Ever watched your production costs skyrocket because of unexpected equipment failure? I have. The culprit often lurks in the invisible world of surface interactions. When two surfaces meet in your pneumatic systems, friction becomes your biggest enemy or your greatest ally.

Tribology1—the science of friction, wear, and lubrication—directly impacts pneumatic system performance by affecting energy efficiency, component lifespan, and operational reliability. Understanding these fundamental principles can reduce maintenance costs by up to 30% and extend equipment life by years.

Last month, I visited a manufacturing plant in Boston where their rodless cylinders were failing every few weeks. The maintenance team was puzzled until we examined the tribological factors. By the end of this article, you’ll understand how to apply tribology fundamentals to solve similar issues in your own systems.

Table of Contents

- Coulomb Friction Verification: How Can You Test This Law in Real Applications?

- Surface Roughness Grades: Which Standards Matter for Pneumatic Components?

- Boundary Lubrication: Why Is This Mechanism Critical for Pneumatic Systems?

- Conclusion

- FAQs About Tribology in Pneumatic Systems

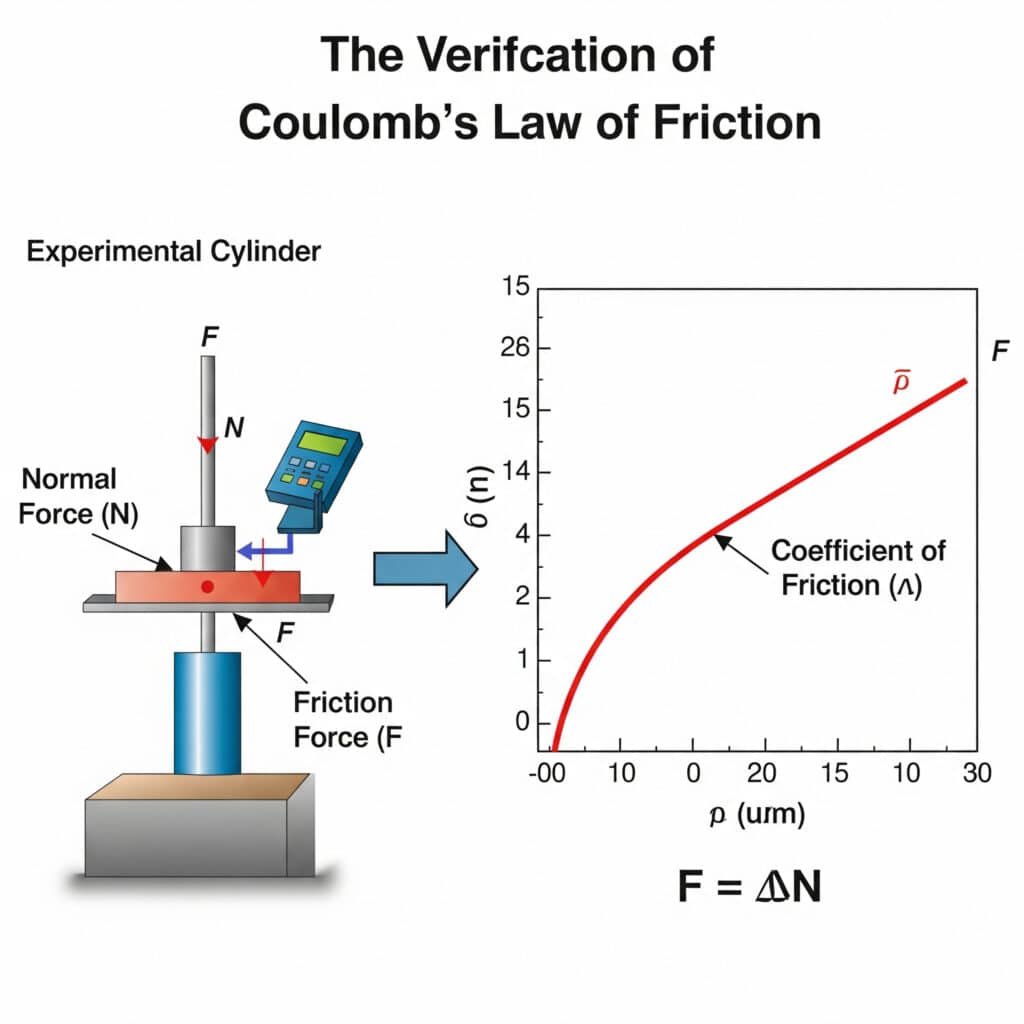

Coulomb Friction Verification: How Can You Test This Law in Real Applications?

The foundation of modern friction analysis begins with Coulomb’s Law, but how do we verify its applicability in real-world pneumatic systems? This question has significant implications for predicting component behavior.

