Every plant manager I’ve worked with faces the same problem: unpredictable maintenance costs that wreck budgets and production schedules. The anxiety of not knowing when critical components will fail leads to either wasteful over-maintenance or costly emergency repairs. There’s a better approach that transforms this uncertainty into predictable expenses.

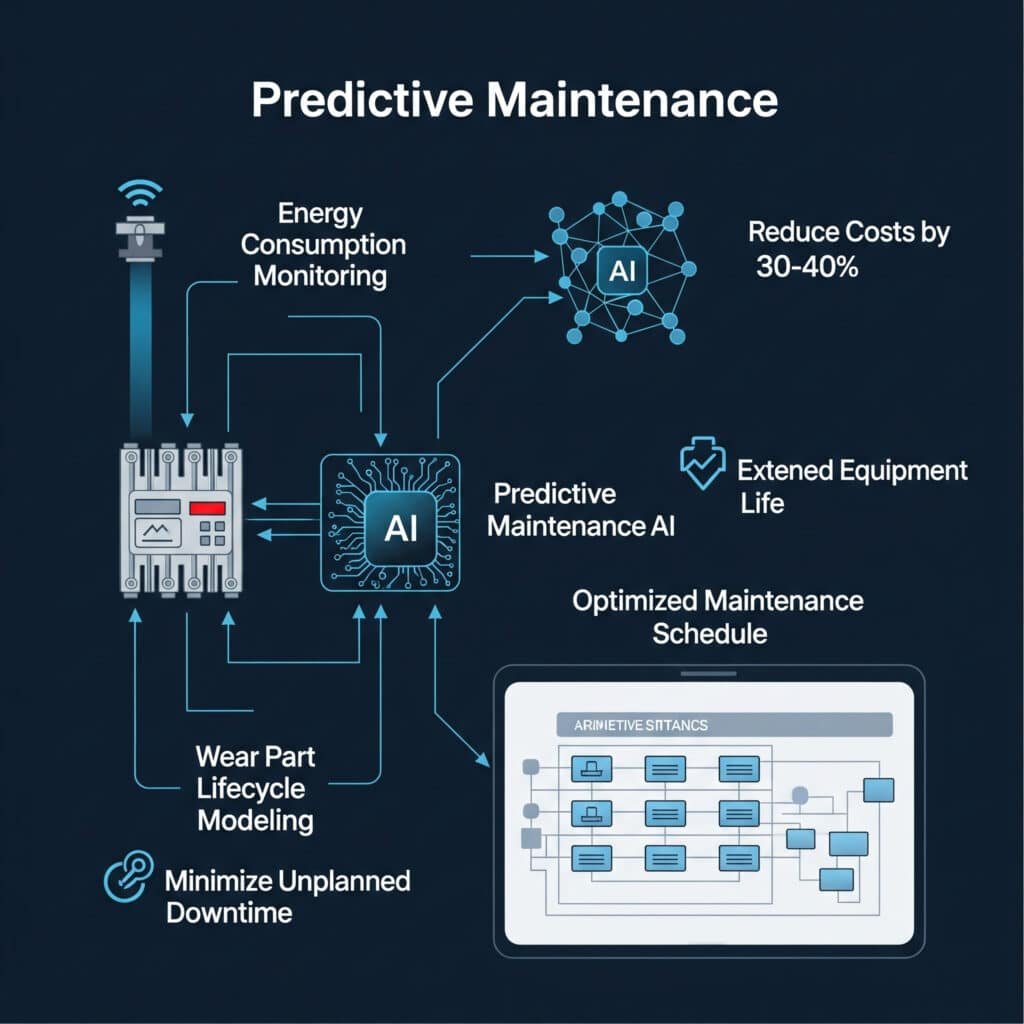

Predictive maintenance1 for pneumatic systems combines wear part lifecycle modeling, energy consumption monitoring, and preventive maintenance scheduling to reduce overall maintenance costs by 30-40% while extending equipment life and minimizing unplanned downtime.

Last quarter, I visited a manufacturing facility in Wisconsin where the maintenance supervisor showed me their “wall of shame” – a collection of failed rodless cylinders that had caused production stoppages. After implementing our predictive maintenance approach, they haven’t added a single cylinder to that wall in over 8 months. Let me show you how we did it.

