Marine environments destroy standard pneumatic cylinders within months, leaving vessel operators facing costly emergency repairs, dangerous equipment failures, and extended downtime in remote locations where replacement parts are impossible to source. Salt spray, temperature extremes, and constant moisture create the perfect storm for rapid corrosion that can compromise critical ship systems when they’re needed most.

Selecting proper corrosion-resistant cylinders for marine applications requires 316 stainless steel construction, specialized coatings, enhanced sealing systems, and marine-grade mounting hardware that can withstand saltwater exposure, temperature cycling, and vibration while maintaining reliable operation for 5-10 years in harsh maritime conditions.

Just last week, I received an urgent call from Captain Martinez, whose fishing vessel’s deck crane cylinders had failed 200 miles offshore, forcing his crew to manually handle 500-pound nets in dangerous seas. His standard cylinders had corroded through in just 18 months, creating a safety hazard that could have been prevented with proper marine-grade equipment. ⚓

Table of Contents

- What Makes Marine Environments So Destructive to Standard Cylinders?

- Which Materials and Coatings Provide the Best Corrosion Protection?

- How Do You Size and Configure Cylinders for Marine Applications?

- What Maintenance Practices Extend Marine Cylinder Life?

What Makes Marine Environments So Destructive to Standard Cylinders?

Marine environments combine multiple corrosive factors that rapidly destroy conventional pneumatic equipment.

Marine environments accelerate corrosion through salt spray containing chlorides, constant humidity above 80%, temperature cycling from freezing to 120°F, UV radiation, vibration from wave action, and galvanic corrosion1 from dissimilar metals, creating conditions 10-20 times more aggressive than typical industrial environments.

Primary Corrosion Mechanisms

Salt Spray and Chloride Attack

- Sodium chloride concentration up to 35,000 ppm in seawater

- Aerosol penetration into smallest crevices and gaps

- Accelerated pitting on exposed metal surfaces

- Crevice corrosion2 in threaded connections and seals

Environmental Stress Factors

- Constant humidity prevents protective oxide formation

- Temperature cycling creates thermal stress and condensation

- UV exposure degrades seals and protective coatings

- Mechanical vibration accelerates fatigue and wear

Galvanic Corrosion Risks

When dissimilar metals contact in saltwater:

- Aluminum components become anodic and corrode rapidly

- Steel fasteners in aluminum housings create galvanic cells

- Stainless steel grades vary significantly in corrosion resistance

- Protective coatings must isolate dissimilar metals

Failure Mode Analysis

| Component | Standard Environment Life | Marine Environment Life | Primary Failure Mode |

|---|---|---|---|

| Carbon steel body | 10+ years | 6-18 months | Uniform corrosion |

| Aluminum components | 15+ years | 3-12 months | Pitting corrosion |

| Standard seals | 5+ years | 6-24 months | Salt crystallization |

| Zinc-plated hardware | 8+ years | 2-6 months | Galvanic corrosion |

Real-World Consequences

Marine cylinder failures result in:

- Safety hazards from equipment malfunction

- Emergency repairs at sea with limited resources

- Extended downtime waiting for parts in remote ports

- Cascade failures affecting dependent systems

Which Materials and Coatings Provide the Best Corrosion Protection?

Material selection is critical for marine cylinder longevity and reliability.

Marine-grade cylinders require 316L stainless steel construction, specialized marine coatings like epoxy or polyurethane, Viton or EPDM seals, and passivated stainless hardware, with material selection based on specific exposure levels from splash zone to fully submerged applications.