Coulomb’s Friction Law2 can be verified in pneumatic applications through controlled load testing where friction force (F) equals the coefficient of friction (μ) multiplied by the normal force (N). This relationship remains linear until material deformation or lubrication breakdown occurs, making it essential for predicting rodless cylinder performance.

I remember working with an automotive parts manufacturer in Michigan who couldn’t understand why their guided rodless cylinders performed inconsistently. We set up a simple Coulomb verification test and discovered that their assumed friction coefficient was off by nearly 40%. This single insight transformed their maintenance approach.

Practical Verification Methods

Testing Coulomb’s Law doesn’t require complex equipment—just a methodical approach:

- Static Testing: Measuring the force required to initiate movement

- Dynamic Testing: Measuring the force required to maintain constant velocity

- Variable Load Testing: Confirming linearity across different normal forces

Factors Affecting Friction Coefficient Accuracy

| Factor | Impact on Friction Coefficient | Mitigation Strategy |

|---|---|---|

| Surface Cleanliness | Up to 200% variation | Standardized cleaning protocol |

| Temperature | 5-15% change per 10°C | Temperature-controlled testing |

| Humidity | 3-8% variation in non-sealed systems | Environmental control during testing |

| Break-in Period | Up to 30% reduction after initial use | Pre-condition components before testing |

| Material Pairing | Fundamental determinant | Document exact material specifications |

Common Misconceptions in Friction Testing

When verifying Coulomb’s Law in pneumatic systems, several misconceptions can lead to errors:

Assumption of Constant Friction Coefficient

Many engineers assume the friction coefficient remains constant across all conditions. In reality, it varies with:

- Velocity: Static coefficient differs from dynamic coefficient

- Temperature: Most materials show temperature-dependent friction

- Contact Time: Extended contact can increase static friction

- Surface Condition: Wear changes friction characteristics over time

Overlooking Stick-Slip Phenomena

The transition between static and dynamic friction often creates a jerky motion called stick-slip3:

- Component is stationary (static friction applies)

- Force increases until movement begins

- Friction suddenly drops to dynamic level

- Component accelerates

- Force decreases, component slows

- Cycle repeats

This phenomenon is particularly relevant for rodless pneumatic cylinders operating at low speeds.

Surface Roughness Grades: Which Standards Matter for Pneumatic Components?

Surface roughness significantly impacts pneumatic component performance, but which measurement standards should you focus on? The answer varies by application and component type.

Surface roughness grades for pneumatic components typically range from Ra 0.1 to 1.6 μm4, with critical sealing surfaces requiring smoother finishes (0.1-0.4 μm) and bearing surfaces needing specific roughness profiles (0.4-0.8 μm) to retain lubricant while minimizing friction and wear.

During a troubleshooting visit to a food processing plant in Wisconsin, I discovered their rodless cylinder failures stemmed from incorrect surface specifications. Their maintenance team had replaced seals with standard components, but the surface roughness mismatch caused accelerated wear. Understanding roughness standards would have prevented this costly mistake.

Critical Surface Roughness Parameters

While Ra (average roughness) is commonly specified, other parameters provide crucial information:

- Rz (Maximum Height): The difference between highest peak and lowest valley

- Rsk (Skewness): Indicates if the profile has more peaks or valleys

- Rku (Kurtosis): Describes the sharpness of the profile

- Rp (Maximum Peak Height): Important for initial contact and running-in

Surface Roughness Requirements by Component Type

| Component | Recommended Ra Range (μm) | Critical Parameter | Reason |

|---|---|---|---|

| Cylinder Bore | 0.1-0.4 | Rsk (negative preferred) | Seal life, leakage prevention |

| Piston Rod | 0.2-0.6 | Rz (controlled) | Seal wear, lubrication retention |

| Bearing Surfaces | 0.4-0.8 | Rku (platykurtic preferred) | Lubricant retention, wear resistance |

| Valve Seats | 0.05-0.2 | Rp (minimized) | Sealing efficiency, leakage prevention |

| External Surfaces | 0.8-1.6 | Ra (consistent) | Corrosion resistance, appearance |

Measurement Methods and Their Applications

Different measurement techniques provide varying insights into surface characteristics:

Contact Methods

- Stylus Profilometers: Standard for Ra measurement, but can damage delicate surfaces

- Portable Roughness Testers: Convenient for field use but less precise

Non-Contact Methods

- Optical Profilometry: Excellent for soft materials or finished components

- Laser Scanning: Provides high-resolution 3D surface maps

- Atomic Force Microscopy: For nanoscale analysis of critical surfaces

Surface Roughness Evolution During Component Life

Surface roughness isn’t static—it evolves throughout a component’s lifecycle:

- Manufacturing Stage: Initial machined or ground finish

- Running-In Period: Peaks are worn down, roughness decreases

- Steady-State Operation: Stabilized roughness profile

- Wear Acceleration: Increasing roughness signals approaching failure

Monitoring these changes can provide early warning of component failure, especially in critical rodless pneumatic cylinder applications.

