Manufacturing engineers face catastrophic production failures when rodless cylinder sealing bands deteriorate, leading to compressed air leakage, reduced force output, contamination ingress, and complete system breakdown that can halt entire production lines for days while waiting for replacement components.

Rodless cylinder sealing band technology utilizes advanced polymer materials, precision-engineered profiles, and magnetic coupling systems1 to create leak-proof barriers that maintain consistent pneumatic pressure while enabling smooth linear motion across the entire stroke length without traditional rod seal limitations.

Just last week, I helped Robert, a senior maintenance engineer at an automotive parts facility in Michigan, diagnose mysterious pressure drops in his assembly line’s rodless cylinders. The culprit? Worn sealing bands that were allowing 30% air leakage, costing his company $2,000 daily in wasted compressed air. 🔧

Table of Contents

- How Do Rodless Cylinder Sealing Bands Actually Work?

- What Materials and Design Features Make Sealing Bands Effective?

- Which Factors Cause Sealing Band Failure and Performance Degradation?

- How Can You Optimize Sealing Band Performance and Longevity?

How Do Rodless Cylinder Sealing Bands Actually Work?

The sealing band represents the most critical component in rodless cylinder technology, determining overall system performance and reliability.

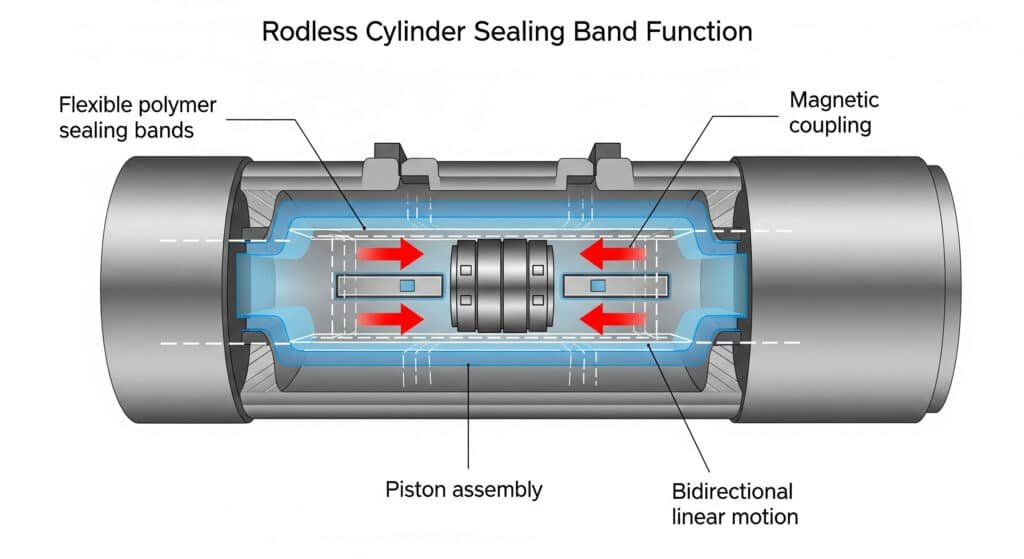

Rodless cylinder sealing bands function through flexible polymer strips that create dynamic seals around the piston assembly while allowing the magnetic coupling to pass through, maintaining pressure separation between chambers while enabling bidirectional linear motion without external rod penetration.

Fundamental Operating Principles

Magnetic Coupling Integration

The sealing band works in harmony with the magnetic coupling system:

- Internal magnet assembly moves within the sealed cylinder bore

- External magnet carriage follows the internal assembly through magnetic attraction

- Sealing band flexes around the internal magnets while maintaining pressure integrity

- Continuous seal prevents air leakage throughout the entire stroke length

- Dynamic flexibility accommodates magnet movement without compromising seal effectiveness

Pressure Differential Management

| Operating Parameter | Standard Range | Critical Threshold |

|---|---|---|

| Working pressure | 1-10 bar | Maximum 16 bar |

| Temperature range | -20°C to +80°C | Varies by material |

| Stroke speed | 0.1-2.0 m/s | Depends on application |

| Cycle frequency | Up to 10 Hz | Limited by heat buildup |

The sealing band must withstand constant pressure differentials while flexing thousands of times per day. Our Bepto sealing bands are engineered to handle 2 million cycles at full working pressure, significantly outperforming standard OEM specifications.

