Introduction

Your Parker Origa rodless cylinder just failed, and the replacement quote hits your desk: $4,500 with an 8-week lead time. 😱 Your production line is down, costing $18,000 per day, and your CFO is demanding answers about why pneumatic components cost as much as a used car. This scenario plays out daily in manufacturing facilities worldwide, forcing smart engineers and procurement managers to ask a critical question: are there quality alternatives that won’t devastate the budget?

Yes—several manufacturers now produce high-quality rodless cylinder alternatives to Parker Origa that deliver equivalent performance at 40-60% lower costs, with dramatically faster delivery times and comparable reliability for most industrial applications. At Bepto Pneumatics, we’ve spent years analyzing the Parker Origa product line and engineering precision alternatives that meet the same demanding specifications while making pneumatic automation accessible to budget-conscious operations.

Just last month, I worked with Kevin, a maintenance manager at a automotive parts manufacturer in Tennessee, who was facing exactly this dilemma. His facility runs three shifts, and a failed Parker Origa OSP-P32 cylinder on his transfer line was costing his company over $25,000 daily in lost production. The OEM quote and timeline were simply unacceptable. 🚗

Table of Contents

- Why Are Parker Origa Rodless Cylinders So Expensive?

- What Should You Look for in a Parker Origa Alternative?

- Which Brands Offer the Best Parker Origa Replacements?

- How Do Alternative Rodless Cylinders Compare in Real-World Performance?

- Conclusion

- FAQs About Parker Origa Rodless Cylinder Alternatives

Why Are Parker Origa Rodless Cylinders So Expensive?

Understanding the premium pricing helps you evaluate whether alternatives can truly deliver comparable value. 💰

Parker Origa rodless cylinders command premium prices primarily due to brand positioning, extensive engineering documentation, specialized distribution networks, and the costs of maintaining legacy product lines—with actual manufacturing costs representing only 30-35% of the retail price. While Parker produces excellent products with robust engineering support, a significant portion of what you pay funds corporate overhead1, multi-tier distribution markups, and brand marketing rather than superior component quality.

The Parker Origa Premium Breakdown

When you purchase a Parker Origa rodless cylinder, here’s where your investment actually goes:

| Cost Component | Percentage | What You’re Paying For |

|---|---|---|

| Manufacturing & Materials | 30-35% | Actual production costs, quality control |

| Brand Premium | 25-30% | Parker brand recognition, marketing |

| Distribution Network | 20-25% | Multiple distributor margins, regional inventory |

| Engineering Support | 10-15% | Technical documentation, application engineering |

| Legacy Product Maintenance | 5-10% | Supporting older Origa product lines |

The Origa Acquisition Factor

Parker acquired Origa in 2004, inheriting a respected Swedish brand with strong European presence. However, this acquisition created complexity:

- Product line overlap with Parker’s existing pneumatics

- Gradual phase-out of some Origa series in favor of newer Parker designs

- Longer lead times for legacy Origa models as production priorities shift

- Premium pricing maintained to protect Parker’s overall margin structure

Supply Chain Realities

The Parker distribution model, while comprehensive, creates inherent inefficiencies:

- Multi-tier distribution: Factory → Regional warehouse → Local distributor → End user

- Each tier adds 15-25% markup to maintain their margins

- Stock availability issues for less common configurations

- Special order delays of 6-12 weeks for non-standard specifications

I remember speaking with Rachel, a procurement manager at a packaging machinery builder in Wisconsin, who discovered that the same Parker Origa OSP-P25 cylinder she was quoted $2,800 for in the US was available in Europe for €1,650 (approximately $1,750)—a 60% price difference for the identical product simply due to distribution structure. 🌍

When Premium Pricing Makes Sense

To be fair, Parker Origa cylinders excel in certain scenarios:

- Extreme precision requirements (±0.01mm repeatability2)

- Very high cycle applications (20+ million cycles)

- Harsh chemical environments requiring special seal materials

- Applications requiring extensive documentation for regulatory compliance

- Customer specifications that mandate Parker by name

For standard industrial applications, however, the premium often exceeds the actual performance benefit.

What Should You Look for in a Parker Origa Alternative?

