Gas cylinder failures cause millions in production losses annually. Many engineers confuse gas cylinders with pneumatic cylinders, leading to improper selection and catastrophic failures. Understanding the fundamental mechanisms prevents costly mistakes and safety hazards.

Gas cylinder mechanism operates through controlled gas expansion or compression using pistons, valves, and chambers to convert chemical or thermal energy into mechanical motion, fundamentally different from pneumatic systems that use compressed air.

Last year, I consulted for a Japanese automotive manufacturer named Hiroshi Tanaka whose hydraulic press system kept failing. They were using pneumatic cylinders where gas cylinders were needed for high-force applications. After explaining gas cylinder mechanisms and implementing proper nitrogen gas cylinders, their system reliability improved by 85% while reducing maintenance costs.

Table of Contents

- What Are the Fundamental Operating Principles of Gas Cylinders?

- How Do Different Types of Gas Cylinders Work?

- What Are the Key Components That Enable Gas Cylinder Operation?

- How Do Gas Cylinders Compare to Pneumatic and Hydraulic Systems?

- What Are the Industrial Applications of Gas Cylinder Mechanisms?

- How to Maintain and Optimize Gas Cylinder Performance?

- Conclusion

- FAQs About Gas Cylinder Mechanisms

What Are the Fundamental Operating Principles of Gas Cylinders?

Gas cylinders operate on thermodynamic principles where gas expansion, compression, or chemical reactions create mechanical force and motion. Understanding these principles is crucial for proper application and safety.

Gas cylinder mechanisms work through controlled gas pressure changes within sealed chambers, using pistons to convert gas energy into linear or rotary mechanical motion through thermodynamic processes.

Thermodynamic Foundation

Gas cylinders operate based on fundamental gas laws that govern pressure, volume, and temperature relationships in confined spaces.

Key Gas Laws Applied:

| Law | Formula | Application in Gas Cylinders |

|---|---|---|

| Boyle’s Law | P₁V₁ = P₂V₂ | Isothermal compression/expansion |

| Charles’s Law | V₁/T₁ = V₂/T₂ | Temperature-dependent volume changes |

| Gay-Lussac’s Law | P₁/T₁ = P₂/T₂ | Pressure-temperature relationships |

| Ideal Gas Law | PV = nRT | Complete gas behavior prediction |

Energy Conversion Mechanisms

Gas cylinders convert different forms of energy into mechanical work through various mechanisms depending on the gas type and application.

Energy Conversion Types:

- Thermal Energy: Heat expansion drives piston movement

- Chemical Energy: Gas generation from chemical reactions

- Pressure Energy: Stored compressed gas expansion

- Phase Change Energy: Liquid-to-gas conversion forces

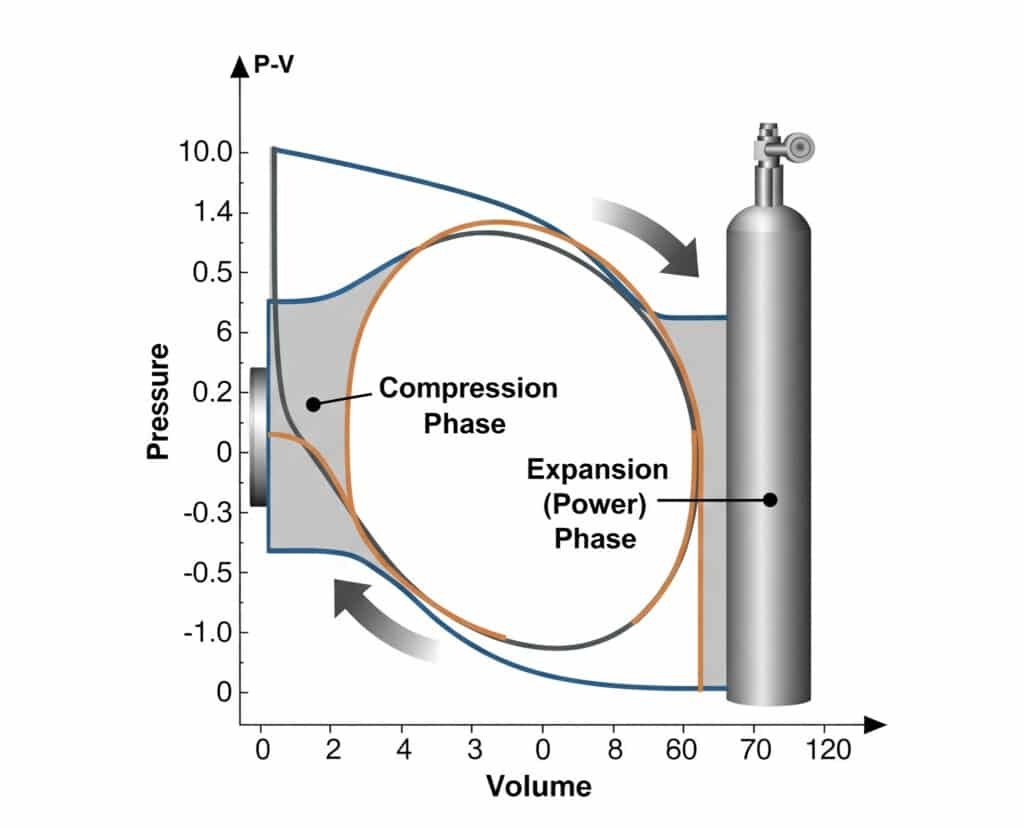

Pressure-Volume Work Calculation

The work output of gas cylinders follows thermodynamic work equations that determine force and displacement characteristics.

Work Formula: W = ∫P dV (Pressure × Volume change)

For constant pressure processes: W = P × ΔV

For isothermal processes: W = nRT × ln(V₂/V₁)

For adiabatic processes: W = (P₂V₂ – P₁V₁)/(γ-1)

