Your production line grinds to a halt when another solenoid coil burns out unexpectedly, marking the third failure this month. The acrid smell of burnt copper fills the air as you realize this isn’t just bad luck—there’s a systematic problem destroying your automation components. 🔥

Solenoid coil burnout typically results from excessive current flow caused by overvoltage, continuous duty operation beyond design limits, inadequate heat dissipation, or mechanical binding that prevents proper valve switching and increases power consumption.

Last week, I investigated a series of coil failures at Robert’s automotive parts manufacturing facility in Michigan, where five solenoid valves had burned out within two weeks, costing over $15,000 in downtime and emergency replacements.

Table of Contents

- What Are the Primary Electrical Causes of Coil Burnout?

- How Do Mechanical Issues Lead to Coil Failure?

- Why Does Environmental Stress Accelerate Coil Degradation?

- What Preventive Measures Can Eliminate Coil Burnout?

What Are the Primary Electrical Causes of Coil Burnout?

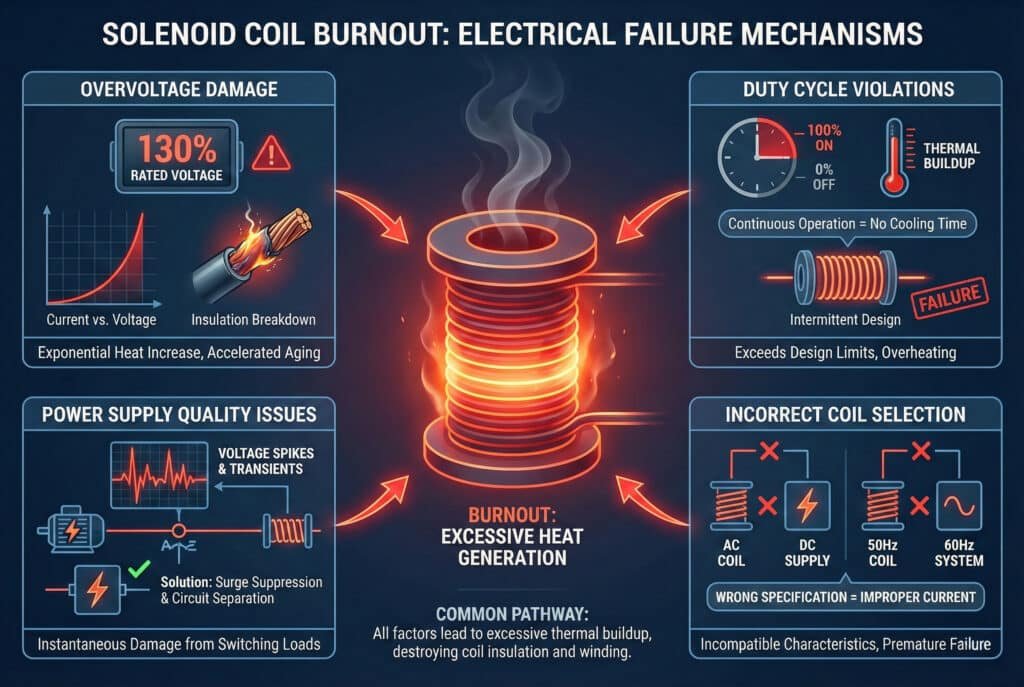

Understanding electrical failure mechanisms is crucial for preventing solenoid coil burnout and ensuring reliable pneumatic system operation.

Electrical coil burnout primarily occurs due to overvoltage conditions, incorrect duty cycle operation, power supply instability, and inadequate current limiting, with excessive heat generation being the common failure pathway in all cases.

Overvoltage Damage

Applying voltage above the coil’s rated specification increases current flow exponentially, generating excessive heat that breaks down wire insulation. Even 15% overvoltage can reduce coil life by 50% through accelerated thermal aging1.

Duty Cycle Violations

Many solenoid coils are designed for intermittent duty (typically 25% or 50% duty cycle2) but are operated continuously. Continuous operation without adequate cooling time causes thermal buildup that eventually destroys the coil winding.

| Voltage Condition | Current Increase | Heat Generation | Expected Life |

|---|---|---|---|

| 100% rated | Normal | Baseline | 100% |

| 110% rated | 21% increase | 46% increase | 60% |

| 120% rated | 44% increase | 107% increase | 25% |

| 130% rated | 69% increase | 185% increase | 10% |

Power Supply Quality Issues

Voltage spikes, harmonics3, and transients from switching loads or poor power conditioning can cause instantaneous coil damage. Inductive kickback4 from other solenoids on the same circuit creates particularly damaging voltage spikes.

Robert’s facility was experiencing voltage spikes up to 150% during motor startups, which were reaching the solenoid circuits through shared electrical panels. We solved this by installing surge suppressors and separating pneumatic control circuits from high-power loads. ⚡

Incorrect Coil Selection

Using AC coils on DC supplies or vice versa creates improper current characteristics that lead to overheating. Similarly, using 50Hz coils on 60Hz systems or incorrect voltage ratings guarantees premature failure.

How Do Mechanical Issues Lead to Coil Failure?

Mechanical problems that prevent proper valve operation force solenoid coils to work harder, generating excessive heat and ultimately causing electrical failure.

Mechanical binding, contamination, spring fatigue, and improper installation create conditions where solenoid coils must maintain higher current draw to overcome resistance, leading to thermal overload and coil burnout.

Valve Binding and Sticking

When valve components bind due to contamination, corrosion, or mechanical wear, the solenoid must work harder to actuate the valve. This increased effort translates to higher current draw and heat generation that can destroy the coil.