Sealing Mechanism Details

Dynamic Seal Formation

The sealing process involves multiple contact points:

- Primary seal contact between band and cylinder wall

- Secondary seal interface around the piston assembly

- Flexible deformation zone that accommodates magnet passage

- Recovery region where the band returns to original shape

- Continuous pressure barrier maintained throughout the cycle

What Materials and Design Features Make Sealing Bands Effective?

Advanced material science and precision engineering determine sealing band performance under demanding industrial conditions.

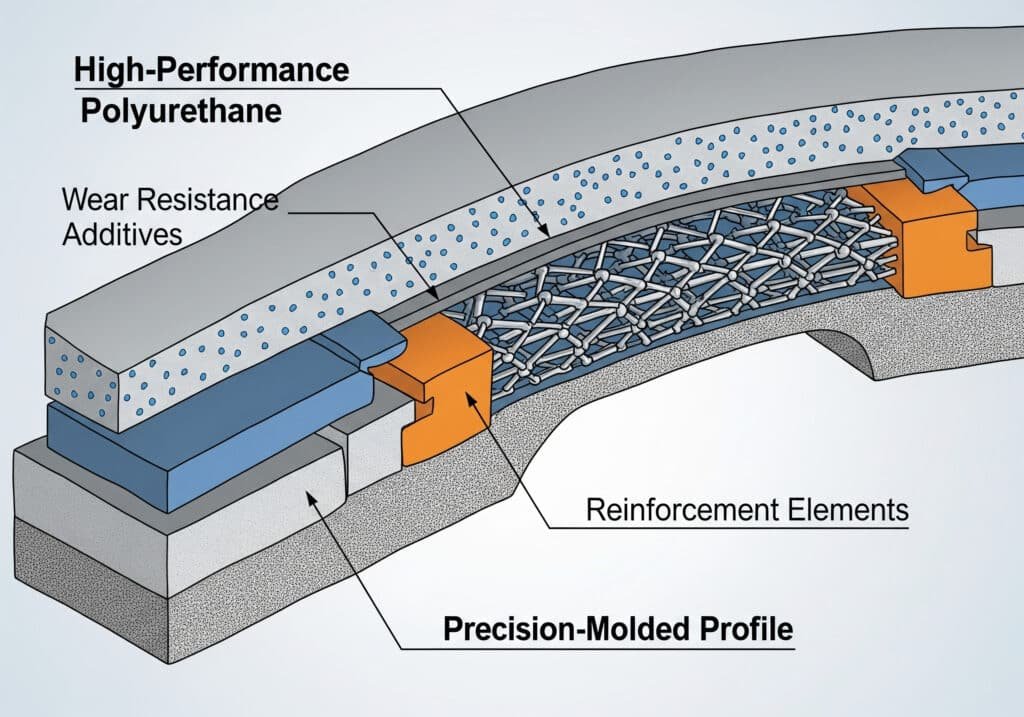

Effective sealing bands utilize high-performance polyurethane compounds2, specialized additives for wear resistance, precision-molded profiles with optimized contact geometry, and reinforcement elements that provide durability while maintaining flexibility for millions of operating cycles.