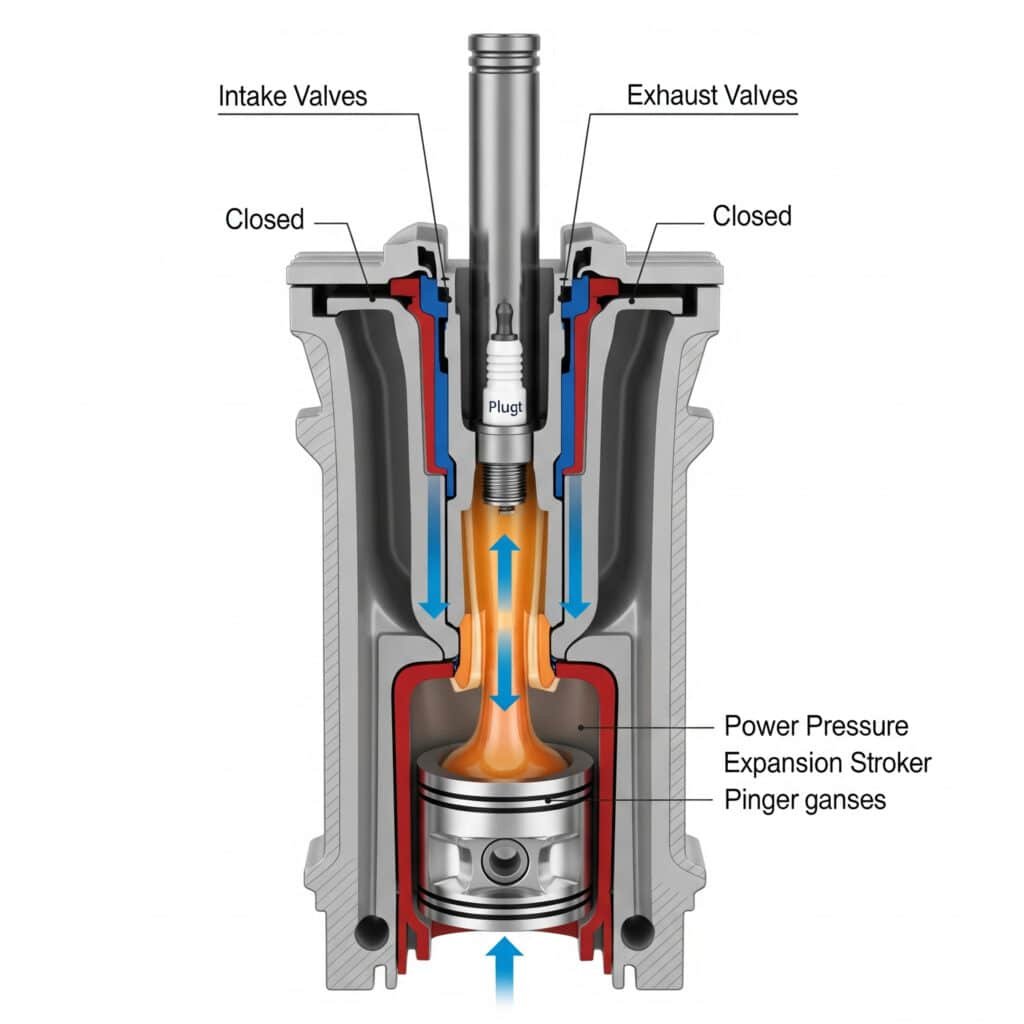

Gas Cylinder Operating Cycles

Most gas cylinders operate in cycles that involve intake, compression, expansion, and exhaust phases similar to internal combustion engines but adapted for linear motion.

Four-Stroke Gas Cylinder Cycle:

- Intake: Gas enters cylinder chamber

- Compression: Gas volume reduces, pressure increases

- Power: Gas expansion drives piston motion

- Exhaust: Spent gas exits cylinder

How Do Different Types of Gas Cylinders Work?

Various gas cylinder designs serve different industrial applications through specialized mechanisms optimized for specific gas types, pressure ranges, and performance requirements.

Gas cylinder types include nitrogen gas springs, CO₂ cylinders, combustion gas cylinders, and specialty gas actuators, each using unique mechanisms to convert gas energy into mechanical motion.

Nitrogen Gas Springs

Nitrogen gas springs1 use compressed nitrogen gas to provide consistent force output over long strokes. They operate as sealed systems with no external gas supply required.

Operating Mechanism:

- Sealed Chamber: Contains pressurized nitrogen gas

- Floating Piston: Separates gas from hydraulic oil

- Progressive Force: Force increases as stroke compresses

- Self-Contained: No external connections required

Force Characteristics:

- Initial Force: Determined by gas precharge pressure

- Progressive Rate: Increases 3-5% per inch of compression

- Maximum Force: Limited by gas pressure and piston area

- Temperature Sensitivity: ±2% per 50°F change

CO₂ Gas Cylinders

CO₂ cylinders2 use liquid carbon dioxide that vaporizes to create expansion force. The phase change provides consistent pressure over a wide operating range.

Unique Operating Features:

- Phase Change: Liquid CO₂ vaporizes at -109°F

- Constant Pressure: Vapor pressure remains stable

- High Force Density: Excellent force-to-weight ratio

- Temperature Dependent: Performance varies with ambient temperature

Combustion Gas Cylinders

Combustion gas cylinders3 use controlled fuel combustion to create high-pressure gas expansion for maximum force output applications.

Combustion Mechanism:

| Component | Function | Operating Parameters |

|---|---|---|

| Fuel Injection | Delivers measured fuel | 10-100 mg per cycle |

| Ignition System | Initiates combustion | 15,000-30,000 volt spark |

| Combustion Chamber | Contains explosion | 1000-3000 PSI peak pressure |

| Expansion Chamber | Converts pressure to motion | Variable volume design |

Specialty Gas Actuators

Specialty gas cylinders use specific gases like helium, argon, or hydrogen for unique applications requiring particular characteristics.