Table of Contents

- Wear Parts Replacement Prediction Model

- Energy Monitoring System Selection Guide

- Preventive Maintenance Cost Comparison

- Conclusion

- FAQs About Maintenance Cost Analysis

How Can You Accurately Predict When Rodless Cylinder Parts Will Fail?

Predicting wear part failure has traditionally been more art than science, with most maintenance schedules based on manufacturer recommendations that rarely account for your specific operating conditions.

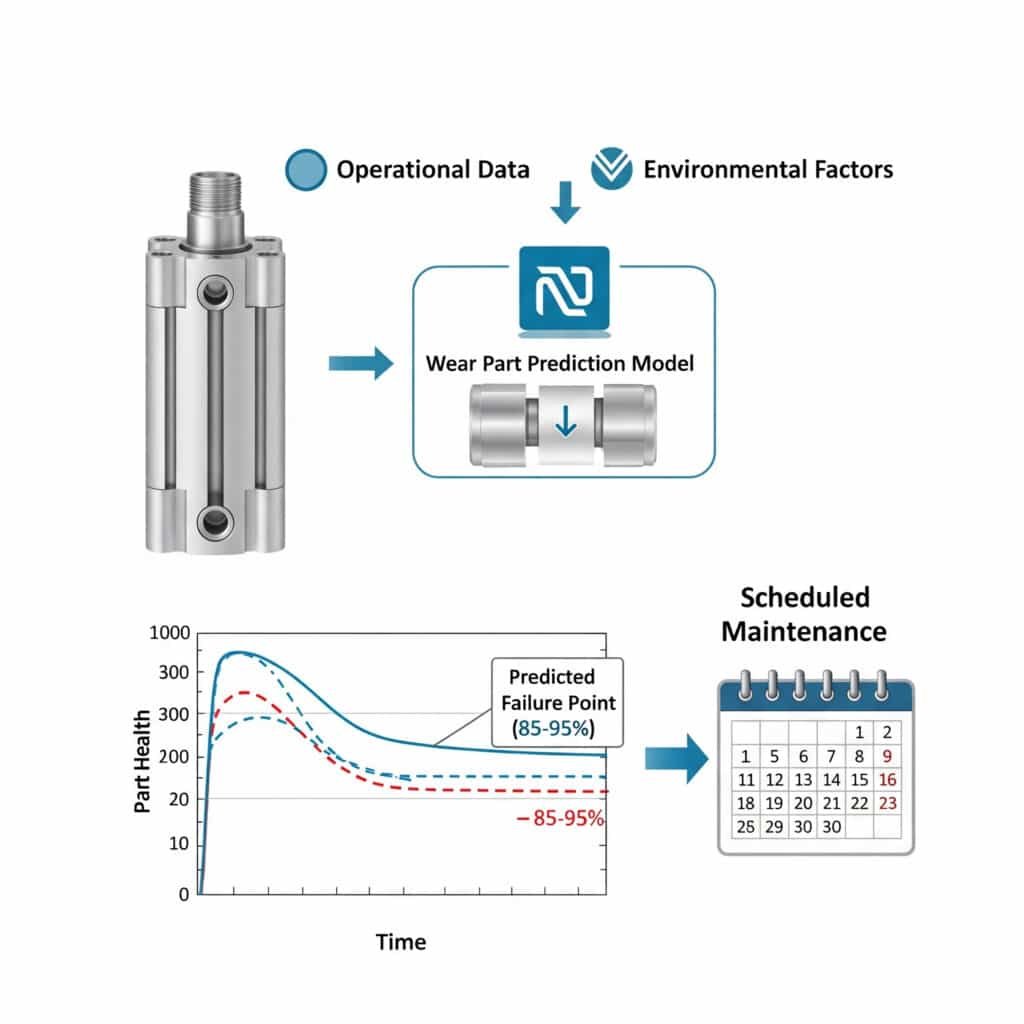

Wear part prediction models2 use operational data, environmental factors, and component-specific algorithms to forecast failure points with 85-95% accuracy, allowing maintenance to be scheduled during planned downtime rather than emergency situations.