Material Technology Breakdown

Polymer Composition Analysis

Modern sealing bands employ sophisticated material formulations:

- Base polymer matrix – Typically polyurethane for optimal flexibility

- Wear resistance additives – Carbon black or silica reinforcement

- Temperature stabilizers – Prevent degradation in extreme conditions

- Anti-extrusion compounds – Maintain shape under high pressure

- Lubricity enhancers – Reduce friction and heat generation

Design Feature Optimization

| Design Element | Standard Configuration | Bepto Enhancement |

|---|---|---|

| Cross-sectional profile | Basic rectangular | Optimized curved geometry |

| Contact pressure distribution | Uniform | Variable pressure zones |

| Material hardness | Single durometer | Dual-durometer construction |

| Reinforcement | None | Embedded fabric layers |

| Surface treatment | Standard | Proprietary coating |

Manufacturing Precision Requirements

Critical Dimensional Tolerances

Sealing band effectiveness depends on extremely tight manufacturing tolerances:

- Width variation must be within ±0.05mm across the entire length

- Thickness uniformity requires ±0.02mm consistency

- Hardness variation cannot exceed ±2 Shore A3 points

- Surface finish must achieve Ra 0.8μm or better

- Material homogeneity ensures consistent performance characteristics

I recently worked with Jennifer, who manages a packaging equipment company in Oregon, to solve recurring sealing failures in her rodless cylinders. After analyzing her application requirements, we provided Bepto sealing bands with our enhanced dual-durometer design, resulting in 300% longer service life and eliminating her monthly replacement cycles. 🎯

Which Factors Cause Sealing Band Failure and Performance Degradation?

Understanding failure mechanisms enables proactive maintenance strategies and optimal sealing band selection for specific applications.

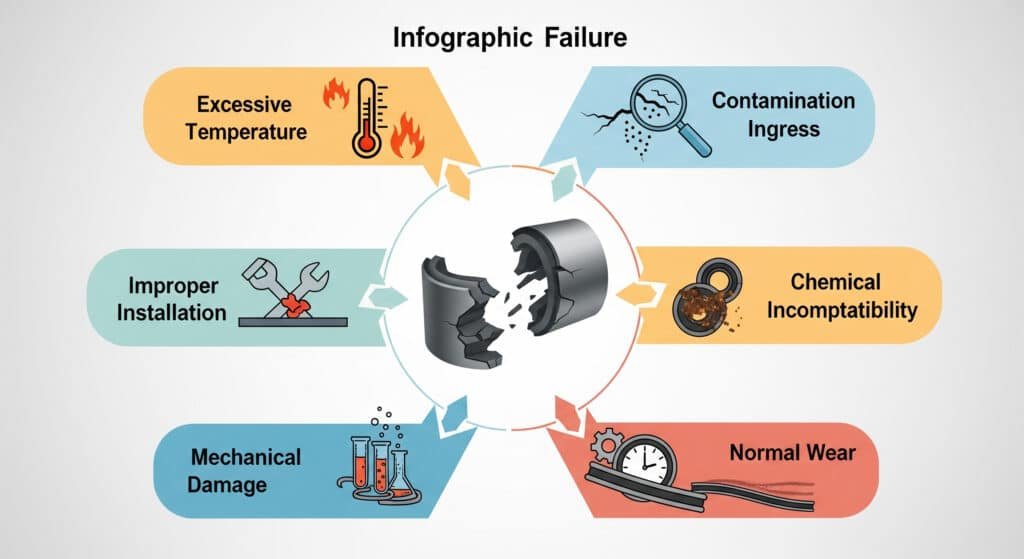

Sealing band failure typically results from excessive operating temperatures, contamination ingress, improper installation procedures, chemical incompatibility, mechanical damage from misalignment, and normal wear progression that can be predicted and prevented through proper system design and maintenance protocols.

Primary Failure Mechanisms

Thermal Degradation Patterns

Heat represents the most common cause of premature sealing band failure:

- Excessive friction from misalignment or contamination

- High-frequency cycling generating heat buildup

- Ambient temperature exposure beyond material limits

- Chemical reactions accelerated by elevated temperatures

- Thermal cycling stress from temperature fluctuations

Contamination Impact Analysis

| Contaminant Type | Damage Mechanism | Prevention Strategy |

|---|---|---|

| Metal particles | Abrasive wear | Improved filtration |

| Chemical vapors | Material swelling | Compatible materials |

| Moisture ingress | Hydrolysis degradation4 | Environmental sealing |

| Oil contamination | Softening/swelling | Material selection |

| Dust accumulation | Friction increase | Regular cleaning |

Predictive Failure Indicators

Early Warning Signs

Experienced engineers can identify impending sealing band failure through:

- Gradual pressure loss during static holding

- Increased air consumption during normal operation

- Irregular motion patterns or stick-slip behavior5

- Visible wear marks on the cylinder tube

- Performance inconsistency between cycles

How Can You Optimize Sealing Band Performance and Longevity?

