Manufacturing facilities waste over $50,000 annually on excessive compressed air consumption, with 71% of pneumatic systems operating with incorrectly calculated air consumption rates, leading to oversized compressors and inflated energy costs. 😰

Calculating pneumatic cylinder air consumption (SCFM) involves determining cylinder volume, cycle frequency, and pressure requirements to optimize compressor sizing, reduce energy costs, and ensure adequate air supply for reliable system operation and maximum efficiency.

This morning, I helped Patricia, a facilities engineer from Florida, whose plant was experiencing air pressure drops during peak production. After properly calculating their cylinder SCFM requirements, we rightsized their system and reduced their compressed air costs by 35%. 🎯

Table of Contents

- What Is SCFM and Why Is Accurate Calculation Critical for Cost Control?

- How Do You Calculate Basic SCFM for Single and Multiple Cylinder Systems?

- Which Factors Affect Real-World Air Consumption Beyond Basic Calculations?

- What Are the Best Practices for Optimizing Pneumatic System Air Efficiency?

What Is SCFM and Why Is Accurate Calculation Critical for Cost Control?

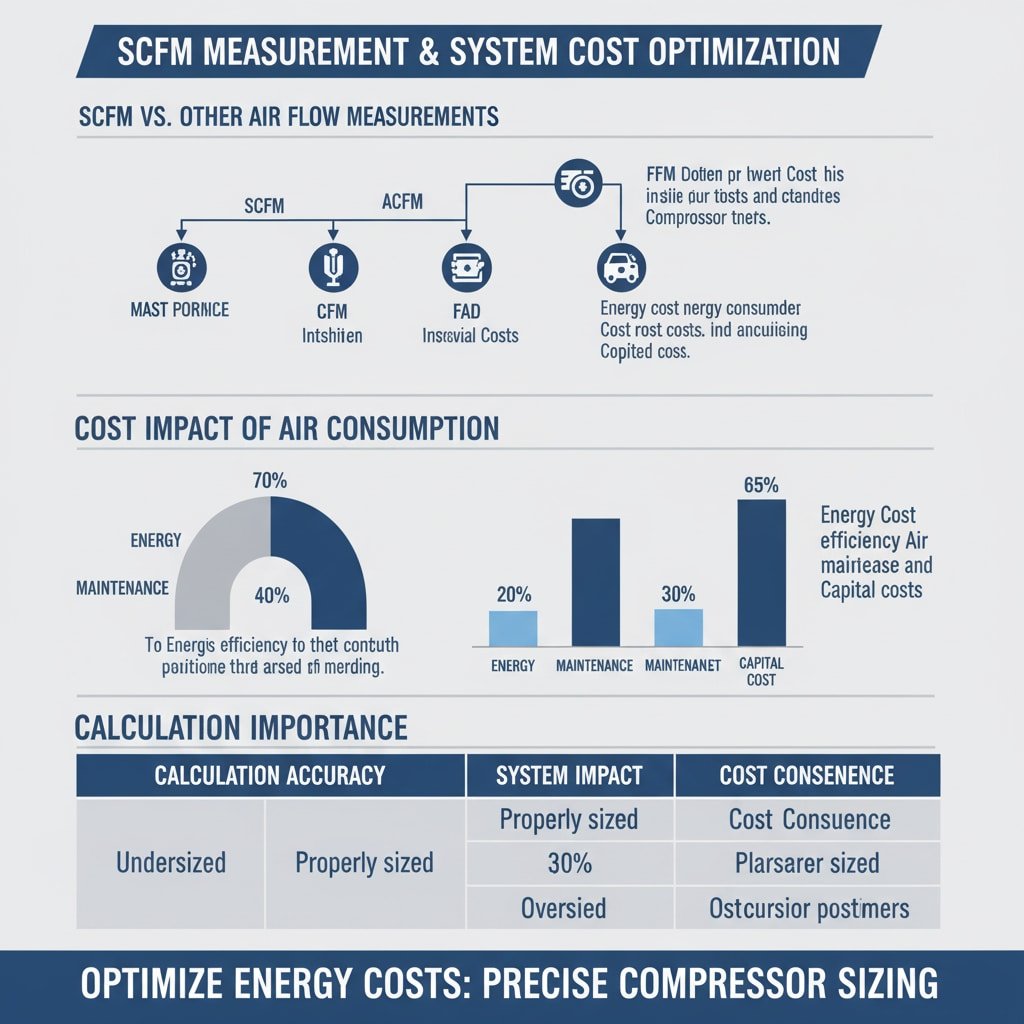

Understanding SCFM measurement and its impact on system costs enables proper compressor sizing and energy optimization.

SCFM (Standard Cubic Feet per Minute)1 measures compressed air flow at standard conditions (14.7 PSIA, 68°F), providing consistent measurement for compressor sizing, energy cost calculation, and system efficiency optimization that can reduce operating costs by 20-40%.

