Are you puzzled by unexplained efficiency losses in your pneumatic systems? You’re not alone. Many engineers focus exclusively on mechanical aspects while overlooking a major culprit: thermodynamic losses. These invisible efficiency killers can drain your compressed air system of both performance and profitability.

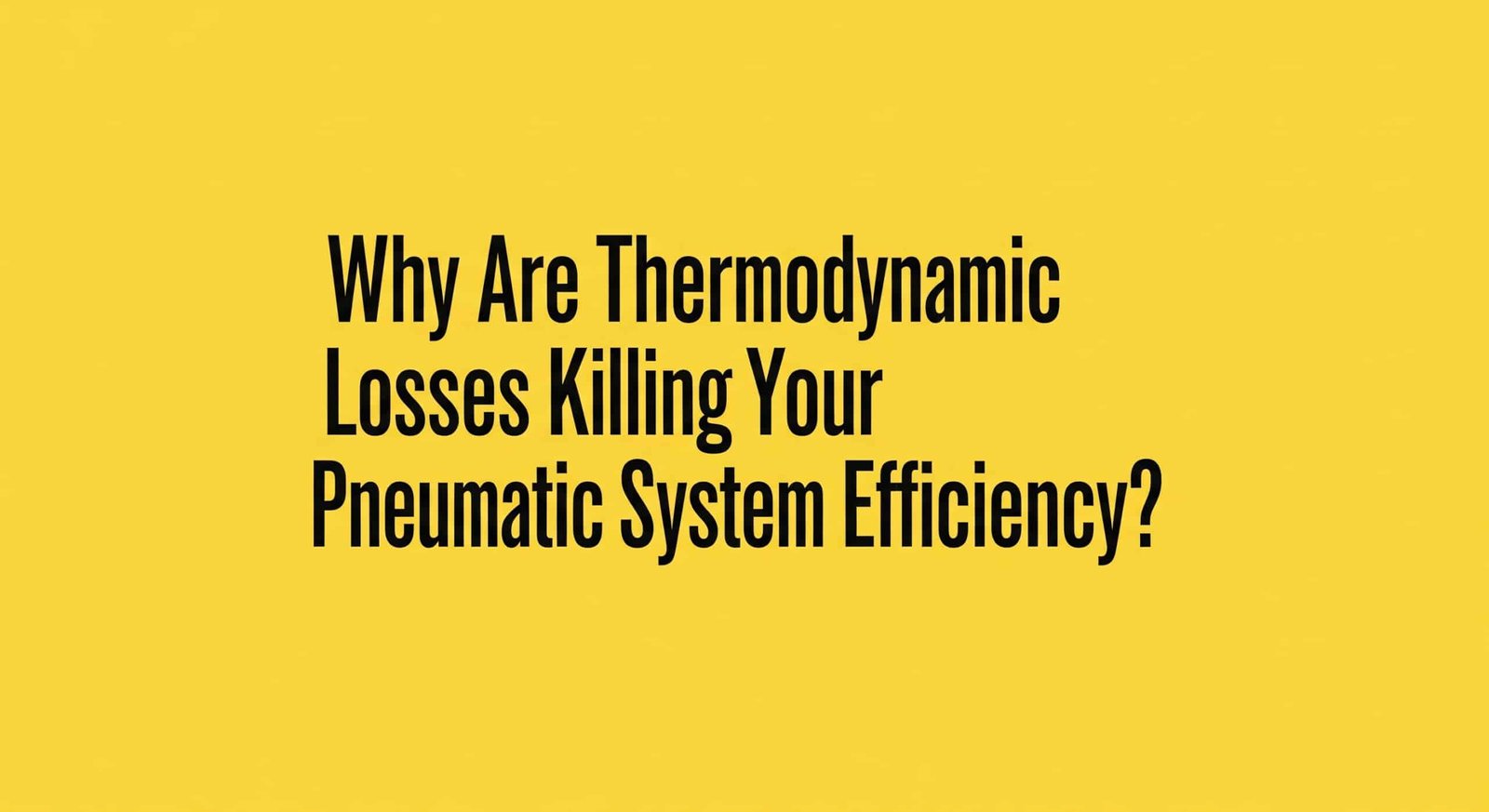

Thermodynamic losses in pneumatic systems occur through temperature changes during adiabatic expansion1, heat transfer through cylinder walls, and energy wasted in condensate formation. These losses typically account for 15-30% of total energy consumption in industrial pneumatic systems, yet are frequently overlooked in system design and optimization.

