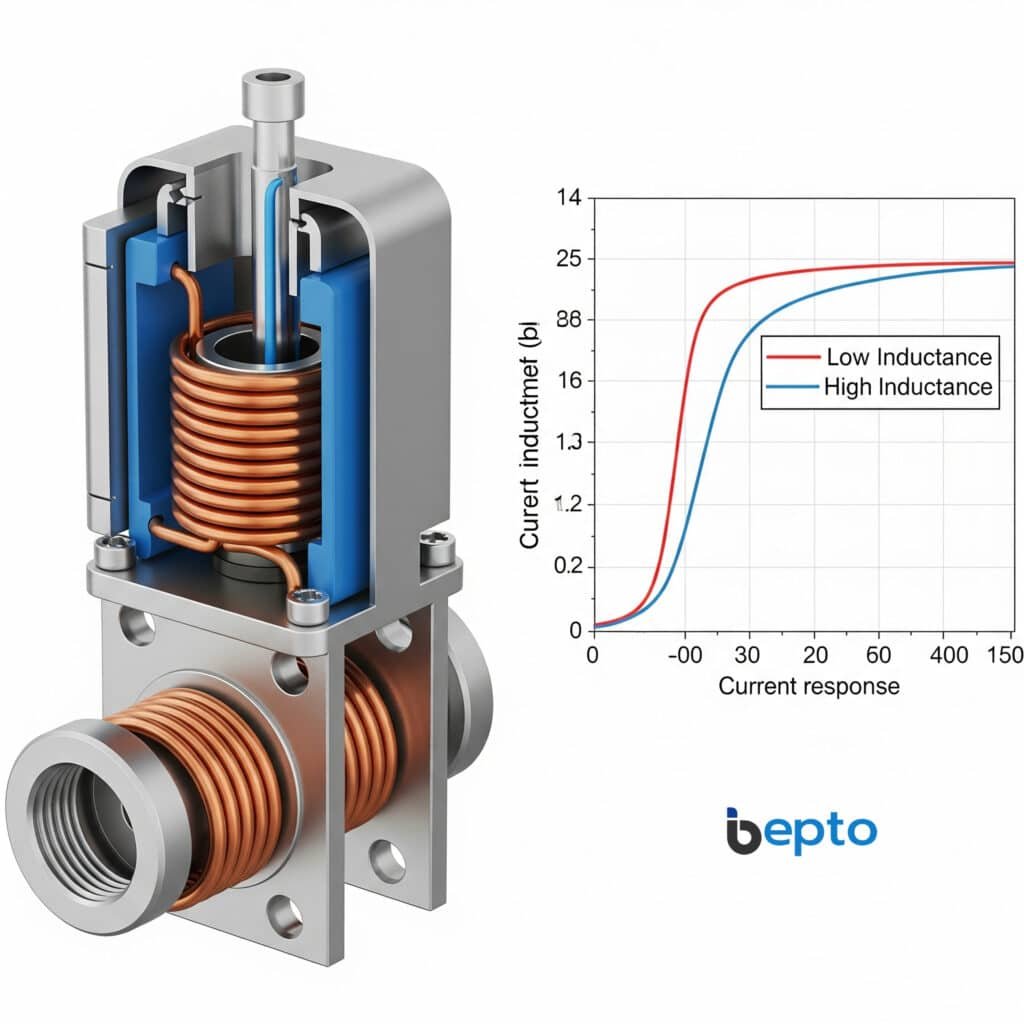

When your production line suddenly slows down due to sluggish solenoid valves, every millisecond counts toward your bottom line. The culprit behind delayed pneumatic responses often lies in a fundamental electrical property that many engineers overlook. Coil inductance directly determines solenoid response time by controlling how quickly current can build up or decay in the electromagnetic coil – higher inductance creates slower response times due to increased resistance to current changes.

Last month, I worked with a packaging equipment manufacturer in Michigan whose production speeds dropped 15% overnight, and the root cause traced back to this exact issue with their solenoid valve timing.

Table of Contents

- What Is Coil Inductance and Why Does It Matter?

- How Does Inductance Create Response Delays?

- What Factors Control Solenoid Coil Inductance?

- How Can You Optimize Response Time in Your Systems?

What Is Coil Inductance and Why Does It Matter?

Understanding inductance is crucial for optimizing your pneumatic system performance. 🔧

Coil inductance is the electromagnetic property that opposes changes in current flow, measured in henries (H), and directly impacts how fast your solenoid valves can switch between open and closed positions.

The Physics Behind Solenoid Operation

When voltage is applied to a solenoid coil, inductance prevents instantaneous current flow. This creates a time delay governed by the L/R time constant1, where L represents inductance and R represents resistance. Higher inductance means longer delays.

Real-World Impact on Production

I remember working with Tom, a maintenance engineer at a automotive parts facility in Ohio. His assembly line was experiencing inconsistent cycle times, and we discovered that high-inductance replacement solenoids were adding 50-100 milliseconds to each operation cycle. Over thousands of cycles daily, this translated to significant production losses.

