Lubrication failure often means machine failure. Yet most people barely understand what makes a lubricant truly work under stress.

Advanced lubrication relies on fluid film formation, chemical protection, and real-time monitoring to reduce friction and prevent wear.

I’ve worked with countless industrial engineers who thought “oil is oil”—until their equipment failed under heavy load. Let’s dig into the science that keeps your machines alive.

[Table of contents]

- What is a hydrodynamic lubrication model?

- How do EP additives actually protect under extreme pressure?

- What are the modern ways to measure oil film thickness?

- Conclusion

- FAQs About Advanced Lubrication Principles

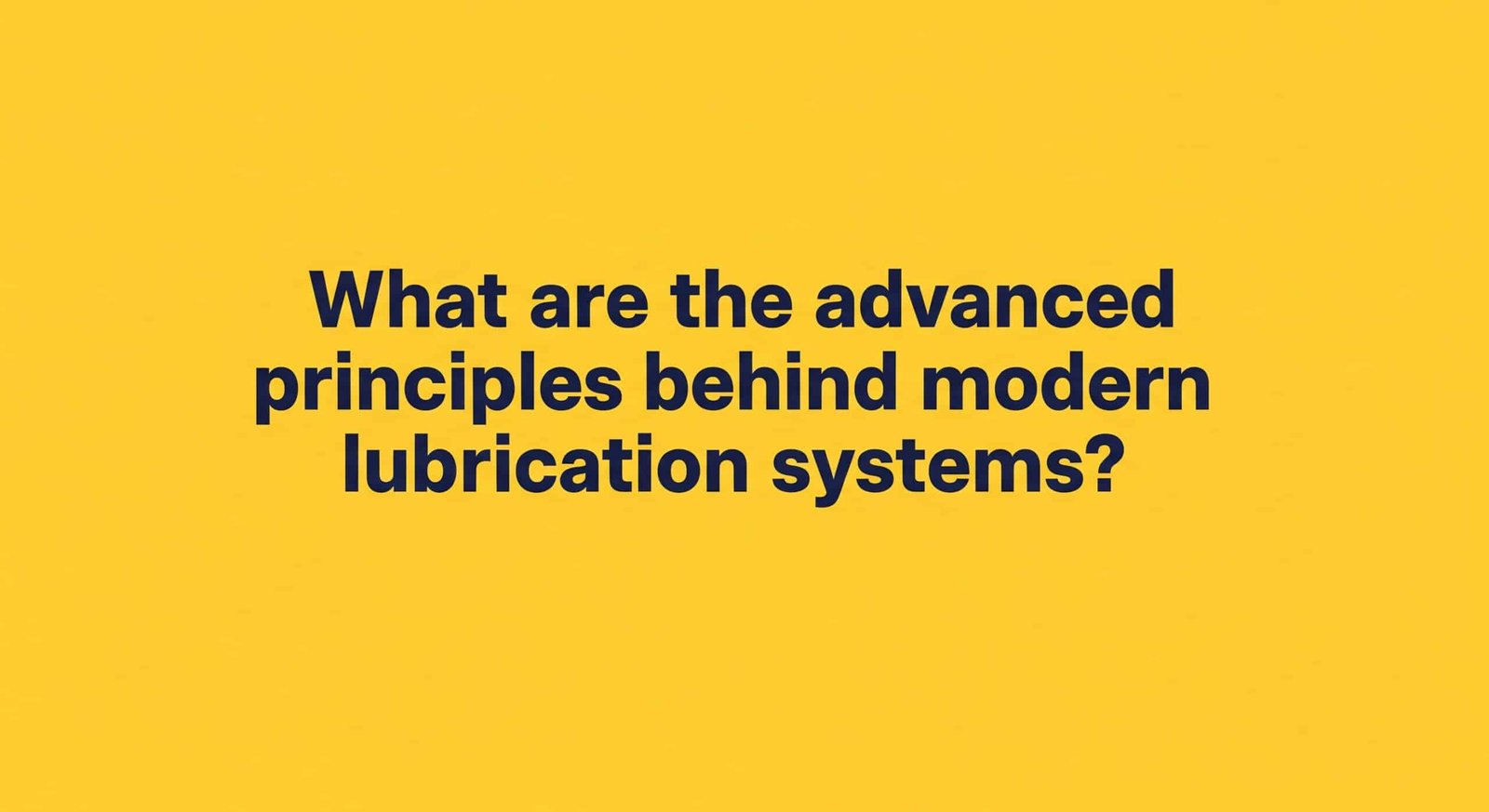

What is a hydrodynamic lubrication model?

When two metal surfaces move fast with a lubricant in between, something remarkable happens—a full oil film forms and keeps them apart.

The hydrodynamic lubrication model1 describes how fluid pressure supports moving surfaces, avoiding direct metal-to-metal contact.

Dive Deeper

In a hydrodynamic lubrication model, the moving surface drags lubricant into a wedge-shaped gap. As speed increases, so does pressure. This self-sustaining pressure builds an oil film that carries the entire load.

