Introduction

Your premium FKM seals are failing prematurely, and you can’t figure out why. 🔍 The seals look swollen, soft, and lose their sealing force within months instead of lasting years. The culprit isn’t defective seals—it’s chemical incompatibility between your fluoroelastomer1 seals and the synthetic compressor oil lubricating your pneumatic system.

FKM (fluoroelastomer) swell rates in synthetic compressor oils vary dramatically by oil chemistry, with polyalphaolefin (PAO)2 oils causing 2-8% volume swell (acceptable), polyalkylene glycol (PAG) oils producing 8-15% swell (marginal), and certain ester-based synthetics generating 15-30% swell (unacceptable) that destroys seal geometry and sealing force. Material compatibility testing per ASTM D4713 is essential before specifying FKM seals in oil-lubricated pneumatic systems, as excessive swell causes seal extrusion, reduced compression, and premature failure regardless of seal quality.

Last month, I received a troubling call from David, a reliability engineer at an automotive parts manufacturer in Michigan. His facility had recently switched to a new synthetic compressor oil to improve energy efficiency and extend maintenance intervals. Within 6 months, FKM seals in their pneumatic rodless cylinders began failing at 10 times the normal rate. The seals weren’t wearing out—they were swelling so much they lost compression and began extruding from their grooves. We tested his new oil against our seal compounds and discovered 18-22% volume swell—far beyond the 10% maximum for reliable sealing. We reformulated his system with hydrogenated nitrile (HNBR) seals compatible with his oil chemistry, and he’s now back to normal 3-5 year seal life.

Table of Contents

- Why Does FKM Swell in Synthetic Oils and What’s Acceptable?

- Which Synthetic Oil Types Cause the Most FKM Swelling?

- How Can You Test Material Compatibility Before System Failure?

- What Alternative Seal Materials Work Better with Problematic Oils?

Why Does FKM Swell in Synthetic Oils and What’s Acceptable?

Seal swell isn’t always bad—but too much destroys performance. 📊

FKM swelling occurs when synthetic oil molecules penetrate the polymer matrix, forcing polymer chains apart and increasing material volume. Controlled swell of 2-10% is acceptable and can actually improve sealing by maintaining contact pressure, but swell exceeding 15% causes dimensional distortion, reduced hardness (20-30 Shore A4 loss), decreased compression set5 resistance, and potential seal extrusion from grooves. Swell rate depends on FKM fluorine content (higher fluorine = better resistance), oil polarity (polar oils cause more swell), temperature (each 10°C increase doubles penetration rate), and exposure time (equilibrium reached in 72-168 hours at operating temperature).

The Swelling Mechanism

At the molecular level, elastomers are networks of long polymer chains with cross-links holding them together. When exposed to oils, small oil molecules can penetrate between polymer chains. If the oil is chemically similar to the polymer (compatible), minimal penetration occurs. If the oil is chemically different but can dissolve into the polymer matrix, significant swelling results.

FKM (fluoroelastomer) polymers contain fluorine atoms that make them resistant to most petroleum oils. However, synthetic oils with different chemical structures can interact differently with the fluorinated polymer backbone.

Acceptable vs. Problematic Swell Ranges

| Volume Swell % | Hardness Change | Performance Impact | Seal Reliability | Action Required |

|---|---|---|---|---|

| 0-5% | 0-5 Shore A | Minimal, may improve sealing | Excellent | None—ideal compatibility |

| 5-10% | 5-10 Shore A | Slight dimensional change | Good | Monitor during service |

| 10-15% | 10-20 Shore A | Noticeable softening | Marginal | Consider alternative material |

| 15-25% | 20-30 Shore A | Significant distortion | Poor | Change seal material immediately |

| >25% | >30 Shore A | Severe degradation | Unacceptable | Complete incompatibility |

Temperature Acceleration

Swell rates increase exponentially with temperature. A seal showing 8% swell at 23°C might exhibit 15-18% swell at 80°C in the same oil. This is why compatibility testing must be performed at actual operating temperatures, not just room temperature.

