Piston rod buckling failures cost manufacturers over $1.2 million annually in damaged equipment and production delays, yet 70% of engineers still use outdated safety calculations that ignore critical factors like mounting conditions, side loading, and dynamic forces that can reduce buckling strength by up to 80%. 😰

Preventing piston rod buckling requires calculating the critical buckling load using Euler’s formula1, considering effective length based on mounting conditions, applying safety factors of 4-10x, and often switching to rodless cylinder technology for strokes exceeding 1000mm to eliminate buckling risks entirely.

Just last month, I helped David, a design engineer at a packaging facility in Michigan, whose 1500mm stroke cylinders were failing every few weeks due to rod buckling. After switching to our Bepto rodless cylinders, his system has run flawlessly for over 2000 hours without a single failure. 🎯

Table of Contents

- What Are the Critical Factors That Cause Piston Rod Buckling?

- How Do You Calculate Safe Operating Loads for Long-Stroke Cylinders?

- When Should You Consider Rodless Cylinder Alternatives?

- What Are the Best Practices for Preventing Rod Buckling Failures?

What Are the Critical Factors That Cause Piston Rod Buckling?

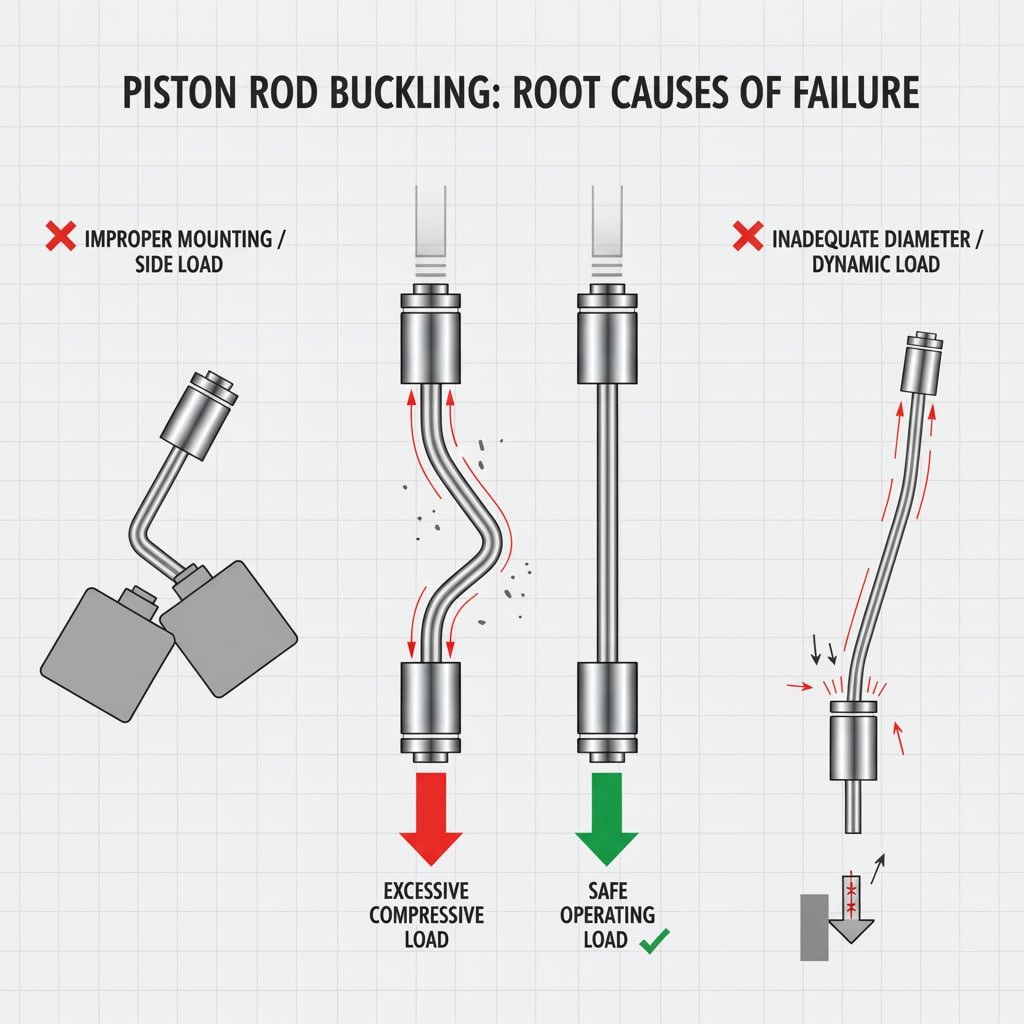

Understanding the root causes of piston rod buckling helps engineers identify high-risk applications before failures occur.