This model is heavily used in:

- Bearing design

- Gearboxes

- Rodless pneumatic cylinder assemblies

| Parameter | Effect on Film Thickness |

|---|---|

| Lubricant Viscosity | Thicker film |

| Surface Speed | Thicker film |

| Load | Thinner film |

| Temperature | Thinner film (lower viscosity) |

If you’re designing or replacing components like a pneumatic rodless pneumatic cylinder, applying this model helps ensure stable operation under varying loads.

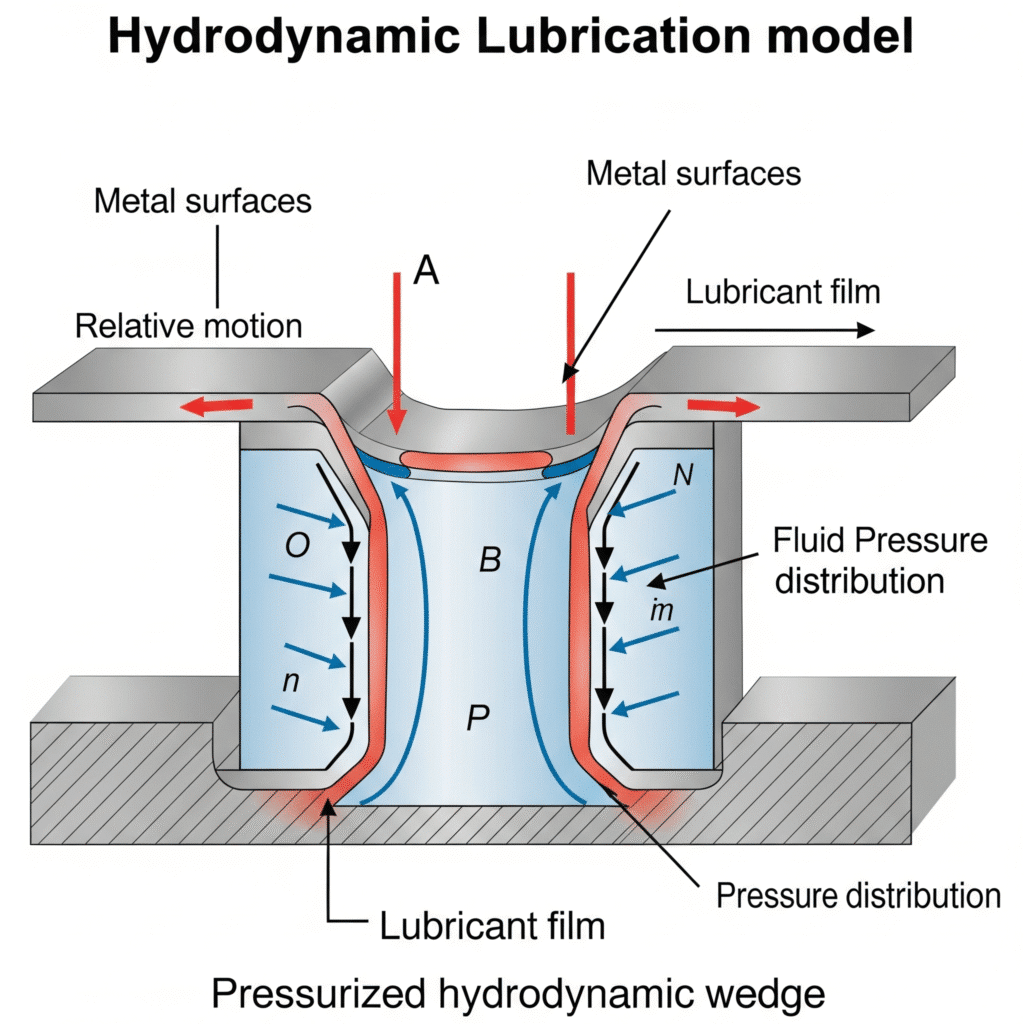

How do EP additives actually protect under extreme pressure?

When pressure and heat go beyond what normal oil can handle, additives step in.

EP additives2 form protective layers during high-pressure metal contact, reducing wear and seizure.

Dive Deeper

Extreme Pressure (EP) additives react chemically with metal surfaces. Under high loads and temperatures, they form sulfide or phosphate films that prevent welding between contacting surfaces.

Common EP additive types:

- Sulfurized olefins

- Chlorinated paraffins

- Zinc dialkyldithiophosphates (ZDDPs)3

These are critical for:

- Gear oils

- Hydraulic fluids

- High-load pneumatic tools

In our industry, many rodless air cylinder users mistake visible lubrication for adequate protection. But EP protection happens invisibly, on the molecular level—especially during sudden shocks or heavy-duty cycles.

