Industrial operations face catastrophic seal failures when temperature extremes compromise cylinder performance, with 84% of premature seal failures occurring in applications operating outside optimal temperature ranges, leading to costly downtime and safety hazards. 🌡️

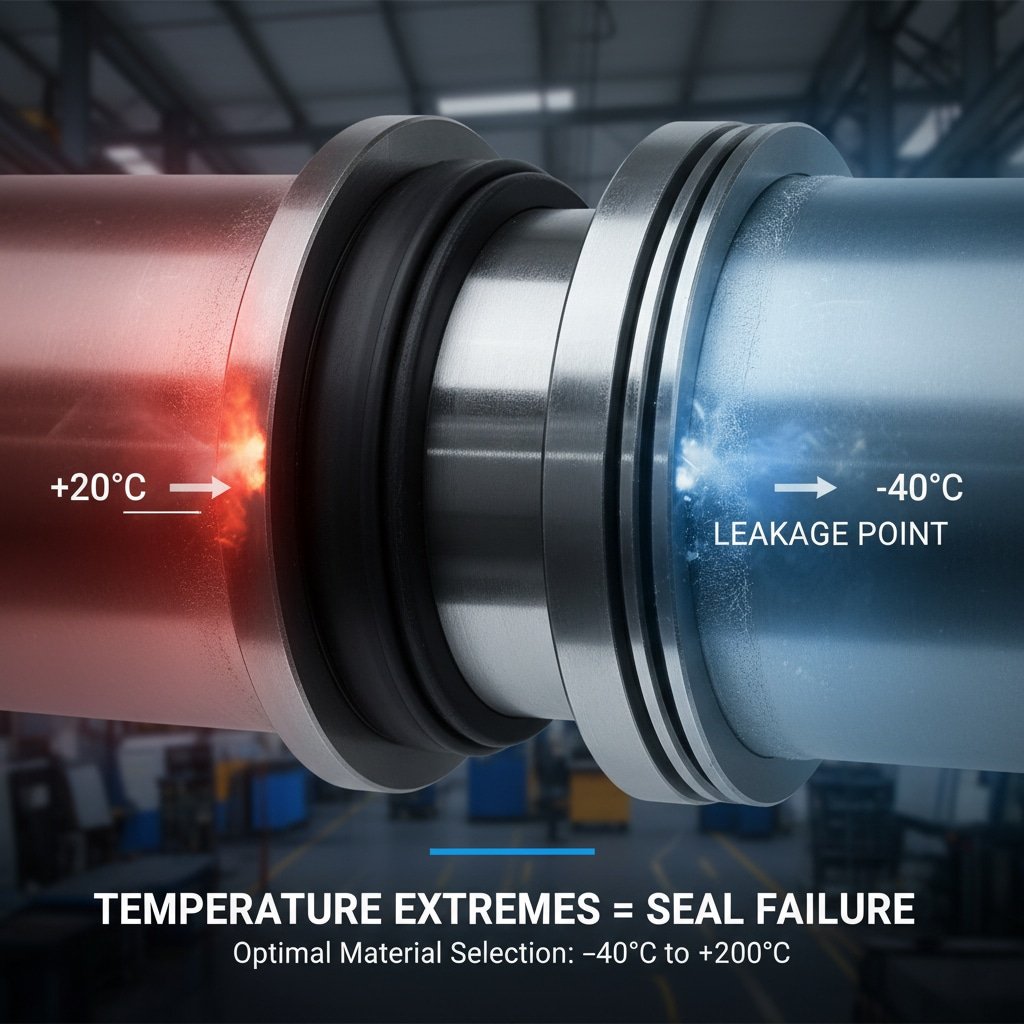

Temperature directly affects cylinder seal performance through material expansion, hardness changes, and chemical degradation, with proper material selection enabling reliable operation from -40°C to +200°C while maintaining leak-tight performance and extended service life.

Yesterday, I helped Marcus, a process engineer from Minnesota, whose outdoor packaging equipment was experiencing daily seal failures during winter operations at -30°C because standard seals couldn’t handle the extreme cold conditions. ❄️

Table of Contents

- What Temperature Effects Impact Cylinder Seal Performance?