Gas Selection Criteria:

- Helium: Inert, low density, high thermal conductivity

- Argon: Inert, dense, good for welding applications

- Hydrogen: High energy density, explosive hazard considerations

- Oxygen: Oxidizing properties, fire/explosion risks

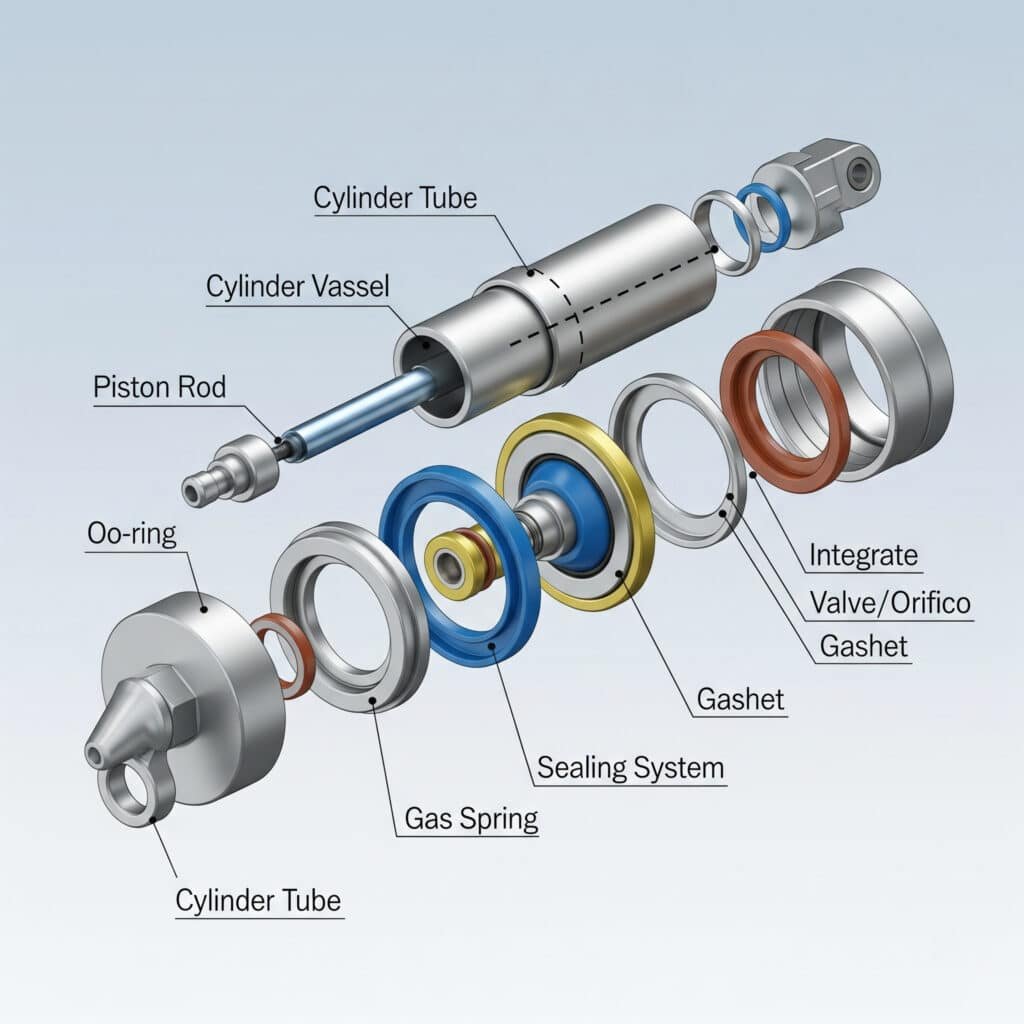

What Are the Key Components That Enable Gas Cylinder Operation?

Gas cylinder mechanisms require precisely engineered components that work together to safely contain and control gas energy conversion into mechanical motion.

Key components include pressure vessels, pistons, sealing systems, valves, and safety devices that must withstand high pressures while providing reliable motion control and operator safety.

Pressure Vessel Design

The pressure vessel forms the foundation of gas cylinder operation, containing high-pressure gases safely while allowing piston movement.

Design Requirements:

- Wall Thickness: Calculated using pressure vessel codes

- Material Selection: High-strength steel or aluminum alloys

- Safety Factors: 4:1 minimum for industrial applications

- Pressure Testing: Hydrostatic testing at 1.5× working pressure

- Certification: ASME4, DOT, or equivalent standards compliance

Hoop Stress Analysis Calculations:

Hoop Stress5: σ = (P × D)/(2 × t)

Longitudinal Stress: σ = (P × D)/(4 × t)

Where:

- P = Internal pressure

- D = Cylinder diameter

- t = Wall thickness

Piston Assembly Design

Pistons transfer gas pressure into mechanical force while maintaining separation between gas chambers and external environment.

