Luchtregelkleppen | gebruiken luchtsignalen om de stroom te regelen voor veilige, niet-elektrische automatisering. Ontdek ons assortiment luchtgestuurde regelkleppen. Ze gebruiken een luchtsignaal onder lage druk om de hoofdklepspoel te verschuiven, waardoor het stromingstraject zonder elektrische voeding wordt geregeld. Dit maakt ze de inherent veilige en betrouwbare keuze voor gevaarlijke omgevingen zoals chemische fabrieken of mijnbouw, of in toepassingen met een hoge vochtigheidsgraad. Vind nu de juiste klep voor uw niet-elektrisch regelsysteem.

Producten nodig voor je project?

We begrijpen dat sourcing een uitdaging kan zijn.

Vul het formulier in met uw specifieke items - aarzel niet om zelfs unieke of moeilijk te vinden onderdelen te vermelden - dien uw aanvraag in en ontvang de precies op maat gemaakte oplossingen die u zoekt! Vergeet algemene aanbiedingen; wij zijn gespecialiseerd in het begrijpen van uw exacte behoeften en het leveren van resultaten die passen als een handschoen

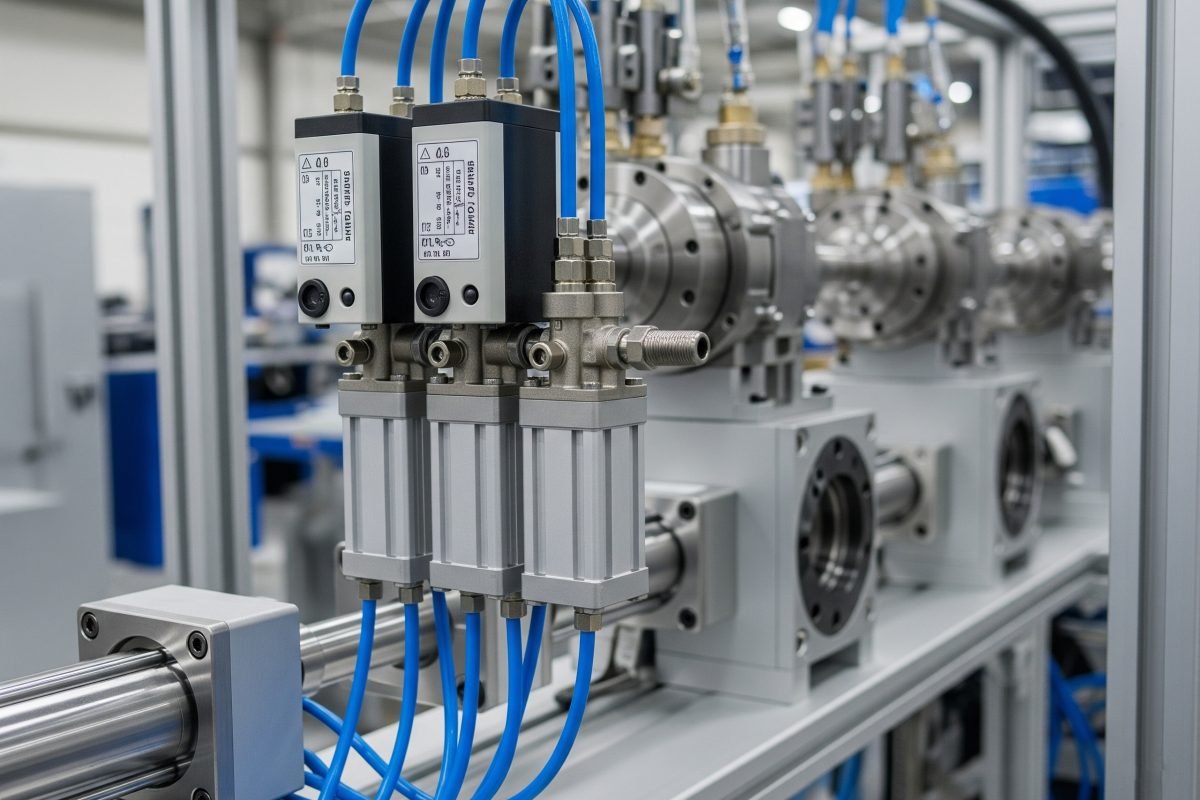

Onze luchtregelkleppen zijn vakkundig ontworpen om de luchtstroom in uw pneumatische systemen met uitzonderlijke betrouwbaarheid te sturen en te beheren. Deze kleppen zijn ideaal voor toepassingen die een robuuste, niet-elektrische bediening vereisen en zorgen voor een soepele werking en nauwkeurige regeling voor een breed scala aan industriële automatiseringstaken.

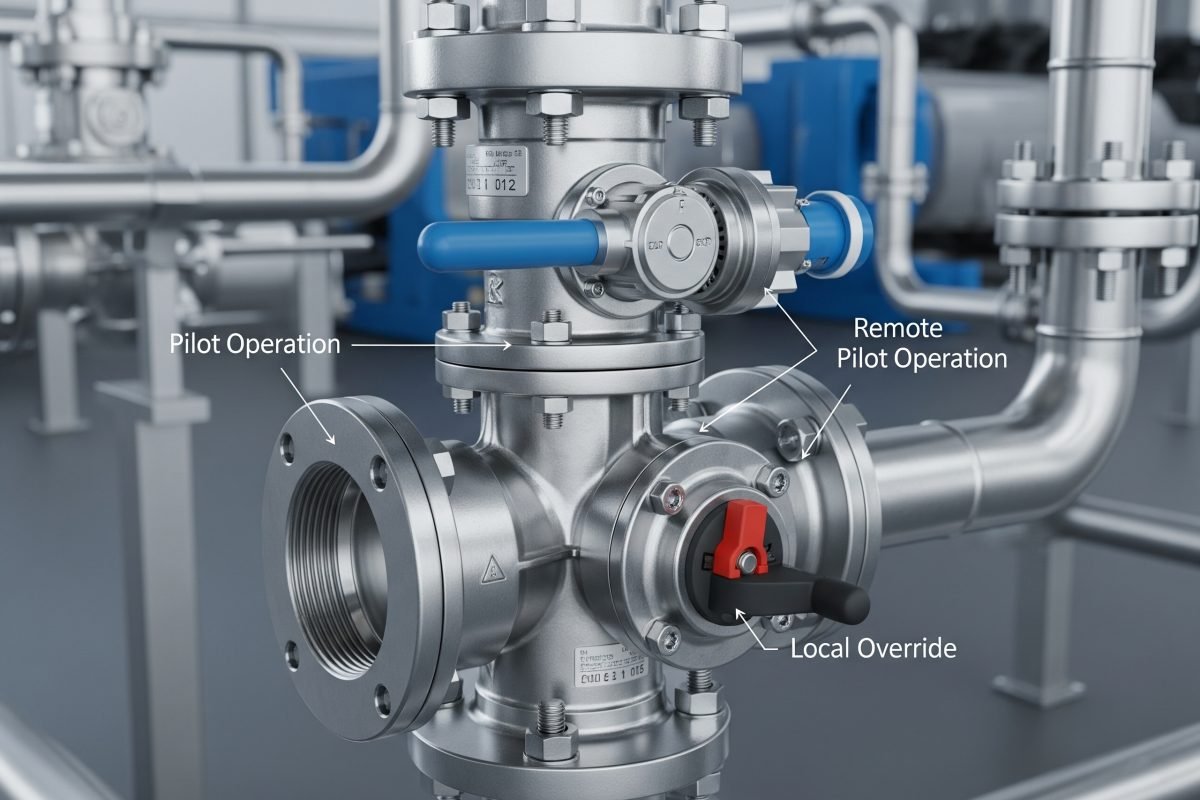

Wordt bediend door luchtsignalen (pilootbediening) en biedt betrouwbare prestaties, vooral in omgevingen waar elektrische bediening niet de voorkeur heeft of niet haalbaar is.

