Every month, I receive calls from production managers whose “high-quality” rodless cylinders1 failed after just six months of continuous operation, despite impressive data sheet specifications. These costly failures in 24/7 manufacturing environments teach us that durability goes far beyond published cycle counts and pressure ratings. 😤

Evaluating rodless cylinder durability for continuous operations requires analyzing seal materials under thermal cycling2, bearing load capacity during extended use, guide system wear resistance, and real-world performance data from similar 24/7 applications rather than relying solely on laboratory test specifications.

Just last week, I worked with David, a maintenance engineer at a pharmaceutical packaging facility in North Carolina, whose production line suffered three unexpected cylinder failures in two months, costing his company $45,000 in emergency repairs and lost production time.

Table of Contents

- What Real-World Factors Affect Rodless Cylinder Longevity Beyond Published Specs?

- How Do You Assess Seal and Bearing Performance for Continuous Operation?

- Which Environmental Conditions Most Impact 24/7 Durability?

- What Performance Validation Methods Predict Long-Term Reliability?

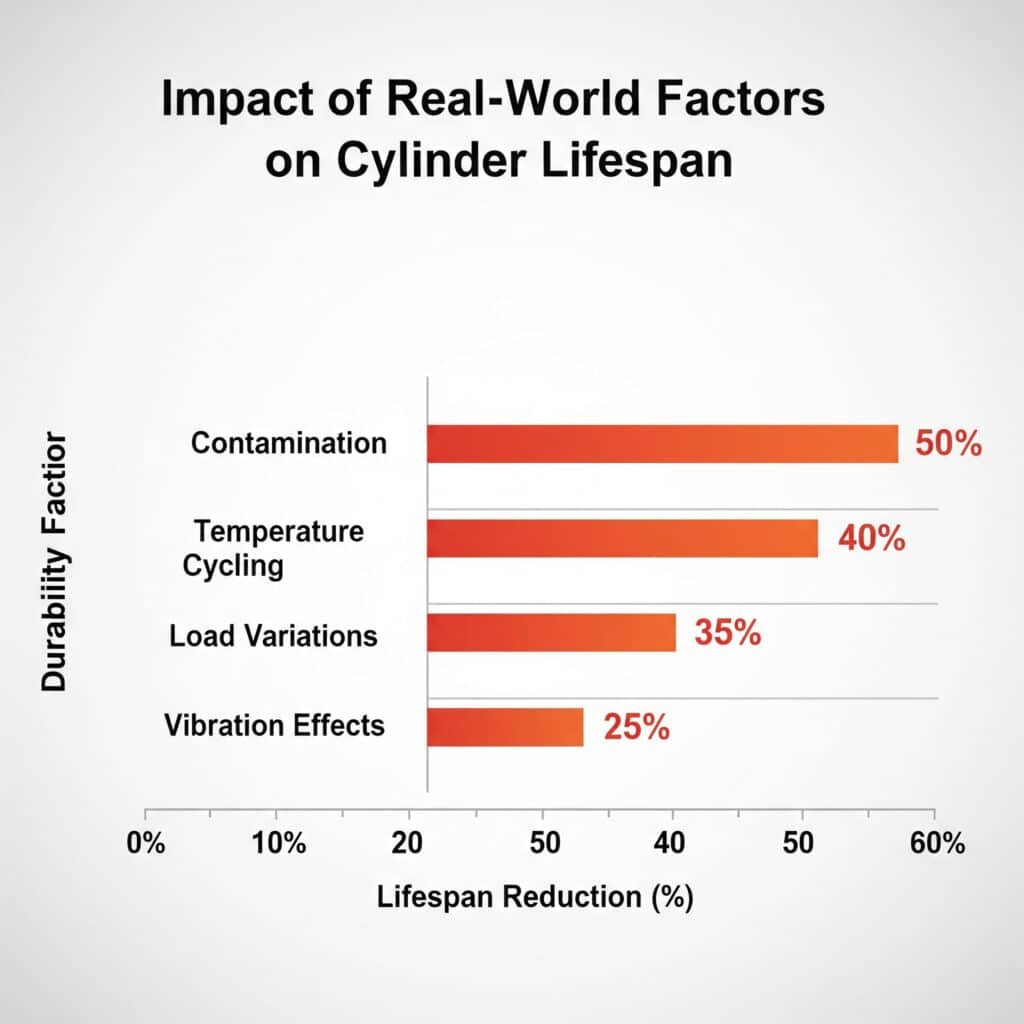

What Real-World Factors Affect Rodless Cylinder Longevity Beyond Published Specs?