Key Variables in Wear Part Lifecycle Prediction

After analyzing thousands of component failures across various industries, I’ve identified these critical factors that determine wear part lifespan:

Operating Environment Factors

| Factor | Impact Level | Effect on Lifespan |

|---|---|---|

| Temperature | High | ±15% per 10°C deviation |

| Humidity | Medium | -5% per 10% above optimal |

| Contaminants | Very High | Up to -70% in dirty environments |

| Cycle frequency | High | Linear relationship with wear |

Component-Specific Considerations

For rodless pneumatic cylinders specifically, these factors have the greatest impact on wear part life:

- Seal material compatibility

- Lubrication consistency

- Side-loading conditions

- Stroke utilization percentage

Building Your Prediction Model

I recommend a three-phase approach to developing your wear part prediction model:

Phase 1: Data Collection

Start by documenting current replacement patterns and operating conditions. For one automotive client in Michigan, we installed simple cycle counters on their rodless cylinders and tracked ambient conditions for just 30 days. This baseline data revealed that their maintenance schedule was misaligned with actual wear patterns by an average of 42%.

Phase 2: Pattern Recognition

Look for correlations between operating conditions and failure rates. Our data analysis typically reveals that:

- Cylinders operating at >80% of rated pressure fail 2.3x faster

- Temperature fluctuations >15°C accelerate seal wear by 37%

- Inconsistent lubrication reduces bearing life by up to 60%

Phase 3: Model Implementation

Implement a predictive model that accounts for your specific conditions. This can range from a simple spreadsheet to advanced monitoring systems.

Case Study: Food Processing Plant

A food processing plant in Pennsylvania was replacing rodless cylinder seals every 3 months based on the manufacturer’s recommendation. After implementing our prediction model, they discovered that some units could safely operate for 5 months while others in harsher environments needed replacement at 2.5 months. This targeted approach reduced their overall replacement parts costs by 23% while decreasing unplanned downtime by 47%.

Which Energy Monitoring System Will Give You the Most Actionable Data?

Energy consumption often accounts for 70-80% of a pneumatic system’s lifetime cost, yet most maintenance programs focus exclusively on component replacement while ignoring this major expense driver.

