Have you ever heard that sickening “crack” sound when a pneumatic cylinder hits the end of its stroke too hard? It is a nightmare scenario. The end cap shatters, high-pressure air hisses out, and your machine stops dead. You are left wondering why a solid piece of metal failed so easily. Is it bad material? Or is it bad design? 💥

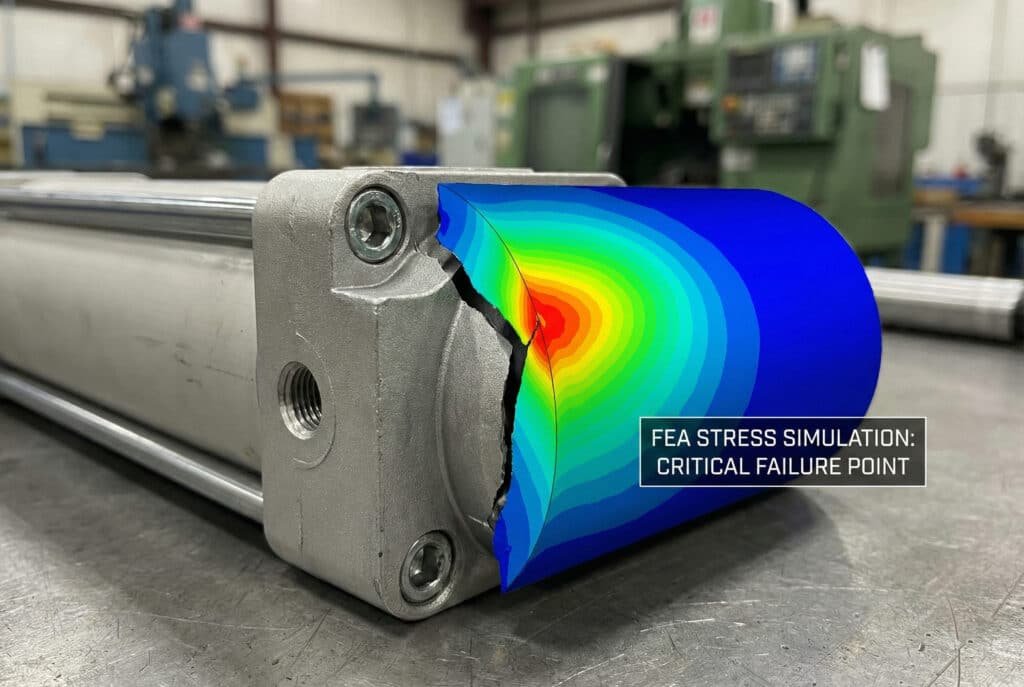

Finite Element Analysis (FEA)1 simulates high-impact stress distribution on cylinder end caps to identify weak points and optimize geometry, ensuring the component can withstand repeated shock loads without catastrophic failure. By digitally visualizing where stress accumulates, engineers can reinforce critical areas before a physical part is ever cast.

I remember meeting Maria, a business owner running a packaging machinery company in Germany. She was frustrated because the OEM end caps on her high-speed sorting machines were cracking every few months. The downtime was killing her margins, and the OEM’s response was simply to sell her the same fragile part again. She needed a solution that looked beneath the surface.

Table of Contents

- Why Do Cylinder End Caps Fail Under Shock Loads?

- How Does FEA Improve the Durability of Bepto Replacement Parts?

- Can High-Quality Aftermarket End Caps Save You Money?

- Conclusion

- FAQs About FEA of Cylinder End Caps

Why Do Cylinder End Caps Fail Under Shock Loads?

It is not always about the quality of the aluminum; often, it is about where the kinetic energy goes when the piston slams home.

End caps fail because kinetic energy2 from the piston transfers instantly upon impact, creating stress concentrations (hot spots) that exceed the material’s yield strength3, leading to micro-cracks and eventual fracture. If the design has sharp corners or thin walls in the wrong places, it acts like a fuse waiting to blow.