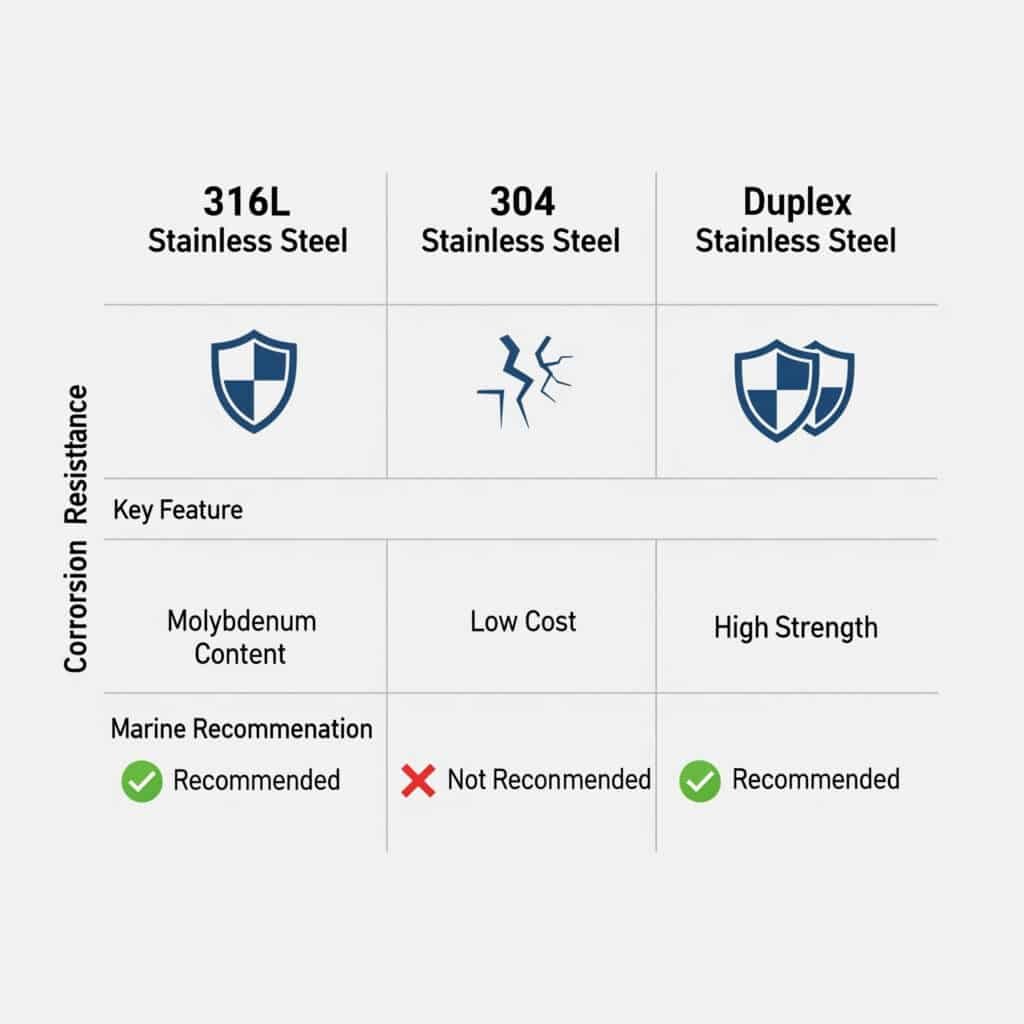

Stainless Steel Grades for Marine Use

316L Stainless Steel (Recommended)

- Molybdenum content provides superior chloride resistance

- Low carbon prevents carbide precipitation3

- Pitting resistance equivalent number (PREN)4 of 25-26

- Proven performance in marine applications worldwide

304 Stainless Steel (Not Recommended)

- Lower corrosion resistance in chloride environments

- Pitting susceptibility in saltwater exposure

- Cost savings don’t justify reduced reliability

- Acceptable only for protected interior applications

Duplex Stainless Steels (Premium Option)

- Superior strength and corrosion resistance

- 2205 grade offers PREN of 35+

- Higher cost justified for critical applications

- Excellent fatigue resistance under cyclic loading

Protective Coating Systems

Marine-Grade Epoxy Coatings

- Barrier protection against salt spray

- Chemical resistance to cleaning agents

- Thickness range 5-15 mils for optimal protection

- Color coding available for system identification

Polyurethane Topcoats

- UV resistance prevents coating degradation

- Abrasion resistance for high-wear areas

- Gloss retention maintains appearance

- Easy maintenance with standard cleaning

Remember Captain Martinez? After his cylinder failure, we supplied 316L stainless steel rodless cylinders with marine epoxy coating for his new crane system. Eighteen months later, they’re still performing flawlessly in the harsh North Atlantic environment, and he’s retrofitted his entire fleet with our marine-grade cylinders after seeing the reliability improvement. 🌊

Sealing System Requirements

Fluoroelastomer (Viton) Seals

- Chemical resistance to saltwater and cleaning agents

- Temperature range -20°F to 400°F

- Low compression set maintains sealing over time

- Ozone resistance prevents UV degradation

EPDM Alternative

- Lower cost than Viton

- Good saltwater resistance

- Temperature limitations compared to fluoroelastomers

- Suitable for moderate exposure applications

How Do You Size and Configure Cylinders for Marine Applications?

Marine applications require special consideration for sizing and mounting configurations.

Marine cylinder sizing must account for corrosion allowances, safety factors for emergency conditions, vibration resistance, accessibility for maintenance, and integration with vessel systems while meeting classification society requirements and maritime safety standards.