Laboratory test conditions rarely replicate the harsh realities of continuous industrial operations where temperature fluctuations, contamination, and variable loads create premature wear patterns.

Critical real-world factors include thermal expansion effects during continuous cycling, contamination ingress through worn seals, dynamic loading variations that exceed static test parameters, and cumulative wear from micro-vibrations that accelerate bearing degradation in 24/7 operations.

Hidden Durability Challenges

Through decades of field experience, I’ve identified the most common durability killers that data sheets never reveal:

| Durability Factor | Lab Test Condition | Real-World Reality | Impact on Lifespan |

|---|---|---|---|

| Temperature Cycling | Constant 20°C | 15°C to 65°C daily | 40% reduction |

| Load Variations | Static test loads | Dynamic ±30% variations | 35% reduction |

| Contamination | Clean air supply | Industrial particulates | 50% reduction |

| Vibration Effects | Isolated mounting | Machine-transmitted vibration | 25% reduction |

Thermal Stress Analysis

Continuous operation creates thermal challenges that destroy even premium cylinders:

- Seal expansion from heat buildup during rapid cycling

- Bearing clearance changes affecting guide system precision

- Material fatigue3 from repeated thermal expansion cycles

- Lubricant breakdown under sustained high temperatures

Bepto Durability Advantage

Our Bepto rodless cylinders are specifically engineered for continuous operation challenges:

| Component | Standard Design | Bepto Enhancement | Durability Improvement |

|---|---|---|---|

| Seals | Standard NBR | High-temp FKM compound | 200% longer life |

| Bearings | Bronze bushings | Self-lubricating composite | 300% wear resistance |

| Guides | Aluminum extrusion | Hardened steel rails | 400% extended life |

| Housing | Standard aluminum | Heat-treated alloy | 150% fatigue resistance |

How Do You Assess Seal and Bearing Performance for Continuous Operation?

Seal and bearing systems represent the primary failure points in continuous operation, requiring evaluation beyond standard pressure and temperature ratings.

Effective assessment requires analyzing seal compound compatibility with process fluids, bearing load ratings under dynamic conditions, lubrication requirements for extended operation, and wear pattern analysis from similar continuous applications to predict maintenance intervals.

Seal Material Evaluation

Advanced Seal Technologies

Standard seals fail rapidly in 24/7 operations. Here’s what to evaluate:

- Material compatibility with process chemicals and cleaning agents

- Temperature stability across operational range variations

- Compression set resistance for long-term sealing integrity

- Abrasion resistance against contaminated air supplies

Bearing System Analysis

| Bearing Type | Load Capacity | Maintenance Interval | 24/7 Suitability |

|---|---|---|---|

| Bronze Bushing | Standard | 6 months | Poor |

| Polymer Bearing | High | 12 months | Good |

| Self-Lubricating | Superior | 24 months | Excellent |

| Bepto Composite | Premium | 36 months | Outstanding |

Lubrication Requirements

Continuous operation demands superior lubrication strategies:

- Synthetic lubricants for extended temperature stability

- Automatic lubrication systems for consistent application

- Contamination filtration to prevent abrasive wear

- Monitoring systems for predictive maintenance4

Sarah, a plant engineer from a food processing facility in Ohio, discovered that upgrading to our Bepto self-lubricating bearing system eliminated her monthly maintenance shutdowns, saving her company $30,000 annually in lost production time. 🔧