The Hidden Danger of Stress Risers

In Maria’s case, we analyzed the broken OEM parts. The failure always started at a sharp internal corner near the port thread.

- Shock Load: When the piston hits, the force isn’t static; it’s a dynamic hammer blow.

- Stress Concentration: Sharp angles amplify this force.

- Fatigue4: After 10,000 cycles, the metal gets tired and snaps.

At Bepto, we understand that a robust supply chain relies on robust parts. We don’t just sell replacements; we ensure they are engineered to handle the reality of your factory floor.

How Does FEA Improve the Durability of Bepto Replacement Parts?

We don’t just copy parts; we reverse-engineer and improve them using digital twins5 and simulation technology.

FEA allows us to virtually test thousands of impact cycles, tweaking wall thickness and ribbing structures to dissipate energy evenly, resulting in replacement parts that often outperform the original OEM designs. This “heat map” of stress tells us exactly where to add material and where we can save weight.

Optimizing for Longevity

When we redesigned the replacement cap for Maria, we used FEA to smooth out those sharp corners.

| Feature | Standard OEM Design | Bepto Optimized Design |

|---|---|---|

| Stress Distribution | Concentrated at corners (High Risk) | Evenly spread across ribs |

| Impact Resistance | Standard | Enhanced via FEA geometry |

| Material Usage | Uniform thickness | Reinforced at stress points |

| Failure Mode | Cracking at threads | High cycle fatigue resistance |

By using FEA, we created a replacement part for Maria that was 100% compatible with her existing cylinders but structurally superior. She hasn’t had a cracked cap in over a year. 🛠️

Can High-Quality Aftermarket End Caps Save You Money?

There is a misconception that “aftermarket” means “lower quality.” In the world of precision pneumatics, that is simply not true.

Yes, high-quality aftermarket caps optimized via FEA reduce replacement frequency and downtime costs, offering a lower price point than OEM parts while delivering equal or superior structural integrity. You are paying for the engineering, not just the brand logo.

The Bottom Line for Business Owners

Maria is a savvy business owner. She cares about the bottom line.

1. Direct Savings: Bepto parts cost her 30% less than the OEM list price.

2. Indirect Savings: The biggest win was eliminating the $2,000/hour cost of unexpected downtime.

Whether you need a rodless cylinder repair kit or a standard cylinder end cap, choosing a supplier that understands structural analysis is key. We ensure that our replacements—whether for rodless cylinders or standard pneumatics—are built to last.

Conclusion

Finite Element Analysis (FEA) transforms the way we look at simple components like cylinder end caps. It proves that design geometry is just as important as material strength. By choosing Bepto replacement parts that are engineered with these insights, you aren’t just buying a spare part; you are buying reliability and peace of mind for your production line.

FAQs About FEA of Cylinder End Caps

What causes cylinder end caps to crack?

The primary cause is repeated shock loads creating stress concentrations at sharp corners or weak points in the casting. Over time, these stress risers lead to fatigue failure and cracking.

How does FEA help prevent cylinder failure?

FEA helps by visualizing where stress accumulates during impact, allowing engineers to redesign the geometry to distribute forces more evenly. This eliminates weak spots before the part is manufactured.

Are Bepto replacement parts as strong as OEM parts?

Yes, and often they are stronger because we use FEA to identify and correct design flaws found in the original OEM components. We focus on durability and cost-efficiency for the end-user.

-

Learn more about how numerical simulations solve complex structural and thermal engineering problems. ↩

-

Understand the mathematical relationship between mass, velocity, and the energy transferred during a collision. ↩

-

Explore how mechanical engineers determine the point at which a material begins to deform permanently. ↩

-

Discover how repeated loading and unloading causes structural damage over millions of operation cycles. ↩

-

Explore how virtual replicas of physical components are used to predict performance and maintenance needs. ↩