Spring Force Problems

Worn or incorrect springs can create excessive closing force that the solenoid must overcome. Similarly, weak springs may allow valve chatter, causing rapid on-off cycling that generates heat through frequent switching.

Contamination Effects

Dirt, moisture, or chemical contamination can cause valve components to stick or create electrical leakage paths. Both conditions increase power consumption and heat generation, accelerating coil failure.

I recently helped Sarah, who manages a food processing plant in California, solve recurring coil failures. Her washdown procedures were allowing moisture into valve housings, creating both mechanical binding and electrical leakage. After upgrading to our IP69K5-rated Bepto solenoid valves, her failure rate dropped by 90%. 🌊

Installation Errors

Improper mounting, misaligned components, or incorrect pressure ratings force solenoids to operate outside design parameters, increasing stress and reducing service life significantly.

Why Does Environmental Stress Accelerate Coil Degradation?

Environmental factors create additional stress on solenoid coils, accelerating normal aging processes and contributing to premature failure.

Environmental stress from high temperatures, humidity, vibration, and chemical exposure degrades coil insulation, increases electrical resistance, and creates conditions that accelerate thermal breakdown and electrical failure.

Temperature Effects

High ambient temperatures reduce the coil’s ability to dissipate heat, while temperature cycling causes expansion and contraction that can crack insulation. Every 10°C temperature increase typically halves coil life expectancy.

Humidity and Moisture

Moisture penetration creates electrical leakage paths and accelerates corrosion of copper windings. High humidity environments require special attention to sealing and drainage to prevent moisture-related failures.

Vibration Damage

Continuous vibration can cause wire fatigue, loosen connections, and create intermittent contacts that generate heat and arcing. Proper mounting and vibration isolation are essential in high-vibration environments.

| Environmental Factor | Impact on Coil Life | Mitigation Strategy |

|---|---|---|

| High temperature (>60°C) | 50% reduction per 10°C | Improved ventilation, heat shields |

| High humidity (>85% RH) | 30-40% reduction | Better sealing, drainage |

| Continuous vibration | 40-60% reduction | Isolation mounts, flexible connections |

| Chemical exposure | Variable, severe | Chemical-resistant enclosures |

Chemical Exposure

Aggressive chemicals can attack coil insulation, wire coatings, and housing materials. Even seemingly mild chemicals can cause long-term degradation that leads to eventual failure.

What Preventive Measures Can Eliminate Coil Burnout?

Implementing comprehensive preventive measures addresses root causes of coil burnout and ensures reliable long-term operation of solenoid valve systems.

Effective coil burnout prevention requires proper electrical design, regular maintenance, environmental protection, and quality component selection, with systematic monitoring to detect developing problems before they cause failures.

Electrical System Design

Install proper voltage regulation, surge protection, and circuit isolation to maintain stable electrical conditions. Use appropriately rated components and ensure correct duty cycle operation for all solenoid applications.

Maintenance Protocols

Establish regular inspection schedules that include voltage measurements, temperature monitoring, and mechanical operation checks. Early detection of developing problems prevents catastrophic failures.

Environmental Controls

Provide adequate ventilation, moisture protection, and vibration isolation based on actual operating conditions. Consider upgrading to higher-rated components when environmental conditions exceed standard specifications.

Our Bepto solenoid valves incorporate advanced coil designs with enhanced thermal management and environmental protection. We offer comprehensive technical support to help you identify and eliminate the root causes of coil burnout in your applications. 🛡️

Quality Component Selection

Choose solenoid valves with appropriate ratings for your specific application, including voltage tolerance, duty cycle, temperature range, and environmental protection. Investing in quality components reduces long-term maintenance costs significantly.

Systematic failure analysis and preventive measures eliminate coil burnout problems, ensuring reliable pneumatic system operation and reducing costly downtime and emergency repairs.

FAQs About Solenoid Coil Burnout

Q: How can I tell if a solenoid coil is starting to fail before it burns out completely?

Monitor coil temperature, measure electrical resistance, and check for unusual sounds or vibrations during operation, as these often indicate developing problems before complete failure occurs.

Q: Can I repair a burned-out solenoid coil, or must I replace the entire valve?

While coil replacement is sometimes possible, it’s usually more cost-effective to replace the entire solenoid assembly to ensure reliable operation and proper warranty coverage.

Q: What’s the most common cause of solenoid coil burnout in industrial applications?

Overvoltage conditions and continuous duty operation beyond design limits are the most frequent causes, often combined with inadequate heat dissipation in enclosed control panels.

Q: How often should I inspect solenoid valves to prevent coil burnout?

Monthly visual inspections and quarterly electrical measurements help detect problems early, with more frequent monitoring recommended for critical applications or harsh environments.

Q: Will using higher-rated solenoid coils prevent burnout problems?

Higher ratings provide safety margin but won’t solve underlying problems like voltage instability, mechanical binding, or environmental stress that must be addressed at the system level.

-

Understand the process where heat gradually degrades the chemical structure of insulating materials over time. ↩

-

Learn the formula representing the ratio of “on” time to the total cycle time in electromagnetic devices. ↩

-

Read about the distortion of the normal electrical current waveform caused by non-linear loads. ↩

-

Explore the voltage spike phenomenon that occurs when current flowing through an inductor is suddenly interrupted. ↩

-

Review the ingress protection rating standard for equipment that must withstand high-pressure, high-temperature washdowns. ↩