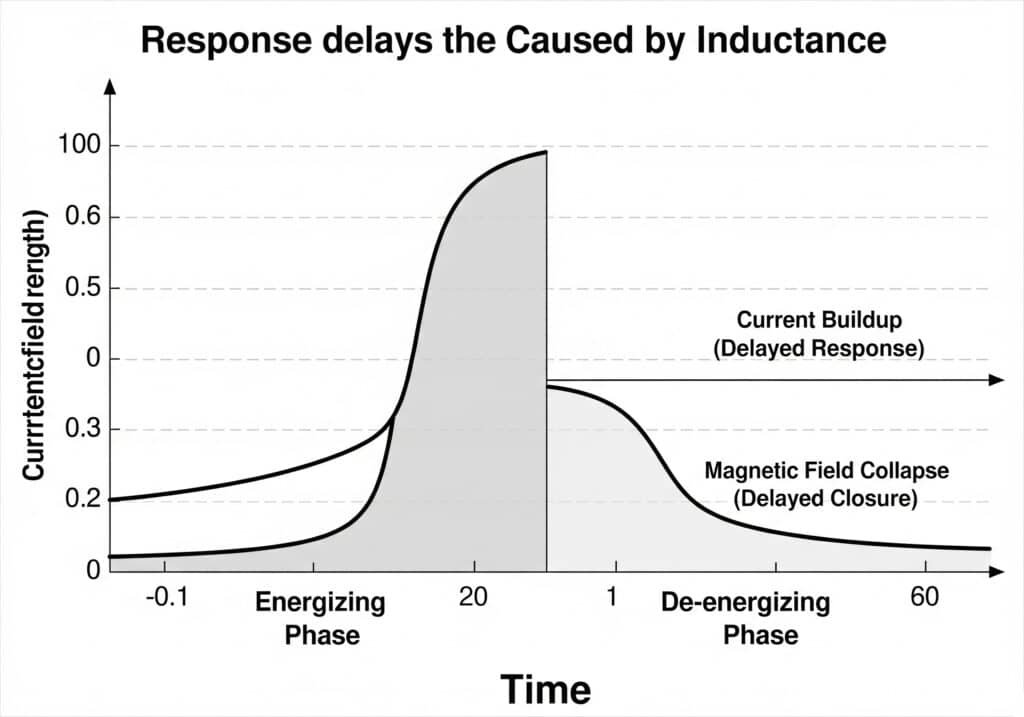

How Does Inductance Create Response Delays?

The relationship between inductance and timing affects every aspect of valve operation.

Inductance creates response delays through electromagnetic inertia – when energizing, current builds up exponentially rather than instantly, and when de-energizing, magnetic field collapse takes time, preventing immediate valve closure.

Energizing Response Time

During valve activation, current must reach approximately 63% of its steady-state value before sufficient magnetic force develops. The time constant formula (τ = L/R) determines this delay:

| Inductance (mH) | Resistance (Ω) | Time Constant (ms) | Response Impact |

|---|---|---|---|

| 50 | 10 | 5 | Fast response |

| 150 | 10 | 15 | Moderate delay |

| 300 | 10 | 30 | Significant delay |

De-energizing Response Time

When power is removed, the magnetic field doesn’t collapse instantly. Back-EMF2 (electromotive force) generated by the collapsing field maintains current flow, delaying valve closure. This is why many solenoids include flyback diodes3 or surge suppressors.