Onze luchtregelkleppen zijn gebouwd met het oog op een lange levensduur en zijn bestand tegen veeleisende industriële omstandigheden, zodat ze consistent werken en minimaal onderhoud vergen.

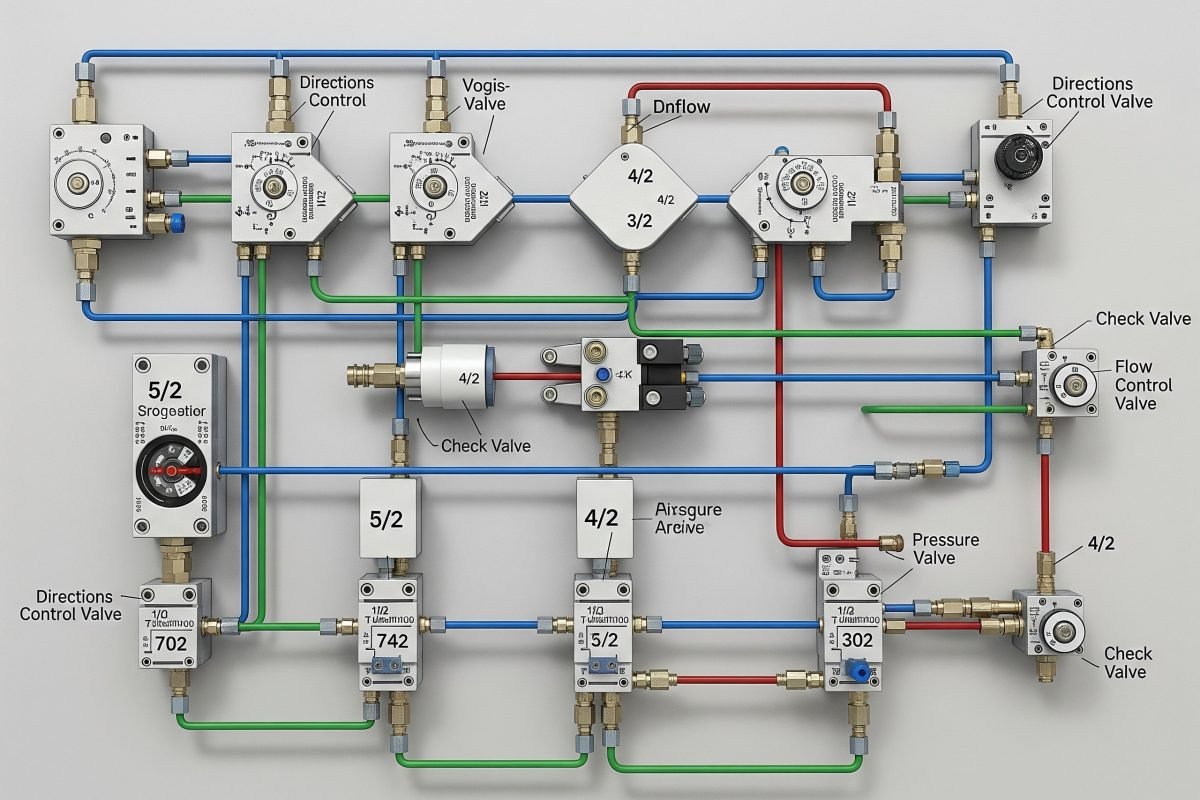

Verkrijgbaar in verschillende configuraties (bijv. 3/2, 5/2, 5/3 weg) om de luchtstroomrichting nauwkeurig te regelen voor enkel- en dubbelwerkende actuators.

Luchtregelkleppen, vooral pilootgestuurde types, gebruiken een kleine hoeveelheid luchtdruk (het pilootsignaal) om een grotere interne spoel of schotel te verschuiven. Deze actie leidt de hoofdluchtstroom door verschillende poorten en regelt zo de werking van pneumatische cilinders, actuators of andere apparaten. Deze methode maakt een robuuste besturing mogelijk zonder directe elektrische input op de klep zelf.