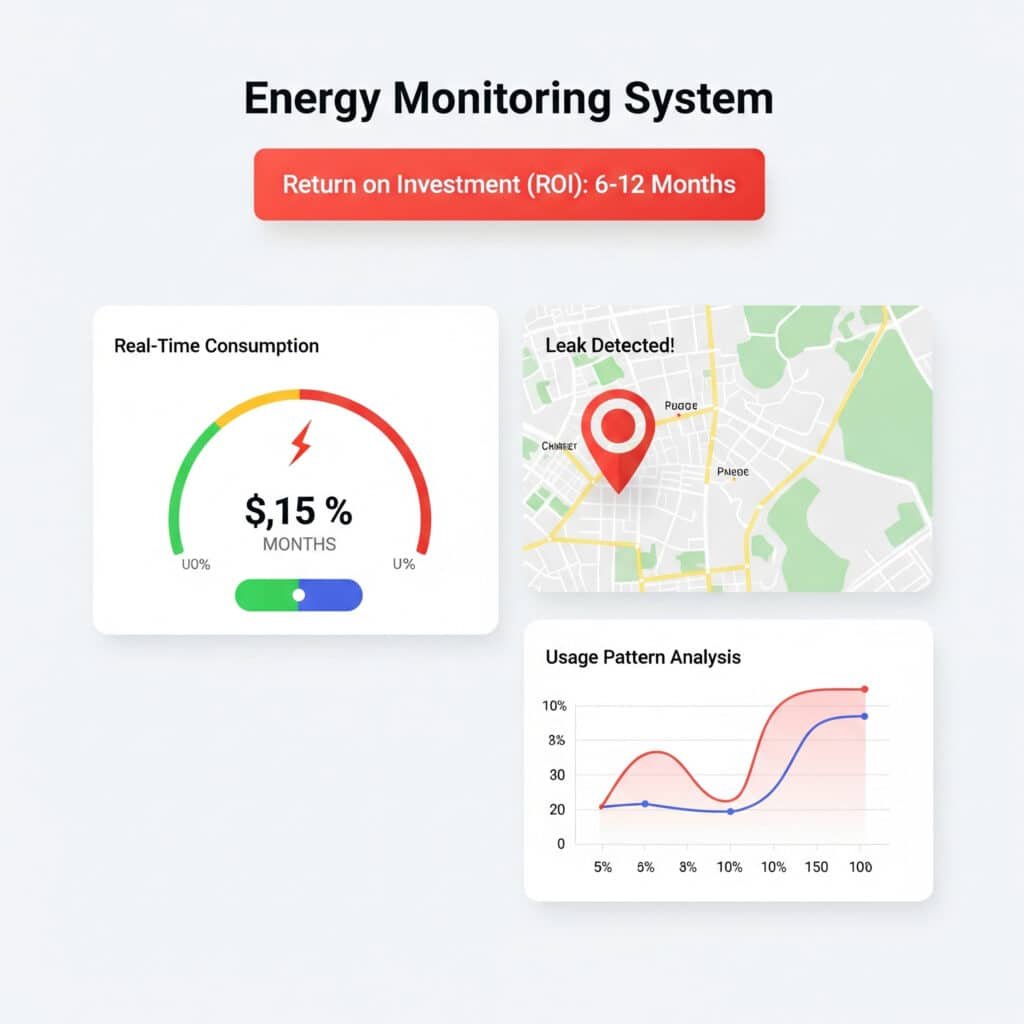

The ideal energy monitoring system provides real-time consumption data, leak detection capabilities, and usage pattern analysis that identifies inefficiencies. Systems with these features typically deliver ROI within 6-12 months through reduced energy costs and early problem detection.

Monitoring System Selection Criteria

When helping clients select energy monitoring systems, I evaluate options against these critical requirements:

| Feature | Importance | Benefit |

|---|---|---|

| Real-time monitoring | Essential | Immediate problem identification |

| Historical data analysis | High | Pattern recognition and trending |

| Integration capability | Medium | Connection to existing systems |

| Alert functionality | High | Proactive notification of issues |

| Visualization tools | Medium | Easier interpretation by staff |

Monitoring System Types

Based on your system complexity and budget, these are the three main categories to consider:

Basic Monitoring Systems

- Cost: $500-2,000

- Features: Flow meters, pressure sensors, basic data logging

- Best for: Small systems, limited budgets

- Limitations: Manual data analysis required

Intermediate Monitoring Systems

- Cost: $2,000-8,000

- Features: Networked sensors, automated reporting, basic analytics

- Best for: Medium-sized operations with multiple pneumatic systems

- Limitations: Limited predictive capabilities

Advanced Monitoring Systems

- Cost: $8,000-25,000

- Features: AI-powered analytics3, predictive maintenance alerts, comprehensive integration

- Best for: Large operations where downtime is extremely costly

- Limitations: Requires technical expertise to maximize value

Implementation Strategy

For most clients, I recommend this phased approach:

- Baseline Assessment: Install temporary monitoring on critical systems to establish consumption patterns

- Hotspot Identification: Target permanent monitoring on the 20% of systems that consume 80% of energy

- Gradual Expansion: Extend monitoring to additional systems as ROI is proven

Energy Monitoring Success Metrics

When evaluating system performance, focus on these key indicators:

- Leak detection rate (target: identification of 90%+ of leaks >1 CFM)

- Energy consumption reduction (typical: 15-30% in first year)

- Anomaly detection time (target: <24 hours from occurrence)

- Correlation with production volume (enables per-unit energy cost calculation)

