Are you struggling to find off-the-shelf cylinders that meet your specialized requirements? Many engineers waste valuable time trying to adapt standard components to unique applications, often resulting in compromised performance and reliability. But there’s a better approach to solving these challenging design problems.

Custom pneumatic cylinders enable solutions for extreme operating conditions through specialized designs incorporating unique features like special-shaped guide rails machined using 5-axis CNC1 and wire EDM2 processes, high-temperature seals made from advanced materials like PEEK3 and PTFE compounds capable of withstanding up to 300°C, and structural reinforcements that maintain alignment and prevent deflection in strokes exceeding 3 meters.

I’ve personally overseen the design of hundreds of custom cylinders during my 15-year career, and I’ve learned that success depends on understanding the critical manufacturing processes, material selection factors, and structural engineering principles that separate exceptional custom cylinders from mediocre ones. Let me share the insider knowledge that will help you create truly effective custom solutions.

Table of Contents

- How Are Special-Shaped Guide Rails Manufactured for Custom Cylinders?

- Which Seal Materials Perform Best in High-Temperature Applications?

- What Techniques Prevent Deflection in Extra-Long Stroke Cylinders?

- Conclusion

- FAQs About Custom Cylinder Design

How Are Special-Shaped Guide Rails Manufactured for Custom Cylinders?

The guide rail system is often the most challenging aspect of custom cylinder design, requiring specialized manufacturing processes to achieve the necessary precision and performance.

Special-shaped guide rails for custom cylinders are manufactured through a multi-stage process typically involving CNC machining, wire EDM cutting, precision grinding, and heat treatment. These processes can produce complex profiles with tolerances as tight as ±0.005mm, creating specialized geometries like dovetail guides, T-slot profiles, and compound curve surfaces that enable unique cylinder functions impossible with standard designs.

Manufacturing Process Breakdown

Creating specialized guide rails involves several critical manufacturing stages:

Process Sequence and Capabilities

| Manufacturing Stage | Equipment Used | Tolerance Capability | Surface Finish | Best Applications |

|---|---|---|---|---|

| Rough Machining | 3-axis CNC Mill | ±0.05mm | 3.2-6.4 Ra | Material removal, basic shaping |

| Precision Machining | 5-axis CNC Mill | ±0.02mm | 1.6-3.2 Ra | Complex geometries, compound angles |

| Wire EDM | CNC Wire EDM | ±0.01mm | 1.6-3.2 Ra | Internal features, hardened materials |

| Heat Treatment | Vacuum Furnace | – | – | Hardness enhancement, stress relief |

| Precision Grinding | CNC Surface Grinder | ±0.005mm | 0.4-0.8 Ra | Critical dimensions, bearing surfaces |

| Superfinishing | Honing/Lapping | ±0.002mm | 0.1-0.4 Ra | Sliding surfaces, sealing areas |

I once worked with a semiconductor equipment manufacturer who needed a cylinder with an integrated dovetail guide capable of supporting precision wafer handling equipment. The complex profile required both 5-axis machining for the basic shape and wire EDM to create the precise engagement surfaces. The final grinding operation achieved a straightness tolerance of 0.008mm over a 600mm length – critical for the nanometer-level positioning their application required.

Special Profile Types and Applications

Different guide rail profiles serve specific functional purposes:

Common Special-Shaped Profiles

| Profile Type | Cross-Section | Manufacturing Challenge | Functional Advantage | Typical Application |

|---|---|---|---|---|

| Dovetail | Trapezoidal | Precise angle cutting | High load capacity, zero backlash | Precision positioning |

| T-slot | T-shaped | Internal corner machining | Adjustable components, modular design | Configurable systems |

| Compound Curve | S-shaped curve | 3D contour machining | Custom motion paths, specialized kinematics | Non-linear movement |

| Multi-Channel | Multiple parallel tracks | Maintaining parallel alignment | Multiple independent carriages | Multi-point actuation |

| Helical | Spiral groove | 4/5-axis simultaneous cutting | Rotational-linear combined motion | Rotary-linear actuators |

Material Selection for Guide Rails

The base material significantly impacts manufacturing process selection and performance:

Material Properties Comparison

| Material | Machinability (1-10) | EDM Compatibility | Heat Treatment | Wear Resistance | Corrosion Resistance |

|---|---|---|---|---|---|

| 1045 Carbon Steel | 7 | Good | Excellent | Moderate | Poor |

| 4140 Alloy Steel | 6 | Good | Excellent | Good | Moderate |

| 440C Stainless | 4 | Good | Good | Very Good | Excellent |

| A2 Tool Steel | 5 | Excellent | Excellent | Excellent | Moderate |

| Aluminum Bronze | 6 | Poor | Limited | Good | Excellent |

| Hardcoat Aluminum | 8 | Poor | Not Required | Moderate | Good |

For a food processing equipment manufacturer, we selected 440C stainless steel for their custom guide rails despite its more challenging machinability. The washdown environment with caustic cleaning agents would have quickly corroded standard steel options. The 440C material was machined in the annealed state, then hardened to 58 HRC and finish-ground to create a corrosion-resistant, durable guide system.

