Are you struggling with finding the right technical information for your pneumatic systems1? Many engineers waste countless hours searching through scattered documents, risking costly production delays.

The SMC Technical Whitepaper serves as a comprehensive resource for rodless cylinder specifications, containing detailed mounting dimensions, catalog access methods, and flow control valve matching solutions to optimize your pneumatic systems.

Let me share something from my experience – last year, a client in Germany lost nearly $20,000 in production downtime because they couldn’t quickly access the right technical specifications for their damaged SMC MY1B rodless cylinder2. This guide will help you avoid similar situations.

How Can You Interpret the MY1B Mounting Dimension Atlas Correctly?

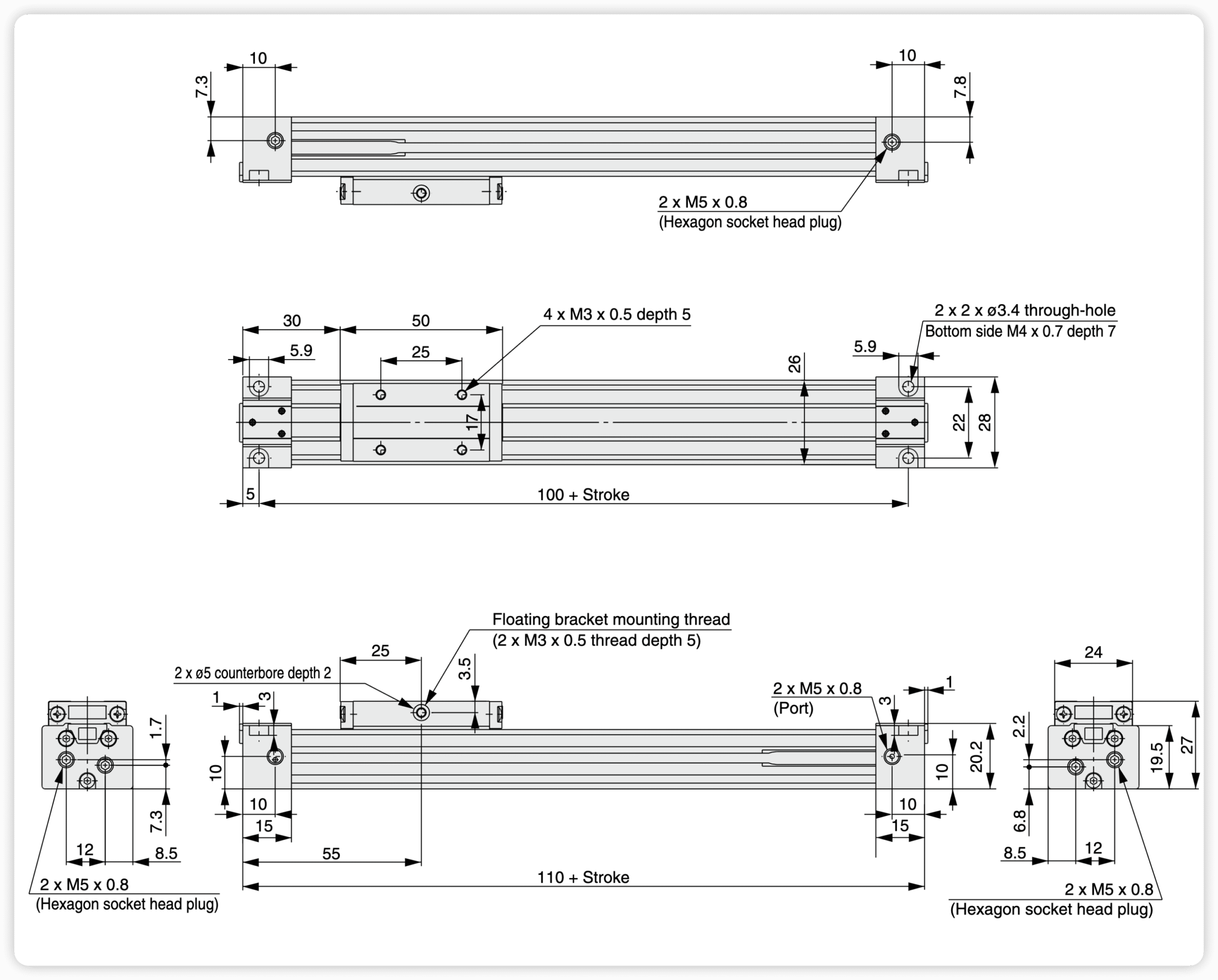

The MY1B mounting dimension atlas is often the first technical document engineers consult when planning installations or replacements.