In my 15+ years at Bepto working with pneumatic systems across various industries, I’ve seen companies recover thousands in energy costs by addressing these often-neglected thermodynamic factors. Let me share what I’ve learned about identifying and minimizing these losses.

Table des matières

- How Does Adiabatic Expansion Affect Your Pneumatic System Performance?

- What’s the Real Cost of Heat Conduction Losses in Pneumatic Cylinders?

- Why Is Condensate Formation a Hidden Efficiency Killer?

- Conclusion

- FAQs About Thermodynamic Losses in Pneumatic Systems

How Does Adiabatic Expansion Affect Your Pneumatic System Performance?

When compressed air expands in a cylinder, it doesn’t just create motion—it also undergoes significant temperature changes that affect system performance, component life, and energy efficiency.

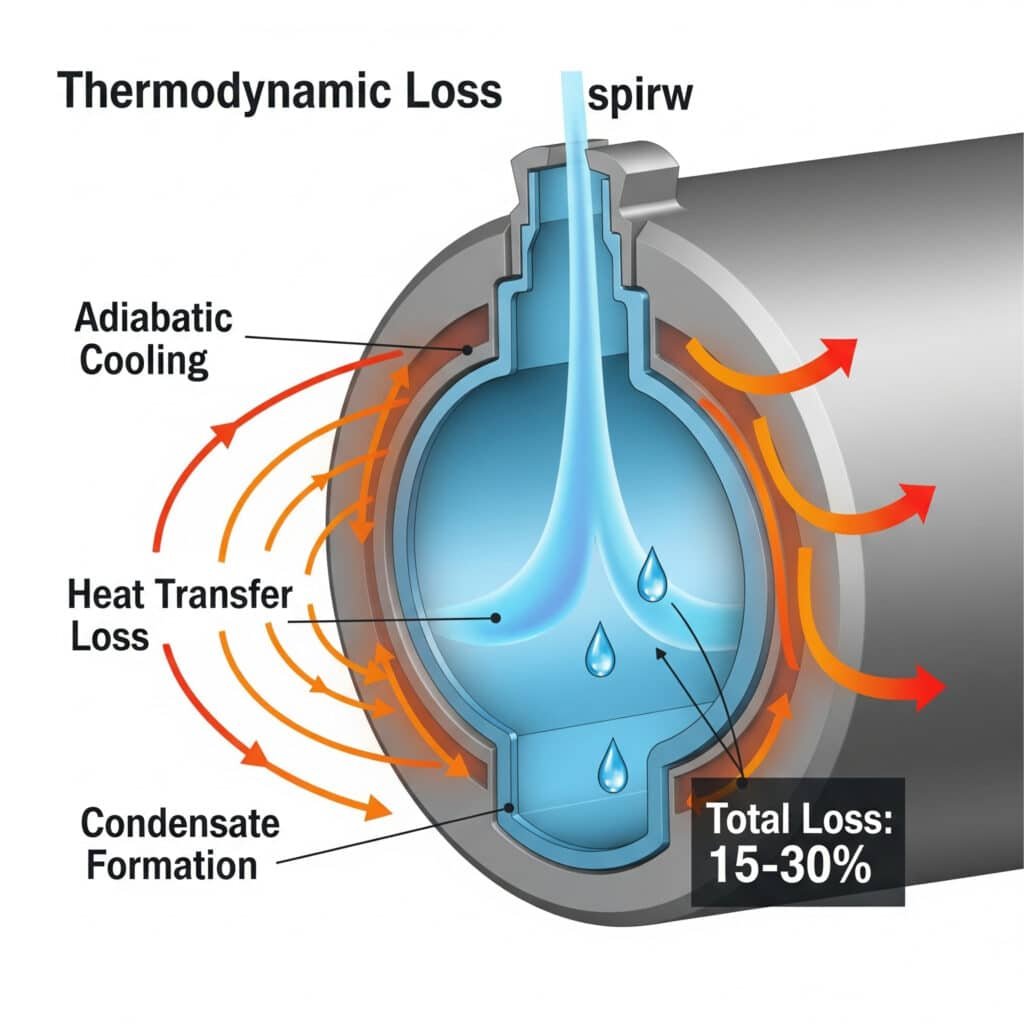

Adiabatic expansion in pneumatic systems causes air temperature to drop according to the equation T₂ = T₁(P₂/P₁)^((γ-1)/γ), where γ is the heat capacity ratio2 (1.4 for air). This temperature drop can reach 50-70°C below ambient temperature during rapid expansion, causing reduced force output, condensation issues, and material stress.