Surface Treatment Options

Post-machining treatments enhance performance characteristics:

Surface Enhancement Methods

| Treatment | Process | Hardness Increase | Wear Improvement | Corrosion Protection | Thickness |

|---|---|---|---|---|---|

| Hard Chrome Plating | Electroplating | +20% | 3-4× | Good | 25-50μm |

| Nitriding | Gas/Plasma/Salt Bath | +30% | 5-6× | Moderate | 0.1-0.5mm |

| PVD Coating (TiN) | Vacuum Deposition | +40% | 8-10× | Good | 2-4μm |

| DLC Coating | Vacuum Deposition | +50% | 10-15× | Excellent | 1-3μm |

| PTFE Impregnation | Vacuum Infusion | Minimal | 2-3× | Good | Surface only |

Manufacturing Tolerance Considerations

Achieving consistent quality requires understanding tolerance relationships:

Critical Tolerance Factors

Straightness Tolerance

– Critical for smooth operation and wear characteristics

– Typically 0.01-0.02mm per 300mm length

– Measured using precision straight edge and feeler gaugesProfile Tolerance

– Defines allowable deviation from theoretical profile

– Typically 0.02-0.05mm for engagement surfaces

– Verified using custom gauges or CMM measurementSurface Finish Requirements

– Affects friction, wear, and sealing effectiveness

– Bearing surfaces: 0.4-0.8 Ra

– Sealing surfaces: 0.2-0.4 Ra

– Measured using profilometerHeat Treatment Distortion

– Can affect final dimensions by 0.05-0.1mm

– Requires post-heat treatment finishing operations

– Minimized through proper fixturing and stress relief

Which Seal Materials Perform Best in High-Temperature Applications?

Selecting the right sealing materials is critical for custom cylinders operating in extreme temperature environments.