SCFM vs. Other Air Flow Measurements

Understanding different air flow units:

Cost Impact of Air Consumption

Compressed air costs typically represent:

- Energy costs: $0.25-0.35 per 1000 SCF

- System efficiency: 10-15% of total plant energy

- Maintenance costs: Higher with oversized systems

- Capital costs: Compressor sizing affects initial investment

Calculation Importance

| Calculation Accuracy | System Impact | Cost Consequence |

|---|---|---|

| Undersized (20%) | Pressure drops, poor performance | Production losses |

| Properly sized | Optimal performance | Baseline costs |

| Oversized (30%) | Wasted capacity | 25% higher energy costs |

| Oversized (50%) | Excessive waste | 40% higher energy costs |

Energy Cost Examples

Annual operating costs for 100 HP compressor:

- Properly sized: $35,000/year

- 30% oversized: $45,500/year

- 50% oversized: $52,500/year

At Bepto, we help customers optimize their pneumatic systems by providing accurate SCFM calculations and efficient rodless cylinder solutions that reduce overall air consumption by 15-25% compared to traditional cylinders. ⚡

How Do You Calculate Basic SCFM for Single and Multiple Cylinder Systems?

Proper SCFM calculation requires understanding cylinder volumes, operating pressures, and cycle frequencies.

Basic SCFM calculation uses the formula: SCFM = (Cylinder Volume × Pressure Ratio × Cycles per Minute) ÷ 60, where cylinder volume includes both chambers, pressure ratio accounts for Gauge pressure2, and cycle frequency determines total air demand.

Cylinder Air Consumption Calculator

Calculate the air consumption for a cylinder

Input Parameters

Basic SCFM Formula

SCFM = (V × PR × CPM) ÷ 60

Where:

- V = Cylinder volume (cubic inches)

- PR = Pressure ratio (Gauge pressure + 14.7) ÷ 14.7

- CPM = Cycles per minute

Cylinder Volume Calculation

Single-Acting Cylinder:

V = π × (D/2)² × S

Double-Acting Cylinder:

V = π × (D/2)² × S × 2 – π × (d/2)² × S

Where D = bore diameter, d = rod diameter, S = stroke length

SCFM Calculation Examples

| Cylinder Size | Stroke | Pressure | CPM | Volume (in³) | SCFM |

|---|---|---|---|---|---|

| 2″ bore, 4″ stroke | 4″ | 80 PSI | 10 | 25.1 | 2.8 |

| 3″ bore, 6″ stroke | 6″ | 100 PSI | 15 | 84.8 | 14.5 |

| 4″ bore, 8″ stroke | 8″ | 80 PSI | 8 | 201.0 | 18.9 |

| 6″ bore, 12″ stroke | 12″ | 90 PSI | 5 | 678.6 | 35.2 |

Multiple Cylinder Systems

For multiple cylinders operating simultaneously:

Total SCFM = SCFM₁ + SCFM₂ + SCFM₃ + …

For cylinders operating in sequence:

Calculate each cylinder individually and sum based on timing overlap.

Pressure Ratio Examples

| Gauge Pressure | Absolute Pressure | Pressure Ratio |

|---|---|---|

| 60 PSI | 74.7 PSIA | 5.08 |

| 80 PSI | 94.7 PSIA | 6.44 |

| 100 PSI | 114.7 PSIA | 7.80 |

| 120 PSI | 134.7 PSIA | 9.16 |

Bepto SCFM Calculator

We provide free SCFM calculation tools including:

- Online calculator: Input cylinder specs for instant results

- Mobile app: Field calculations for technicians

- Excel templates: Batch calculations for multiple systems

- Engineering support: Complex system analysis

Tom, a maintenance manager in Georgia, was surprised to learn his 20-cylinder system was consuming 40% more air than calculated. Our analysis revealed leakage and inefficient cycling, leading to $12,000 annual savings after optimization. 💡

Which Factors Affect Real-World Air Consumption Beyond Basic Calculations?

Real-world air consumption differs from theoretical calculations due to system inefficiencies and operating conditions.

Factors affecting actual air consumption include system leakage (10-30% losses), cylinder cushioning air usage, pressure drops through valves and fittings, temperature variations, and duty cycle inefficiencies that can increase consumption by 40-60% above calculated values.

System Efficiency Factors

Leakage Losses:

- Typical systems: 15-25% air loss

- Well-maintained: 5-10% air loss

- Poor maintenance: 30-50% air loss

- Detection methods: Ultrasonic leak detection3

Real-World Multipliers

| System Condition | Efficiency Factor | SCFM Multiplier |

|---|---|---|

| New, well-designed | 85-90% | 1.1-1.2x |

| Average maintenance | 70-80% | 1.3-1.4x |

| Poor maintenance | 50-65% | 1.5-2.0x |

| Neglected system | 30-45% | 2.2-3.3x |

Additional Air Consumption Sources

Cushioning Air:

- Adds 10-20% to basic calculation

- Variable based on cushioning adjustment

- More significant at higher speeds

Valve Operation:

- Pilot air for valve actuation

- Typically 0.1-0.5 SCFM per valve

- Continuous consumption when energized

Temperature Effects

Air consumption varies with temperature:

- Hot environments: 10-15% increase in volume

- Cold environments: 5-10% decrease in volume

- Temperature compensation: Adjust calculations accordingly

Pressure Drop Impact

| Component | Typical Pressure Drop | Flow Impact |

|---|---|---|

| Filter | 1-3 PSI | Minimal |

| Regulator | 2-5 PSI | 5-10% increase |

| Valve | 3-8 PSI | 10-15% increase |

| Fittings | 1-2 PSI per fitting | Cumulative |

Duty Cycle Considerations

Continuous operation: Use full calculated SCFM

Intermittent operation: Apply duty cycle factor

Peak demand: Size for maximum simultaneous operation

What Are the Best Practices for Optimizing Pneumatic System Air Efficiency?

