers3 – Chemical resistance to 320°C

- Metal seals – Ultimate temperature resistance above 350°C

- Ceramic composites – Specialized applications requiring extreme durability

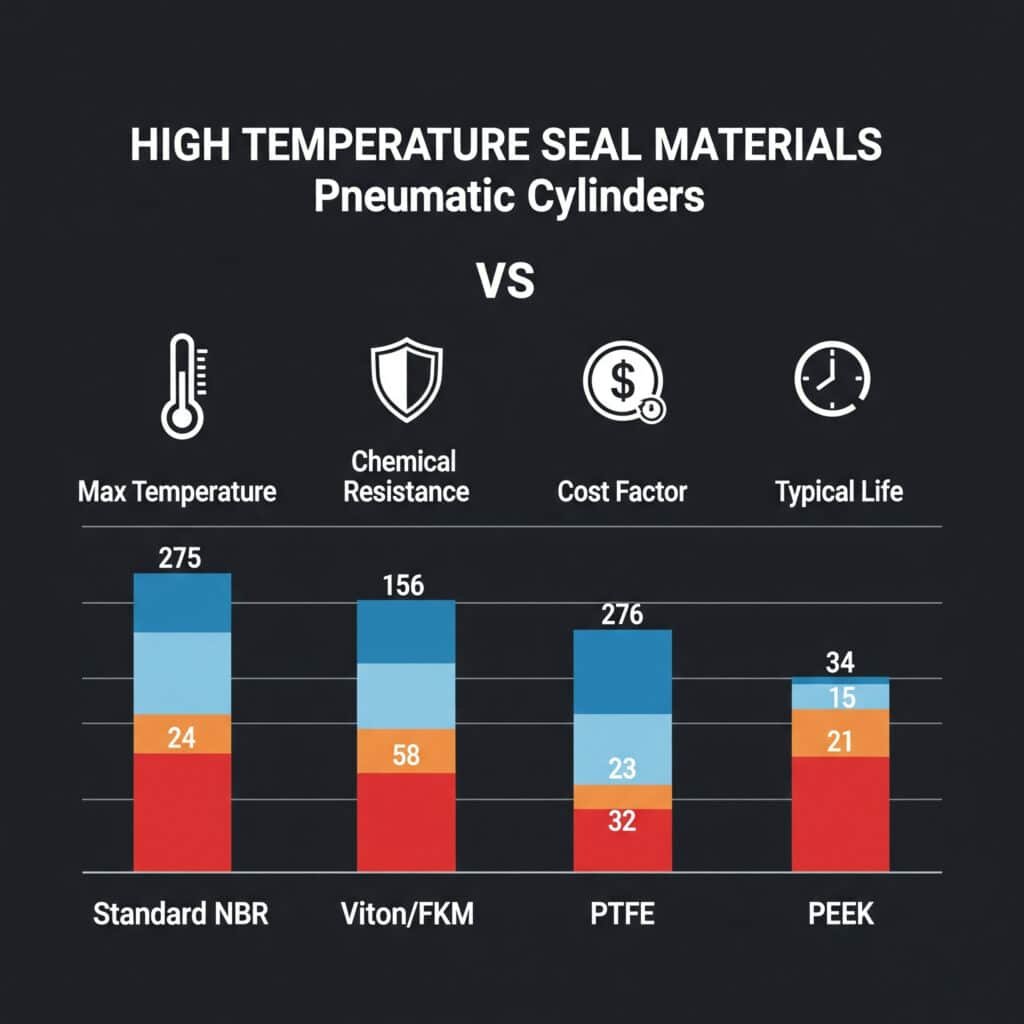

Seal Performance Comparison

| Material Type | Max Temperature | Chemical Resistance | Cost Factor | Typical Life |

|---|---|---|---|---|

| Standard NBR | 80°C | Limited | 1x | 6-12 months |

| Viton/FKM | 200°C | Excellent | 3x | 12-18 months |

| PTFE | 260°C | Outstanding | 4x | 18-24 months |

| PEEK | 300°C | Superior | 6x | 24-36 months |

Housing and Component Materials

Heat-Resistant Housing Options

- Stainless steel 316 – Corrosion resistance with 300°C capability

- Inconel alloys – Extreme temperature and oxidation resistance

- Ceramic-coated aluminum – Lightweight with thermal barrier properties

- Cast iron with treatments – Cost-effective for moderate temperatures

Internal Component Considerations

- Piston materials must resist thermal expansion and wear

- Rod coatings prevent galling4 and corrosion at high temperatures

- Bearing surfaces require specialized treatments for durability

- Fasteners need matching thermal expansion coefficients

I recently helped Maria, a design engineer at a glass manufacturing company in California, solve persistent seal failures in their 240°C forming line. By upgrading to our PEEK seal technology and implementing proper thermal management, her cylinders now operate reliably for over 18 months between services, compared to monthly failures with standard seals. 🏭

Lubrication System Requirements

High-Temperature Lubricant Properties

- Thermal stability to prevent breakdown and carbonization

- Oxidation resistance for extended service intervals

- Viscosity retention across wide temperature ranges

- Compatibility with seal materials and system components

- Low volatility to minimize lubricant loss

Specialized Lubrication Solutions

- Synthetic PAO oils for temperatures up to 200°C

- Perfluorinated fluids for extreme chemical environments

- Solid lubricants (MoS2, graphite) for dry applications

- Grease formulations for sealed bearing applications

Which Design Features Enable Reliable High-Temperature Operation?

Specialized design elements address thermal challenges and ensure consistent performance.

Reliable high-temperature operation requires thermal expansion compensation through floating mounts, enhanced cooling systems with heat sinks or active cooling, pressure regulation for gas expansion effects, and robust sealing systems with multiple backup seals to prevent catastrophic failures.