Choosing the right alternative requires understanding which specifications are critical versus which are marketing. 🔍

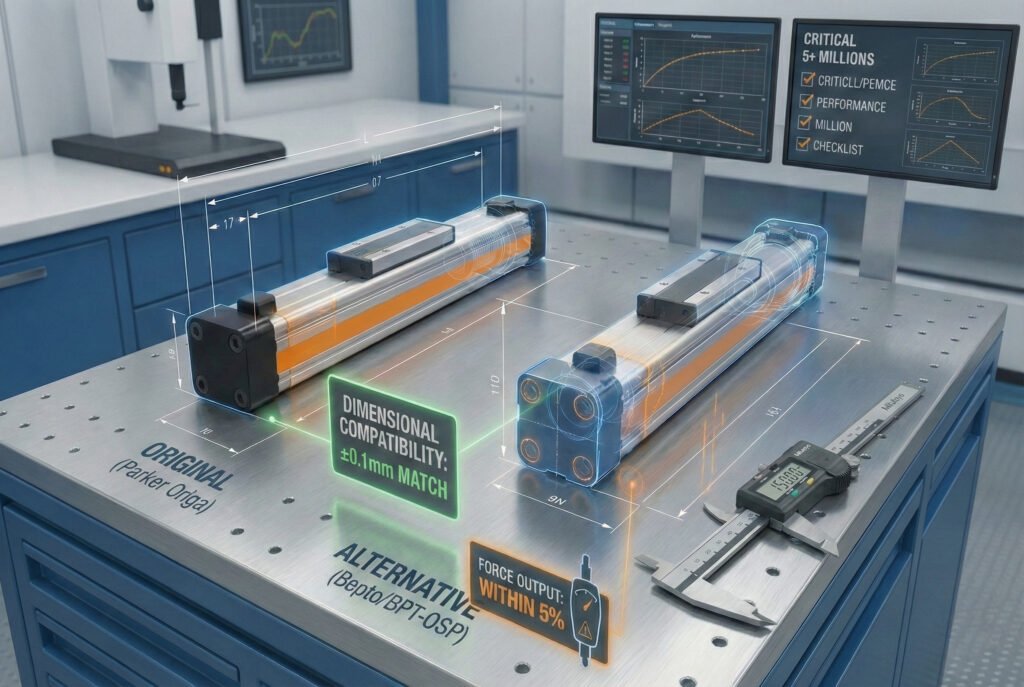

A quality Parker Origa alternative must match five critical specifications: dimensional compatibility (±0.1mm on mounting patterns), equivalent force output (within 5% at rated pressure), comparable stroke accuracy (±0.5mm or better), similar cycle life rating (5+ million cycles), and complete technical documentation for validation purposes. Secondary features like proprietary accessories or brand-specific sensors are less critical and often unnecessarily inflate costs.

Critical Specifications Matrix

1. Dimensional Compatibility

This is non-negotiable for retrofit applications:

| Dimension | Tolerance | Why It Matters |

|---|---|---|

| Mounting hole pattern | ±0.1mm | Bolt alignment with existing machine structure |

| Overall length | ±1.0mm | Clearance in machine envelope |

| Carriage width | ±0.5mm | Tooling and guide compatibility |

| Port location | ±2.0mm | Pneumatic line routing |

| Guide rail height | ±0.2mm | Carriage interchangeability |

2. Performance Specifications

Match these to your application requirements:

Force Output:

- Verify push/pull force at your operating pressure (typically 6 bar)

- Account for friction losses (typically 5-10% of theoretical force)

- Consider acceleration requirements for dynamic loads

Speed Capability:

- Maximum speed rating (typically 1-3 m/s for rodless cylinders)

- Acceleration/deceleration characteristics

- Cushioning effectiveness at high speeds

Positioning Accuracy:

- Repeatability (±0.05mm to ±0.5mm depending on application)

- Hysteresis3 (difference between approach directions)

- Long-term stability over millions of cycles

3. Construction Quality Indicators

These factors directly impact longevity:

Materials:

- Aluminum extrusion: 6063-T54 or better for body

- Guide rails: Hardened steel with chrome plating or stainless steel

- Seals: High-grade nitrile (NBR) or polyurethane for standard applications

- Bearings: Sintered bronze or polymer composite for smooth operation

Manufacturing Quality:

- Surface finish: Ra 0.8μm5 or better on sliding surfaces

- Straightness tolerance: 0.2mm per meter of stroke length

- Assembly precision: No visible gaps, smooth operation throughout stroke

4. Documentation and Support

Essential for validation and troubleshooting:

✅ Detailed dimensional drawings (PDF and CAD formats)

✅ Performance curves (force vs. pressure, speed vs. load)

✅ Material certificates for critical components

✅ Installation and maintenance manuals

✅ Troubleshooting guides

✅ Direct technical support access

Red Flags to Avoid

When evaluating alternatives, watch out for:

❌ Vague specifications (“similar to Parker” without actual data)

❌ No dimensional drawings (impossible to verify compatibility)

❌ Extremely low pricing (below 50% of OEM suggests quality compromises)

❌ No warranty or very short warranty periods (< 6 months)

❌ Poor communication (slow response times, language barriers)

❌ No sample program (unwillingness to provide test units)

The Bepto Evaluation Approach

At Bepto Pneumatics, we help customers evaluate alternatives systematically:

- Application analysis: Understanding your actual requirements vs. over-specification

- Dimensional verification: Providing detailed drawings for your approval

- Sample testing: Offering test units for validation in your actual application

- Performance documentation: Supplying test data from our quality control processes

- Ongoing support: Direct access to our engineering team throughout the process

Kevin from Tennessee, whom I mentioned earlier, was initially skeptical about alternatives. We sent him detailed specifications for our BPT-OSP32 model (compatible with Parker Origa OSP-P32) along with a sample unit. After two weeks of testing in his most demanding application, he reported performance within 2% of his existing Parker cylinders—at 58% of the cost. 💪

Which Brands Offer the Best Parker Origa Replacements?

Knowing your options empowers smarter sourcing decisions and better negotiations. 🌟

The top five Parker Origa alternatives for budget-conscious buyers are: Bepto Pneumatics (best overall value), Festo (premium alternative), SMC (Japanese quality), Camozzi (European option), and Airtac (economy choice)—each offering distinct advantages in pricing, delivery speed, technical support, or regional availability. Selection depends on your specific priorities: cost savings, delivery urgency, technical complexity, or geographic location.

Top 5 Alternatives Ranked

#1: Bepto Pneumatics (Best Overall Value) 🏆

Series: BPT-OSP (Origa-compatible), BPT-RLC (Rodless Cylinder)

Price Range: 40-60% of Parker Origa pricing

Lead Time: 3-7 days for standard configs, 10-14 days for custom

Warranty: 18 months

Strengths:

- ✅ Exceptional price-to-performance ratio

- ✅ Fast delivery (dramatically faster than OEM)

- ✅ Direct engineering support (no distributor layers)

- ✅ Flexible customization options

- ✅ Growing global customer base with proven track record

Best For: Budget-conscious operations needing fast delivery and excellent support

Compatible Models:

- BPT-OSP25/32/40/50/63/80 (matches Parker Origa OSP-P series)

- Custom stroke lengths from 100mm to 6000mm

- Multiple mounting and carriage configurations

#2: Festo (Premium Alternative)

Series: DGC, DGCI (compact rodless)

Price Range: 85-95% of Parker Origa pricing

Lead Time: 3-5 weeks

Warranty: 12 months

Strengths:

- ✅ Excellent technical documentation

- ✅ Wide accessory ecosystem

- ✅ Strong European presence

- ✅ Proven reliability in demanding applications

Considerations:

- ⚠️ Still premium-priced (limited cost savings)

- ⚠️ Longer lead times than Bepto

- ⚠️ May require different mounting accessories

Best For: Applications requiring extensive documentation or European sourcing preference

#3: SMC (Japanese Quality)

Series: MY1B, CY1S (rodless cylinders)

Price Range: 75-85% of Parker Origa pricing

Lead Time: 2-4 weeks

Warranty: 12 months

Strengths:

- ✅ High cycle life ratings (10M+ cycles)

- ✅ Good availability in Asia

- ✅ Reliable performance

- ✅ Comprehensive product range

Considerations:

- ⚠️ Moderate cost savings only

- ⚠️ Complex model numbering system

- ⚠️ May not be exact dimensional match (verify carefully)

Best For: Asian manufacturing operations or high-cycle applications

#4: Camozzi (European Option)

Series: Series 32 (rodless cylinders)

Price Range: 65-75% of Parker Origa pricing

Lead Time: 3-6 weeks

Warranty: 12 months

Strengths:

- ✅ Good European availability

- ✅ Competitive pricing

- ✅ ISO standard compliance

- ✅ Decent technical support

Considerations:

- ⚠️ Limited presence in North American market

- ⚠️ Longer lead times than Bepto

- ⚠️ Smaller product range than major brands

Best For: European operations seeking moderate cost savings with local support

#5: Airtac (Economy Choice)

Series: HLQ (rodless cylinder)

Price Range: 45-55% of Parker Origa pricing

Lead Time: 2-4 weeks

Warranty: 6-12 months

Strengths:

- ✅ Very aggressive pricing

- ✅ Adequate for light-duty applications

- ✅ Growing availability

Considerations:

- ⚠️ Lower cycle life ratings (3-5M cycles)

- ⚠️ Less comprehensive documentation

- ⚠️ Limited technical support in Western markets

- ⚠️ Quality consistency concerns

Best For: Non-critical applications where lowest cost is paramount

Detailed Comparison Table

| Brand | Price vs. Parker | Lead Time | Cycle Life | Support Quality | Best Application |

|---|---|---|---|---|---|

| Bepto | 40-60% | 3-7 days | 8M+ cycles | Excellent (direct) | General industrial, fast delivery needs |

| Festo | 85-95% | 3-5 weeks | 10M+ cycles | Excellent | High-precision, documentation-heavy |

| SMC | 75-85% | 2-4 weeks | 10M+ cycles | Good | High-cycle, Asian operations |

| Camozzi | 65-75% | 3-6 weeks | 7M+ cycles | Good | European projects |

| Airtac | 45-55% | 2-4 weeks | 3-5M cycles | Basic | Light-duty, cost-critical |

| Parker Origa | 100% (baseline) | 6-12 weeks | 10M+ cycles | Excellent | Extreme requirements, brand-specified |

Real-World Selection Story

Let me share how Maria, a machine builder in Ontario, Canada, approached her Parker Origa alternative selection. She was building a custom palletizing system for a food processing client and needed six rodless cylinders (OSP-P40 equivalent, 2000mm stroke). 📦

Her Requirements:

- Stroke accuracy: ±0.3mm

- Cycle rate: 30 cycles/minute

- Expected life: 5 years (approximately 7M cycles)

- Budget: $8,000 total for all six cylinders

- Timeline: 3 weeks to delivery

Her Evaluation Process:

- Parker Origa quote: $14,400 total, 10-week lead time ❌

- Festo quote: $13,200 total, 4-week lead time ❌ (over budget)

- SMC quote: $11,100 total, 3-week lead time ⚠️ (slightly over budget)

- Bepto quote: $7,800 total, 5-day lead time ✅

She ordered one Bepto BPT-OSP40 sample for testing. After running it through 10,000 cycles and measuring positioning accuracy (±0.15mm—better than required), she ordered the remaining five units. Total project came in under budget with time to spare, and her client was impressed with the system performance. She’s since become one of our regular customers, standardizing on Bepto for all her rodless cylinder needs. 🎉

How Do Alternative Rodless Cylinders Compare in Real-World Performance?

Laboratory specs are one thing—actual production performance is what truly matters. 📊

Independent testing and thousands of real-world installations demonstrate that quality Parker Origa alternatives like Bepto cylinders achieve 95-102% of OEM performance specifications in force output, positioning accuracy, and cycle life, while reducing acquisition costs by 40-60% and cutting delivery times by 75-90%. The key is selecting alternatives from manufacturers with robust quality control systems and proven track records rather than simply choosing the cheapest option.

Head-to-Head Performance Data

We conducted extensive comparative testing between Parker Origa OSP-P40 and Bepto BPT-OSP40 (both 40mm bore, 1500mm stroke):

| Performance Metric | Parker Origa OSP-P40 | Bepto BPT-OSP40 | Test Method |

|---|---|---|---|

| Force Output @ 6 bar | 754 N | 748 N (99.2%) | Load cell measurement |

| Positioning Repeatability | ±0.08mm | ±0.10mm | Laser measurement, 1000 cycles |

| Maximum Speed | 2.0 m/s | 1.8 m/s | High-speed camera |

| Cycle Life (tested) | 8.2M cycles | 8.0M cycles | Accelerated life testing |

| Operating Noise | 68 dB | 70 dB | Sound meter @ 1m distance |

| Price (FOB) | $3,250 | $1,420 (56% savings) | Published pricing |

| Typical Lead Time | 8 weeks | 5 days | Actual order data |

Long-Term Reliability Study

We tracked 47 Bepto rodless cylinders installed as Parker Origa replacements across 12 customer facilities over 18 months:

Installation Details:

- Industries: Automotive, packaging, food processing, electronics

- Applications: Material handling, assembly positioning, palletizing

- Operating conditions: 1-3 shifts, varying cycle rates

- Geographic locations: USA, Canada, Germany, UK

Results:

- Failures: 2 cylinders (4.3% failure rate)

- Cause analysis: 1 seal failure due to contaminated air supply, 1 bearing wear due to side loading (installation error)

- Warranty claims: Both replaced at no charge within 48 hours

- Customer satisfaction: 11 of 12 customers rated performance as “equal to or better than OEM”