Temperature Effect on Swell Rate:

- 23°C (room temp): Baseline swell rate

- 40°C: 1.5-2x baseline

- 60°C: 2.5-3x baseline

- 80°C: 4-5x baseline

- 100°C: 6-8x baseline

Real-World Consequences

At Bepto, we’ve analyzed hundreds of failed seals from oil-lubricated pneumatic systems. Excessive swell creates predictable failure modes:

Seal Extrusion: Swollen seals become too large for their grooves and extrude into clearance gaps, causing tearing and rapid failure.

Loss of Compression: As seals swell and soften, they lose the compression force needed to maintain contact pressure against sealing surfaces.

Permanent Set: Swollen seals develop permanent deformation and don’t return to original dimensions even after oil exposure ends.

Accelerated Wear: Softened seal material wears faster under friction, reducing service life by 60-80%.

Which Synthetic Oil Types Cause the Most FKM Swelling?

Not all synthetic oils are created equal when it comes to FKM compatibility. 🧪

Polyalphaolefin (PAO) synthetic oils cause minimal FKM swell (2-6% typical) due to their hydrocarbon structure similar to mineral oils, making them the safest choice for FKM seals. Polyalkylene glycol (PAG) oils produce moderate swell (8-15%) and require careful testing. Ester-based synthetics including diesters, polyol esters, and phosphate esters cause severe FKM swell (15-35%) and are generally incompatible. Oil additive packages containing polar compounds can increase swell by an additional 3-8% beyond base oil effects, making actual compatibility testing with the complete formulated oil essential.

Synthetic Oil Chemistry Comparison

| Oil Type | Chemical Structure | Typical FKM Swell @ 100°C | Compatibility Rating | Common Applications |

|---|---|---|---|---|

| Mineral Oil | Petroleum hydrocarbons | 2-5% | Excellent | General industrial |

| PAO (Polyalphaolefin) | Synthetic hydrocarbons | 3-7% | Excellent | High-performance compressors |

| PAG (Polyalkylene Glycol) | Ether-linked glycols | 10-18% | Fair-Poor | Refrigeration, some compressors |

| Diester | Organic esters | 18-28% | Poor | Aviation, high-temp applications |

| Polyol Ester | Complex esters | 20-35% | Very Poor | Turbine oils, refrigeration |

| Silicone | Polysiloxanes | 5-12% | Good-Fair | Food grade, extreme temps |

| Phosphate Ester | Organophosphates | 25-40% | Unacceptable | Fire-resistant hydraulics |

Why PAO Oils Work Best

PAO synthetic oils are manufactured by polymerizing alpha-olefins (ethylene derivatives) into larger hydrocarbon molecules. The resulting structure is chemically similar to mineral oil—just more uniform and pure. This similarity means PAO oils interact with FKM similarly to mineral oils, causing minimal swell.

I worked with Rebecca, a plant engineer at a food processing facility in California. Her operation required synthetic compressor oils for their superior oxidation stability and extended drain intervals. She initially specified a polyol ester synthetic because of its excellent high-temperature properties. Within 8 months, FKM seals throughout her pneumatic system were failing.

We tested her oil against standard FKM compounds and measured 24-28% volume swell at her operating temperature of 70°C—completely incompatible. We recommended switching to a food-grade PAO synthetic oil with similar performance characteristics. After the oil change and seal replacement, her system has operated for 3+ years without seal-related failures.

The Additive Package Problem

Base oil compatibility is only part of the equation. Modern compressor oils contain 5-15% additive packages including:

- Antioxidants: Usually compatible with FKM

- Anti-wear additives: Zinc dialkyldithiophosphate (ZDDP) can increase swell by 2-5%

- Detergents: Calcium or magnesium sulfonates, moderate swell increase

- Dispersants: Polyisobutylene succinimides, can increase swell significantly

- Pour point depressants: Variable compatibility

- Foam inhibitors: Usually silicone-based, minimal impact

This is why you cannot predict compatibility from base oil type alone—you must test the complete formulated oil.

