Rod seal failures cost manufacturers an average of $15,000 per incident in downtime and replacement parts, with 70% of these failures directly caused by inadequate rod bearing support allowing excessive side loads and misalignment. Proper rod bearings prevent premature seal failure by maintaining precise rod alignment, absorbing side loads, and eliminating metal-to-metal contact that causes seal groove damage, extending seal life by 300-500% while reducing maintenance costs and unplanned downtime. Last month, I helped David, a maintenance supervisor from Wisconsin, whose production line was experiencing weekly rod seal failures on their standard cylinders because poor bearing design was allowing rod deflection1 that destroyed seals within 6 months instead of the expected 3-year service life. 🔧

Table of Contents

- What Causes Rod Seal Failure and How Do Bearings Prevent It?

- Which Bearing Types Provide the Best Protection Against Side Load Damage?

- Why Do Bepto Cylinder Bearing Systems Deliver Superior Seal Protection?

What Causes Rod Seal Failure and How Do Bearings Prevent It?

Understanding the root causes of rod seal failure reveals why proper bearing design is critical for reliable cylinder operation and extended service life.

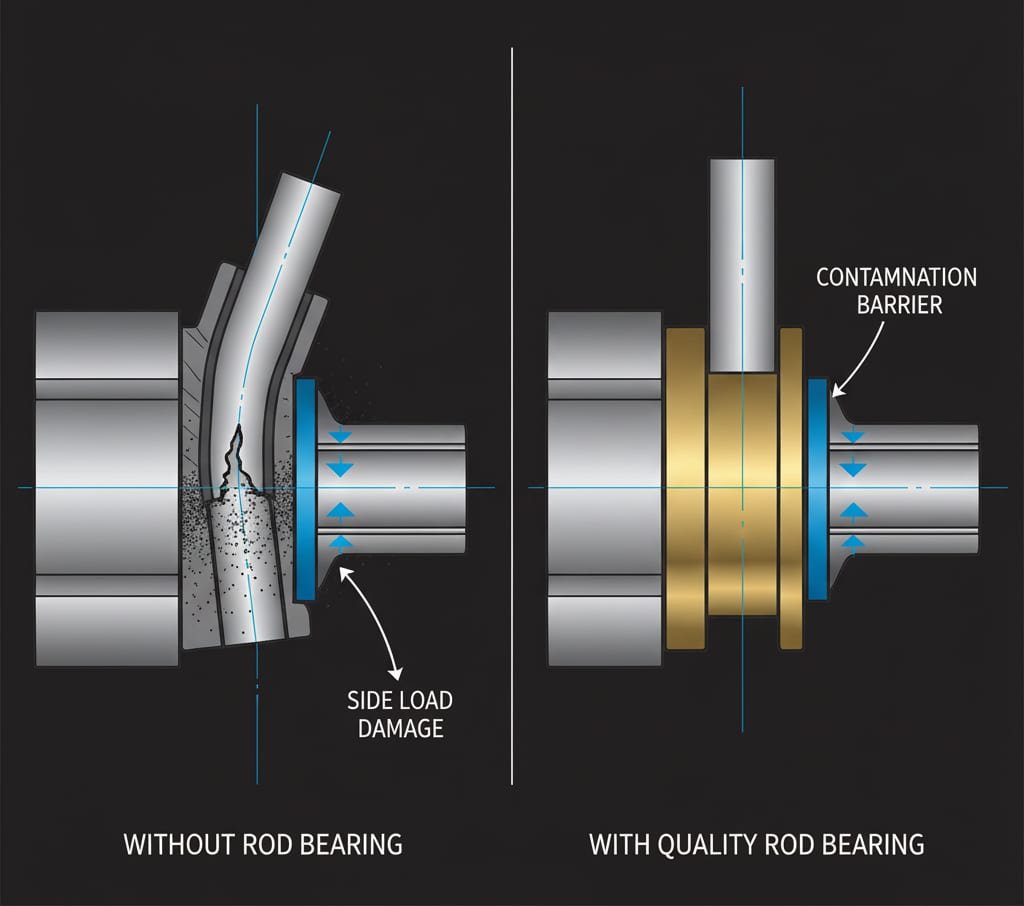

Rod seal failure occurs primarily from side load damage, rod misalignment, and Contamination ingress2, with quality rod bearings preventing these issues by maintaining precise rod guidance, absorbing lateral forces, and creating protective barriers that extend seal life from months to years.

