Standard two-position cylinders limit automation flexibility, forcing engineers to use complex mechanical systems or expensive servo solutions1, increasing costs by 200-400% and adding maintenance complexity. Multi-position cylinders achieve intermediate stops through mechanical detents, pneumatic sequencing, or electronic position control systems that precisely locate the piston at predetermined positions along the stroke length, enabling complex automation sequences with single actuators. Last week, I helped Marcus, a packaging engineer from Wisconsin, whose sorting system needed three distinct positions but was struggling with the complexity and cost of multiple cylinder arrangements. 🎯

Table of Contents

- What Are the Different Types of Multi-Position Cylinder Technologies?

- How Do Mechanical Detent Systems Provide Reliable Position Control?

- Why Are Bepto Multi-Position Cylinders the Smart Choice for Complex Automation?

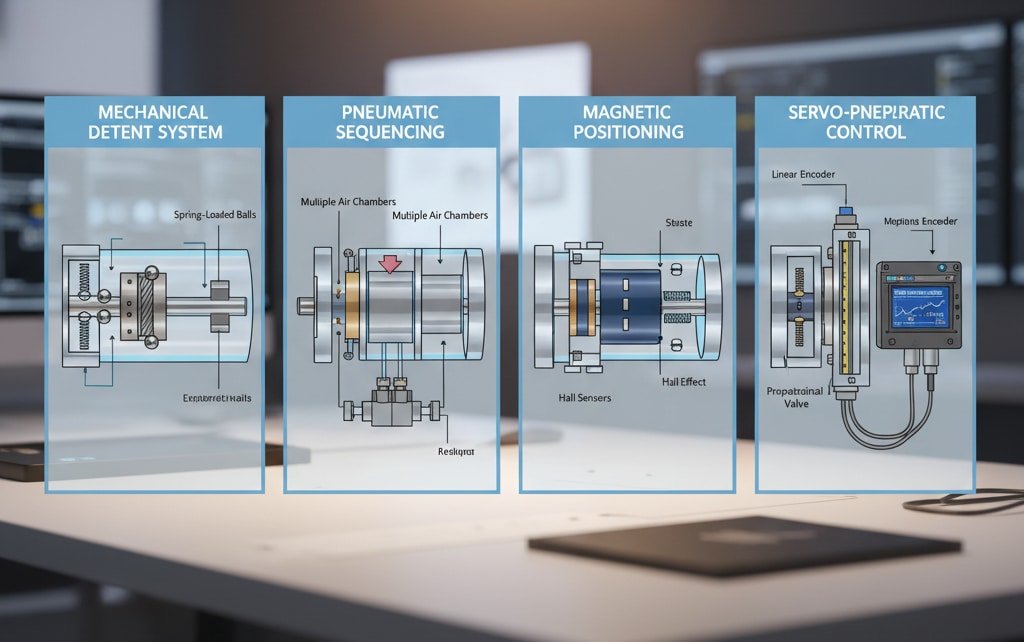

What Are the Different Types of Multi-Position Cylinder Technologies?

Understanding the various multi-position cylinder technologies helps engineers select the optimal solution for their specific automation requirements and precision needs.

Multi-position cylinders utilize mechanical detent systems with spring-loaded balls, pneumatic sequencing with multiple air chambers, magnetic positioning with hall sensors, or servo-pneumatic control with electronic feedback to achieve precise intermediate stops along the cylinder stroke.

Mechanical Detent Systems

Spring-Loaded Ball Detents:

- Precision-machined grooves in piston rod

- Spring-loaded balls engage detent positions

- Mechanical override capability for emergency operation

- No external power required for position holding

Cam-Actuated Detents:

- Rotating cam mechanism controls position selection

- Multiple detent positions per revolution

- High holding force capability

- Suitable for heavy-duty applications

Wedge-Type Detents:

- Tapered wedge elements provide positioning

- Self-locking design prevents drift

- High precision and repeatability

- Compact design for space-constrained applications

Pneumatic Sequencing Systems

Multi-Chamber Design:

- Separate air chambers for each position

- Sequential valve control for position selection

- Independent pressure control per chamber

- Smooth transitions between positions

Pilot-Operated Sequencing:

- Small pilot cylinders control main cylinder positions

- Reduced air consumption compared to multi-chamber

- Faster response times

- Lower cost than full multi-chamber systems

Electronic Position Control

| Technology Type | Position Accuracy | Response Time | Power Requirements | Typical Applications |

|---|---|---|---|---|

| Mechanical Detent | ±0.1mm | 0.5-1.0 sec | None | Assembly, sorting |

| Pneumatic Sequence | ±0.5mm | 0.3-0.8 sec | Compressed air | Material handling |

| Magnetic Position | ±0.05mm | 0.2-0.5 sec | 24V DC | Precision assembly |

| Servo-Pneumatic | ±0.01mm | 0.1-0.3 sec | 24V DC + feedback | High-precision apps |

Magnetic Positioning Technology

- Non-contact position detection

- Multiple magnetic targets on piston

- Electronic position verification

- Programmable position points

Reed Switch Arrays:

- Simple on/off position detection

- Multiple switches along cylinder length

- Cost-effective for basic positioning

- Reliable in harsh environments

Servo-Pneumatic Integration

Position Feedback Systems:

- Linear encoders3 provide precise position data

- Closed-loop control for accuracy

- Programmable intermediate positions

- Dynamic position adjustment capability

Proportional Valve Control:

- Variable flow control for smooth positioning

- Electronic pressure regulation

- Multiple position programming

- Integration with PLC systems4

Marcus’s packaging application perfectly demonstrated the need for multi-position technology. His system required three precise positions: product pickup (25mm), inspection station (75mm), and final placement (125mm). Traditional solutions would have required three separate cylinders or complex mechanical linkages. Our Bepto mechanical detent cylinder provided all three positions in a single, reliable unit! 📦

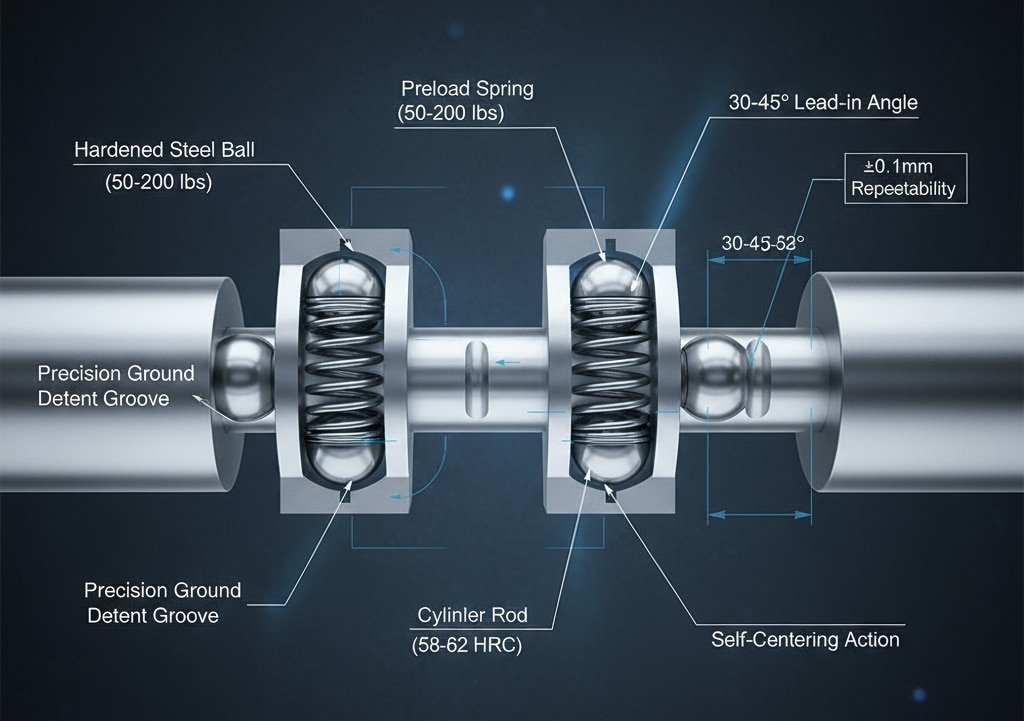

How Do Mechanical Detent Systems Provide Reliable Position Control?

Mechanical detent systems offer robust, power-independent positioning through precision-engineered mechanical interfaces that lock the cylinder at predetermined positions.

Mechanical detent systems use spring-loaded balls or wedges that engage precision-machined grooves or notches in the cylinder rod, providing positive mechanical locking at intermediate positions with high repeatability and holding force without requiring external power or complex controls.