Understanding this temperature change has practical implications for your pneumatic system design and operation. Let me break this down into actionable insights.

The Physics Behind Adiabatic Expansion

Adiabatic expansion occurs when a gas expands without heat transfer to or from the surroundings:

- As compressed air expands in volume, its internal energy decreases

- This energy decrease manifests as a temperature drop

- The process happens quickly enough that minimal heat transfer occurs with cylinder walls

- The temperature change is proportional to the pressure ratio raised to a power

Calculating Temperature Changes in Real Systems

Let’s look at how to calculate the temperature change in a typical pneumatic cylinder:

| Paramètres | Formule | Exemple |

|---|---|---|

| Initial Temperature (T₁) | Ambient or supply temperature | 20°C (293K) |

| Initial Pressure (P₁) | Supply pressure | 6 bar (600 kPa) |

| Final Pressure (P₂) | Atmospheric or back pressure | 1 bar (100 kPa) |

| Heat Capacity Ratio (γ) | For air = 1.4 | 1.4 |

| Final Temperature (T₂) | T₁(P₂/P₁)^((γ-1)/γ) | 293K × (1/6)^(0.286) = 173K (-100°C) |

| Practical Final Temp | Higher due to non-ideal conditions | Typically -20°C to -40°C |

Real-World Impacts of Adiabatic Cooling

This dramatic temperature drop has several practical consequences:

- Reduced force output: Colder air has lower pressure for the same volume

- Condensation and freezing: Moisture in the air can condense or freeze

- Material embrittlement: Some polymers become brittle at low temperatures

- Seal performance changes: Elastomers harden and may leak at low temperatures

- Thermal stress: Repeated temperature cycling can cause material fatigue

I once worked with Jennifer, a process engineer at a food packaging plant in Minnesota. Her rodless cylinders were experiencing mysterious failures during winter months. After investigation, we discovered that the plant’s air dryer wasn’t removing enough moisture, and the adiabatic cooling was causing ice formation inside the cylinders. The temperature was dropping from 15°C to approximately -25°C during expansion.

By installing a better air dryer and using cylinders with seals rated for lower temperatures, we eliminated the failures completely.

Strategies to Mitigate Adiabatic Cooling Effects

To minimize the negative impacts of adiabatic cooling:

- Use appropriate seal materials: Select low-temperature compatible elastomers

- Ensure proper air drying: Maintain low dew points to prevent condensation

- Consider pre-heating: In extreme cases, pre-heat the supply air

- Optimize cycle times: Allow sufficient time for temperature equalization

- Use appropriate lubricants: Select lubricants that maintain performance at low temperatures