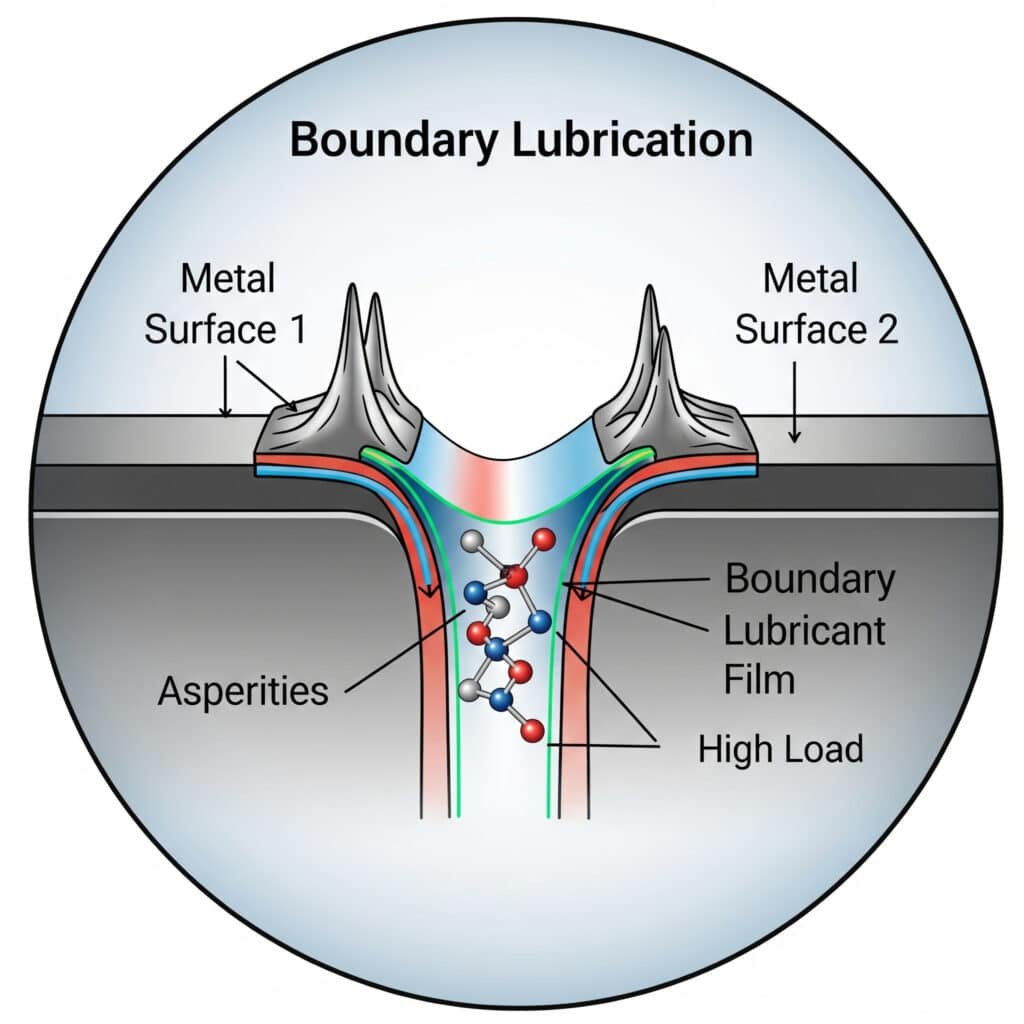

Boundary Lubrication: Why Is This Mechanism Critical for Pneumatic Systems?

Boundary lubrication represents the thin line between acceptable operation and catastrophic failure in pneumatic systems. Understanding this mechanism is essential for proper maintenance and design.

Boundary lubrication occurs when a molecular-thin film of lubricant separates two surfaces under high load or low speed conditions. This regime is critical in pneumatic systems because it protects components during start-up, low-speed operation, and high-load scenarios when full fluid film lubrication cannot be maintained.

I recently consulted with a packaging equipment manufacturer in California whose magnetic rodless cylinders were experiencing premature seal failure. Their engineers had selected a lubricant based solely on viscosity, overlooking boundary lubrication properties. After switching to a lubricant with superior boundary additives, seal life increased threefold.