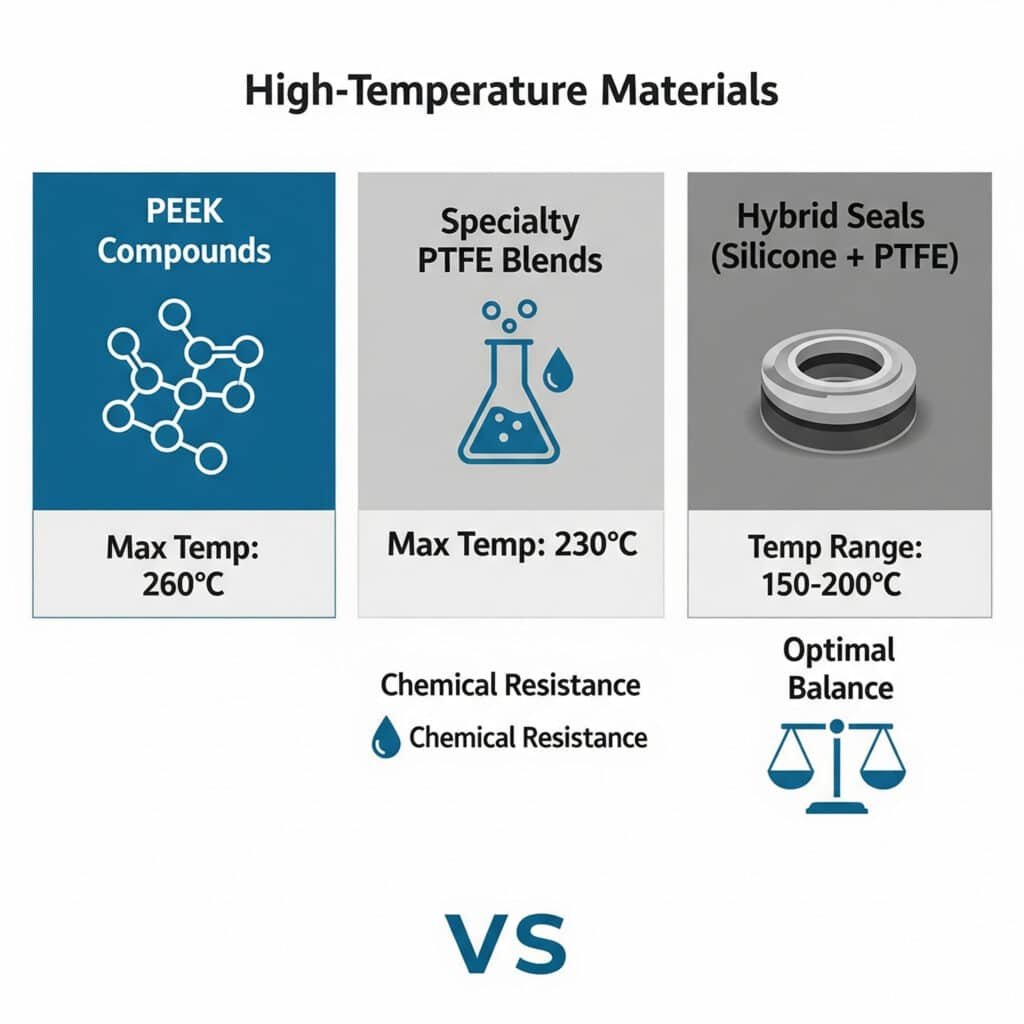

High-temperature pneumatic applications require specialized seal materials that maintain elasticity, wear resistance, and chemical stability at elevated temperatures. Advanced polymers like PEEK compounds can function continuously at temperatures up to 260°C, while specialty PTFE blends offer exceptional chemical resistance up to 230°C. Hybrid seals combining silicone elastomers with PTFE facing provide an optimal balance of compliance and durability for temperatures between 150-200°C.

High-Temperature Seal Material Matrix

This comprehensive comparison helps select the optimal material for specific temperature ranges:

Temperature Performance Comparison

| Material | Max Continuous Temp | Max Intermittent Temp | Pressure Capability | Chemical Resistance | Relative Cost |

|---|---|---|---|---|---|

| FKM (Viton®) | 200°C | 230°C | Excellent (35 MPa) | Very Good | 2.5× |

| FFKM (Kalrez®) | 230°C | 260°C | Very Good (25 MPa) | Excellent | 8-10× |

| PTFE (Virgin) | 230°C | 260°C | Good (20 MPa) | Excellent | 3× |

| PTFE (Glass-filled) | 230°C | 260°C | Very Good (30 MPa) | Excellent | 3.5× |

| PEEK (Unfilled) | 240°C | 300°C | Excellent (35 MPa) | Good | 5× |

| PEEK (Carbon-filled) | 260°C | 310°C | Excellent (40 MPa) | Good | 6× |

| Silicone | 180°C | 210°C | Poor (10 MPa) | Moderate | 2× |

| PTFE/Silicone Composite | 200°C | 230°C | Good (20 MPa) | Very Good | 4× |

| Metal-Energized PTFE | 230°C | 260°C | Excellent (40+ MPa) | Excellent | 7× |

| Graphite Composite | 300°C | 350°C | Moderate (15 MPa) | Excellent | 6× |

During a project for a glass manufacturing facility, we developed custom cylinders that operated adjacent to annealing ovens with ambient temperatures reaching 180°C. Standard seals failed within weeks, but by implementing carbon-filled PEEK piston seals and metal-energized PTFE rod seals, we created a solution that has operated continuously for over three years without seal replacement.

Material Selection Factors Beyond Temperature

Temperature is just one consideration in high-temperature seal selection:

Critical Selection Factors

Pressure Requirements

– Higher pressures require materials with greater mechanical strength

– Pressure × Temperature relationship is non-linear

– Pressure capability typically decreases 5-10% for every 20°C increaseChemical Environment

– Process chemicals, cleaning agents, and lubricants

– Oxidation resistance at elevated temperatures

– Hydrolysis resistance (for water vapor exposure)Cycling Requirements

– Thermal cycling causes different expansion rates

– Dynamic vs. static seal applications

– Frequency of actuation at temperatureInstallation Considerations

– Harder materials require more precise machining

– Installation damage risk increases with material hardness

– Special tooling often required for composite materials

Seal Design Modifications for High Temperatures

Standard seal designs often require modification for extreme temperatures:

Design Adaptations

| Design Modification | Purpose | Temperature Impact | Implementation Complexity |

|---|---|---|---|

| Reduced Interference | Compensates for thermal expansion | +20-30°C capability | Low |

| Floating Seal Rings | Allows thermal growth | +30-50°C capability | Medium |

| Multi-Component Seals | Optimizes materials by function | +50-70°C capability | High |

| Metal Backup Rings | Prevents extrusion at temperature | +20-40°C capability | Medium |

| Labyrinth Auxiliary Seals | Reduces temperature at main seal | +50-100°C capability | High |

| Active Cooling Channels | Creates cooler microenvironment | +100-150°C capability | Very High |

Material Aging and Lifecycle Considerations

High-temperature operation accelerates material degradation:

Lifecycle Impact Factors

| Material | Typical Life at 100°C | Life Reduction at 200°C | Primary Failure Mode | Predictability |

|---|---|---|---|---|

| FKM | 2-3 years | 75% (6-9 months) | Hardening/cracking | Good |

| FFKM | 3-5 years | 60% (1.2-2 years) | Compression set | Very Good |

| PTFE | 5+ years | 40% (3+ years) | Deformation/cold flow | Moderate |

| PEEK | 5+ years | 30% (3.5+ years) | Wear/abrasion | Good |

| Silicone | 1-2 years | 80% (2-5 months) | Tearing/degradation | Poor |

| Metal-Energized PTFE | 4-5 years | 35% (2.6-3.3 years) | Spring relaxation | Excellent |

I worked with a steel mill that operated hydraulic cylinders in their continuous casting area with ambient temperatures of 150-180°C. By implementing a predictive maintenance program based on these lifecycle factors, we were able to schedule seal replacements during planned maintenance outages, completely eliminating unplanned downtime that had previously cost them approximately $50,000 per hour.

Installation and Maintenance Best Practices

Proper handling significantly impacts high-temperature seal performance:

Critical Procedures

Storage Considerations

– Maximum shelf life varies by material (1-5 years)

– Temperature-controlled storage recommended

– UV protection essential for some materialsInstallation Techniques

– Specialized installation tools prevent damage

– Lubricant compatibility critical

– Calibrated torque for gland componentsBreak-in Procedures

– Gradual temperature increase when possible

– Initial pressure reduction (60-70% of maximum)

– Controlled cycling before full operationMonitoring Methods

– Regular durometer testing of accessible seals

– Leak detection systems with temperature compensation

– Predictive replacement based on operating conditions

What Techniques Prevent Deflection in Extra-Long Stroke Cylinders?

Long-stroke cylinders present unique engineering challenges that require specialized structural solutions.

Extra-long stroke cylinders prevent rod deflection and maintain alignment through multiple reinforcement techniques: oversized rod diameters (typically 1.5-2× standard ratios), intermediate support bushings at calculated intervals, external guide systems with precision alignment, composite rod materials with enhanced stiffness-to-weight ratios, and specialized tube designs that resist bending under pressure and side loads.

Rod Deflection Calculation and Prevention

Understanding deflection physics is essential for proper reinforcement design:

Deflection Formula for Extended Rods

δ = (F × L³) / (3 × E × I)

Where:

- δ = Maximum deflection (mm)

- F = Side load or rod weight (N)

- L = Unsupported length (mm)

- E = Modulus of elasticity4 (N/mm²)

- I = Moment of inertia5 (mm⁴) = (π × d⁴) / 64 for circular rods

For a 5-meter stroke cylinder we designed for a lumber mill, the standard rod would have deflected over 120mm at full extension. By increasing the rod diameter from 40mm to 63mm, we reduced the theoretical deflection to just 19mm – still excessive for their application. The addition of intermediate support bushings at 1.5-meter intervals further reduced deflection to under 3mm, meeting their alignment requirements.

Rod Diameter Optimization

Selecting the appropriate rod diameter is the first defense against deflection:

Rod Diameter Sizing Guidelines

| Stroke Length | Minimum Rod/Bore Ratio | Typical Diameter Increase | Deflection Reduction | Weight Penalty |

|---|---|---|---|---|

| 0-500mm | 0.3-0.4 | Standard | Baseline | Baseline |

| 500-1000mm | 0.4-0.5 | 25% | 60% | 56% |

| 1000-2000mm | 0.5-0.6 | 50% | 85% | 125% |

| 2000-3000mm | 0.6-0.7 | 75% | 94% | 206% |

| 3000-5000mm | 0.7-0.8 | 100% | 97% | 300% |

| >5000mm | 0.8+ | 125%+ | 99% | 400%+ |

Intermediate Support Systems

For the longest strokes, intermediate supports become necessary:

Support Bushing Configurations

| Support Type | Maximum Spacing | Installation Method | Maintenance Requirement | Best Application |

|---|---|---|---|---|

| Fixed Bushing | L = 100 × d | Press-fit in tube | Periodic lubrication | Vertical orientation |

| Floating Bushing | L = 80 × d | Retained with snap ring | Periodic replacement | Horizontal, heavy duty |

| Adjustable Bushing | L = 90 × d | Threaded adjustment | Regular alignment check | Precision applications |

| Roller Support | L = 120 × d | Bolted to tube | Bearing replacement | Highest speed applications |

| External Guide | L = 150 × d | Independent mounting | Alignment verification | Highest precision needs |

Where:

- L = Maximum spacing between supports (mm)

- d = Rod diameter (mm)

Tube Design Enhancements

The cylinder tube itself requires reinforcement in long-stroke designs:

Tube Reinforcement Methods

| Reinforcement Method | Strength Increase | Weight Impact | Cost Factor | Best Application |

|---|---|---|---|---|

| Increased Wall Thickness | 30-50% | High | 1.3-1.5× | Simplest solution, moderate lengths |

| External Reinforcing Ribs | 40-60% | Medium | 1.5-1.8× | Horizontal mounting, concentrated loads |

| Composite Overwrap | 70-100% | Low | 2.0-2.5× | Lightest solution, longest strokes |

| Dual-Wall Construction | 100-150% | High | 2.2-2.8× | Highest pressure applications |

| Truss Support Structure | 200%+ | Medium | 2.5-3.0× | Extreme lengths, variable orientation |

For a 4-meter stroke cylinder designed for a bridge inspection platform, we implemented external aluminum truss supports along the cylinder tube. This increased the bending stiffness by over 300% while adding only 15% to the total weight – critical for the mobile application where excess weight would have required a larger vehicle platform.

Material Selection for Extended Strokes

Advanced materials can significantly improve performance:

Material Performance Comparison

| Material | Relative Stiffness | Weight Ratio | Corrosion Resistance | Cost Premium | Best Application |

|---|---|---|---|---|---|

| Chrome-plated Steel | 1.0 (baseline) | 1.0 | Good | Baseline | General purpose |

| Induction-hardened Steel | 1.0 | 1.0 | Moderate | 1.2× | Heavy duty, wear resistance |

| Hard-anodized Aluminum | 0.3 | 0.35 | Very Good | 1.5× | Weight-sensitive applications |

| Stainless Steel | 0.9 | 1.0 | Excellent | 1.8× | Corrosive environments |

| Carbon Fiber Composite | 2.3 | 0.25 | Excellent | 3.5× | Highest performance, lightest weight |

| Ceramic-coated Aluminum | 0.4 | 0.35 | Excellent | 2.2× | Balanced performance, moderate weight |

Installation and Alignment Considerations

Proper installation becomes increasingly critical with stroke length:

Alignment Requirements

| Stroke Length | Maximum Misalignment | Alignment Method | Verification Technique |

|---|---|---|---|

| 0-1000mm | 0.5mm | Standard mounting | Visual inspection |

| 1000-2000mm | 0.3mm | Adjustable mounts | Straight edge and feeler gauge |

| 2000-3000mm | 0.2mm | Precision machined surfaces | Dial indicator |

| 3000-5000mm | 0.1mm | Laser alignment | Laser measurement |

| >5000mm | <0.1mm | Multi-point alignment system | Optical transit or laser tracker |

During installation of a 6-meter stroke cylinder for a theater stage mechanism, we discovered that the mounting surfaces had a 0.8mm misalignment. Despite seeming minor, this would have created binding and premature wear. By implementing an adjustable mounting system with laser alignment verification, we achieved alignment within 0.05mm over the entire length, ensuring smooth operation and full design life.

Dynamic Considerations for Long Strokes

Operating dynamics create additional challenges:

Dynamic Factors

Acceleration Forces

– Longer, heavier rods have greater inertia

– End-of-stroke cushioning critical

– Typical design: 25-50mm cushion length per meter of strokeResonant Frequency

– Long rods can develop harmful vibrations

– Critical speeds must be avoided

– Damping systems may be requiredThermal Expansion

– Expansion of 1-2mm per meter at 100°C temperature rise

– Floating mounts or compensation joints

– Material selection affects expansion ratePressure Dynamics

– Longer air columns create pressure wave effects

– Larger valve ports and flow capacity required

– Speed control more challenging over long distances

Conclusion

Custom cylinder design for extreme applications requires specialized knowledge in manufacturing processes for special-shaped guide rails, material selection for high-temperature seals, and structural engineering for long-stroke reinforcement. By understanding these critical aspects, engineers can create pneumatic solutions that perform reliably in the most demanding environments.