The MY1B mounting dimension atlas provides precise measurements for all connection points, stroke lengths, and physical parameters essential for proper installation and replacement of rodless pneumatic cylinders in your equipment.

Understanding the MY1B dimension atlas requires attention to several critical details. I’ve helped hundreds of engineers navigate these specifications, and here are the key components you should focus on:

Critical Dimensions for MY1B Installation

The MY1B rodless cylinder series features several crucial measurements that determine compatibility with your existing equipment:

- Mounting Bracket Positions: The exact positioning of mounting holes is critical for proper alignment

- Stroke Length Variations: Available in increments from 50mm to 1000mm

- Overall Width and Height: Essential for space constraint considerations

MY1B Series Compatibility Chart

| Equipment Type | Compatible MY1B Models | Special Notes |

|---|---|---|

| CNC Machinery | MY1B16-100 to MY1B25-400 | Requires special end caps |

| Packaging Lines | MY1B32-200 to MY1B40-800 | High-speed applications |

| Assembly Systems | MY1B16-50 to MY1B25-300 | Precision positioning |

| Material Handling | MY1B40-500 to MY1B63-1000 | Heavy load capacity |

Replacement Considerations for MY1B Series

When replacing an SMC MY1B rodless cylinder, you must verify:

- Exact stroke length (not just approximate)

- Mounting bracket type and orientation

- Port connections and positioning

- Magnetic sensor compatibility

I recently helped a manufacturing plant in the UK replace their damaged MY1B40-600 cylinders with our Bepto equivalents, saving them over 40% on replacement costs while maintaining identical mounting dimensions. The key was precise measurement verification before ordering.

How to Access SMC Catalog PDFs Efficiently?

Finding the right catalog documentation quickly can mean the difference between a quick repair and costly downtime.

SMC catalog PDFs can be accessed through their official website, authorized distributor portals, engineering reference platforms, and through direct request to sales representatives – though these methods often involve delays and registration barriers.

While SMC provides multiple access points for their technical documentation, each comes with certain limitations. Let me walk you through the options and their practical implications:

Official Channels vs. Alternative Sources

SMC Official Website Navigation

The SMC website organizes catalogs by:

- Product category (pneumatic, electric, vacuum)

- Model series (MY1, CY3R, etc.)

- Technical specification type

However, this approach requires:

- Multiple clicks through navigation menus

- Registration for full access

- Waiting periods for approval on certain documents

Distributor Portal Access Methods

Many authorized distributors maintain their own document libraries with:

- Simplified navigation

- Pre-filtered content

- Sometimes outdated versions

Quick Access Alternatives for Emergency Situations

When facing production downtime, waiting for document access isn’t an option. Here are faster alternatives:

| Access Method | Response Time | Limitations | Best For |

|---|---|---|---|

| Direct Sales Contact | 1-3 days | Business hours only | Detailed guidance |

| Engineering Forums | 1-24 hours | Variable accuracy | Quick reference |

| Bepto Technical Support | 2-4 hours | Limited to compatible models | Replacement solutions |

| Local Distributor | 4-24 hours | Stock-dependent | Immediate needs |

One of my clients in France, Marc, was struggling with a failed rodless cylinder on his packaging line. Rather than waiting 5 days for SMC’s replacement documentation, we provided compatible dimension specifications within 3 hours, allowing him to order a replacement immediately and resume production the next day.

What’s the Best Approach for Flow Control Valve Matching?

Proper flow control valve3 matching is crucial for optimal rodless cylinder performance and longevity.