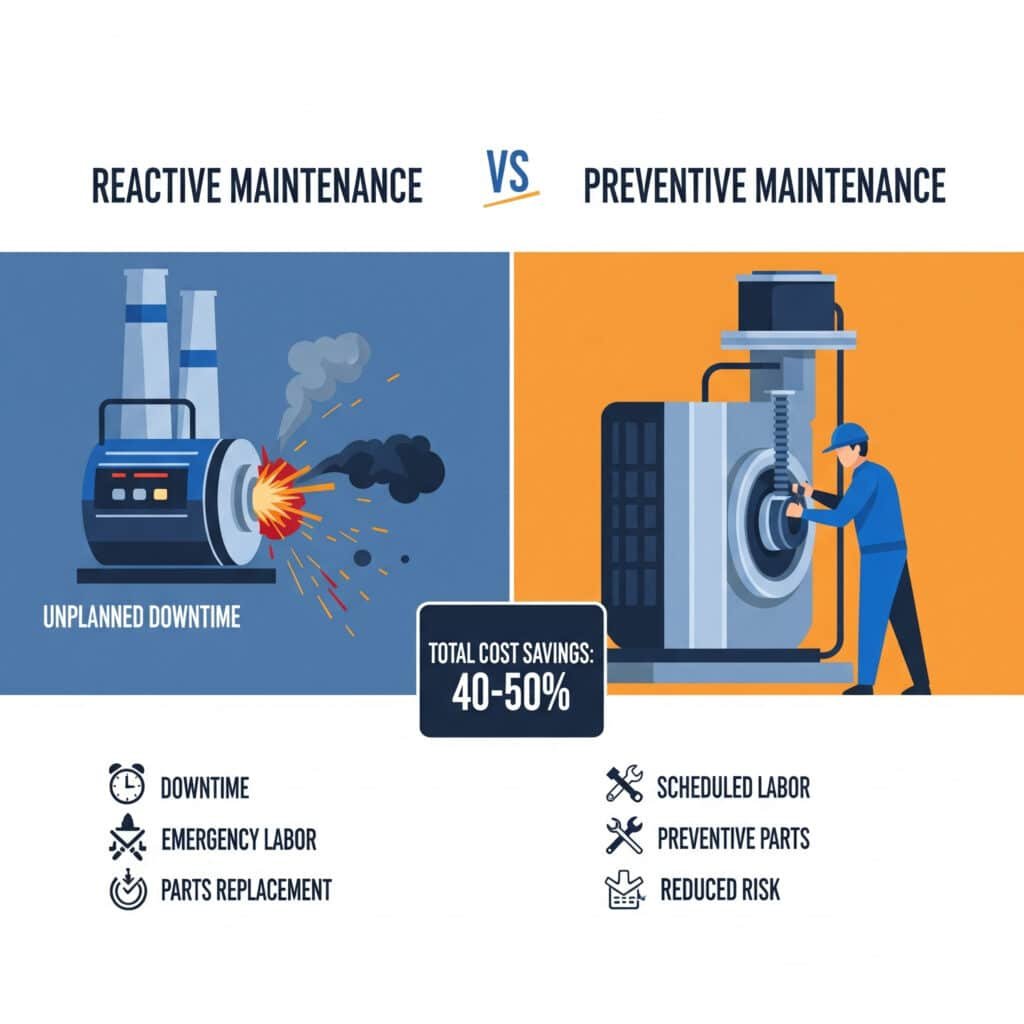

Is Preventive Maintenance Actually Cheaper Than Reactive Maintenance?

The debate between preventive and reactive maintenance approaches often focuses on immediate costs rather than total financial impact. This narrow view leads many operations to make costly long-term mistakes.

Preventive maintenance typically costs 25-35% less than reactive maintenance when accounting for all factors including parts costs, labor, downtime losses, and equipment lifespan. For pneumatic systems specifically, the savings can reach 40-50% due to the cascading nature of component failures.

Comprehensive Cost Comparison

This analysis compares the true costs of different maintenance approaches for a typical manufacturing line with 24 rodless pneumatic cylinders:

| Cost Factor | Reactive Approach | Preventive Approach | Predictive Approach |

|---|---|---|---|

| Parts costs (annual) | $12,400 | $9,800 | $7,200 |

| Labor hours (annual) | 342 | 286 | 198 |

| Downtime hours (annual) | 78 | 32 | 14 |

| Production loss value | $156,000 | $64,000 | $28,000 |

| Equipment lifespan | 5.2 years | 7.8 years | 9.3 years |

| Total 5-year cost | $923,000 | $408,000 | $215,000 |

Hidden Costs of Reactive Maintenance

When calculating the true cost of reactive maintenance, don’t overlook these often-missed factors:

Direct Hidden Costs

- Emergency shipping premiums (typically 20-50% above standard parts costs)

- Overtime labor rates (average 1.5x standard rates)

- Expedited production to catch up after failures

Indirect Hidden Costs

- Quality issues from rushed repairs (average 2-5% defect increase)

- Customer satisfaction impact from missed deliveries

- Staff stress and turnover from crisis management culture

Preventive Maintenance Implementation Framework

For clients transitioning to preventive maintenance, I recommend this implementation approach:

Phase 1: Critical System Identification

Start with systems that have the highest downtime cost or failure frequency. For a packaging client in Texas, we identified that their case packing line’s pneumatic system caused 43% of total downtime despite representing only 12% of total equipment value.