FAQs About Custom Cylinder Design

What is the maximum temperature a pneumatic cylinder can operate at with specialized seals?

With specialized seal materials and design modifications, pneumatic cylinders can operate continuously at temperatures up to 260°C using carbon-filled PEEK or metal-energized PTFE seals. For intermittent exposure, graphite composite seals can withstand temperatures approaching 350°C. However, these extreme temperature applications require additional considerations beyond sealing, including special lubricants (or dry-running designs), thermal expansion compensation, and materials with matching thermal expansion coefficients to prevent binding at temperature.

How long can a pneumatic cylinder stroke be before intermediate supports become necessary?

The need for intermediate supports depends on the rod diameter, orientation, and precision requirements. As a general guideline, horizontal cylinders with standard rod-to-bore ratios (0.3-0.4) typically require intermediate supports when strokes exceed 1.5 meters. The exact threshold can be calculated using the deflection formula: δ = (F × L³) / (3 × E × I), where significant deflection (typically >1mm) indicates support is needed. Vertical cylinders can often extend to 2-3 meters before requiring support due to the absence of gravitational side loading.

What manufacturing tolerance is achievable for special-shaped guide rails?

Using a combination of 5-axis CNC machining, wire EDM, and precision grinding, special-shaped guide rails can achieve tolerances of ±0.005mm for critical dimensions and surface finishes as fine as 0.2-0.4 Ra. Profile accuracy (the conformance to the theoretical shape) can be maintained within 0.01-0.02mm using modern manufacturing techniques. For the highest precision applications, final hand fitting and selective assembly may be employed to achieve functional tolerances below ±0.003mm for specific mating components.

How do you prevent binding in long-stroke cylinders with multiple support bushings?

Preventing binding in long-stroke cylinders with multiple supports requires several techniques: (1) implementing a progressive alignment approach where only one bushing provides primary alignment while others offer floating support with slight clearance; (2) using self-aligning bushings with spherical outer surfaces that can accommodate slight misalignments; (3) ensuring precise alignment during installation using laser measurement systems; and (4) employing materials with matched thermal expansion coefficients for all structural components to prevent temperature-induced binding.

What is the cost premium for custom cylinders compared to standard models?

The cost premium for custom cylinders varies significantly based on the degree of customization, but typically ranges from 2-10× the cost of standard models. Simple modifications like special mounting or port configurations might add 30-50% to the base price. Moderate customization including non-standard strokes or specialized seals typically doubles the cost. Highly specialized designs with custom guide rails, extreme temperature capabilities, or extra-long stroke reinforcements can cost 5-10× standard models. However, this premium must be evaluated against the cost of attempting to adapt standard components to unsuitable applications, which often results in frequent replacements and system downtime.

How do you test and validate custom cylinder designs before production?

Custom cylinder designs are validated through a multi-stage process: (1) computer simulation using FEA (Finite Element Analysis) to verify structural integrity and identify potential stress concentrations; (2) prototype testing under controlled conditions, often with accelerated life testing at 1.5-2× the design pressure and cycle rate; (3) environmental chamber testing for temperature extremes; (4) instrumented field trials measuring parameters like internal temperatures, friction forces, and alignment stability; and (5) destructive testing of prototypes to verify safety margins. For critical applications, custom test fixtures may be built to simulate the exact application conditions before final production approval.

-

Provides a detailed explanation of 5-axis CNC machining, an advanced manufacturing process that allows for the cutting of parts on five different axes simultaneously, enabling the creation of highly complex geometries. ↩

-

Explains the principles of Wire Electrical Discharge Machining (Wire EDM), a non-traditional machining process that uses an electrically charged wire to cut conductive materials with extreme precision. ↩

-

Offers comprehensive information on Polyether ether ketone (PEEK), a high-performance engineering thermoplastic known for its excellent mechanical properties and resistance to extreme temperatures and harsh chemicals. ↩

-

Describes the Modulus of Elasticity (also known as Young’s Modulus), a fundamental material property that measures a material’s stiffness and its resistance to being elastically deformed under stress. ↩

-

Provides a clear explanation of the Area Moment of Inertia, a geometrical property of a cross-section that reflects how its points are distributed with regard to an arbitrary axis, which is crucial for calculating beam deflection. ↩