Critical Piston Features:

- Sealing Elements: Multiple seals prevent gas leakage

- Guidance Systems: Prevent side loading and binding

- Material Selection: Compatible with gas chemistry

- Surface Treatments: Reduce friction and wear

- Pressure Balance: Equal pressure areas where required

Sealing System Technology

Sealing systems prevent gas leakage while allowing smooth piston movement under high pressure and temperature variations.

Seal Types and Applications:

| Seal Type | Pressure Range | Temperature Range | Gas Compatibility |

|---|---|---|---|

| O-Rings | 0-1500 PSI | -40°F to +200°F | Most gases |

| Lip Seals | 0-500 PSI | -20°F to +180°F | Non-corrosive gases |

| Piston Rings | 500-5000 PSI | -40°F to +400°F | All gases |

| Metal Seals | 1000-10000 PSI | -200°F to +1000°F | Corrosive/extreme gases |

Valve and Control Systems

Valves control gas flow into and out of cylinders, enabling precise timing and force control for various applications.

Valve Classifications:

- Check Valves: Prevent reverse flow

- Relief Valves: Protect against overpressure

- Control Valves: Regulate gas flow rates

- Solenoid Valves: Provide remote control capability

- Manual Valves: Allow operator control

Safety and Monitoring Systems

Safety systems protect operators and equipment from gas cylinder hazards including overpressure, leakage, and component failure.

Essential Safety Features:

- Pressure Relief: Automatic overpressure protection

- Burst Discs: Ultimate pressure protection

- Leak Detection: Monitor gas containment integrity

- Temperature Monitoring: Prevent thermal hazards

- Emergency Shutoff: Rapid system isolation capability

How Do Gas Cylinders Compare to Pneumatic and Hydraulic Systems?

Gas cylinders offer unique advantages and limitations compared to conventional pneumatic and hydraulic systems. Understanding these differences helps engineers select optimal solutions for specific applications.

Gas cylinders provide higher force density than pneumatic systems and cleaner operation than hydraulic systems, but require specialized handling and safety considerations due to stored energy levels.

Performance Comparison Analysis

Gas cylinders excel in applications requiring high force output, long stroke capability, or operation in extreme environments where conventional systems fail.

Comparative Performance Metrics:

| Characteristic | Gas Cylinders | Pneumatic | Hydraulic |

|---|---|---|---|

| Force Output | 1000-50000 lbs | 100-5000 lbs | 500-100000 lbs |

| Pressure Range | 500-10000 PSI | 80-150 PSI | 1000-5000 PSI |

| Speed Control | Good | Excellent | Excellent |

| Positioning Accuracy | ±0.5 inch | ±0.1 inch | ±0.01 inch |

| Energy Storage | High | Low | Medium |

| Maintenance | Medium | Low | High |

Energy Density Advantages

Gas cylinders store significantly more energy per unit volume than compressed air systems, making them ideal for portable or remote applications.

Energy Storage Comparison:

- Compressed Air (150 PSI): 0.5 BTU per cubic foot

- Nitrogen Gas (3000 PSI): 10 BTU per cubic foot

- CO₂ Liquid/Gas: 25 BTU per cubic foot

- Combustion Gas: 100+ BTU per cubic foot

Safety Considerations

Gas cylinders require enhanced safety measures due to higher stored energy levels and potential gas hazards.

Safety Comparison:

| Safety Aspect | Gas Cylinders | Pneumatic | Hydraulic |

|---|---|---|---|

| Stored Energy | Very High | Low | Medium |

| Leak Hazards | Gas-dependent | Minimal | Oil contamination |

| Fire Risk | Variable | Low | Medium |

| Explosion Risk | High (some gases) | Low | Very Low |

| Training Required | Extensive | Basic | Intermediate |

Cost Analysis

Initial costs for gas cylinder systems are typically higher than pneumatic systems but can be lower than hydraulic systems for equivalent force output.