Phase 2: Maintenance Schedule Development

Create optimized maintenance schedules based on:

- Manufacturer recommendations (starting point only)

- Historical failure data (your most valuable resource)

- Operating environment factors

- Production schedule constraints

Phase 3: Resource Allocation

Determine optimal staffing and parts inventory based on:

- Maintenance task duration and complexity

- Required skill levels

- Parts lead times and storage requirements

Measuring Preventive Maintenance Success

Track these KPIs to validate your preventive maintenance program:

- Mean Time Between Failures (MTBF)4 – target: increase by >40%

- Maintenance Cost as % of Asset Value – target: <5% annually

- Planned vs. Unplanned Maintenance Ratio – target: >85% planned

- Overall Equipment Effectiveness (OEE)5 – target: increase by >15%

Conclusion

Implementing a comprehensive maintenance cost analysis approach through wear part prediction modeling, energy monitoring, and preventive maintenance strategies can transform your pneumatic system reliability while significantly reducing total costs. The data-driven approach eliminates guesswork and creates predictable maintenance budgets.

FAQs About Maintenance Cost Analysis

What is the average ROI timeframe for implementing predictive maintenance?

The typical ROI timeframe for predictive maintenance implementation is 6-18 months, with pneumatic systems often showing faster returns due to their high energy consumption and critical role in production processes.

How do you calculate the true cost of downtime for maintenance planning?

Calculate true downtime cost by adding direct production losses (hourly production value × hours down), labor costs (repair hours × labor rate), parts costs, and indirect costs like missed deliveries, quality issues, and overtime to catch up.

Which wear parts in rodless pneumatic cylinders typically fail first?

In rodless pneumatic cylinders, seals and bearings typically fail first, with seals being the most common failure point (accounting for approximately 60% of failures) due to their constant friction and exposure to contaminants.

How often should energy monitoring systems be calibrated?

Energy monitoring systems should be calibrated at least annually, with critical systems requiring semi-annual calibration. Systems exposed to harsh environments or measuring highly variable loads may require quarterly calibration.

What percentage of maintenance budget should be allocated to preventive vs. reactive activities?

In a well-optimized maintenance program, approximately 70-80% of the budget should be allocated to preventive activities, 15-20% to predictive technologies, and only 5-10% reserved for truly unpredictable reactive maintenance.

How does air quality affect pneumatic system maintenance costs?

Air quality dramatically impacts maintenance costs, with studies showing that every 3-point improvement in ISO air quality classification (e.g., from ISO 8573-1 Class 4 to Class 1) reduces wear part replacement frequency by 30-45% and extends overall system life by 15-25%.

-

Provides a detailed explanation of predictive maintenance (PdM), a proactive strategy that uses data analysis tools and techniques to detect anomalies in operation and possible defects in processes and equipment so that they can be fixed before they result in failure. ↩

-

Describes the “bathtub curve,” a classic reliability engineering model that represents the failure rate of a product over its lifetime, consisting of three phases: infant mortality, normal life, and wear-out. This is a key concept in lifecycle modeling. ↩

-

Offers an overview of how Artificial Intelligence (AI) is applied in manufacturing for tasks like predictive maintenance, quality control, supply chain optimization, and production scheduling, often as part of Industry 4.0 initiatives. ↩

-

Provides a clear definition of Mean Time Between Failures (MTBF), a key performance indicator that measures the average time elapsed between a repairable asset’s inherent failures during normal system operation, indicating its reliability. ↩

-

Explains Overall Equipment Effectiveness (OEE), a standard metric for measuring manufacturing productivity, which is calculated by multiplying three factors: Availability, Performance, and Quality. ↩