The Four Lubrication Regimes

To understand boundary lubrication’s importance, we must place it in context:

- Boundary Lubrication: Surface asperities in direct contact, protected only by molecular films

- Mixed Lubrication: Partial fluid film with some asperity contact

- Elastohydrodynamic Lubrication: Thin fluid film with surface deformation

- Hydrodynamic Lubrication: Complete separation by fluid film

Boundary Lubrication Mechanisms

How exactly does boundary lubrication protect surfaces? Several mechanisms work together:

Adsorption

Polar molecules in the lubricant attach to metal surfaces, creating protective layers:

- The polar “head” bonds to the metal surface

- The non-polar “tail” extends outward

- These aligned molecules resist penetration

- Multiple layers can form for enhanced protection

Chemical Reaction

Some additives react with surfaces to form protective compounds:

- ZDDP (Zinc Dialkyldithiophosphate)[^5]: Forms protective phosphate glass

- Sulfur Compounds: Create iron sulfide protective layers

- Fatty Acids: React to form metallic soaps on surfaces

Selecting Lubricants for Boundary Conditions

For pneumatic components like rodless cylinders that frequently operate in boundary conditions:

| Additive Type | Function | Best Application |

|---|---|---|

| Anti-wear (AW) | Forms protective films under moderate loads | General pneumatic components |

| Extreme Pressure (EP) | Creates sacrificial surface layers under high loads | Heavy-duty applications |

| Friction Modifiers | Reduces stick-slip in boundary conditions | Precision positioning systems |

| Solid Lubricants (PTFE, Graphite) | Provides physical separation when fluid film fails | High-load, low-speed applications |

Optimizing Boundary Lubrication in Pneumatic Systems

To maximize component life through improved boundary lubrication:

- Surface Preparation: Controlled roughness creates lubricant reservoirs

- Additive Selection: Match additives to material pairs and operating conditions

- Relubrication Intervals: More frequent than with full-film lubrication

- Contamination Control: Particles disrupt boundary films more severely than fluid films

- Temperature Management: Boundary additives have temperature-dependent effectiveness

Conclusion

Understanding tribology fundamentals—Coulomb friction verification, surface roughness standards, and boundary lubrication mechanisms—is essential for optimizing pneumatic system performance. By applying these principles, you can significantly reduce maintenance costs, extend component life, and improve operational reliability.

FAQs About Tribology in Pneumatic Systems

What is tribology and why is it important for pneumatic systems?

Tribology is the science of interacting surfaces in relative motion, including friction, wear, and lubrication. In pneumatic systems, tribological factors directly impact energy efficiency, component lifespan, and operational reliability. Proper tribological management can reduce energy consumption by 10-15% and extend component life by 2-3 times.

How does surface roughness affect seal life in rodless cylinders?

Surface roughness affects seal life through multiple mechanisms: too smooth a surface provides insufficient lubricant retention, while too rough a surface causes accelerated seal wear. Optimal surface roughness (typically Ra 0.1-0.4 μm) creates microscopic valleys that act as lubricant reservoirs while maintaining a smooth enough profile to prevent seal damage.

What’s the difference between boundary and hydrodynamic lubrication?

Boundary lubrication occurs when surfaces are separated only by molecular-thin films of lubricant additives, with some asperity contact still occurring. Hydrodynamic lubrication features complete separation of surfaces by a fluid film. Pneumatic components typically operate in boundary or mixed lubrication regimes during start-up and low-speed operation.

How can I verify if Coulomb’s friction law applies to my specific application?

Conduct a simple test by measuring friction force at different normal loads while maintaining constant speed and temperature. Plot the results—if the relationship is linear (friction force = friction coefficient × normal force), Coulomb’s law applies. Deviations from linearity indicate other factors like adhesion or material deformation are significant.

What lubricant properties are most important for pneumatic components?

For pneumatic components, particularly rodless cylinders, key lubricant properties include: appropriate viscosity for operating temperature range, strong boundary lubrication additives, compatibility with seal materials, water and oxidation resistance, and good adhesion to metal surfaces. Synthetic lubricants often outperform mineral oils in these applications.

-

Provides a comprehensive overview of tribology, the interdisciplinary science that studies friction, wear, lubrication, and the design of interacting surfaces in relative motion. ↩

-

Offers a detailed explanation of Coulomb’s laws of dry friction, which are fundamental models used to approximate the forces of static and kinetic friction. ↩

-

Explains the dynamics of stick-slip friction, a spontaneous jerky motion that can occur as two objects slide over each other, which is critical for understanding low-speed instabilities. ↩

-

Provides a technical definition of Ra, the arithmetic average of the absolute values of the profile height deviations from the mean line, which is the most widely used parameter for surface finish. ↩