Engineers often struggle with TSA and CSA calculations when designing rodless pneumatic cylinder1 systems. This confusion leads to costly material estimation errors and project delays.

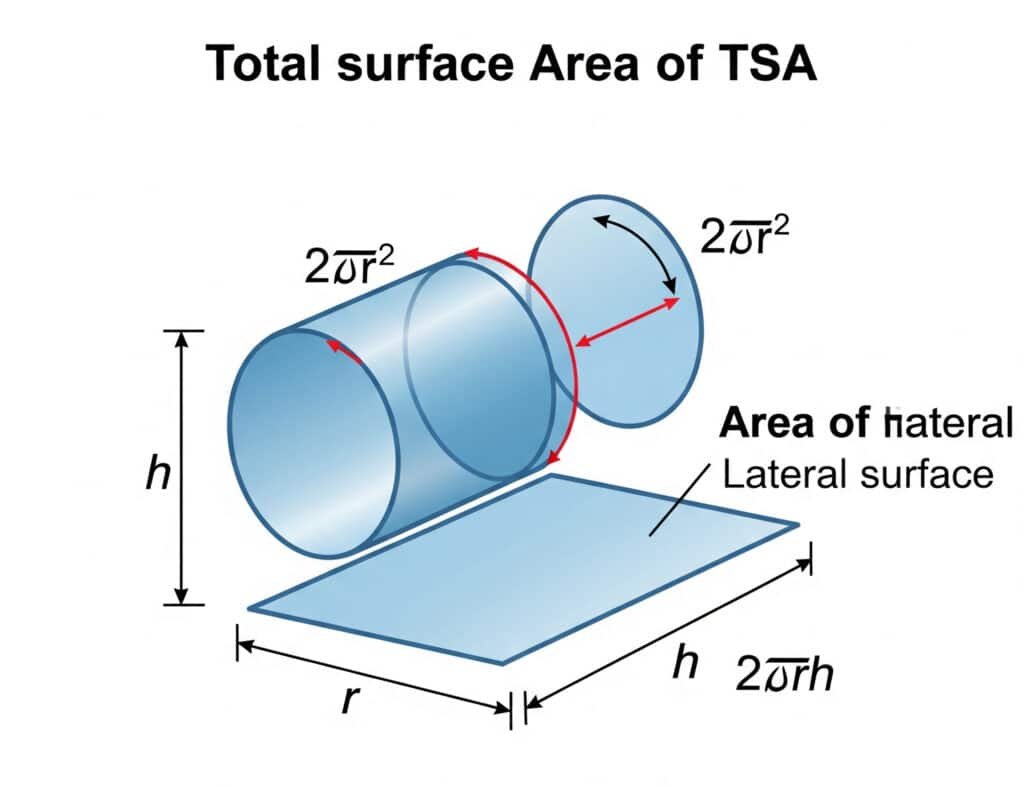

TSA (Total Surface Area) includes all cylinder surfaces using formula 2πr² + 2πrh, while CSA (Curved Surface Area) only covers the lateral surface using formula 2πrh.

Last month, I helped Marcus, a maintenance engineer from Germany, who miscalculated coating materials for his magnetic rodless cylinder2 replacement project by using CSA instead of TSA.

Table of Contents

- What Does TSA Include in Rodless Cylinder Design?

- What Does CSA Cover in Pneumatic Applications?

- When Should You Use TSA vs CSA for Rodless Air Cylinders?

- How Do TSA and CSA Affect Material Costs?

What Does TSA Include in Rodless Cylinder Design?

TSA calculations become critical when you need complete surface coverage for rodless pneumatic cylinder projects. Most engineers underestimate the complexity involved.

TSA includes both circular end caps (2πr²) plus the curved lateral surface (2πrh), giving you the total surface area needed for complete material calculations.