Implementing efficiency best practices can reduce air consumption by 20-40% while maintaining performance.

Best practices for air efficiency include regular leak detection and repair, proper pressure regulation, optimized cylinder sizing, efficient valve selection, and implementing air-saving technologies like rodless cylinders4 that can reduce consumption by 25% compared to traditional designs.

Leak Detection and Repair

Systematic approach:

- Monthly ultrasonic surveys: Identify leaks early

- Immediate repair: Fix leaks within 24 hours

- Documentation: Track leak locations and costs

- Prevention: Use quality fittings and proper installation

Pressure Optimization

Right-sizing pressure:

- Audit requirements: Determine actual pressure needs

- Zone regulation: Different pressures for different areas

- Pressure reduction: Each 2 PSI reduction saves 1% energy

Efficient Component Selection

| Component Type | Standard Option | High-Efficiency Option | Savings |

|---|---|---|---|

| Cylinders | Rod cylinders | Rodless cylinders | 20-25% |

| Valves | Standard 4-way | High-flow, low-drop | 10-15% |

| Fittings | Barbed fittings | Push-to-connect | 5-10% |

| Filters | Standard | High-flow, low-drop | 5-8% |

Bepto Efficiency Solutions

Our rodless cylinders offer superior efficiency:

- Reduced air volume: No rod displacement

- Lower friction: Magnetic coupling technology

- Precise control: Reduced air waste from overshooting

- Integrated features: Built-in cushioning and flow control

System Monitoring

Air consumption tracking:

- Flow meters: Monitor actual consumption

- Pressure monitoring: Detect system issues

- Energy tracking: Correlate air use with production

- Trend analysis: Identify optimization opportunities

ROI Calculations

Typical efficiency improvements:

- Leak repair: 15-30% reduction, 3-6 month ROI

- Pressure optimization: 5-15% reduction, immediate ROI

- Component upgrades: 10-25% reduction, 6-18 month ROI

- System redesign: 20-40% reduction, 12-24 month ROI

Angela, a plant engineer in North Carolina, implemented our comprehensive efficiency program and achieved 38% air consumption reduction, saving $28,000 annually while improving system reliability. 🔧

Conclusion

Accurate SCFM calculation and system optimization are essential for controlling compressed air costs, with proper implementation delivering 20-40% energy savings and improved system performance.

FAQs About Pneumatic Cylinder Air Consumption

Q: How do I calculate SCFM for a double-acting pneumatic cylinder?

Use the formula: SCFM = (Cylinder Volume × Pressure Ratio × Cycles per Minute) ÷ 60. For double-acting cylinders, volume = π × (bore diameter/2)² × stroke × 2, minus the rod volume on one side. Include pressure ratio as (gauge pressure + 14.7) ÷ 14.7.

Q: Why is my actual air consumption higher than calculated SCFM?

Real-world consumption typically exceeds calculations by 30-60% due to system leakage (15-25%), pressure drops through components, cushioning air usage, and inefficient cycling. Regular maintenance and leak detection can reduce this gap significantly.

Q: What’s the difference between SCFM and ACFM in pneumatic calculations?

SCFM measures air flow at standard conditions (14.7 PSIA, 68°F) for consistent compressor sizing. ACFM measures actual flow at operating conditions. SCFM is preferred for system design because it provides standardized measurements regardless of operating pressure and temperature.

Q: How can I reduce air consumption without affecting cylinder performance?

Consider rodless cylinders (20-25% less consumption), optimize operating pressure (2 PSI reduction = 1% energy savings), fix leaks immediately, use high-efficiency valves, and implement proper system design with minimal pressure drops through components.

Q: Can Bepto help optimize my pneumatic system’s air consumption?

Yes, we provide comprehensive SCFM calculations, system efficiency audits, and rodless cylinder solutions that typically reduce air consumption by 25% compared to traditional systems. Our engineering team offers free consultation to identify optimization opportunities and calculate potential savings.

-

Learn the definition of Standard Cubic Feet per Minute (SCFM) and how it provides a standardized measure for comparing air flow rates. ↩

-

Understand the difference between gauge pressure (PSIG), which is relative to atmospheric pressure, and absolute pressure (PSIA). ↩

-

Discover the technology behind ultrasonic leak detectors, which identify the high-frequency sound of air escaping from pipes and fittings. ↩

-

Explore the design and operation of rodless cylinders, which provide linear motion within a compact footprint by eliminating the external piston rod. ↩