Introduction

Your high-speed cylinders are destroying themselves from the inside out. Each violent end-of-stroke impact sends shockwaves through your equipment, cracking mounting brackets, loosening fasteners, and gradually destroying precision components. You’ve adjusted cushioning valves, but cylinders still fail prematurely. The problem isn’t adjustment—it’s that you’ve exceeded your cushion’s fundamental energy absorption capacity. 💥

Internal air cushions have finite kinetic energy absorption limits determined by cushion chamber volume, maximum allowable pressure (typically 800-1200 psi), and compression stroke length, with typical limits ranging from 5-50 joules depending on cylinder bore size. Exceeding these limits causes cushion seal failure, structural damage, and violent impacts as the cushion “bottoms out” unable to decelerate the mass, making accurate energy calculation essential for preventing catastrophic failures in high-speed pneumatic systems.

Two weeks ago, I worked with Kevin, a maintenance supervisor at an automotive parts manufacturer in Michigan. His production line used 63mm bore rodless cylinders moving 25kg loads at 2.0 m/s—generating 50 joules of kinetic energy per stroke. His cylinders were failing every 6-8 weeks with blown cushion seals and cracked end caps. His OEM supplier kept sending replacement parts but never addressed the root cause: his application was generating nearly double the cushion’s 28-joule absorption capacity. No amount of adjustment could fix a fundamental physics problem. 🔧

Table of Contents

- What Determines Air Cushion Energy Absorption Capacity?

- How Do You Calculate Kinetic Energy in Pneumatic Systems?

- What Happens When You Exceed Cushion Absorption Limits?

- How Can You Increase Energy Absorption Capacity?

- Conclusion

- FAQs About Air Cushion Energy Limits

What Determines Air Cushion Energy Absorption Capacity?

Understanding the physical factors that limit cushion performance reveals why some applications exceed safe operating boundaries. 📊