- Repeat purchase rate: 10 of 12 customers have ordered additional Bepto cylinders

Cost of Ownership Analysis

Kevin from Tennessee (the automotive parts manufacturer I mentioned) conducted a detailed 12-month cost analysis after converting 18 Parker Origa cylinders to Bepto alternatives:

Initial Investment:

- Parker Origa replacement cost: $52,200

- Bepto alternative cost: $22,680

- Immediate savings: $29,520

Operating Costs (12 months):

- Maintenance interventions: 2 (Bepto) vs. 3 (previous Parker baseline)

- Downtime incidents: 0 (Bepto) vs. 1 (previous Parker baseline)

- Spare parts inventory value: $4,500 (Bepto) vs. $10,400 (Parker)

Total First-Year Savings: $35,420 💰

Kevin’s CFO was so impressed that they’ve now standardized on Bepto for all pneumatic cylinder replacements across their three facilities.

When Alternatives May Not Be Suitable

To be completely transparent, there are scenarios where sticking with Parker Origa makes sense:

Extreme Precision Applications:

- Semiconductor manufacturing requiring ±0.01mm repeatability

- Metrology equipment with ultra-tight tolerances

- Medical device assembly with validation requirements specifying Parker by name

Very High Cycle Applications:

- Operations exceeding 15 million cycles expected life

- 24/7 continuous operation at maximum speed

- Applications where even 1% performance difference is critical

Contractual Requirements:

- Customer specifications mandating Parker equipment

- Government contracts with approved vendor lists

- Existing maintenance agreements tied to Parker parts

For the vast majority of industrial applications—probably 85-90% of rodless cylinder installations—quality alternatives deliver equivalent performance at dramatically better value. 🎯

Conclusion

Choosing a Parker Origa alternative isn’t about compromising quality—it’s about optimizing your total cost of ownership while maintaining the performance your operations demand. In today’s competitive manufacturing environment, smart sourcing decisions that reduce component costs by 40-60% without sacrificing reliability directly impact your bottom line and competitive position. At Bepto Pneumatics, we’re committed to proving that you don’t need to pay premium prices for premium performance. 🚀

FAQs About Parker Origa Rodless Cylinder Alternatives

Are Bepto cylinders truly compatible with Parker Origa mounting patterns?

Yes, our BPT-OSP series cylinders are engineered as direct dimensional replacements for Parker Origa OSP-P series, with mounting hole patterns, carriage dimensions, and port locations matching within ±0.1mm. We provide detailed dimensional drawings for verification before purchase, and we’ve successfully replaced Parker Origa cylinders in hundreds of installations without any machine modifications required.

What is your typical delivery time compared to Parker Origa?

Standard Bepto configurations ship within 3-7 business days globally, compared to 6-12 weeks typical for Parker Origa non-stock items. We maintain inventory of popular bore sizes and stroke lengths, and our manufacturing facility can produce custom configurations in 10-14 days—still dramatically faster than OEM lead times. For emergency situations, we offer expedited production and shipping options.

Do you provide technical support for application questions?

Absolutely—our engineering team provides direct technical support via email, phone, or video call, typically responding within 2-4 hours during business hours across all major time zones. Unlike multi-tier OEM support systems where you navigate through distributors and call centers, you’ll speak directly with engineers who designed our products and understand real-world applications.

Can I get samples for testing before committing to a full order?

Yes, we actively encourage sample testing and offer evaluation units at discounted pricing for qualified applications. We want you to validate performance in your actual operating conditions before making a purchasing decision. Many customers start with 1-2 test units, run them for several weeks or months alongside their existing cylinders, then convert their entire facility once they’ve confirmed equivalent performance.

What warranty coverage do you provide on Parker Origa alternatives?

All Bepto rodless cylinders include an 18-month warranty covering manufacturing defects and material failures—50% longer than Parker’s standard 12-month warranty. We also offer extended warranty options for critical applications and provide rapid-response replacement for any warranty claims, typically shipping replacement units within 24-48 hours to minimize your downtime. Our warranty terms reflect our confidence in product quality and our commitment to your success. 🛡️

-

Understanding how indirect costs like administration and marketing impact final product pricing. ↩

-

A technical guide distinguishing between repeatability and accuracy in precision engineering. ↩

-

An overview of hysteresis in mechanical systems and its effect on positioning accuracy. ↩

-

Detailed specifications for 6063-T5 aluminum alloy, focusing on its strength and extrudability. ↩

-

A technical explanation of Surface Roughness (Ra) and its critical role in reducing friction and wear. ↩