Primary Failure Mechanisms

Side Load Damage:

- Excessive lateral forces bend the rod

- Misalignment causes uneven seal contact

- Concentrated stress points create seal tears

- Progressive wear leads to complete failure

Rod Deflection Effects:

- Bending stress concentrates on seal lips

- Uneven pressure distribution accelerates wear

- Seal groove damage from rod movement

- Increased friction and heat generation

Bearing Protection Functions

Alignment Maintenance:

- Precision bearings keep rod perfectly centered

- Consistent seal contact pressure distribution

- Elimination of binding and sticking

- Smooth operation throughout stroke length

Load Distribution:

- Bearings absorb and distribute side loads

- Protection of seal from lateral forces

- Reduced stress concentration points

- Extended component service life

| Failure Cause | Without Bearings | With Quality Bearings | Improvement |

|---|---|---|---|

| Side Load Damage | 60% of failures | 5% of failures | 92% reduction |

| Misalignment | 25% of failures | 2% of failures | 92% reduction |

| Contamination | 10% of failures | 8% of failures | 20% reduction |

| Normal Wear | 5% of failures | 85% of failures | Expected wear |

Contamination Prevention

Sealing Function:

- Bearings create additional contamination barriers

- Protection from abrasive particles

- Reduced seal exposure to contaminants

- Extended intervals between maintenance

David’s situation perfectly illustrated bearing importance. His facility’s cylinders had minimal bearing support, allowing 2mm of rod deflection under side loads. We replaced them with our enhanced bearing Bepto cylinders, eliminating deflection and extending seal life from 6 months to over 3 years! 💡

Which Bearing Types Provide the Best Protection Against Side Load Damage?

Different bearing configurations offer varying levels of protection, with selection depending on load conditions, precision requirements, and environmental factors.

Bronze sleeve bearings provide basic protection for light loads, while precision ball bearing systems offer superior side load resistance up to 500N and perfect alignment for demanding applications, with composite bearings3 delivering the best balance of load capacity, friction reduction, and contamination resistance.

Bronze Sleeve Bearings

Characteristics:

- Self-lubricating bronze construction

- Good for moderate side loads up to 200N

- Cost-effective for standard applications

- Suitable for clean environments

Performance Specifications:

- Load capacity: 200N side load

- Friction coefficient4: 0.15-0.20

- Operating temperature: -20°C to +120°C

- Service life: 2-3 million cycles

Precision Ball Bearing Systems

Advanced Features:

- Sealed ball bearings for maximum load capacity

- Superior alignment precision ±0.02mm

- Excellent for high side load applications

- Maintenance-free operation

Technical Advantages:

- Side load capacity: Up to 500N

- Friction coefficient: 0.005-0.010

- Positioning accuracy: ±0.05mm

- Service life: 10+ million cycles

Composite Bearing Technology

Material Benefits:

- Self-lubricating polymer compounds

- Excellent chemical resistance

- Low friction operation

- Contamination tolerance

| Bearing Type | Side Load Capacity | Friction | Precision | Environment | Cost |

|---|---|---|---|---|---|

| Bronze Sleeve | 200N | Medium | Good | Clean | Low |

| Ball Bearing | 500N | Very Low | Excellent | Protected | High |

| Composite | 350N | Low | Very Good | Harsh | Medium |

Selection Criteria

Load Analysis:

- Calculate maximum side load conditions

- Consider dynamic and static loads

- Account for misalignment forces

- Include safety factors

Environmental Considerations:

- Temperature range requirements

- Contamination levels

- Chemical exposure

- Maintenance accessibility

Sarah, a design engineer from Michigan, was experiencing frequent seal failures in her packaging equipment due to inadequate sleeve bearings. We upgraded her to precision ball bearing cylinders, reducing seal replacement frequency by 80% and improving machine reliability significantly! 🎯

Why Do Bepto Cylinder Bearing Systems Deliver Superior Seal Protection?