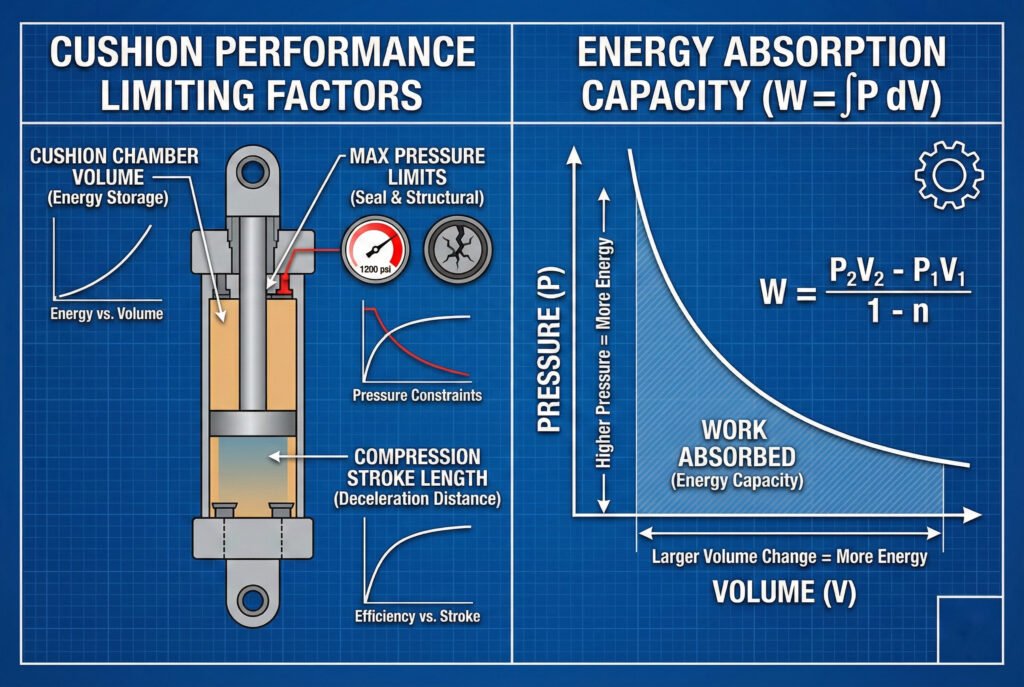

Air cushion energy absorption capacity is determined by three primary factors: cushion chamber volume (larger volume stores more energy), maximum safe pressure (typically limited to 800-1200 psi by seal and structural ratings), and effective compression stroke (distance over which deceleration occurs). The energy absorption formula W = ∫P dV shows that work capacity equals the area under the pressure-volume curve during compression, with practical limits of 0.3-0.8 joules per cm³ of cushion chamber volume.

Cushion Chamber Volume

The trapped air volume directly determines energy storage capacity:

Volume-Based Capacity:

- Small bore (25-40mm): 20-60 cm³ chamber = 6-18 J capacity

- Medium bore (50-80mm): 80-200 cm³ chamber = 24-60 J capacity

- Large bore (100-125mm): 250-500 cm³ chamber = 75-150 J capacity

Each cubic centimeter of cushion chamber can absorb approximately 0.3-0.8 joules depending on compression ratio and maximum pressure limits.

Maximum Pressure Limits

Cushion pressure cannot exceed component ratings:

Pressure Constraints:

- Seal limits: Standard seals rated to 800-1000 psi

- Structural limits: Cylinder body and end caps rated to 1000-1500 psi

- Safety factor: Typically design for 60-70% of maximum rating

- Practical limit: 600-800 psi peak cushion pressure for reliability

Exceeding these pressures causes seal extrusion, end cap failure, or catastrophic structural damage.

Compression Stroke Length

The distance over which compression occurs affects energy absorption:

| Cushion Stroke | Compression Ratio | Energy Efficiency | Typical Application |

|---|---|---|---|

| 10-15mm | Low (2-3:1) | 60-70% | Compact designs |

| 20-30mm | Medium (4-6:1) | 75-85% | Standard cylinders |

| 35-50mm | High (8-12:1) | 85-92% | Heavy-duty systems |

Longer strokes allow more gradual compression, improving energy absorption efficiency and reducing peak pressures.

The Energy Absorption Formula

The work capacity of an air cushion follows thermodynamic principles, specifically the Work-Energy Principle1:

$$

W = \int P \, dV = \frac{P_{2} V_{2} – P_{1} V_{1}}{1 – n}

$$

Where:

- W = Work absorbed (joules)

- P₁, V₁ = Initial pressure and volume

- P₂, V₂ = Final pressure and volume

- n = Polytropic exponent2 (1.2-1.4 for air)

This formula reveals that energy absorption is maximized by large volume changes and high final pressures—but constrained by material limits. ⚙️

How Do You Calculate Kinetic Energy in Pneumatic Systems?

Accurate energy calculation is the foundation for matching cushion capacity to application requirements. 🔬

Calculate kinetic energy using KE = ½mv² where m equals total moving mass (piston + rod + load) in kilograms and v equals velocity at cushion engagement in meters per second. For rodless cylinders, include carriage mass; for horizontal applications, exclude gravity effects; for vertical applications, add potential energy (PE = mgh). Always add 20-30% safety margin to account for pressure spikes, friction variations, and component tolerances.

Basic Kinetic Energy Calculation

The fundamental formula for Kinetic energy3 is straightforward:

$$

KE = \frac{1}{2} m v^{2}

$$

Example 1 – Light Load:

- Moving mass: 8 kg

- Velocity: 1.0 m/s

- KE = ½ × 8 × 1.0² = 4 joules

Example 2 – Medium Load:

- Moving mass: 15 kg

- Velocity: 1.5 m/s

- KE = ½ × 15 × 1.5² = 16.9 joules

Example 3 – Heavy Load:

- Moving mass: 25 kg

- Velocity: 2.0 m/s

- KE = ½ × 25 × 2.0² = 50 joules

Notice that doubling velocity quadruples kinetic energy—velocity has exponential impact on cushion requirements.