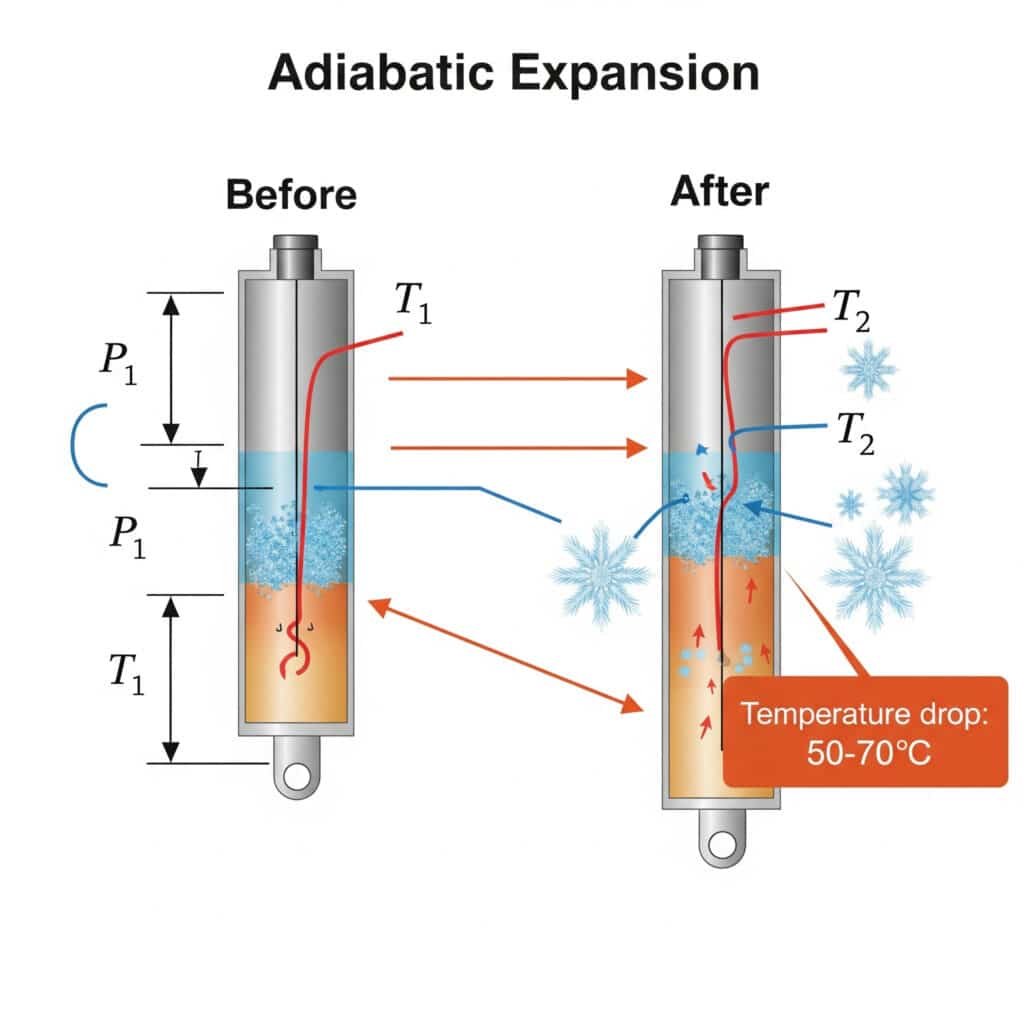

What’s the Real Cost of Heat Conduction Losses in Pneumatic Cylinders?

Heat conduction through cylinder walls represents a significant but often overlooked energy loss in pneumatic systems. Understanding and quantifying these losses can help you improve system efficiency and reduce operating costs.

Heat conduction losses in pneumatic cylinders occur when temperature differences cause energy transfer through cylinder walls. These losses can be quantified using the equation Q = kA(T₁-T₂)/d, where Q is heat transfer rate, k is thermal conductivity3, A is surface area, and d is wall thickness. In typical industrial systems, these losses account for 5-15% of total energy consumption.

Let’s explore how these losses affect your pneumatic systems and what you can do about them.

Quantifying Heat Conduction Losses

The heat conduction through cylinder walls can be calculated using:

| Paramètres | Formula/Value | Exemple |

|---|---|---|

| Thermal Conductivity (k) | Material-specific | Aluminum: 205 W/m·K |

| Surface Area (A) | π × D × L | For 40mm × 200mm cylinder: 0.025m² |

| Temperature Difference (ΔT) | T₁ – T₂ | 30°C (typical during operation) |

| Wall Thickness (d) | Design parameter | 3mm (0.003m) |

| Heat Transfer Rate (Q) | Q = kA(T₁-T₂)/d | Q = 205 × 0.025 × 30 / 0.003 = 51,250W (theoretical max) |

| Practical Heat Loss | Lower due to intermittent operation | Typically 50-500W depending on duty cycle |

Material Impact on Heat Conduction Losses

Different cylinder materials conduct heat at vastly different rates:

| Matériau | Conductivité thermique (W/m-K) | Relative Heat Loss | Applications courantes |

|---|---|---|---|

| Aluminium | 205 | Haut | Standard industrial cylinders |

| Acier | 50 | Moyen | Heavy-duty applications |

| Acier inoxydable | 16 | Faible | Food, chemical, corrosive environments |

| Engineering Polymers | 0.2-0.5 | Très faible | Lightweight, specialized applications |

Case Study: Energy Savings Through Material Selection

Last year, I worked with David, a sustainability engineer at a pharmaceutical company in New Jersey. His facility was using standard aluminum rodless cylinders in a temperature-controlled clean room environment. The HVAC system was working overtime to remove the heat generated by the pneumatic system.

By switching to composite cylinders with polymer bodies for non-critical applications, we reduced heat transfer by over 90%. This change saved approximately 12,000 kWh annually in HVAC energy costs while maintaining the required process temperatures.