Complete TSA Components

TSA covers every surface of your rodless cylinder housing:

Both End Surfaces

- Top circular area: πr²

- Bottom circular area: πr²

- Combined end areas: 2πr²

Lateral Curved Surface

- Circumference: 2πr

- Height: h (cylinder length)

- Lateral area: 2πrh

TSA Formula Breakdown

TSA = 2πr² + 2πrh

| Component | Formula | Purpose |

|---|---|---|

| End caps | 2πr² | Both circular faces |

| Lateral surface | 2πrh | Curved side wall |

| Total | 2πr² + 2πrh | Complete coverage |

When I Use TSA Calculations

I apply TSA when customers need:

- Complete anodizing3 for guided rodless cylinders

- Full coating specifications for double acting rodless cylinders

- Total material procurement for new installations

- Heat transfer analysis4 for electric rodless cylinders

TSA Calculation Example

For a standard rodless air cylinder:

- Diameter: 80mm (radius = 40mm)

- Length: 500mm

- End areas: 2π(40)² = 10,053 mm²

- Lateral area: 2π(40)(500) = 125,664 mm²

- Total TSA: 135,717 mm²

What Does CSA Cover in Pneumatic Applications?

CSA calculations focus exclusively on the curved surface, making them perfect for specific rodless cylinder maintenance and repair scenarios.

CSA only includes the lateral curved surface area calculated as 2πrh, excluding both circular end caps from the measurement.

CSA Specific Coverage

CSA measures only the curved “barrel” surface of your rodless pneumatic cylinder:

Lateral Surface Only

- Curved wall: Complete 360° coverage

- Length coverage: Full cylinder height

- Exclusions: No end cap surfaces

CSA Formula

CSA = 2πrh

CSA Applications in Rodless Systems

I recommend CSA calculations for:

Tube Replacement Projects

- Magnetic rodless cylinder tube refurbishment

- Guided rodless cylinder lateral surface repairs

- Double acting rodless cylinder sleeve replacements

Selective Surface Treatments

- Lateral coating only: When ends use different materials

- Wear pattern analysis: Focus on sliding surfaces

- Cost optimization: Reduced material requirements

CSA vs TSA Comparison

| Aspect | CSA | TSA |

|---|---|---|

| Surface coverage | Lateral only | Complete cylinder |

| Formula | 2πrh | 2πr² + 2πrh |

| Material cost | Lower | Higher |

| Applications | Repairs/replacements | New installations |

CSA Calculation Example

Using the same 80mm × 500mm rodless cylinder:

- CSA: 2π(40)(500) = 125,664 mm²

- Difference from TSA: 10,053 mm² less (7.4% savings)

When Should You Use TSA vs CSA for Rodless Air Cylinders?

Choosing between TSA and CSA depends on your specific rodless cylinder application, budget constraints, and performance requirements.

Use TSA for complete new installations and full refurbishments. Use CSA for tube replacements and lateral surface treatments only.

TSA Application Scenarios

Complete System Projects

I recommend TSA when you’re dealing with:

- New rodless pneumatic cylinder installations

- Complete system refurbishments

- Full surface treatment requirements

- Heat transfer calculations

Quality Standards Compliance

TSA becomes mandatory for:

- Food processing applications: Complete sanitary surface coverage

- Pharmaceutical equipment: Total contamination control

- Automotive production: Full surface quality standards

CSA Application Scenarios

Maintenance and Repairs

CSA works perfectly for:

- Tube replacement projects

- Lateral surface refurbishment

- Cost-controlled repairs

- Selective maintenance programs

Budget-Conscious Projects

I suggest CSA when customers need:

- Immediate cost reduction

- Prototype development

- Non-critical applications

- Temporary solutions

Decision Matrix

| Project Type | Surface Requirement | Recommended Method | Cost Impact |

|---|---|---|---|

| New installation | All surfaces | TSA | Higher initial cost |

| Tube replacement | Lateral only | CSA | 30-40% savings |

| Complete refurbishment | All surfaces | TSA | Full restoration |

| Prototype testing | Essential surfaces | CSA | Budget optimization |

Real Customer Example

Sarah, a procurement manager from Canada, contacted me about replacing rodless cylinder parts in her packaging equipment. Her original quote used TSA calculations for what was actually a tube-only replacement. I recalculated using CSA and saved her company $2,400 on the project.