Mass Calculation Components

Accurately determining total moving mass is critical:

For Standard Cylinders:

- Piston assembly: 0.5-3 kg (depending on bore)

- Rod: 0.2-1.5 kg (depending on diameter and length)

- External load: Actual payload mass

- Total = Piston + Rod + Load

For Rodless Cylinders:

- Internal piston: 0.3-2 kg

- External carriage: 1-5 kg

- Mounting brackets: 0.5-2 kg

- External load: Actual payload mass

- Total = Piston + Carriage + Brackets + Load

Velocity Determination

Measure or calculate actual velocity at cushion engagement:

Measurement Methods:

- Timing sensors: Measure time over known distance

- Velocity = Distance / Time

- Account for acceleration/deceleration before cushion engagement

- Use velocity at cushion start, not average velocity

Calculation from Air Flow:

- Velocity = (Flow Rate × 60) / (Piston Area × 1000)

- Requires accurate flow measurement

- Less accurate due to compressibility effects

Vertical Application Adjustments

For vertical cylinders, add Gravitational potential energy4:

Downward Motion (Gravity-Assisted):

- Total Energy = KE + PE

- PE = mgh (where h = stroke length in meters, g = 9.81 m/s²)

- Cushion must absorb both kinetic and potential energy

Upward Motion (Gravity-Opposed):

- Gravity assists deceleration

- Net Energy = KE – PE

- Cushion requirements reduced

Kevin’s Michigan Application Analysis:

When we analyzed Kevin’s failing cylinders, the numbers revealed the problem immediately:

- Moving mass: 25 kg (18 kg product + 7 kg carriage)

- Velocity: 2.0 m/s (measured with timing sensors)

- Kinetic energy: ½ × 25 × 2.0² = 50 joules

- Cushion capacity: 63mm bore, 120 cm³ chamber = 28 joules maximum

- Energy excess: 78% over capacity 🚨

No wonder his cylinders were self-destructing. The cushion was absorbing all it could, then the remaining 22 joules were being absorbed by structural components—causing the failures. 💡

What Happens When You Exceed Cushion Absorption Limits?

Understanding failure modes helps diagnose problems and prevent catastrophic damage. ⚠️

Exceeding cushion energy limits causes progressive failure: first, peak pressures exceed seal ratings causing extrusion and blow-by; second, excessive pressure creates structural stress leading to end cap cracks or fastener failure; third, the cushion “bottoms out” with piston contacting end cap at high velocity, causing violent impacts, noise levels exceeding 95 dB, and rapid component destruction. Typical failure progression occurs over 10,000-50,000 cycles depending on severity of overload.

Stage 1: Seal Degradation (0-20% Overload)

Initial symptoms appear in cushion seals:

Early Warning Signs:

- Increased air consumption (0.5-2 SCFM excess)

- Slight hissing noise during cushioning

- Gradual increase in impact harshness

- Seal life reduced from 2-3 years to 6-12 months

Physical Damage:

- Seal extrusion5 into clearance gaps

- Surface cracking from pressure cycling

- Hardening from excessive heat generation

Stage 2: Structural Stress (20-50% Overload)

Excessive pressure damages cylinder structure:

| Component | Failure Mode | Time to Failure | Repair Cost |

|---|---|---|---|

| End cap | Cracking at port threads | 50,000-100,000 cycles | $150-400 |

| Tie rods | Loosening/stretching | 30,000-80,000 cycles | $80-200 |

| Cushion sleeve | Deformation/cracking | 40,000-90,000 cycles | $120-300 |

| Cylinder body | Bulging at end caps | 100,000+ cycles | Replacement |

Stage 3: Catastrophic Failure (>50% Overload)

Severe overload causes rapid destruction:

Failure Characteristics:

- Loud banging noise (>95 dB) at each stroke

- Visible cylinder movement/vibration

- Rapid seal failure (weeks instead of years)

- End cap cracking or complete separation

- Safety hazard from flying components

The “Bottoming Out” Phenomenon

When cushion capacity is completely exceeded:

What Happens:

- Cushion chamber compresses to minimum volume

- Pressure reaches maximum (1000+ psi)

- Piston continues moving (energy not fully absorbed)

- Metal-to-metal impact occurs

- Shock wave propagates through entire system

Consequences:

- Impact forces: 2000-5000N (vs. 50-200N with proper cushioning)

- Noise levels: 90-100 dB

- Equipment damage: Loosened fasteners, cracked welds, bearing damage

- Positioning errors: ±1-3mm due to bounce and vibration

Real-World Failure Timeline

Kevin’s Michigan facility provided clear documentation:

Failure Progression (50J energy, 28J capacity):

- Week 1-2: Slight increase in noise, no visible damage

- Week 3-4: Noticeable hissing, air consumption up 15%

- Week 5-6: Loud impacts, visible cylinder vibration

- Week 7-8: Cushion seal failure, end cap cracks visible

- Week 8: Complete failure requiring cylinder replacement

This predictable progression occurs because each cycle inflicts cumulative damage that accelerates failure. 📉

How Can You Increase Energy Absorption Capacity?

When calculations reveal insufficient cushion capacity, several solutions can restore safe operation. 🔧

Increase energy absorption capacity through four primary methods: enlarge cushion chamber volume (most effective, requires cylinder redesign), extend cushion stroke length (improves efficiency 15-25%), reduce approach velocity (cutting speed 25% reduces energy 44%), or add external shock absorbers (handles 20-100+ joules). For existing cylinders, velocity reduction and external absorbers provide practical retrofits, while new installations should specify adequate internal cushioning from the start.

Solution 1: Increase Cushion Chamber Volume

The most effective but most involved solution:

Implementation:

- Requires cylinder redesign or replacement

- Increase chamber volume 50-100% for proportional capacity increase

- Bepto offers enhanced cushioning options with 15-20% chamber volumes

- Cost: $200-600 depending on cylinder size

Effectiveness:

- Directly proportional: 2x volume = 2x capacity

- No operational changes required

- Permanent solution

Solution 2: Extend Cushion Stroke Length

Improve compression efficiency:

Modifications:

- Extend cushion spear/sleeve by 10-20mm

- Increase engagement distance

- Improves energy absorption 15-25%

- Cost: $80-200 for custom cushion components

Limitations:

- Requires available stroke length

- Diminishing returns beyond 40-50mm

- May affect cycle time slightly

Solution 3: Reduce Operating Velocity

Most immediate and cost-effective solution:

Velocity Reduction Impact:

- 25% speed reduction = 44% energy reduction

- 50% speed reduction = 75% energy reduction

- Achieved through flow control adjustment

- Cost: $0 (adjustment only)

Trade-offs:

- Increases cycle time proportionally

- May reduce production throughput

- Temporary solution until proper cushioning installed

Solution 4: Add External Shock Absorbers

Handle excess energy externally:

| Shock Absorber Type | Energy Capacity | Cost | Best Application |

|---|---|---|---|

| Hydraulic adjustable | 20-100 J | $150-400 | High-energy systems |

| Self-compensating | 10-50 J | $80-200 | Variable loads |

| Elastomer bumpers | 5-20 J | $20-60 | Light overload |

Installation Considerations:

- Requires mounting space at stroke ends

- Adds mechanical complexity

- Maintenance item (rebuild every 1-2 years)

- Excellent for retrofit applications

Kevin’s Michigan Solution

We implemented a comprehensive fix for Kevin’s overloaded cylinders:

Immediate Actions (Week 1):

- Reduced velocity from 2.0 m/s to 1.5 m/s

- Energy reduced from 50J to 28J (within capacity)

- Production throughput reduced 15% temporarily

Permanent Solution (Week 4):

- Replaced cylinders with Bepto enhanced cushioning models

- Chamber volume increased from 120 cm³ to 200 cm³

- Energy capacity increased from 28J to 55J

- Restored full 2.0 m/s velocity

Results After 6 Months:

- Zero cushion failures (vs. 6 failures in previous 6 months)

- Cylinder life projected 4-5 years (vs. 2-3 months)

- Noise reduced from 94 dB to 72 dB

- Equipment vibration reduced 80%

- Annual savings: $32,000 in replacement parts and downtime 💰

The key was matching cushion capacity to actual energy requirements through proper calculation and appropriate component selection.