The best approach for flow control valve matching involves selecting valves with appropriate flow capacity ratings, considering cylinder bore size, required speed control precision, and application-specific factors like back pressure requirements and environmental conditions.

Matching flow control valves to rodless cylinders requires both technical knowledge and practical experience. Let me share some insights from my 15+ years in the pneumatic industry:

Flow Capacity Calculation Fundamentals

The relationship between cylinder size and flow control requirements follows these principles:

- Bore Size Correlation: Larger cylinders require proportionally higher flow capacity

- Speed Control Precision: More precise control requires valves with finer adjustment capabilities

- Pressure Drop Considerations: Minimize pressure drops for energy efficiency

Application-Specific Matching Guidelines

Different applications demand different flow control characteristics:

High-Speed Applications

For high-cycle operations:

- Use valves with minimal internal restriction

- Consider dual flow control (both extension and retraction)

- Implement shock absorption for end positions

Precision Positioning Applications

When exact positioning matters:

- Select valves with fine adjustment capability

- Consider meter-out control methodology4

- Evaluate potential for electronic proportional control5

Flow Control Valve Selection Matrix

| Cylinder Bore | Recommended Flow Range | Valve Connection Size | Control Type |

|---|---|---|---|

| 16mm | 0-100 L/min | M5 | Precision needle |

| 25mm | 100-300 L/min | G1/8 | Standard needle |

| 32mm | 300-600 L/min | G1/4 | Standard needle |

| 40mm | 600-1000 L/min | G1/4 | High-flow needle |

| 63mm | 1000-2000 L/min | G3/8 | High-flow needle |

I recently consulted with a medical equipment manufacturer in Switzerland who was experiencing inconsistent movement in their SMC rodless cylinders. The issue wasn’t the cylinders themselves but improperly sized flow control valves. By implementing our matching methodology, they achieved the smooth, controlled motion their application required.

Conclusion

The SMC Technical Whitepaper provides essential information for rodless cylinder implementation, but accessing and applying this knowledge efficiently requires expertise. With proper understanding of mounting dimensions, catalog access methods, and flow control matching, you can minimize downtime and optimize system performance.

FAQs About SMC Rodless Cylinders

What are the most common SMC rodless cylinder series?

SMC’s most common rodless cylinder series include the MY1B (mechanical rodless), CY3R (magnetically coupled), and REA (electric actuator) series. Each serves different applications based on load requirements, environmental conditions, and control precision needs.

How do SMC rodless cylinders compare to other brands?

SMC rodless cylinders typically offer high precision and reliability but at premium prices. Alternatives like Bepto provide comparable performance specifications and identical mounting dimensions at 30-40% lower cost, with faster delivery times for replacement parts.

What’s the typical lifespan of an SMC rodless cylinder?

Under normal operating conditions, SMC rodless cylinders typically last 5-7 million cycles. However, this varies based on application factors like load, speed, environment, and maintenance practices. Proper flow control valve matching can extend this lifespan significantly.

Can I replace an SMC rodless cylinder with a different brand?

Yes, SMC rodless cylinders can be replaced with compatible alternatives from manufacturers like Bepto. The key is ensuring exact matching of mounting dimensions, stroke length, and performance specifications. Always verify critical dimensions before ordering replacements.

How do I troubleshoot uneven movement in SMC rodless cylinders?

Uneven movement in rodless cylinders typically stems from improper flow control valve settings, internal seal damage, contamination, or lubrication issues. Start by checking and adjusting flow controls, then inspect for air leaks or unusual noise that might indicate mechanical problems.

-

Provides foundational knowledge on how pneumatic systems work, their components, and common applications, helping you understand the context of rodless cylinders. ↩

-

Offers direct access to the official manufacturer’s technical data for the MY1B series, ensuring you have the most accurate and up-to-date mounting dimensions and specifications. ↩

-

Explains the function and importance of flow control valves in pneumatic systems, helping you understand how they regulate cylinder speed and performance. ↩

-

Details the differences between control methodologies, which is crucial for applications requiring high-precision movement and stability. ↩

-

Describes advanced electronic control technology for pneumatics, offering insight into achieving superior precision and automated adjustments compared to manual valves. ↩