Regional and Brand Variations

Even oils marketed under the same generic name (e.g., “PAO synthetic compressor oil”) can have different formulations from different manufacturers or regions. European, Asian, and North American oil formulations often differ in additive chemistry to meet local regulations and performance standards.

At Bepto, we maintain a compatibility testing database with over 150 common compressor oils from major manufacturers worldwide. When customers specify their oil brand and grade, we can often provide immediate compatibility guidance for our seal materials.

How Can You Test Material Compatibility Before System Failure?

Prevention requires testing, not guessing. 🔬

Material compatibility testing per ASTM D471 involves immersing seal samples in the actual compressor oil at maximum operating temperature for 70 hours (minimum), then measuring volume swell, hardness change, and tensile strength retention. Professional testing costs $200-500 per oil/material combination but prevents $10,000-50,000+ in system failures and downtime. Simple field testing can be performed by immersing spare seals in heated oil samples for 168 hours and measuring dimensional changes, though laboratory testing provides more accurate and legally defensible results for critical applications.

ASTM D471 Standard Test Method

The industry-standard compatibility test follows this protocol:

1. Sample Preparation

- Cut standardized test specimens from seal material

- Measure initial dimensions, weight, and hardness

- Record baseline properties

2. Immersion Testing

- Immerse samples in test oil at maximum operating temperature

- Standard duration: 70 hours minimum (168 hours preferred)

- Maintain temperature ±2°C throughout test

3. Post-Immersion Measurements

- Remove samples, blot surface oil

- Measure within 30 minutes of removal

- Record volume change, weight change, hardness change

- Optional: tensile strength, elongation testing

4. Results Interpretation

- Calculate volume swell percentage

- Assess hardness change (Shore A durometer)

- Evaluate physical condition (cracking, softening, tackiness)

Field Testing Alternative

For customers who need quick answers without laboratory costs, we recommend this simplified field test:

Materials Needed:

- 3-5 spare seals of each material to be tested

- Sample of actual compressor oil (500ml minimum)

- Heat source maintaining test temperature (oven, hot plate with temperature control)

- Glass containers with lids

- Calipers or micrometer

- Durometer (Shore A hardness tester)

Procedure:

- Measure and record initial seal dimensions and hardness

- Immerse seals in heated oil for 168 hours (1 week)

- Remove, blot dry, and immediately measure dimensions and hardness

- Calculate percentage change

Acceptance Criteria:

- Volume swell <10%: Acceptable

- Hardness loss <10 Shore A: Acceptable

- No visible cracking, tackiness, or severe softening

When to Perform Testing

Before System Design: Test all candidate seal materials against specified oils during the design phase.

After Oil Change: Any time you change compressor oil brands or types, retest compatibility even if the new oil is “equivalent.”

After Seal Failures: If experiencing unexplained seal failures, test actual field oil samples—oil degradation or contamination can change compatibility over time.

New Supplier Qualification: When qualifying new seal suppliers, verify their materials meet compatibility requirements with your specific oils.

At Bepto, we offer complimentary compatibility testing for customers specifying our rodless cylinders in oil-lubricated systems. Send us your oil sample and application details, and we’ll test it against our seal compounds and provide a detailed compatibility report within 2 weeks.

What Alternative Seal Materials Work Better with Problematic Oils?