Maximizing sealing band service life requires systematic attention to installation, operation, and maintenance practices.

Optimizing sealing band performance involves proper material selection for operating conditions, precise installation procedures, contamination prevention measures, regular inspection protocols, and proactive replacement scheduling based on cycle counting and performance monitoring rather than reactive failure response.

Installation Best Practices

Critical Installation Steps

Proper installation directly impacts sealing band longevity:

- Cylinder preparation – Clean all surfaces thoroughly

- Alignment verification – Ensure perfect bore straightness

- Band positioning – Follow manufacturer’s orientation guidelines

- Tension adjustment – Apply specified preload without overstretching

- System testing – Verify leak rates before full operation

Performance Optimization Strategies

| Optimization Area | Standard Practice | Bepto Recommendation |

|---|---|---|

| Operating pressure | Maximum rated | 80% of maximum rating |

| Cycle frequency | As needed | Optimized duty cycles |

| Temperature control | Ambient operation | Active cooling if needed |

| Contamination control | Basic filtration | Multi-stage filtration |

| Maintenance schedule | Failure-based | Predictive monitoring |

Bepto Advantage in Sealing Technology

Our Technical Superiority

At Bepto, we’ve invested heavily in sealing band technology development:

- Advanced material formulations tested for 5 million cycles

- Precision manufacturing with automated quality control

- Application-specific designs optimized for different industries

- Technical support from experienced pneumatic engineers

- Cost-effective solutions delivering 40% savings over OEM parts

Our sealing bands consistently outperform OEM specifications while providing significant cost savings. We maintain extensive inventory for immediate delivery, ensuring your production lines never wait for critical sealing components. 🚀

Conclusion

Rodless cylinder sealing band technology represents a sophisticated engineering solution that requires deep understanding of materials, design principles, and application requirements to achieve optimal performance and longevity in demanding industrial environments.

FAQs About Rodless Cylinder Sealing Band Technology

Q: How often should rodless cylinder sealing bands be replaced?

Sealing band replacement intervals depend on operating conditions, but typically range from 1-3 years or 2-5 million cycles, with proactive replacement recommended at 80% of expected service life to prevent unexpected failures.

Q: Can different sealing band materials be used in the same cylinder?

Material compatibility is critical for proper sealing performance, and mixing different compounds can cause uneven wear patterns, so always use identical sealing band materials throughout the entire cylinder assembly.

Q: What are the signs that sealing bands need immediate replacement?

Immediate replacement indicators include visible air leakage, pressure drops exceeding 5% during static holding, irregular cylinder motion, increased compressed air consumption, or any visible damage to the sealing band surface.

Q: How do Bepto sealing bands compare to original equipment manufacturer parts?

Bepto sealing bands offer equivalent or superior performance to OEM parts while providing 30-40% cost savings, faster delivery times, and enhanced durability through our advanced material formulations and precision manufacturing processes.

Q: What installation tools are required for sealing band replacement?

Sealing band installation requires basic hand tools, clean work environment, proper alignment fixtures, torque specifications for assembly bolts, and compressed air testing equipment to verify proper installation and leak-free operation.

-

Learn about the fundamental principles of how magnetic couplings transmit force without physical contact. ↩

-

Explore the material properties of polyurethane elastomers, including their flexibility and durability. ↩

-

Understand the Shore A hardness scale and how it is used to measure the durometer of soft polymers and elastomers. ↩

-

Discover the chemical process of hydrolysis and how it leads to the degradation of polymer materials like polyurethane. ↩

-

Delve into the causes and effects of the stick-slip phenomenon, a common issue in systems with sliding friction. ↩