- How Do Different Seal Materials Perform Across Temperature Ranges?

- Which Applications Require Special Temperature-Resistant Sealing Solutions?

- Why Do Bepto Temperature-Optimized Seals Outperform Standard Options?

What Temperature Effects Impact Cylinder Seal Performance?

Understanding how temperature affects seal materials reveals why proper selection is critical for reliable cylinder operation across diverse environments.

Temperature impacts seal performance through thermal expansion1 affecting compression, material hardness changes altering sealing force, chemical degradation reducing elastomer properties, and dimensional stability affecting groove fit and sealing effectiveness.

Primary Temperature Effects

Thermal Expansion:

- Seal growth: Materials expand with heat, potentially causing binding

- Groove clearance: Cold temperatures create gaps, reducing sealing force

- Differential expansion: Different materials expand at different rates

- Stress concentration: Thermal cycling creates fatigue points

Material Property Changes:

- Hardness variation: Cold makes seals brittle, heat makes them soft

- Elasticity loss: Extreme temperatures reduce spring-back ability

- Compression set2: Permanent deformation under temperature stress

- Tear resistance: Temperature affects material strength

Temperature Failure Modes

| Temperature Range | Primary Failure Mode | Typical Symptoms | Service Life Impact |

|---|---|---|---|

| Below -20°C | Brittleness, cracking | Sudden leakage | 70% reduction |

| -20°C to +80°C | Normal wear | Gradual degradation | Normal life |

| +80°C to +150°C | Accelerated aging | Hardening, shrinkage | 50% reduction |

| Above +150°C | Chemical breakdown | Complete failure | 90% reduction |

Critical Temperature Thresholds

Low Temperature Limits:

- Glass transition3: Material becomes brittle

- Crystallization: Loss of elasticity

- Shrinkage: Reduced sealing contact

- Embrittlement: Crack initiation

High Temperature Limits:

- Thermal degradation: Chemical breakdown

- Oxidation: Material deterioration

- Plasticizer loss: Hardening and shrinkage

- Compression set: Permanent deformation

Marcus’s situation illustrates low-temperature challenges perfectly – his standard NBR seals were operating below their glass transition temperature, becoming brittle and cracking within hours of exposure to -30°C conditions. 🥶

How Do Different Seal Materials Perform Across Temperature Ranges?

Seal material selection determines operational temperature range and performance characteristics under thermal stress conditions.

Different seal materials offer distinct temperature capabilities, with NBR4 suitable for -30°C to +100°C, FKM (Viton)5 performing from -20°C to +200°C, and specialized compounds like FFKM enabling operation from -40°C to +300°C for extreme applications.

Material Temperature Comparison

| Material | Low Temp Limit | High Temp Limit | Optimal Range | Cost Factor |

|---|---|---|---|---|

| NBR (Nitrile) | -30°C | +100°C | -10°C to +80°C | 1.0x |

| HNBR | -40°C | +150°C | -20°C to +130°C | 2.5x |

| FKM (Viton) | -20°C | +200°C | 0°C to +180°C | 4.0x |

| EPDM | -45°C | +150°C | -30°C to +120°C | 1.8x |

| FFKM (Kalrez) | -40°C | +300°C | -20°C to +250°C | 15.0x |

Performance Characteristics

NBR (Nitrile Rubber):

- Advantages: Cost-effective, good oil resistance, wide availability

- Limitations: Limited high-temperature capability, poor ozone resistance

- Applications: General industrial, moderate temperature ranges

- Temperature behavior: Hardens significantly below -20°C

FKM (Fluoroelastomer):

- Advantages: Excellent chemical resistance, high-temperature capability

- Limitations: Higher cost, limited low-temperature flexibility

- Applications: Chemical processing, high-temperature environments

- Temperature behavior: Maintains properties across wide range

HNBR (Hydrogenated Nitrile):

- Advantages: Enhanced temperature range, better ozone resistance

- Limitations: Higher cost than standard NBR

- Applications: Automotive, outdoor equipment, temperature cycling

- Temperature behavior: Improved low-temperature flexibility

Application-Specific Selection

Cold Environment Applications:

- Outdoor equipment: HNBR or EPDM for flexibility

- Refrigeration: Specialized low-temperature compounds

- Arctic operations: Custom formulations for extreme cold

- Thermal cycling: Materials resistant to fatigue

High-Temperature Applications:

- Heat treatment: FKM for sustained high temperatures

- Engine applications: HNBR for automotive environments

- Chemical processing: FFKM for extreme conditions

- Steam applications: Specialized high-temperature elastomers

Material Selection Guidelines

Consider these factors:

- Operating temperature range: Continuous vs. intermittent exposure

- Chemical compatibility: Media contact requirements

- Pressure requirements: High pressure needs harder materials

- Dynamic vs. static: Movement affects material choice

- Cost considerations: Balance performance vs. economics

At Bepto, we stock temperature-optimized seals for every application, from Arctic outdoor equipment to high-temperature industrial processes. 🌡️

Which Applications Require Special Temperature-Resistant Sealing Solutions?

Specific industrial environments demand specialized sealing solutions to handle extreme temperature conditions and thermal cycling.

Applications requiring temperature-resistant seals include outdoor equipment exposed to weather extremes, high-temperature manufacturing processes, food processing with steam cleaning, and mobile equipment operating across seasonal temperature variations.

Extreme Environment Applications

Cold Weather Operations:

- Construction equipment: -40°C to +40°C seasonal variation

- Agricultural machinery: Outdoor storage and operation

- Mining equipment: Underground and surface temperature extremes

- Transportation: Refrigerated trucks and cold storage

High-Temperature Processes:

- Steel manufacturing: Furnace and hot rolling operations

- Glass production: High-temperature forming processes

- Chemical processing: Reactor and distillation equipment

- Food processing: Steam cleaning and sterilization

Application-Specific Requirements

| Application | Temperature Range | Special Requirements | Recommended Material |

|---|---|---|---|

| Outdoor construction | -30°C to +60°C | UV resistance, flexibility | HNBR |

| Food processing | +5°C to +140°C | FDA compliance, steam | FKM |

| Chemical plant | -10°C to +180°C | Chemical resistance | FKM/FFKM |

| Mobile equipment | -40°C to +80°C | Dynamic sealing | HNBR |

Thermal Cycling Challenges

Daily Temperature Cycles:

- Expansion/contraction: Materials must accommodate movement

- Fatigue resistance: Repeated stress cycles

- Dimensional stability: Maintaining seal integrity

- Groove design: Accommodating thermal growth

Seasonal Variations:

- Long-term exposure: Extended temperature extremes

- Storage conditions: Off-season temperature effects

- Start-up performance: Cold weather operation

- Material aging: Temperature-accelerated degradation

Success Stories

Arctic Mining Operation:

Lisa, an equipment manager from Alaska, was losing $50,000 per week due to seal failures in -45°C conditions. Our specialized HNBR seals with low-temperature additives eliminated failures and extended service intervals from weekly to quarterly maintenance. ⛄

Steel Mill Application:

A steel processing plant needed cylinders operating near 200°C furnaces. Standard seals lasted only days before hardening and cracking. Our FKM seal solution provided 6-month service life with consistent performance throughout the temperature range.

Design Considerations

Groove Design:

- Thermal expansion clearance: Account for material growth

- Backup ring support: Prevent extrusion at high temperatures

- Surface finish: Critical for high-temperature sealing

- Installation clearances: Allow for thermal effects

System Integration:

- Cooling provisions: Heat management for extreme applications

- Insulation: Protecting seals from radiant heat

- Ventilation: Preventing heat buildup

- Monitoring: Temperature sensing for preventive maintenance

Our engineering team provides complete thermal analysis and seal selection for the most challenging temperature environments. 🔥

Why Do Bepto Temperature-Optimized Seals Outperform Standard Options?

Our advanced seal technology and material selection deliver superior performance across extreme temperature ranges through specialized engineering.

Bepto temperature-optimized seals outperform standard options through custom material formulations, precision manufacturing tolerances, advanced groove designs, and comprehensive testing that ensures reliable operation across -40°C to +200°C temperature ranges.