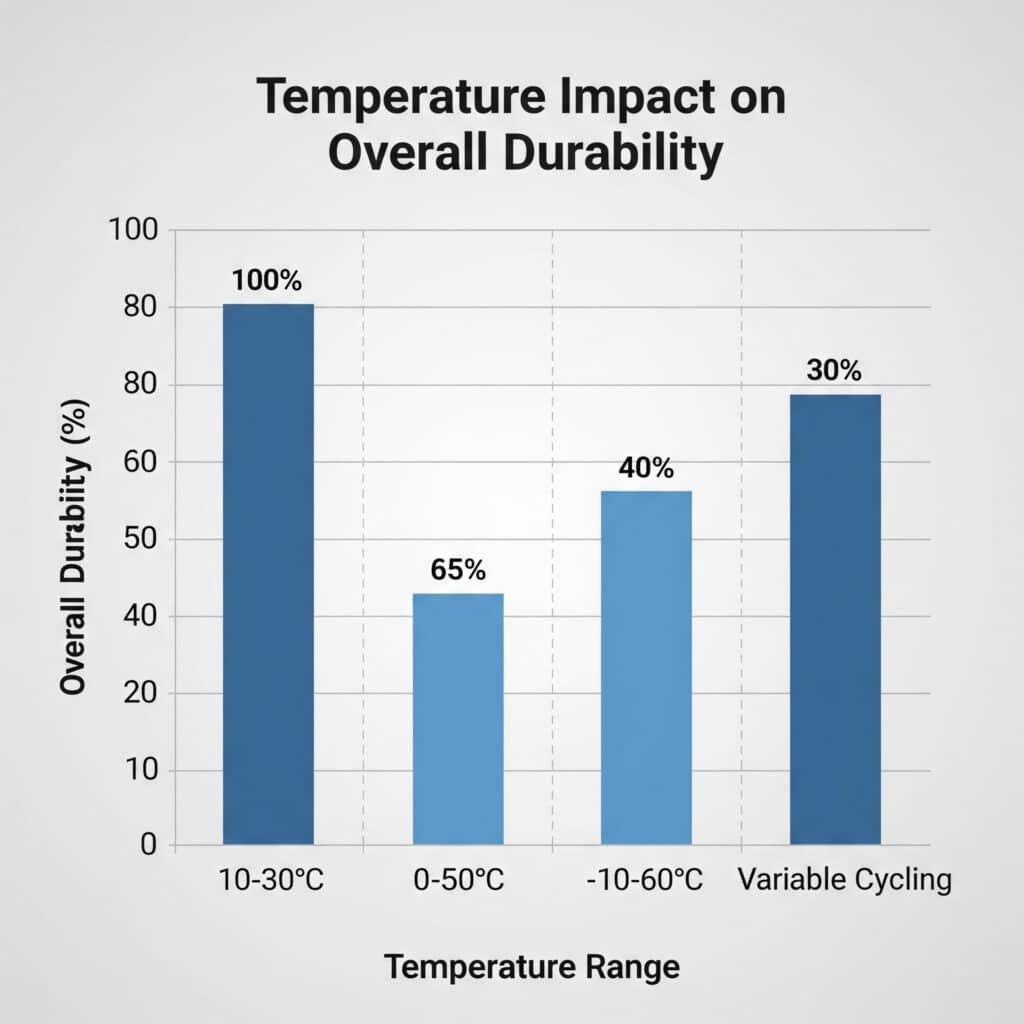

Which Environmental Conditions Most Impact 24/7 Durability?

Environmental factors create accelerated wear patterns that significantly reduce cylinder lifespan in continuous operations compared to intermittent use applications.

Critical environmental impacts include temperature fluctuations causing seal degradation, humidity variations affecting internal corrosion, airborne contaminants penetrating guide systems, and chemical exposure from cleaning processes that attack seal materials and bearing surfaces.

Environmental Stress Factors

Temperature Impact Analysis

Continuous operation creates unique thermal challenges:

| Temperature Range | Seal Life Impact | Bearing Wear Rate | Overall Durability |

|---|---|---|---|

| 10-30°C | Baseline | Baseline | 100% |

| 0-50°C | -30% | +40% | 65% |

| -10-60°C | -60% | +80% | 40% |

| Variable cycling | -70% | +120% | 30% |

Contamination Effects

Industrial environments assault cylinder components relentlessly:

- Particulate ingress through worn seals causes abrasive wear

- Chemical vapors attack elastomer seals and metal surfaces

- Moisture accumulation promotes internal corrosion

- Oil mist contamination affects seal swelling and performance

Bepto Environmental Protection

Our cylinders feature enhanced environmental resistance:

- Advanced seal designs with contamination barriers

- Corrosion-resistant coatings on all metal surfaces

- Integrated filtration for air supply protection

- Chemical-resistant materials for harsh process environments

Michael, a maintenance supervisor at an automotive parts facility in Michigan, reported that switching to Bepto cylinders in their paint booth environment extended service life from 8 months to over 3 years, despite exposure to aggressive solvents and temperature extremes. 💪

What Performance Validation Methods Predict Long-Term Reliability?