Critical factors causing piston rod buckling include excessive compressive loads beyond the rod’s critical buckling strength, improper mounting conditions that increase effective length, side loading from misalignment or external forces, dynamic loading during rapid acceleration/deceleration, and inadequate rod diameter relative to stroke length, with buckling risk increasing exponentially as stroke length exceeds 20 times the rod diameter.

Load vs. Rod Capacity

The fundamental issue is when applied loads exceed the rod’s buckling strength. Unlike simple compression failure, buckling occurs suddenly and catastrophically at much lower loads than the rod’s material strength would suggest.

Mounting Configuration Effects

Different mounting styles dramatically affect buckling resistance:

| Mounting Type | Effective Length Factor | Buckling Strength |

|---|---|---|

| Fixed-Fixed | 0.5 | Highest |

| Fixed-Pinned | 0.7 | High |

| Pinned-Pinned | 1.0 | Medium |

| Fixed-Free | 2.0 | Lowest |

Most cylinder applications use pinned-pinned mounting, which provides moderate buckling resistance.

Side Loading Impact

Even small side loads can dramatically reduce buckling strength. Misalignment as little as 1° can reduce safe operating loads by 30-50%. Common sources include:

- Mounting misalignment

- Guide wear or damage

- External forces on the load

- Thermal expansion effects

Dynamic Loading Considerations

Static calculations often underestimate real-world conditions. Dynamic factors include:

- Acceleration forces during rapid movements

- Vibration effects from machinery or external sources

- Impact loading from sudden stops or starts

- Resonance frequencies that can amplify forces

How Do You Calculate Safe Operating Loads for Long-Stroke Cylinders?

Proper buckling calculations ensure safe operation and prevent costly failures in long-stroke applications.

Safe operating load calculation uses Euler’s buckling formula (Pcr = π²EI/Le²) where E is elastic modulus2, I is moment of inertia3, and Le is effective length, then applies safety factors4 of 4-10x depending on application criticality, with additional considerations for side loading, dynamic effects, and mounting tolerances to determine maximum allowable cylinder force.

Euler’s Buckling Formula

The critical buckling load is calculated as:

Pcr = π² × E × I / Le²

Where:

- Pcr = Critical buckling load (N)

- E = Elastic modulus (typically 200 GPa for steel)

- I = Area moment of inertia (π × d⁴/64 for solid round rod)

- Le = Effective length (stroke × mounting factor)

Practical Calculation Example

Consider a 25mm diameter rod with 1200mm stroke in pinned-pinned mounting:

- Rod diameter: 25mm

- Moment of inertia: π × (25)⁴/64 = 19,175 mm⁴

- Effective length: 1200mm × 1.0 = 1200mm

- Critical load: π² × 200,000 × 19,175 / (1200)² = 26,300 N

With a safety factor of 6, the safe operating load would be 4,380 N.

Safety Factor Selection

| Application Type | Recommended Safety Factor |

|---|---|

| Static loading, precise alignment | 4-5 |

| Dynamic loading, good alignment | 6-8 |

| High dynamics, potential misalignment | 8-10 |

| Critical applications | 10+ |

Side Loading Calculations

When side loads are present, use the interaction formula[^6]:

(P/Pcr) + (M/Mcr) ≤ 1/SF

This accounts for combined axial and bending stresses that reduce overall capacity.

When Should You Consider Rodless Cylinder Alternatives?

Rodless cylinders eliminate buckling concerns entirely, making them ideal for long-stroke applications where traditional cylinders face limitations.

Consider rodless cylinder alternatives when stroke length exceeds 1000mm, when buckling calculations show inadequate safety margins, when space constraints prevent larger rod diameters, when side loading is unavoidable, or when application requires strokes beyond 2000mm where traditional cylinders become impractical, with rodless technology offering unlimited stroke length and superior rigidity.