Conclusion

Calculating kinetic energy absorption limits isn’t optional engineering—it’s essential for preventing catastrophic failures in high-speed pneumatic systems. By accurately determining kinetic energy using ½mv², comparing it to cushion capacity based on chamber volume and pressure limits, and implementing appropriate solutions when limits are exceeded, you can eliminate destructive impacts and achieve reliable long-term operation. At Bepto, we engineer cushioning systems with adequate capacity for demanding applications and provide the technical support to ensure your systems operate within safe boundaries.

FAQs About Air Cushion Energy Limits

How do you calculate the maximum energy absorption capacity of an existing cylinder?

Calculate maximum cushion capacity using the formula: Energy (J) = 0.5 × Chamber Volume (cm³) × (P_max – P_system) / 100, where P_max is maximum safe pressure (typically 800 psi) and P_system is operating pressure. For a 63mm bore cylinder with 120 cm³ cushion chamber at 100 psi system pressure: Energy = 0.5 × 120 × (800-100)/100 = 42 joules maximum. This simplified formula provides conservative estimates suitable for safety verification. Contact Bepto for detailed analysis of your specific cylinder model.

What’s the typical energy absorption capacity per cylinder bore size?

Energy absorption capacity scales roughly with bore area: 40mm bore = 8-15J, 63mm bore = 20-35J, 80mm bore = 35-60J, and 100mm bore = 60-100J, depending on cushion design quality. These ranges assume standard cushioning with 8-12% chamber volume and 600-800 psi peak pressure limits. Enhanced cushioning designs with larger chambers can increase capacity 50-100%. Always verify actual capacity through calculation or manufacturer specifications rather than assuming based on bore size alone.

Can you retrofit existing cylinders to handle higher energy loads?

Retrofitting is possible but limited: you can extend cushion stroke length (15-25% capacity increase) or add external shock absorbers (handle 20-100+ joules), but significantly increasing internal cushion capacity requires cylinder replacement. For applications exceeding capacity by 20-40%, external shock absorbers provide cost-effective solutions at $150-400 per cylinder. For larger overloads or new installations, specify cylinders with adequate internal cushioning from the start—Bepto offers enhanced cushioning options at modest cost premiums.

What happens if you operate at exactly the calculated energy limit?

Operating at 100% of calculated capacity leaves no safety margin for variations in mass, velocity, pressure, or component condition, leading to premature failures within 6-12 months in most applications. Best practice: design for 60-70% of maximum capacity under normal conditions, providing 30-40% safety margin for load variations, pressure fluctuations, seal wear, and unexpected conditions. This margin extends component life 3-5x and prevents catastrophic failures from minor operating variations.

How does temperature affect cushion energy absorption capacity?

Higher temperatures reduce air density and viscosity, decreasing energy absorption capacity by 10-20% at 60-80°C compared to 20°C, while also accelerating seal degradation that further reduces cushion effectiveness. Cold temperatures (<0°C) increase air density slightly but cause seal hardening that impairs cushioning performance. For applications with wide temperature ranges, calculate capacity at highest expected operating temperature and verify seal material compatibility. Bepto offers temperature-compensated cushioning designs for extreme environment applications.

-

Review the principle stating that work done on a system equals the change in its energy. ↩

-

Learn about the thermodynamic process that describes expansion and compression of gases where $PV^n = C$. ↩

-

Understand the energy that an object possesses due to its motion. ↩

-

Explore the energy an object possesses because of its position in a gravitational field. ↩

-

Read about the failure mode where seal material is forced into the clearance gap under high pressure. ↩