Thermal Insulation Strategies for Pneumatic Systems

To reduce heat conduction losses:

- Select appropriate materials: Consider thermal conductivity in material selection

- Apply insulation: External insulation can reduce heat transfer

- Optimize duty cycles: Minimize continuous operation time

- Control ambient conditions: Reduce temperature differentials where possible

- Consider composite designs: Use thermal breaks in cylinder construction

Calculating the Financial Impact of Heat Conduction Losses

To determine the cost impact of heat conduction losses:

- Calculate the heat loss in watts using the formula above

- Convert to kWh by multiplying by operating hours and dividing by 1000

- Multiply by your electricity cost per kWh

- For HVAC-controlled environments, add the additional cooling costs

For a system with 500W average heat loss operating 2000 hours per year at $0.12/kWh:

- Annual energy cost = 500W × 2000h ÷ 1000 × $0.12 = $120

- For a facility with 50 cylinders: $6,000 per year

Why Is Condensate Formation a Hidden Efficiency Killer?

Condensate formation in pneumatic systems is more than just a maintenance nuisance—it’s a significant source of energy waste, component damage, and performance issues.

Condensate forms in pneumatic systems when air temperature drops below its dew point4 according to the formula m = V × ρ × (ω₁ – ω₂), where m is condensate mass, V is air volume, ρ is air density, and ω is humidity ratio. This condensation can reduce efficiency by 3-8%, cause corrosion, and lead to unpredictable operation in rodless cylinders and other pneumatic components.

Let’s explore the practical implications of condensate formation and how to predict and prevent it.

Predicting Condensate Formation

To predict condensate formation in your pneumatic system:

| Paramètres | Formula/Source | Exemple |

|---|---|---|

| Air Volume (V) | Cylinder volume × cycles | 0.25L cylinder × 1000 cycles = 250L |

| Densité de l'air (ρ) | Depends on temperature and pressure | ~1.2 kg/m³ at standard conditions |

| Initial Humidity Ratio (ω₁) | From psychrometric chart5 | 0.010 kg water/kg air at 20°C, 60% RH |

| Final Humidity Ratio (ω₂) | At lowest system temperature | 0.002 kg water/kg air at -10°C |

| Condensate Mass (m) | m = V × ρ × (ω₁ – ω₂) | 250L × 0.0012 kg/L × (0.010-0.002) = 0.0024 kg |

| Daily Condensate | Multiply by daily cycles | ~2.4g per day for this example |

The Hidden Costs of Condensate

Condensate formation impacts pneumatic systems in several ways:

- Energy losses: Condensation releases heat that was previously input during compression

- Increased friction: Water reduces lubrication effectiveness and increases friction

- Component damage: Corrosion and water hammer effects damage valves and cylinders

- Unpredictable operation: Varying amounts of water affect system timing and performance

- Increased maintenance: Draining condensate requires maintenance time and system downtime

Dew Point and System Performance

The dew point temperature is critical for predicting where condensation will occur:

| Pressure Dew Point | System Impact | Recommended Applications |

|---|---|---|

| +10°C | Significant condensation | Only for non-critical, warm environments |

| +3°C | Moderate condensation | General industrial use in heated buildings |

| -20°C | Minimal condensation | Precision equipment, outdoor applications |

| -40°C | Virtually no condensation | Critical systems, food/pharma applications |

| -70°C | No condensation | Semiconductor, specialized applications |

Case Study: Solving Intermittent Failures Through Dew Point Control

I recently worked with Maria, a maintenance supervisor at an automotive parts manufacturer in Michigan. Her plant was experiencing intermittent failures in their rodless cylinder positioning systems, particularly during humid summer months.

Analysis revealed that their compressed air system had a pressure dew point of +5°C. When the air expanded in the cylinders, the temperature dropped to approximately -15°C, causing significant condensation. This water was interfering with the position sensors and causing corrosion in the control valves.

By upgrading their air dryer to achieve a -25°C pressure dew point, we eliminated the condensation issues completely. The system reliability improved from 92% to 99.7%, and maintenance costs decreased by approximately $32,000 annually.