Cost Factors:

- Initial Investment: Higher due to specialized components

- Operating Costs: Lower energy consumption per unit force

- Maintenance Costs: Moderate, specialized service required

- Safety Costs: Higher due to training and safety equipment

- Lifecycle Costs: Competitive for high-force applications

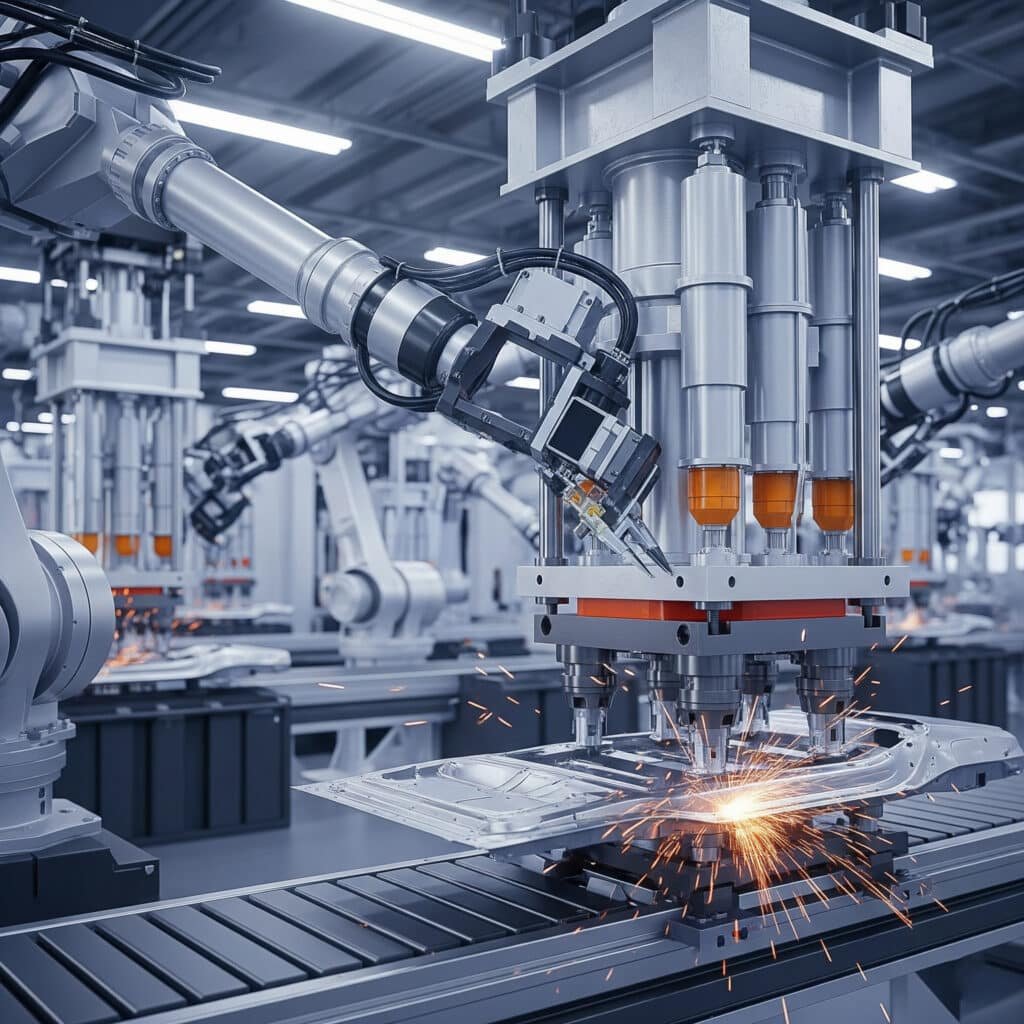

What Are the Industrial Applications of Gas Cylinder Mechanisms?

Gas cylinders serve diverse industrial applications where their unique characteristics provide advantages over conventional pneumatic or hydraulic systems.

Primary applications include metal forming, automotive manufacturing, aerospace systems, mining equipment, and specialty manufacturing where high force, reliability, or extreme environment operation is required.

Metal Forming and Stamping

Gas cylinders provide consistent high forces required for metal forming operations while maintaining precise control over forming pressures.