Stroke Length Guidelines

Traditional cylinders become problematic at longer strokes:

- Under 500mm: Standard cylinders typically adequate

- 500-1000mm: Careful buckling analysis required

- 1000-2000mm: Rodless cylinders often preferred

- Over 2000mm: Rodless cylinders strongly recommended

Performance Comparison

| Feature | Traditional Cylinder | Rodless Cylinder |

|---|---|---|

| Buckling Risk | High on long strokes | Eliminated |

| Space Required | 2x stroke length | 1x stroke length |

| Maximum Stroke | Limited by buckling | Virtually unlimited |

| Side Load Resistance | Poor | Excellent |

| Maintenance | Rod seals wear | Minimal wear points |

Cost-Benefit Analysis

While rodless cylinders have higher initial costs, they often provide better total cost of ownership:

- Reduced downtime from buckling failures

- Lower maintenance requirements

- Space savings in machine design

- Higher reliability in demanding applications

Sarah, a project manager at an automotive plant in Ohio, initially resisted rodless cylinders due to cost concerns. After calculating the total cost including downtime, maintenance, and space savings, she found our Bepto rodless solution actually cost 15% less over the equipment’s lifetime. 💰

What Are the Best Practices for Preventing Rod Buckling Failures?

Implementing systematic design and maintenance practices minimizes buckling risks and extends cylinder life in challenging applications.

Best practices for preventing rod buckling include proper mounting alignment within 0.5°, regular inspection of guides and bushings, implementing side load protection through proper guiding, using appropriate safety factors in calculations, considering rodless alternatives for long strokes, and establishing preventive maintenance schedules to detect wear before failure occurs.

Design Phase Prevention

Start with proper design practices:

Mounting and Alignment

- Precision mounting with alignment within 0.5°

- Quality guides to prevent side loading

- Flexible couplings to accommodate thermal expansion

- Regular alignment checks during maintenance

Operational Monitoring

Implement monitoring systems to detect problems early:

- Load monitoring to ensure operation within safe limits

- Vibration analysis to detect developing problems

- Temperature monitoring for thermal effects

- Position feedback to verify proper operation

Maintenance Best Practices

Regular maintenance prevents gradual degradation:

- Monthly visual inspections for damage or wear

- Quarterly alignment verification using precision tools

- Annual load testing to verify capacity

- Immediate investigation of any unusual behavior

At Bepto, we provide comprehensive application engineering support to help customers avoid buckling issues entirely. Our rodless cylinder technology eliminates these concerns while providing superior performance and reliability. 🔧

Conclusion

Preventing piston rod buckling requires proper calculations, appropriate safety factors, and often switching to rodless cylinder technology for long-stroke applications where traditional cylinders face fundamental limitations.

FAQs About Piston Rod Buckling

Q: What’s the maximum safe stroke length for a traditional pneumatic cylinder?

Generally, strokes over 1000mm require careful buckling analysis and often benefit from rodless cylinder alternatives. The exact limit depends on rod diameter, mounting conditions, and applied loads.

Q: How do I know if my cylinder is at risk of rod buckling?

Calculate the critical buckling load using Euler’s formula and compare to your operating force with appropriate safety factors. If the safety factor is less than 4, consider design changes or rodless alternatives.

Q: Can I prevent buckling by using a larger rod diameter?

Yes, buckling strength increases with the fourth power of rod diameter, but this also increases cylinder size and cost. Rodless cylinders often provide a more practical solution for long strokes.

Q: What are the warning signs of impending rod buckling failure?

Watch for unusual vibration, erratic movement, visible rod deflection, or gradual performance degradation. These often indicate developing problems that could lead to sudden buckling failure.

Q: How do Bepto rodless cylinders eliminate buckling concerns?

Our rodless cylinders use a rigid aluminum extrusion that cannot buckle, with the piston traveling inside the tube. This eliminates rod buckling entirely while providing superior performance for long-stroke applications.

-

Understand Euler’s formula, a fundamental equation for calculating the critical buckling load of slender columns. ↩

-

Learn about the elastic modulus (Young’s Modulus), a key material property indicating stiffness and resistance to elastic deformation. ↩

-

Discover the area moment of inertia, a geometric property of a cross-section that reflects its resistance to bending and buckling. ↩

-

Read about safety factors, crucial ratios applied in engineering design to ensure structural integrity and prevent failure under various loads. ↩