Strategies to Minimize Condensate Issues

To reduce condensate-related problems:

- Install appropriate air dryers: Select dryers based on your required pressure dew point

- Use water separators: Install at strategic points in the system

- Apply heat tracing: Prevent condensation in outdoor or cold environment lines

- Implement proper drainage: Ensure all low points have automatic drains

- Monitor dew point: Use dew point sensors to detect dryer performance issues

Calculating the ROI for Improved Air Drying

To justify investments in better air drying:

- Estimate current condensate-related costs (maintenance, downtime, product quality issues)

- Calculate energy losses from condensate formation

- Determine the cost of upgrading drying equipment

- Compare annual savings to investment cost

For a medium-sized system producing 5L of condensate per day:

- Maintenance cost reduction: ~$15,000/year

- Energy savings: ~$3,000/year

- Reduced product quality issues: ~$20,000/year

- Dryer upgrade cost: $25,000

- Payback period: Less than 1 year

Conclusion

Understanding and addressing thermodynamic losses—from adiabatic expansion temperature effects to heat conduction losses and condensate formation—can significantly improve the efficiency, reliability, and lifespan of your pneumatic systems. By applying the calculation models and strategies outlined in this article, you can optimize your rodless cylinder applications and other pneumatic components for maximum performance and minimum operating costs.

FAQs About Thermodynamic Losses in Pneumatic Systems

How much does air temperature actually drop during expansion in a pneumatic cylinder?

In a typical pneumatic cylinder, air temperature can drop 40-70°C below ambient temperature during rapid expansion from 6 bar to atmospheric pressure. This means that in a 20°C environment, the air inside the cylinder can reach temperatures as low as -50°C momentarily, though heat transfer from cylinder walls moderates this to typically -10°C to -30°C in practice.

What percentage of energy is lost through heat conduction in pneumatic cylinders?

Heat conduction through cylinder walls typically accounts for 5-15% of the total energy consumption in pneumatic systems. This varies based on cylinder material, operating conditions, and duty cycle. Aluminum cylinders have higher losses (closer to 15%) while polymer or insulated cylinders have significantly lower losses (under 5%).

How do I calculate the amount of condensate that will form in my pneumatic system?

Calculate condensate formation using the formula m = V × ρ × (ω₁ – ω₂), where m is condensate mass, V is the volume of air used, ρ is air density, ω₁ is the initial humidity ratio, and ω₂ is the humidity ratio at the lowest system temperature. For a typical industrial system using 1000L of compressed air per hour, this can result in 5-50mL of condensate per hour depending on ambient conditions and air drying.

What pressure dew point do I need for my application?

The required pressure dew point depends on your application and the lowest temperature the air will experience. As a general rule, select a pressure dew point at least 10°C below the lowest expected temperature in your system. For standard indoor industrial applications, a pressure dew point of -20°C is typically sufficient. Critical applications may require -40°C or lower.

How does cylinder material choice affect thermodynamic efficiency?

Cylinder material significantly impacts thermodynamic efficiency through its thermal conductivity. Aluminum cylinders (k=205 W/m·K) conduct heat rapidly, leading to higher energy losses but faster temperature equalization. Stainless steel (k=16 W/m·K) reduces heat transfer by approximately 87% compared to aluminum. Polymer-based cylinders can reduce heat transfer by over 99%, but may have mechanical limitations.

What’s the relationship between air expansion temperature and cylinder performance?

Air expansion temperature directly affects cylinder performance in several ways. Each 10°C drop in temperature reduces the theoretical force output by approximately 3.5% due to the ideal gas law relationship. Low temperatures also increase seal friction by 5-15% due to elastomer hardening, and can reduce lubricant effectiveness. In extreme cases, very low temperatures can cause seal materials to exceed their glass transition temperature, leading to brittleness and failure.

-

Provides a detailed explanation of adiabatic expansion, a fundamental thermodynamic process where a gas expands without any heat transfer to or from its surroundings, causing a significant drop in temperature. ↩

-

Offers a clear definition of the heat capacity ratio (also known as the adiabatic index or gamma), a key property of a gas that determines its temperature change during compression and expansion. ↩

-

Explains the concept of thermal conductivity, an intrinsic property of a material that measures its ability to conduct heat, which is crucial for calculating heat loss through component walls. ↩

-

Describes the dew point, the temperature to which air must be cooled to become saturated with water vapor, a critical parameter for predicting and preventing condensation in pneumatic systems. ↩

-

Provides a guide on how to read and use a psychrometric chart, a complex graph that shows the physical and thermal properties of moist air, which is essential for humidity calculations. ↩