Forming Applications:

- Deep Drawing: Consistent pressure for complex shapes

- Blanking Operations: High-force cutting applications

- Embossing: Precise pressure control for surface texturing

- Coining: Extreme pressure for detailed impressions

- Progressive Dies: Multiple forming operations

Advantages in Metal Forming:

- Force Consistency: Maintains pressure throughout stroke

- Speed Control: Variable forming rates

- Pressure Regulation: Precise force application

- Stroke Length: Long strokes for deep draws

- Reliability: Consistent performance under high loads

Automotive Manufacturing

Automotive industry uses gas cylinders for assembly operations, testing equipment, and specialized manufacturing processes.

Automotive Applications:

| Application | Gas Type | Pressure Range | Key Benefits |

|---|---|---|---|

| Engine Testing | Nitrogen | 500-3000 PSI | Inert, consistent pressure |

| Suspension Systems | Nitrogen | 100-500 PSI | Progressive spring rate |

| Brake Testing | CO₂ | 200-1000 PSI | Consistent, clean operation |

| Assembly Fixtures | Various | 300-2000 PSI | High clamping force |

Aerospace Applications

Aerospace industry requires gas cylinders for ground support equipment, testing systems, and specialized manufacturing processes.

Critical Aerospace Uses:

- Hydraulic System Testing: High-pressure gas generation

- Component Testing: Simulated operating conditions

- Ground Support Equipment: Aircraft servicing systems

- Manufacturing Tools: Composite forming and curing

- Emergency Systems: Backup power for critical functions

I recently worked with a French aerospace manufacturer named Philippe Dubois whose composite forming process needed precise pressure control. By implementing nitrogen gas cylinders with electronic pressure regulation, we achieved 40% better part quality while reducing cycle time by 25%.

Mining and Heavy Industry

Mining operations use gas cylinders in harsh environments where reliability and high force output are essential for safety and productivity.

Mining Applications:

- Rock Breaking: High-impact force generation

- Conveyor Systems: Heavy-duty material handling

- Safety Systems: Emergency equipment actuation

- Drilling Equipment: High-pressure drilling operations

- Material Processing: Crushing and separation equipment

Specialty Manufacturing

Unique manufacturing processes often require gas cylinder capabilities that conventional systems cannot provide.

Specialty Applications:

- Glass Forming: Precise pressure and temperature control

- Plastic Molding: High-force injection systems

- Textile Manufacturing: Fabric forming and processing

- Food Processing: Sanitary high-pressure applications

- Pharmaceutical: Clean, precise manufacturing processes

How to Maintain and Optimize Gas Cylinder Performance?

Proper maintenance and optimization ensure gas cylinder safety, reliability, and performance while minimizing operating costs and downtime risks.

Maintenance includes pressure monitoring, seal inspection, gas purity testing, and component replacement following manufacturer schedules, while optimization focuses on pressure settings, cycle timing, and system integration.

Preventive Maintenance Schedules

Gas cylinders require systematic maintenance programs tailored to operating conditions, gas types, and application demands.

Maintenance Frequency Guidelines:

| Maintenance Task | Frequency | Critical Checkpoints |

|---|---|---|

| Visual Inspection | Daily | Leaks, damage, connections |

| Pressure Check | Weekly | Operating pressure, relief settings |

| Seal Inspection | Monthly | Wear, damage, leakage |

| Gas Purity Test | Quarterly | Contamination, moisture |

| Complete Overhaul | Annually | All components, recertification |

Gas Purity and Quality Control

Gas quality directly affects cylinder performance, safety, and component life. Regular testing and purification maintain optimal operation.

Gas Quality Standards:

- Moisture Content: <10 ppm for most applications

- Oil Contamination: <1 ppm maximum

- Particulate Matter: <5 microns, <10 mg/m³

- Chemical Purity: 99.5% minimum for industrial gases

- Oxygen Content: <20 ppm for inert gas applications

Performance Monitoring Systems

Modern gas cylinder systems benefit from continuous monitoring that tracks performance parameters and predicts maintenance needs.