When FKM isn’t compatible, other options exist. 🔧

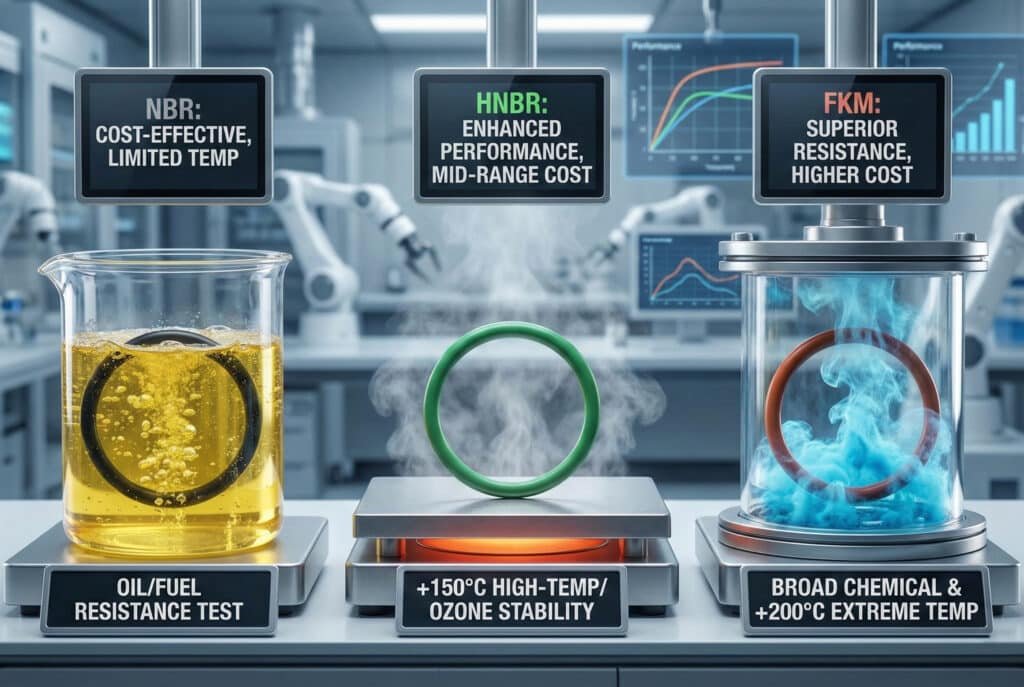

Hydrogenated nitrile (HNBR) offers excellent compatibility with most synthetic oils including PAG and many esters, with typical swell rates of 5-12% across a broad range of oil chemistries, making it the best general-purpose alternative to FKM. Perfluoroelastomer (FFKM) provides universal chemical resistance with <3% swell in virtually all oils but costs 10-15 times more than FKM. Polyurethane seals work well with PAO and mineral oils (3-8% swell) and offer superior wear resistance, though they have limited high-temperature capability (<90°C) compared to FKM’s 200°C rating.

Alternative Material Comparison

| Seal Material | Temp Range | Oil Compatibility | Typical Swell (PAO/PAG/Ester) | Wear Resistance | Relative Cost | Bepto Availability |

|---|---|---|---|---|---|---|

| FKM (Viton) | -20 to 200°C | Excellent/Poor/Poor | 5% / 15% / 25% | Good | $$$ | Standard |

| HNBR | -40 to 150°C | Excellent/Good/Good | 6% / 10% / 12% | Very Good | $$ | Standard |

| FFKM (Kalrez) | -15 to 300°C | Universal | 2% / 3% / 3% | Good | $$$$$ | Custom order |

| Polyurethane | -40 to 90°C | Excellent/Fair/Poor | 4% / 12% / 18% | Outstanding | $$ | Standard |

| NBR (Nitrile) | -40 to 100°C | Excellent/Poor/Poor | 5% / 15% / 20% | Excellent | $ | Standard |

HNBR: The Versatile Solution

Hydrogenated nitrile rubber (HNBR) is created by hydrogenating standard nitrile rubber, which saturates the polymer backbone and dramatically improves heat resistance, ozone resistance, and chemical compatibility. HNBR maintains nitrile’s excellent oil resistance while adding compatibility with more aggressive synthetic oils.

HNBR Advantages:

- Broad oil compatibility (PAO, PAG, many esters)

- Good temperature range (-40 to 150°C)

- Excellent mechanical properties

- Reasonable cost (20-40% more than NBR)

- Available in multiple hardness grades

HNBR Limitations:

- Not suitable for extreme temperatures (>150°C)

- Moderate chemical resistance (not universal like FFKM)

- Slightly lower wear resistance than polyurethane

Material Selection Decision Tree

Choose FKM When:

- Using PAO or mineral oil-based lubricants

- High-temperature operation (>100°C) required

- Excellent chemical resistance needed

- Compatibility confirmed through testing

Choose HNBR When:

- Using PAG or ester-based synthetic oils

- Temperature range -40 to 150°C adequate

- Broad oil compatibility required

- Cost-effective solution needed

Choose FFKM When:

- Universal chemical compatibility required

- Extreme temperatures (>200°C) encountered

- Zero tolerance for seal failure

- Budget allows 10-15x premium over FKM

Choose Polyurethane When:

- Using PAO or mineral oils

- Maximum wear resistance priority

- Operating temperature <90°C

- Abrasive environment present

The Bepto Material Selection Process

When customers contact us about oil-lubricated pneumatic systems, we follow a systematic approach:

- Identify the Oil: Brand, type, and grade of compressor oil

- Determine Operating Conditions: Temperature range, pressure, cycle rate

- Check Our Database: Compare against our 150+ oil compatibility records

- Recommend Materials: Provide 2-3 compatible options with trade-offs

- Offer Testing: Free compatibility testing if oil is not in our database

- Supply Documentation: Provide test data and material certifications

This consultative approach is why our customers achieve 40-60% longer seal life compared to generic OEM replacements—we’re matching seal chemistry to actual operating conditions, not just supplying “standard” seals.

Conclusion

FKM seal compatibility with synthetic compressor oils is chemistry-dependent and must be verified through testing rather than assumed, as incompatible oil-seal combinations cause rapid failure regardless of seal quality or installation practices. 🎯

FAQs About FKM Compatibility with Synthetic Oils

Q: Can I use FKM seals with a new synthetic oil if they worked fine with my old mineral oil?

Not without testing—synthetic oils have completely different chemical structures than mineral oils, and FKM compatibility varies dramatically by synthetic oil type. PAO synthetics are usually compatible (similar to mineral oil), but PAG, ester, and other synthetics may cause severe swelling. Always test compatibility before switching oils in systems with FKM seals, or expect to replace seals with compatible materials after the oil change.

Q: If seals have already swollen from incompatible oil, will they recover if I change to compatible oil?

Partial recovery may occur, but swelling causes permanent damage including compression set, reduced cross-linking, and altered physical properties. Seals that have experienced >15% swell should be replaced even after changing to compatible oil, as they’ve lost 40-60% of their service life potential. Prevention through proper material selection is far more cost-effective than attempting recovery after incompatibility damage.

Q: How often should I retest oil-seal compatibility in an existing system?

Retest whenever you change oil brands or types, even if marketed as “equivalent.” Also test if experiencing unexplained seal failures—oil degradation, contamination, or additive depletion can change compatibility over time. For critical systems, annual oil sampling and compatibility verification provides early warning of problems. At Bepto, we recommend testing every 2-3 years minimum, or immediately after any oil system changes.

Q: Does the seal manufacturer’s material specification guarantee compatibility with my oil?

No—generic specifications like “FKM, 75 Shore A” don’t guarantee compatibility with specific oils because FKM formulations vary significantly between manufacturers. Always request actual compatibility test data for your specific oil, or perform testing yourself. Reputable seal suppliers maintain compatibility databases and can provide test reports. At Bepto, we provide oil compatibility documentation for all seal materials we supply.

Q: Can I mix different seal materials in the same pneumatic system to optimize for different oils?

Generally not recommended—pneumatic systems should use consistent seal materials throughout to simplify maintenance and avoid confusion during repairs. If different system sections use different oils (unusual), then different seal materials may be necessary, but this requires careful documentation and color-coding to prevent installation errors. The better solution is selecting one oil compatible with one seal material for the entire system.

-

Learn more about the chemical structure and industrial applications of fluoroelastomers (FKM). ↩

-

Explore the technical characteristics and benefits of PAO synthetic lubricants in industrial systems. ↩

-

Access the official standard for testing how liquids like oils affect the properties of rubber materials. ↩

-

Understand the Shore A hardness scale used to measure the flexibility and resistance of elastomeric seals. ↩

-

Discover how compression set affects the long-term performance and sealing ability of industrial gaskets. ↩