How Do TSA and CSA Affect Material Costs?

Understanding cost differences between TSA and CSA calculations helps you optimize budgets while maintaining rodless cylinder performance standards.

TSA typically costs 30-50% more than CSA due to additional end surface materials and treatments, but provides complete functionality and longer service life.

Cost Component Analysis

TSA Cost Structure

Complete cylinder costs include:

- End cap materials: 25-40% of total cost

- Lateral materials: 60-75% of total cost

- Complete surface treatment: Full coating requirements

- Assembly complexity: Higher labor costs

CSA Cost Structure

Lateral-only costs focus on:

- Tube materials: Simplified procurement

- Reduced treatments: Single surface focus

- Lower complexity: Streamlined assembly

- Faster delivery: Reduced manufacturing time

Cost Comparison Examples

| Cylinder Size | CSA Cost | TSA Cost | Difference | Savings % |

|---|---|---|---|---|

| 40mm × 300mm | $85 | $125 | $40 | 32% |

| 63mm × 500mm | $145 | $210 | $65 | 31% |

| 80mm × 800mm | $220 | $315 | $95 | 30% |

| 100mm × 1000mm | $310 | $445 | $135 | 30% |

ROI Analysis

Short-term Benefits (CSA)

- Lower initial investment

- Faster project completion

- Immediate cost savings

- Budget flexibility

Long-term Value (TSA)

- Extended service life: 40-60% longer

- Reduced maintenance frequency

- Lower total cost of ownership5

- Better performance reliability

Material Treatment Costs

Surface Treatment Pricing

- Anodizing: $0.15-0.25 per cm²

- Powder coating: $0.10-0.18 per cm²

- Specialized coatings: $0.30-0.50 per cm²

Cost Optimization Strategies

I help customers choose the right approach by:

- Analyzing application requirements

- Calculating total cost of ownership

- Evaluating maintenance schedules

- Considering downtime costs

Conclusion

TSA includes complete cylinder surface area while CSA covers only lateral surfaces. Choose TSA for new installations and complete refurbishments, CSA for tube replacements and cost optimization.

FAQs About TSA and CSA in Rodless Cylinders

What does TSA stand for in rodless cylinder calculations?

TSA stands for Total Surface Area, which includes both end caps and lateral surface area of rodless pneumatic cylinders. The formula is TSA = 2πr² + 2πrh, covering every surface requiring treatment or analysis.

What does CSA mean for rodless air cylinders?

CSA means Curved Surface Area, measuring only the lateral curved surface of rodless cylinders. The formula CSA = 2πrh excludes end caps, making it suitable for tube replacements and lateral surface treatments.

When should I use TSA vs CSA for rodless cylinder projects?

Use TSA for complete new installations, full refurbishments, and total surface treatments. Use CSA for tube replacements, lateral repairs, and cost-optimized maintenance projects where end caps remain unchanged.

How much can I save using CSA instead of TSA calculations?

CSA calculations typically save 30-40% on material costs compared to TSA because they exclude end surface materials and treatments. However, consider long-term performance requirements before choosing cost savings over complete coverage.

Which formula is better for magnetic rodless cylinder repairs?

For magnetic rodless cylinder tube replacements, use CSA (2πrh) to calculate lateral surface requirements only. For complete magnetic rodless cylinder refurbishment including end caps, use TSA (2πr² + 2πrh) for total coverage.

-

Learn more about the fundamental design and operating principles of rodless pneumatic cylinders from a trusted engineering resource. ↩

-

Explore the internal mechanics and advantages of magnetically coupled rodless cylinders for industrial automation. ↩

-

Discover the electrochemical process of anodizing, how it enhances metal durability, and its common industrial applications. ↩

-

Understand the core principles of heat transfer analysis and why it is a critical calculation for thermal management in engineering components. ↩

-

Gain insights into the Total Cost of Ownership (TCO) framework, a critical financial tool for evaluating long-term asset value. ↩