Advanced Material Technology

Custom Formulations:

- Low-temperature plasticizers: Maintain flexibility in cold

- High-temperature stabilizers: Prevent degradation

- Antioxidants: Reduce thermal aging

- Reinforcement: Enhanced durability

Quality Assurance:

- Temperature cycling tests: Validate performance ranges

- Accelerated aging: Predict long-term behavior

- Material certification: Documented properties

- Batch testing: Consistent quality control

Performance Advantages

| Feature | Standard Seals | Bepto Optimized | Improvement |

|---|---|---|---|

| Temperature range | -20°C to +80°C | -40°C to +150°C | 100% wider |

| Service life | 6 months | 18+ months | 200% longer |

| Thermal cycling | 1,000 cycles | 5,000+ cycles | 400% better |

| Leak rate | 5 cc/min | <1 cc/min | 80% reduction |

Engineering Excellence

Precision Manufacturing:

- Dimensional accuracy: ±0.05mm tolerances

- Surface quality: Optimized for sealing

- Material consistency: Uniform properties

- Quality documentation: Full traceability

Application Support:

- Temperature analysis: Operating condition assessment

- Material selection: Optimal compound choice

- Installation guidance: Proper assembly procedures

- Performance monitoring: Ongoing support

Cost-Benefit Analysis

While Bepto temperature-optimized seals may cost 20-40% more initially, the total value proposition is compelling:

- Extended service life: 200-400% longer operation

- Reduced downtime: Fewer emergency repairs

- Lower maintenance costs: Less frequent replacement

- Improved reliability: Consistent performance

Customer Success

Our temperature-optimized solutions have delivered remarkable results:

- 95% reduction in cold-weather seal failures

- 300% increase in high-temperature service life

- 80% decrease in emergency maintenance calls

- 50% reduction in total sealing costs

Technical Support

We provide comprehensive support including:

- Application engineering: Custom solution development

- Temperature testing: Validation of performance

- Installation training: Proper assembly techniques

- Performance monitoring: Ongoing optimization

Conclusion

Temperature significantly impacts cylinder seal performance, making proper material selection and seal design critical for reliable operation across diverse environmental conditions. 🎯

FAQs About Temperature and Cylinder Seals

Q: What temperature range can standard cylinder seals handle reliably?

Standard NBR seals typically operate reliably from -20°C to +80°C, but performance degrades rapidly outside this range. For extreme temperatures, specialized materials like HNBR (-40°C to +150°C) or FKM (-20°C to +200°C) provide much better performance and longer service life.

Q: How do I know if temperature is causing my seal failures?

Temperature-related failures show specific symptoms: brittleness and cracking in cold conditions, hardening and shrinkage in heat, or rapid degradation with temperature cycling. If failures correlate with temperature extremes or seasonal changes, temperature is likely the root cause.

Q: Can I upgrade existing cylinders with better temperature-resistant seals?

Yes, most cylinders can be upgraded with temperature-optimized seals without design changes. We analyze your operating conditions and recommend the best seal material and design for your specific temperature requirements, often extending service life by 200-400%.

Q: What’s the cost difference between standard and temperature-resistant seals?

Temperature-resistant seals typically cost 20-50% more initially, but deliver 200-400% longer service life and dramatically reduce downtime costs. The total cost of ownership is usually 30-60% lower due to extended replacement intervals and improved reliability.

Q: How do Bepto seals perform compared to OEM temperature-rated seals?

Bepto temperature-optimized seals often exceed OEM specifications through advanced materials and precision manufacturing. We typically provide 50-100% wider temperature ranges, 200% longer service life, and better resistance to thermal cycling compared to standard OEM seals.

-

Learn about the principle of thermal expansion and how it affects different materials. ↩

-

Understand the concept of compression set and why it’s a critical property for sealing materials. ↩

-

Explore the science behind the glass transition temperature and why it’s crucial for low-temperature applications. ↩

-

Discover the properties, advantages, and limitations of NBR (Nitrile Rubber) as a common seal material. ↩

-

Learn more about FKM (Viton) fluoroelastomers and their high-performance characteristics. ↩