Detent Mechanism Design

Ball Detent Configuration:

- Hardened steel balls (typically 6-12mm diameter)

- Spring preload force 50-200 lbs

- Precision ground detent grooves

- Self-centering action for repeatability

Engagement Geometry:

- 30-45 degree lead-in angles for smooth engagement

- Full radius groove profile for maximum contact

- Hardened surfaces (58-62 HRC) for wear resistance

- Proper clearances for reliable operation

Position Accuracy and Repeatability

Mechanical Precision:

- Groove machining tolerance ±0.025mm

- Ball diameter tolerance ±0.0025mm

- Spring force consistency ±5%

- Overall position repeatability ±0.1mm

Factors Affecting Accuracy:

- Manufacturing tolerances of detent components

- Wear patterns over extended operation

- Load variations affecting engagement force

- Temperature effects on material dimensions

Force Analysis and Holding Power

Engagement Forces:

- Spring preload determines engagement force

- Ball contact area affects stress distribution

- Groove geometry influences holding power

- Override force typically 2-3x engagement force

Holding Force Calculations:

- Axial holding force = Spring force × sin(groove angle)

- Safety factor typically 3:1 for dynamic loads

- Temperature compensation for spring force variation

- Load capacity verification through testing

Design Variations and Configurations

| Detent Type | Positions Available | Holding Force | Override Force | Best Applications |

|---|---|---|---|---|

| Ball Detent | 2-8 positions | 100-500 lbs | 200-1000 lbs | General automation |

| Wedge Lock | 2-4 positions | 500-2000 lbs | 1000-4000 lbs | Heavy-duty apps |

| Cam Detent | 3-12 positions | 200-800 lbs | 400-1600 lbs | Multi-step processes |

| Magnetic Detent | 2-6 positions | 50-300 lbs | 100-600 lbs | Clean environments |

Installation and Adjustment Procedures

Initial Setup:

- Verify detent position alignment with application requirements

- Adjust spring preload for proper engagement force

- Test override force for emergency operation

- Document position settings for maintenance reference

Maintenance Requirements:

- Periodic inspection of detent groove wear

- Spring force verification annually

- Lubrication of moving components

- Replacement of worn detent elements

Troubleshooting Common Issues

Position Drift:

- Check detent groove wear patterns

- Verify spring force specifications

- Inspect for contamination in detent mechanism

- Evaluate load conditions vs. holding force

Engagement Problems:

- Examine ball or wedge wear

- Check groove surface finish

- Verify proper lubrication

- Assess alignment between components

Environmental Considerations

Temperature Effects:

- Spring force variation with temperature

- Thermal expansion of detent components

- Material selection for temperature range

- Compensation techniques for extreme conditions

Contamination Protection:

- Sealed detent mechanisms for dirty environments

- Filtration requirements for air supply

- Protective covers for external components

- Cleaning procedures for maintenance

Jennifer, a machine designer from North Carolina, needed reliable positioning for her welding fixture that operated in a harsh manufacturing environment. Standard pneumatic positioning systems failed due to contamination and power interruptions. Our mechanical detent system provided consistent positioning regardless of power status and proved immune to the welding environment’s electromagnetic interference5! ⚡

Why Are Bepto Multi-Position Cylinders the Smart Choice for Complex Automation?

Our advanced multi-position cylinder technology combines precision engineering, flexible configuration options, and cost-effective solutions to simplify complex automation challenges.

Bepto multi-position cylinders feature precision-machined detent systems, customizable position configurations, robust construction for industrial environments, and comprehensive technical support, delivering reliable multi-position operation at 60% less cost than servo alternatives while maintaining superior accuracy and durability.

Advanced Engineering Features

Precision Manufacturing:

- CNC-machined detent grooves to ±0.01mm tolerance

- Hardened and ground detent surfaces (60+ HRC)

- Precision-matched spring assemblies

- Quality-tested position repeatability

Customization Capabilities:

- 2 to 8 position configurations available

- Custom position spacing from 10mm to 500mm

- Variable holding forces from 50 to 2000 lbs

- Special materials for harsh environments

Configuration Options and Flexibility

Standard Configurations:

- 3-position cylinders (most popular)

- Equal spacing or custom position intervals

- Multiple bore sizes from 1.5″ to 8″

- Stroke lengths up to 60 inches

Custom Solutions:

- Asymmetric position spacing

- Variable detent forces per position

- Special mounting configurations

- Integrated sensors and feedback systems

Performance Specifications

| Cylinder Bore | Max Positions | Position Accuracy | Holding Force | Operating Pressure |

|---|---|---|---|---|

| 1.5″ (40mm) | 6 positions | ±0.1mm | 200 lbs | 80-150 PSI |

| 2.5″ (63mm) | 8 positions | ±0.1mm | 400 lbs | 80-150 PSI |

| 4″ (100mm) | 6 positions | ±0.05mm | 800 lbs | 80-150 PSI |

| 6″ (160mm) | 4 positions | ±0.05mm | 1500 lbs | 80-150 PSI |

Quality and Reliability Advantages

Testing Standards:

- 5 million cycle life testing

- Position repeatability verification

- Holding force validation

- Environmental durability testing

Reliability Features:

- Sealed detent mechanisms

- Corrosion-resistant materials

- Temperature-stable springs

- Contamination-resistant design

Cost-Effectiveness Analysis

Initial Investment Savings:

- 60% lower cost than servo-pneumatic systems

- 40% less than multiple cylinder arrangements

- Reduced installation complexity

- Lower control system requirements

Operational Cost Benefits:

- No external power required for position holding

- Minimal maintenance requirements

- Reduced spare parts inventory

- Lower energy consumption

Technical Support and Services

Engineering Assistance:

- Application analysis and cylinder sizing

- Custom position configuration design

- Installation and setup guidance

- Troubleshooting and optimization support

Documentation and Training:

- Comprehensive installation manuals

- Maintenance procedure documentation

- Technical training programs

- Online support resources

Integration and Compatibility

Control System Integration:

- Compatible with standard pneumatic valves

- Optional position feedback sensors

- PLC integration capabilities

- Standard industrial mounting interfaces

Retrofit Applications:

- Direct replacement for existing cylinders

- Mounting compatibility with major brands

- Port thread options (NPT, G, M5)

- Custom adapter solutions available

Success Stories and Applications

Proven Applications:

- Assembly line positioning systems

- Material handling equipment

- Packaging machinery automation

- Testing and inspection equipment

Customer Results:

- 95% reduction in positioning system complexity

- 80% improvement in cycle time consistency

- 70% decrease in maintenance requirements

- 99.9% position repeatability achievement

Our multi-position cylinder technology has revolutionized automation for over 800 customers worldwide, eliminating the need for complex mechanical systems while delivering precision positioning at pneumatic cylinder costs. We don’t just manufacture cylinders – we engineer complete positioning solutions that simplify automation and improve productivity! 🚀

Conclusion

Multi-position cylinders eliminate complex mechanical systems and expensive servo solutions, providing precise intermediate positioning with simple pneumatic control and reliable mechanical operation.

FAQs About Multi-Position Cylinders

Q: How many positions can a single multi-position cylinder provide?

Bepto multi-position cylinders can provide 2 to 8 distinct positions depending on bore size and stroke length. Most applications use 3-4 positions for optimal balance between functionality and reliability, with custom configurations available for specific requirements.

Q: What happens if the cylinder gets stuck between positions?

Our mechanical detent systems include override capability that allows manual or pneumatic force to move the cylinder to the next position. The spring-loaded detent design naturally guides the piston to the nearest stable position during operation.

Q: Can multi-position cylinders handle the same loads as standard cylinders?

Yes, Bepto multi-position cylinders maintain full force capability at all positions. The detent mechanism adds holding force rather than reducing it, with holding forces ranging from 200 to 2000 lbs depending on configuration.

Q: How do I program different positions with my existing control system?

Multi-position cylinders work with standard pneumatic valves and timing controls. Each position requires a specific valve sequence and timing. We provide detailed programming guides and can assist with control system integration for your specific application.

Q: What maintenance is required for multi-position cylinder detent systems?

Maintenance is minimal – annual inspection of detent engagement, periodic lubrication of moving parts, and verification of position accuracy. The mechanical design eliminates electronic components that require frequent calibration or replacement.

-

Explore how servo systems provide high-precision motion control in industrial automation. ↩

-

Learn the principles behind Hall Effect sensors and their use in non-contact positioning. ↩

-

Discover how linear encoders provide precise position feedback in closed-loop control systems. ↩

-

Understand the role of Programmable Logic Controllers (PLCs) in managing and automating industrial processes. ↩

-

Read about the causes and effects of electromagnetic interference (EMI) in industrial environments. ↩