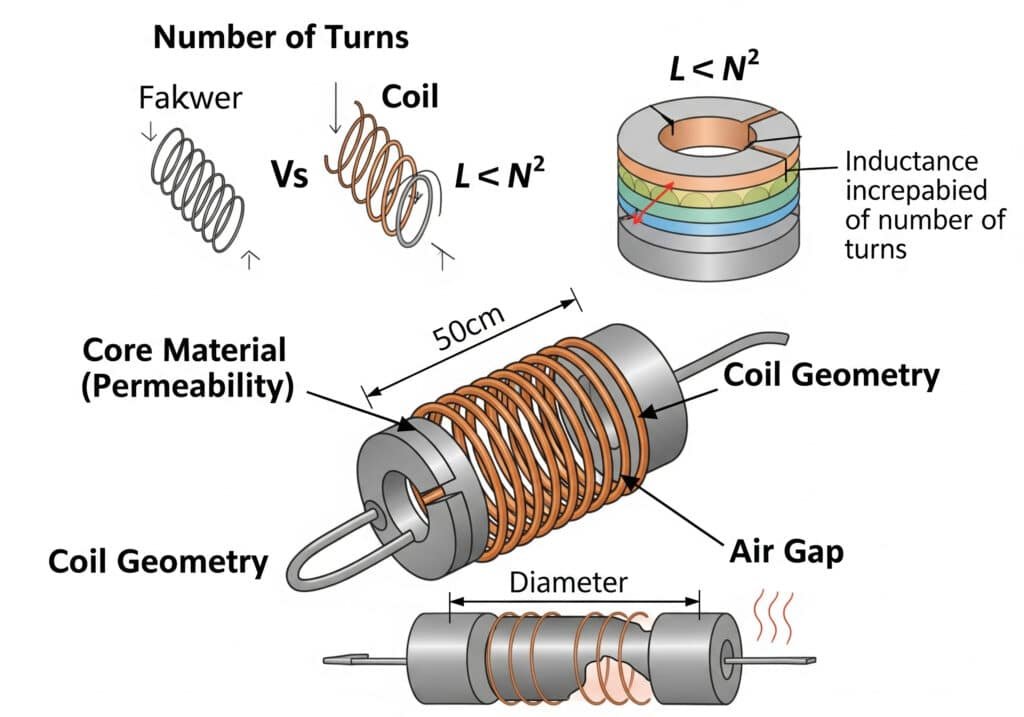

What Factors Control Solenoid Coil Inductance?

Multiple design parameters influence inductance levels in pneumatic solenoids.

Solenoid coil inductance is determined by the number of wire turns, core material permeability4, coil geometry, and air gap size – with turn count having the most dramatic impact since inductance increases with the square of turns.

Primary Design Factors

Wire Turns and Configuration

- Turn count: Inductance ∝ N² (turns squared)

- Wire gauge: Affects resistance, influencing time constant

- Layer arrangement: Single vs. multiple layers impact field distribution

Core Material Properties

Different core materials dramatically affect inductance:

| Core Material | Relative Permeability | Inductance Impact |

|---|---|---|

| Air | 1 | Baseline |

| Ferrite | 1000-3000 | Very high |

| Silicon Steel | 4000-8000 | Extremely high |

| Laminated Iron | 200-5000 | Variable |

Geometric Considerations

The physical dimensions of the coil assembly directly influence inductance. Longer coils with smaller diameters typically exhibit higher inductance, while shorter, wider configurations reduce it.

How Can You Optimize Response Time in Your Systems?

Practical strategies exist for minimizing inductance-related delays in your pneumatic applications.

You can optimize solenoid response time by selecting low-inductance valve designs, implementing electronic drive circuits with current boosting, using fast-acting pilot valves, or upgrading to Bepto’s quick-response solenoid solutions specifically engineered for high-speed applications.

Electronic Solutions

Current Boosting Circuits

Modern drive electronics can overcome inductance limitations:

- Peak-and-hold drivers5: Provide high initial current, then reduce to holding level

- PWM control: Maintains consistent magnetic force while reducing heat

- Flyback diode circuits: Accelerate magnetic field collapse during de-energizing

Mechanical Optimization Strategies

Valve Selection Criteria

When specifying solenoid valves for time-critical applications, consider:

- Coil specifications: Lower inductance ratings

- Response time ratings: Manufacturer-specified switching speeds

- Pilot valve configurations: Smaller pilot valves respond faster

- Spring return mechanisms: Assist closure during de-energizing

Our Bepto Advantage 🚀

At Bepto, we’ve engineered our replacement solenoid valves with optimized inductance characteristics. Our rodless cylinder systems incorporate fast-response solenoids that match or exceed OEM performance while reducing costs by up to 40%.

I recently helped Sarah, who manages a textile machinery operation in North Carolina. Her imported equipment used expensive European solenoids with 25ms response times. Our Bepto alternatives achieved 15ms response while costing 60% less, allowing her to increase production speeds and improve profitability.

Conclusion

Coil inductance fundamentally controls solenoid response time through electromagnetic principles, but understanding these relationships empowers you to optimize your pneumatic systems for maximum efficiency and speed. ⚡

FAQs About Solenoid Response Time

Q: What is considered a fast response time for pneumatic solenoids?

Response times under 10 milliseconds are considered fast for most industrial applications. However, specific requirements depend on your process demands and cycle frequencies.

Q: Can I reduce inductance by modifying existing solenoids?

Generally no – inductance is determined by fundamental coil design parameters. Replacing with purpose-designed low-inductance alternatives is more practical and reliable.

Q: How does temperature affect solenoid inductance and response time?

Higher temperatures increase coil resistance while slightly reducing inductance. The net effect typically improves response time, but excessive heat can damage insulation and reduce valve life.

Q: Do pneumatic solenoids respond faster than hydraulic ones?

Yes, pneumatic solenoids typically respond faster because compressed air is less viscous than hydraulic fluid. However, inductance effects remain the same regardless of the fluid medium being controlled.

Q: What’s the relationship between solenoid power consumption and response time?

Higher power solenoids can overcome inductance faster, but this increases heat generation and energy costs. Optimal design balances response speed with efficiency and longevity.

-

Get a technical explanation of the L/R time constant in an RL circuit and how it governs current rise. ↩

-

Learn the physics behind Back EMF (electromotive force) and how it is generated when a coil is de-energized. ↩

-

See a circuit diagram and explanation of how a flyback diode safely dissipates energy from an inductor. ↩

-

Explore the material science concept of magnetic permeability and see a table of values for common materials. ↩

-

Discover how peak-and-hold driver circuits use a two-stage current profile to achieve fast actuator response. ↩