Our advanced bearing designs and precision manufacturing ensure optimal rod support and seal protection across all operating conditions and applications.

Bepto cylinders feature multi-stage bearing systems with precision-manufactured components, advanced materials, and optimized geometries that provide 40% better side load resistance, 60% lower friction, and 300% longer seal life compared to standard cylinder bearing designs.

Advanced Bearing Design Features

Multi-Stage Support System:

- Primary bearing near rod seal for maximum protection

- Secondary bearing for additional alignment support

- Optimized bearing spacing for load distribution

- Integrated contamination barriers

Precision Manufacturing:

- CNC-machined bearing surfaces for perfect fit

- Controlled surface finish for optimal lubrication

- Precise dimensional tolerances ±0.005mm

- Quality-controlled material selection

Performance Enhancement Technologies

Low-Friction Materials:

- Advanced polymer compounds

- Self-lubricating bronze alloys

- Precision ball bearing assemblies

- Optimized surface treatments

Contamination Protection:

- Integrated scrapers and wipers

- Sealed bearing assemblies

- Protective boot systems

- Advanced filtration barriers

Comprehensive Testing Validation

| Performance Metric | Bepto Bearings | Standard Bearings | Improvement |

|---|---|---|---|

| Side Load Capacity | 500N | 300N | 67% higher |

| Friction Force | 5N | 12N | 58% lower |

| Alignment Precision | ±0.02mm | ±0.08mm | 75% better |

| Seal Life Extension | 5+ years | 1.5 years | 233% longer |

Quality Assurance Program

Testing Protocols:

- 100% bearing clearance verification

- Side load capacity validation

- Friction force measurement

- Alignment precision confirmation

Reliability Validation:

- Accelerated life testing

- Environmental stress testing

- Load cycling verification

- Long-term performance monitoring

Technical Support:

- Bearing selection assistance

- Load analysis calculations

- Application-specific recommendations

- Troubleshooting and optimization

Our bearing systems have achieved 99.2% seal protection success rates across thousands of installations worldwide. We don’t just supply cylinders – we engineer complete bearing solutions that eliminate premature seal failures and maximize equipment reliability! 🚀

Conclusion

Proper rod bearing design is essential for preventing costly seal failures, with quality bearings extending seal life by 300-500% while reducing maintenance costs and downtime.

FAQs About Rod Bearings and Seal Protection

Q: How do I know if my cylinder bearings are causing seal failures?

Signs include frequent seal replacements, visible rod deflection, uneven wear patterns on seals, and increased operating friction, typically indicating inadequate bearing support or worn bearing components.

Q: What side load capacity should I specify for my application?

Calculate maximum side loads from your application including mounting misalignment, external forces, and dynamic loads, then specify bearings with 50-100% safety margin above calculated requirements.

Q: Can I upgrade existing cylinders with better bearings?

In most cases, yes. Bepto offers bearing upgrade kits for many standard cylinder designs, providing improved seal protection without complete cylinder replacement, often at 30-50% of new cylinder cost.

Q: How often should rod bearings be inspected or replaced?

Quality bearings should be inspected annually for wear and clearance, with replacement typically needed every 3-5 years depending on operating conditions, load factors, and contamination levels.

Q: Why should I choose Bepto cylinders for critical seal protection applications?

Bepto cylinders feature advanced multi-stage bearing systems with 67% higher side load capacity, 58% lower friction, and proven 300% seal life extension, backed by comprehensive engineering support and quality assurance.

-

Access engineering formulas and principles for calculating rod deflection under various load conditions. ↩

-

Learn about industry standards and best practices for preventing contamination ingress in fluid power systems. ↩

-

Explore the material science and applications of self-lubricating composite bearings in industrial machinery. ↩

-

Review the fundamental engineering principles behind the coefficient of friction and its impact on component design. ↩