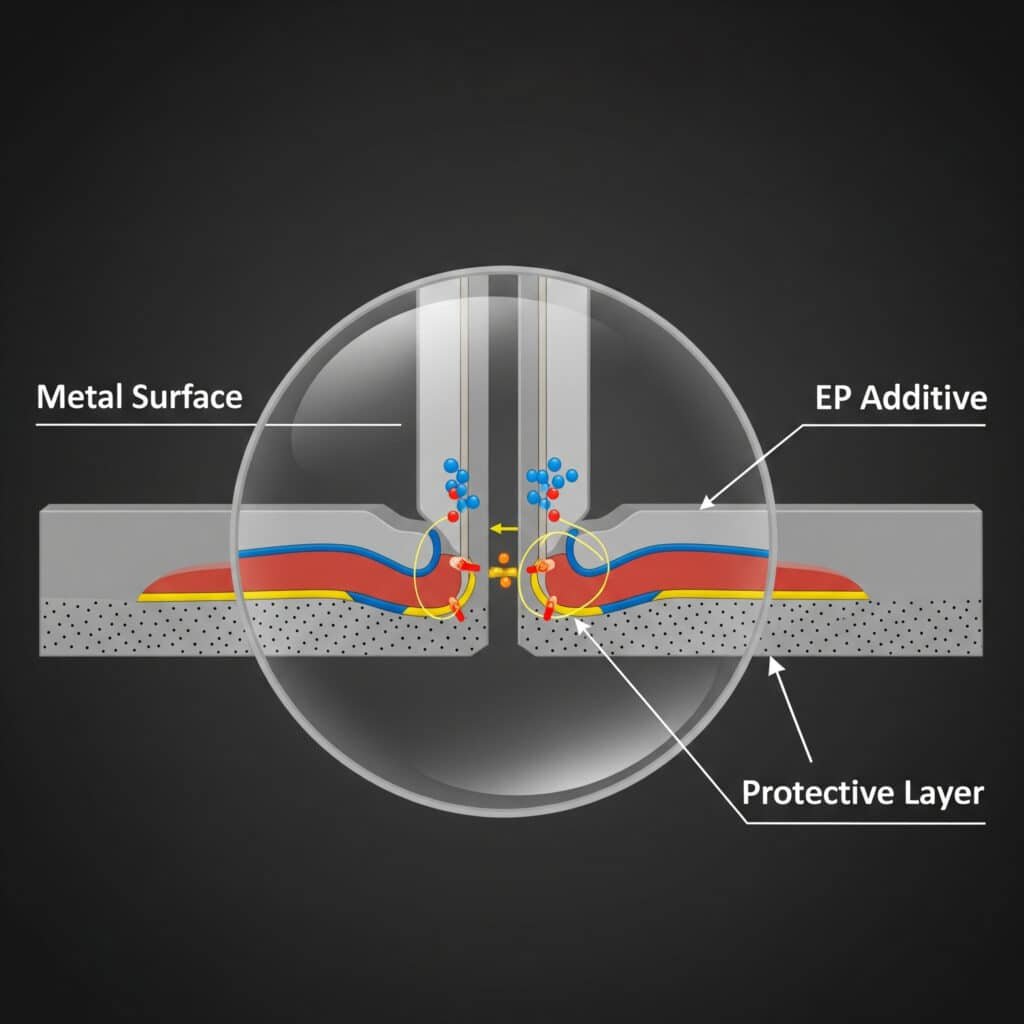

What are the modern ways to measure oil film thickness?

You can’t improve what you don’t measure. And in lubrication, microns matter.

Modern oil film measurement techniques include ultrasound, capacitance, and optical interferometry4.

Dive Deeper

In the past, oil film thickness was often guessed. Now, we have precision tools:

| Method | Principle | Application Example |

|---|---|---|

| Ultrasound Sensors | Reflectivity of sound waves | Bearings, compressors |

| Capacitance Sensors | Gap-based electrical resistance | Thin film measurement in gears |

| Optical Interferometry | Light wave interference | R&D labs, surface testing |

For companies like ours dealing in rodless pneumatic cylinders, this technology helps us design better sliding seals and magnetic coupling units—ensuring oil film is maintained under high-speed linear motion.

Conclusion

Advanced lubrication is a mix of physics, chemistry, and precision sensing.

FAQs About Advanced Lubrication Principles

What is hydrodynamic lubrication?

It’s a fluid pressure mechanism that separates moving surfaces to prevent metal contact.

Why are EP additives important in lubrication?

They chemically protect metal parts when the oil film breaks under extreme pressure.

How is oil film thickness measured today?

With ultrasound, capacitance, and optical sensors for accurate real-time feedback.

Does Bepto offer lubrication-friendly rodless cylinders?

Yes. Our designs minimize wear and support long-term lubrication performance.

Can lubrication reduce downtime for industrial machines?

Absolutely. Proper lubrication prevents wear, extends lifespan, and avoids costly stops.

-

Provides a detailed explanation of the hydrodynamic lubrication regime, including the formation of the fluid film and the principles of the Reynolds equation that govern it. ↩

-

Explains the chemical mechanisms by which EP additives react with metal surfaces under high load and temperature to form a protective, sacrificial layer. ↩

-

Offers in-depth information on Zinc dialkyldithiophosphates (ZDDPs), a crucial anti-wear additive, detailing its chemical function, applications, and history in lubrication. ↩

-

Explains the scientific principles of using light wave interference to achieve highly accurate, non-invasive measurements of lubricant film thickness in research and development. ↩