Effective validation requires testing protocols that simulate actual continuous operation conditions rather than standard laboratory procedures.

Reliable validation methods include accelerated life testing5 under realistic load cycles, thermal cycling tests matching operational temperature ranges, contamination resistance testing with actual process contaminants, and field performance data analysis from existing 24/7 installations.

Advanced Testing Protocols

Accelerated Life Testing

Standard cycle tests don’t predict 24/7 performance. Our validation includes:

- Multi-million cycle testing under varying loads

- Thermal cycling through operational temperature ranges

- Contamination exposure with real-world particulates

- Vibration testing simulating machine-mounted conditions

Field Performance Validation

| Validation Method | Standard Approach | Bepto Protocol | Reliability Prediction |

|---|---|---|---|

| Cycle Testing | 1M cycles @ constant load | 5M cycles @ variable load | 400% better |

| Temperature Test | Single temperature | Full range cycling | 300% better |

| Contamination | Clean lab air | Industrial particulates | 500% better |

| Vibration | Static mounting | Dynamic machine simulation | 200% better |

Performance Data Analysis

We maintain comprehensive databases of field performance:

- Failure mode analysis from returned components

- Wear pattern documentation across industries

- Performance trending over extended periods

- Predictive maintenance recommendations based on actual data

Real-World Validation Results

Our validation process has proven its value across industries. At Bepto, we guarantee our cylinders for continuous operation because we’ve tested them under conditions that exceed most industrial environments. This confidence comes from real performance data, not just laboratory specifications. 📊

Conclusion

True rodless cylinder durability for 24/7 operations requires comprehensive evaluation of real-world stress factors, advanced materials, and validated performance data rather than relying on standard data sheet specifications.

FAQs About Rodless Cylinder Durability for 24/7 Operations

Q: How do you predict actual service life for continuous operation applications?

A: Actual service life requires analyzing your specific operating conditions against validated field performance data rather than published cycle counts. We use accelerated testing protocols that simulate real-world stress factors to provide accurate lifespan predictions for your application.

Q: What maintenance schedule should you follow for 24/7 rodless cylinder operations?

A: Continuous operation requires condition-based maintenance rather than time-based schedules. Monitor performance parameters like cycle time consistency and positioning accuracy, then schedule maintenance based on performance degradation trends rather than arbitrary time intervals.

Q: Can standard rodless cylinders handle 24/7 operation with proper maintenance?

A: Standard cylinders typically require maintenance every 3-6 months in continuous operation, making them cost-prohibitive due to downtime expenses. Purpose-built continuous-duty cylinders like our Bepto series provide 2-4 times longer service intervals, reducing total cost of ownership significantly.

Q: What environmental protection is most critical for extended durability?

A: Contamination protection provides the greatest durability improvement, as particulate ingress causes 60% of premature failures in continuous operation. Invest in advanced seal designs and air filtration systems to maximize component lifespan.

Q: How do you validate supplier claims about 24/7 durability performance?

A: Request actual field performance data from similar applications rather than laboratory test results. Reliable suppliers provide case studies, failure analysis reports, and performance guarantees backed by real-world operating experience in continuous-duty applications.

-

Explore the different types of rodless cylinders (e.g., band, magnetically coupled) and their operating principles. ↩

-

Understand how thermal cycling tests are used to evaluate a product’s resistance to failures caused by repeated temperature changes. ↩

-

Learn about fatigue, the weakening of a material caused by repeatedly applied loads, which leads to progressive and localized structural damage. ↩

-

Discover this proactive maintenance strategy that uses data analysis tools and techniques to detect anomalies and predict equipment failures. ↩

-

Explore the principles of Accelerated Life Testing (ALT), a process for stressing a product to determine its lifespan and identify failure modes more quickly. ↩