Thermal Management Systems

Passive Cooling Solutions

- Heat sinks to dissipate thermal energy

- Thermal barriers to isolate hot zones

- Insulation systems to protect sensitive components

- Radiation shields to reflect heat away from cylinders

- Convection enhancement through fin designs

Active Cooling Technologies

- Air cooling with forced ventilation systems

- Liquid cooling circuits for extreme applications

- Heat exchangers to transfer thermal energy

- Thermoelectric cooling5 for precise temperature control

- Phase change materials for thermal buffering

Expansion Compensation Design

Mechanical Compensation Methods

| Compensation Type | Temperature Range | Advantages | Applications |

|---|---|---|---|

| Floating mounts | Up to 200°C | Simple, reliable | General purpose |

| Bellows expansion | Up to 300°C | Precise control | Critical alignment |

| Sliding joints | Up to 250°C | Low maintenance | Linear applications |

| Flexible couplings | Up to 350°C | Multi-axis | Complex systems |

Precision Positioning Considerations

- Thermal drift compensation in control systems

- Reference point stability during temperature changes

- Calibration procedures for thermal effects

- Sensor placement away from heat sources

Enhanced Sealing Strategies

Multiple Seal Configurations

- Primary seals for main sealing function

- Secondary seals as backup protection

- Wiper seals to exclude contaminants

- Buffer zones between seal stages

- Pressure relief systems for seal protection

Dynamic Sealing Solutions

- Spring-loaded seals maintain contact pressure

- Self-adjusting designs compensate for wear

- Modular seal cartridges for easy replacement

- Monitoring systems for seal condition assessment

What Installation Considerations Ensure Long-Term Success?

Proper installation practices maximize high-temperature cylinder performance and service life.

Successful high-temperature installations require thermal isolation from heat sources, proper mounting flexibility for expansion, adequate clearances for thermal growth, environmental protection from contaminants, and comprehensive monitoring systems to track performance and predict maintenance needs.

Mounting and Alignment Strategies

Thermal Expansion Management

- Flexible mounting systems accommodate growth

- Clearance calculations for maximum expansion

- Alignment maintenance during thermal cycles

- Stress relief in connected piping and wiring

- Foundation stability under thermal loading

Installation Environment Preparation

- Heat shielding installation around cylinders

- Ventilation systems for heat removal

- Access provisions for maintenance and inspection

- Safety systems for personnel protection

- Emergency shutdown capabilities

System Integration Requirements

Control System Adaptations

- Temperature compensation in positioning algorithms

- Thermal monitoring with alarm systems

- Pressure regulation for gas expansion effects

- Cycle timing adjustments for thermal response

- Safety interlocks for over-temperature protection

Maintenance Access Planning

- Service clearances for component replacement

- Lifting provisions for heavy components

- Tool access for specialized maintenance equipment

- Parts storage in controlled environment conditions

- Documentation systems for thermal performance tracking

Performance Monitoring Systems

Critical Parameter Tracking

- Operating temperature continuous monitoring

- Pressure variations throughout cycles

- Position accuracy degradation over time

- Cycle time changes indicating wear

- Vibration analysis for bearing condition

Predictive Maintenance Integration

- Trend analysis for performance degradation

- Alarm thresholds for critical parameters

- Maintenance scheduling based on actual conditions

- Parts inventory optimization for high-temperature components

At Bepto, we specialize in high-temperature pneumatic solutions with extensive experience in steel, glass, and ceramic industries. Our engineering team provides comprehensive application support, from initial design consultation through installation and ongoing maintenance optimization, ensuring reliable operation in the most demanding thermal environments. 🎯

Conclusion

High-temperature pneumatic cylinder success depends on understanding temperature classifications, selecting appropriate materials and sealing technologies, implementing thermal management strategies, and following proper installation practices that accommodate thermal expansion while maintaining precision and reliability.

FAQs About High-Temperature Pneumatic Cylinders

Q: What’s the maximum temperature limit for pneumatic cylinders?

Standard pneumatic cylinders typically operate up to 80°C, while specialized high-temperature units can function reliably up to 350°C with proper material selection, though custom solutions can exceed 400°C for specific applications requiring advanced engineering.

Q: How does temperature affect pneumatic cylinder performance?

High temperatures cause seal degradation, lubricant breakdown, thermal expansion affecting tolerances, pressure variations due to gas laws, and accelerated component wear, requiring specialized materials and design features to maintain reliable operation.

Q: Are high-temperature cylinders significantly more expensive than standard units?

High-temperature cylinders typically cost 200-400% more than standard units due to specialized materials, advanced sealing systems, and enhanced manufacturing processes, but this investment prevents costly failures and downtime in thermal applications.

Q: How often do high-temperature cylinders require maintenance?

Maintenance intervals depend on operating temperature and conditions, typically ranging from 3-6 months for extreme applications (above 250°C) to 12-18 months for elevated temperature service (80-150°C), with proper monitoring extending service life.

Q: Can I retrofit existing cylinders for high-temperature applications?

Retrofitting standard cylinders for high-temperature service is generally not recommended due to housing material limitations, seal groove designs, and thermal expansion considerations, making purpose-built high-temperature units the safer, more reliable choice.

-

Learn about the principles of thermal expansion and how it is calculated for different materials in engineering. ↩

-

Understand the causes and effects of thermal shock and why it leads to material cracking and failure. ↩

-

Explore the chemical resistance and high-temperature properties of perfluoroelastomers (FFKM). ↩

-

Discover the mechanism of galling, a severe form of adhesive wear that occurs between sliding metal surfaces. ↩

-

Find out how thermoelectric coolers (TECs) use the Peltier effect to provide solid-state active cooling. ↩