Ontworpen met geoptimaliseerde interne stromingstrajecten voor een maximale luchtstroom (Cv/Kv) met een minimale drukval, waardoor de actuator efficiënt werkt.

Precisiebewerkte spoelen en slijtvaste afdichtingen van hoge kwaliteit garanderen een lange levensduur en consistente prestaties.

Ontworpen om betrouwbaar te werken over een breed bereik van omgevings- en mediatemperaturen, geschikt voor diverse industriële omgevingen.

Veel series bieden manifoldbasissen voor compacte assemblage van meerdere kleppen, wat het leidingwerk en de installatie vereenvoudigt.

Bijvoorbeeld 3/2, 5/2, 5/3 (midden gesloten, midden uitlaat, midden druk).

Schroefdraadmaat van inlaat-, uitlaat- en uitlaatpoorten (bijv. G1/8, G1/4, G1/2).

Enkele luchtstuurstand, dubbele luchtstuurstand.

Bereik voor hoofdluchttoevoer en stuurluchtsignaal.

Geeft de capaciteit van het ventiel aan om lucht door te laten.

Tijd die de klep nodig heeft om te schakelen nadat het stuursignaal is toegepast.

Typisch een aluminiumlegering voor goede sterkte en corrosiebestendigheid.

Lichaamspoort of spruitstukmonteerbaar.

Raadpleeg voor gedetailleerde parameters de afzonderlijke producthandleidingen of raadpleeg onze technische experts.

Luchtstroom sturen om de beweging te regelen (uitschuiven/intrekken, roteren) van pneumatische cilinders en roterende actuators.

Integrale onderdelen in verpakkingsmachines, assemblagelijnen, materiaalverwerkingssystemen en robottoepassingen.

Gebruikt in diverse productieprocessen voor sorteren, omleiden, klemmen en andere geautomatiseerde taken.

Ideaal voor gebruik in explosie- of stofgevoelige omgevingen waar elektrische componenten een risico vormen.

Kan worden gebruikt om zuiver pneumatische besturingscircuits te bouwen voor specifieke sequentie- of logische functies.

Pilotbediening maakt bediening op afstand mogelijk, terwijl handmatige overrides handige lokale bediening bieden.

Maak het systeem altijd drukloos en spanningsloos voor installatie, onderhoud of probleemoplossing.

Het belangrijkste verschil is de bedieningsmethode:

Hoewel beide de luchtstroom regelen, kunnen hun manier van activeren en typische toepassingsomgevingen aanzienlijk verschillen.

Deze notatie beschrijft de functie van de klep:

Bijvoorbeeld:

De minimale stuurdruk is de laagste luchtdruk die nodig is op de stuurpoort om de hoofdklepspoel betrouwbaar te verschuiven. Deze waarde is specifiek voor elk klepmodel en staat meestal vermeld op het technische gegevensblad.

Het is cruciaal om ervoor te zorgen dat de druk van het stuursignaal aan deze minimumeis voldoet of deze overschrijdt. Als de stuurdruk te laag is, kan het zijn dat de klep niet volledig schakelt, traag schakelt of helemaal niet schakelt, wat leidt tot systeemstoringen. Bij sommige klepontwerpen kan de minimale servodruk ook variëren afhankelijk van de druk in de hoofdleiding.

Ja, veel luchtregelkleppen zijn ontworpen voor montage op spruitstuk. Een spruitstuk is een basisblok met gemeenschappelijke toevoer- en afvoeropeningen, waardoor meerdere kleppen compact naast elkaar kunnen worden gemonteerd.

Voordelen van montage op een spruitstuk zijn onder andere:

Om de levensduur van luchtregelkleppen te maximaliseren:

Voor robuuste en betrouwbare richtingsregeling bieden onze luchtregelkleppen de prestaties die u nodig hebt. Bekijk ons assortiment om de perfecte pasvorm voor uw toepassing te vinden of neem contact op met onze pneumatische specialisten voor deskundige begeleiding en oplossingen.