Marine-Specific Sizing Factors

Safety Factor Considerations

- Higher safety factors (2.5-3.0x) for critical systems

- Emergency operation capability during power loss

- Redundancy planning for essential functions

- Fail-safe positioning in case of system failure

Environmental Load Factors

- Wave loading adds dynamic forces to static loads

- Ice accumulation increases weight and friction

- Wind loading affects exposed equipment

- Thermal expansion from temperature cycling

Mounting and Installation Requirements

Vibration-Resistant Mounting

- Flexible mounting systems absorb vessel motion

- Shock isolation prevents impact damage

- Multiple mounting points distribute loads

- Access for maintenance in confined spaces

Drainage and Ventilation

- Drain holes prevent water accumulation

- Ventilation paths allow moisture escape

- Sloped surfaces shed water effectively

- Sealed cable entries prevent water ingress

Classification Society Requirements

Common Marine Standards

- ABS (American Bureau of Shipping)5 requirements

- DNV GL certification standards

- Lloyd’s Register approval processes

- Coast Guard compliance for commercial vessels

Documentation Requirements

- Material certificates for all components

- Pressure testing documentation

- Installation procedures and maintenance schedules

- Spare parts recommendations and availability

I recently worked with Sarah, a marine engineer designing a new offshore supply vessel in Louisiana. Her deck equipment required cylinders that could operate in -20°F to 120°F conditions while withstanding constant salt spray. We designed custom 316L stainless rodless cylinders with integrated heating elements and enhanced drainage systems. The ABS-certified design has been operating flawlessly for two years across multiple vessels in her fleet. 🚢

What Maintenance Practices Extend Marine Cylinder Life?

Proper maintenance is essential for maximizing marine cylinder service life.

Effective marine cylinder maintenance includes regular freshwater flushing, protective coating inspection and touch-up, seal replacement on scheduled intervals, lubrication with marine-grade products, and comprehensive documentation to track performance and predict maintenance needs.

Preventive Maintenance Schedule

Daily Operations

- Visual inspection for obvious damage or leaks

- Operational testing of critical systems

- Salt spray removal with freshwater rinse

- Lubrication point service as required

Weekly Maintenance

- Detailed inspection of seals and fittings

- Coating condition assessment

- Mounting hardware torque verification

- Performance testing under load

Monthly Service

- Comprehensive cleaning with marine-safe solvents

- Seal condition detailed evaluation

- Pressure testing to verify integrity

- Documentation update in maintenance logs

Cleaning and Protection Procedures

Freshwater Flushing

- Daily rinse removes salt deposits

- Pressure washing for heavy contamination

- Drying procedures prevent trapped moisture

- Protective coating application after cleaning

Corrosion Inhibitor Application

- Marine-grade inhibitors for exposed surfaces

- Penetrating oils for threaded connections

- Barrier coatings for temporary protection

- Sacrificial anodes where applicable

Troubleshooting Common Issues

Early Warning Signs

- Increased operating pressure indicates seal wear

- Erratic movement suggests contamination

- Visible corrosion requires immediate attention

- Unusual noise may indicate bearing wear

Emergency Repair Procedures

- Temporary sealing methods for at-sea repairs

- Bypass procedures for non-critical systems

- Parts inventory for common failure modes

- Shore support communication protocols

Long-term Performance Optimization

Performance Tracking

- Cycle counting for wear prediction

- Pressure monitoring for efficiency trends

- Temperature logging for thermal cycling analysis

- Failure analysis for continuous improvement

Upgrade Opportunities

- Seal technology improvements

- Coating system upgrades

- Monitoring system integration

- Predictive maintenance implementation

Conclusion

Selecting and maintaining proper marine-grade cylinders requires understanding the unique challenges of maritime environments and implementing comprehensive strategies for material selection, installation, and maintenance to ensure reliable operation in harsh saltwater conditions.

FAQs About Marine Cylinder Applications

Q: What’s the expected service life of properly specified marine cylinders?

Marine-grade cylinders with 316L stainless construction and proper maintenance typically achieve 5-10 years of service life in saltwater environments, compared to 6-18 months for standard industrial cylinders.

Q: Can standard cylinders be upgraded or protected for marine use?

While some protection is possible through coatings and enhanced maintenance, the cost and reliability risks usually make purpose-built marine cylinders more economical for critical applications.

Q: What’s the cost difference between standard and marine-grade cylinders?

Marine-grade cylinders typically cost 2-3 times more than standard units, but this premium is quickly recovered through reduced maintenance, longer service life, and avoided emergency repairs.

Q: How do I prevent galvanic corrosion in mixed-metal installations?

Use insulating gaskets, compatible fasteners, protective coatings, and sacrificial anodes while ensuring proper electrical isolation between dissimilar metals in the mounting system.

Q: What spare parts should I stock for marine cylinder maintenance?

Maintain seal kits, common fittings, mounting hardware, touch-up coating materials, and complete cylinders for critical applications, with quantities based on usage rates and supply logistics to your operating areas.

-

Learn about this electrochemical process where one metal corrodes preferentially when in contact with another in the presence of an electrolyte. ↩

-

Understand how this localized form of corrosion occurs in confined spaces where access to the surrounding fluid is limited. ↩

-

Understand this metallurgical phenomenon and why low-carbon (“L” grade) stainless steels are essential for corrosion resistance after welding. ↩

-

Discover how the PREN value is calculated to predict the resistance of stainless steel alloys to localized pitting corrosion. ↩

-

Explore the role of ABS, a leading maritime classification society, in setting standards for safety and excellence at sea. ↩