Monitoring Parameters:

- Pressure Trends: Detect leakage and wear patterns

- Temperature Monitoring: Prevent thermal damage

- Cycle Counting: Track usage for scheduled maintenance

- Force Output: Monitor performance degradation

- Response Time: Detect control system problems

Optimization Strategies

System optimization balances performance requirements with energy efficiency, component life, and operating costs.

Optimization Approaches:

- Pressure Optimization: Minimum pressure for required performance

- Cycle Optimization: Reduce unnecessary operations

- Gas Selection: Optimal gas type for application

- Component Upgrading: Improve efficiency and reliability

- Control Enhancement: Better system integration and control

Troubleshooting Common Problems

Understanding common gas cylinder problems enables quick diagnosis and resolution, minimizing downtime and safety risks.

Common Issues and Solutions:

| Problem | Symptoms | Typical Causes | Solutions |

|---|---|---|---|

| Pressure Loss | Reduced force output | Seal wear, leakage | Replace seals, check connections |

| Slow Operation | Increased cycle time | Flow restrictions | Clean valves, check lines |

| Erratic Motion | Inconsistent performance | Contaminated gas | Purify gas, replace filters |

| Overheating | High temperatures | Excessive cycling | Reduce cycle rate, improve cooling |

| Seal Failure | External leakage | Wear, chemical attack | Replace with compatible materials |

Safety Protocol Implementation

Gas cylinder safety requires comprehensive protocols covering handling, operation, maintenance, and emergency procedures.

Essential Safety Protocols:

- Personnel Training: Comprehensive gas cylinder safety education

- Hazard Assessment: Regular safety audits and risk analysis

- Emergency Procedures: Response plans for various scenarios

- Personal Protective Equipment: Appropriate safety gear requirements

- Documentation: Maintenance records and safety compliance tracking

Conclusion

Gas cylinder mechanisms convert gas energy into mechanical motion through thermodynamic processes, offering high force density and specialized capabilities for demanding industrial applications requiring precise control and reliable performance.

FAQs About Gas Cylinder Mechanisms

How does a gas cylinder mechanism work?

Gas cylinders work by using controlled gas expansion, compression, or chemical reactions within sealed chambers to drive pistons that convert gas energy into linear or rotary mechanical motion.

What is the difference between gas cylinders and pneumatic cylinders?

Gas cylinders use specialized gases at higher pressures (500-10,000 PSI) for high-force applications, while pneumatic cylinders use compressed air at lower pressures (80-150 PSI) for general automation.

What types of gases are used in gas cylinders?

Common gases include nitrogen (inert, consistent pressure), CO₂ (phase change properties), helium (low density), argon (dense, inert), and specialized gas mixtures for specific applications.

What are the safety considerations for gas cylinder mechanisms?

Key safety concerns include high stored energy levels, gas-specific hazards (toxicity, flammability), pressure vessel integrity, proper handling procedures, and emergency response protocols.

How much force can gas cylinders generate?

Gas cylinders can generate forces from 1,000 to over 50,000 pounds depending on cylinder size, gas pressure, and design, significantly higher than standard pneumatic cylinders.

What maintenance do gas cylinders require?

Maintenance includes daily visual inspections, weekly pressure checks, monthly seal inspections, quarterly gas purity testing, and annual complete overhauls with component replacement as needed.

-

Explains the operating principle of gas springs (also known as gas struts or rams), which are sealed pneumatic devices that use compressed nitrogen gas to provide a controlled force output over a specific stroke. ↩

-

Shows the phase diagram for carbon dioxide, a graph of pressure versus temperature that illustrates the conditions under which CO₂ exists as a solid, liquid, or gas, and why it can provide constant pressure through a phase change. ↩

-

Describes pyrotechnic actuators, devices that use the rapid gas expansion from a controlled explosive or pyrotechnic charge to produce mechanical work, often used for single-shot, high-force applications like emergency releases or airbag inflation. ↩

-

Provides information on the ASME Boiler and Pressure Vessel Code (BPVC), a major standard that regulates the design, construction, and inspection of boilers and pressure vessels to ensure safety, which is a critical reference for high-pressure components. ↩

-

Details the concept of hoop stress, which is the circumferential stress in the wall of a cylindrical pressure vessel that acts perpendicular to the axial direction and must be managed to prevent rupture. ↩