Facility managers watch helplessly as production lines grind to a halt when rodless cylinders fail unexpectedly, creating cascading delays that cost thousands per hour while maintenance teams scramble to diagnose problems that could have been prevented with proper preventive care protocols.

Effective rodless cylinder maintenance requires systematic inspection schedules, lubrication protocols, seal monitoring, alignment verification, and performance tracking to prevent costly failures and extend equipment life by 200-300% compared to reactive maintenance approaches.

Just last month, I worked with David, a facility manager at a automotive parts manufacturer in Michigan, whose production line suffered three unexpected rodless cylinder failures in two weeks. After implementing our comprehensive preventive maintenance1 checklist, his facility has operated failure-free for over 60 days while reducing maintenance costs by 40%. 🔧

Table of Contents

- What Should You Include in Daily Rodless Cylinder Inspections?

- How Do You Establish Proper Lubrication Schedules for Maximum Life?

- Which Warning Signs Indicate Immediate Maintenance Needs?

- What Documentation Systems Optimize Maintenance Efficiency?

What Should You Include in Daily Rodless Cylinder Inspections?

Daily inspections catch problems before they become costly failures and production shutdowns.

Daily rodless cylinder inspections should cover visual leak detection, smooth operation verification, mounting security checks, air supply pressure monitoring, and unusual noise identification, taking just 2-3 minutes per cylinder while preventing 90% of unexpected failures.

Visual Inspection Protocol

External Condition Assessment

Start each inspection with these visual checks:

- Housing integrity – Look for cracks, dents, or corrosion

- Mounting bolts – Verify all fasteners are tight and secure

- Cable protection – Check for damaged or worn cable carriers

- Environmental contamination – Remove dust, debris, or chemical buildup

- Safety guards – Ensure all protective covers are in place

Leak Detection Methods

| Inspection Point | Detection Method | Action Required |

|---|---|---|

| Port connections | Soapy water test | Tighten or replace fittings |

| Seal areas | Visual oil traces | Schedule seal replacement |

| Exhaust ports | Listen for air leaks | Check internal seals |

| Pressure gauges | Monitor readings | Investigate pressure drops |

Operational Performance Checks

Movement Quality Assessment

During each cycle, observe:

- Smooth acceleration without jerky starts

- Consistent speed throughout stroke length

- Proper stopping at end positions without bouncing

- Quiet operation without grinding or squealing sounds

- Accurate positioning at programmed locations

Load and Speed Verification

- Cycle time consistency compared to baseline measurements

- Force output adequate for application requirements

- Response time to control signals within specifications

- Temperature stability during continuous operation

How Do You Establish Proper Lubrication Schedules for Maximum Life?

Strategic lubrication prevents premature wear and extends rodless cylinder service life significantly.

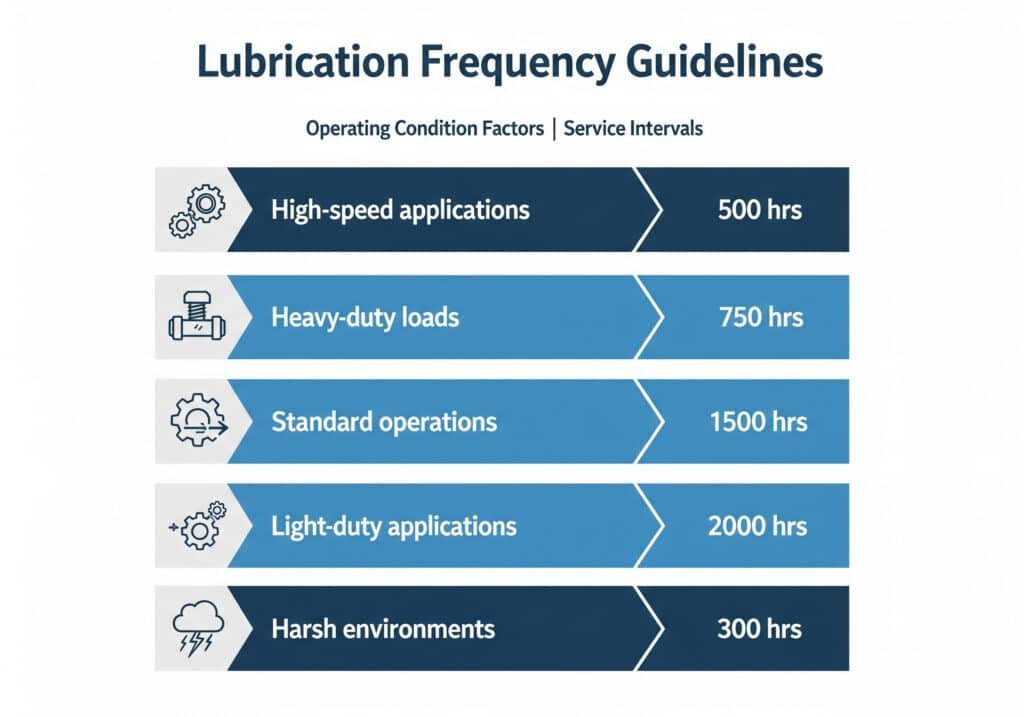

Establish lubrication schedules based on operating hours, cycle counts, environmental conditions, and manufacturer specifications, typically requiring service every 500-2000 operating hours with proper lubricant selection being critical for seal compatibility and performance.

Lubrication Frequency Guidelines

Operating Condition Factors

- High-speed applications (>1000 cycles/hour) – Every 500 hours

- Heavy-duty loads (>80% rated force) – Every 750 hours

- Standard operations (normal loads/speeds) – Every 1500 hours

- Light-duty applications (<50% capacity) – Every 2000 hours

- Harsh environments (dust, chemicals, heat) – Every 300 hours

Environmental Adjustments

Modify schedules based on conditions:

- High temperature environments require 50% more frequent service

- Dusty conditions need filtration and increased frequency

- Chemical exposure demands compatible lubricants and shorter intervals

- High humidity areas require moisture-resistant products

Lubricant Selection and Application

Compatible Lubricant Types

- Synthetic oils for high-temperature applications

- Mineral-based lubricants for standard conditions

- Food-grade2 products for pharmaceutical/food processing

- Anti-corrosion formulations for marine environments

Proper Application Techniques

- Quantity control – Apply manufacturer-specified amounts only

- Distribution method – Use proper lubrication points and tools

- Contamination prevention – Keep lubricants clean and sealed

- Documentation – Record type, quantity, and date of application

I recently helped Jennifer, a maintenance supervisor at a packaging facility in Ohio, redesign her lubrication program after experiencing frequent seal failures. By switching to our recommended synthetic lubricant and adjusting service intervals based on actual operating conditions, her facility reduced rodless cylinder failures by 75% and extended average service life from 18 months to over 4 years. 📊

Which Warning Signs Indicate Immediate Maintenance Needs?

Early recognition of warning signs prevents catastrophic failures and costly emergency repairs.

Critical warning signs requiring immediate attention include irregular movement patterns, unusual noise levels, visible leakage, pressure fluctuations, excessive heat generation, and positioning errors, with prompt response preventing minor issues from becoming major system failures.

Performance Degradation Indicators

Movement Abnormalities

Watch for these concerning symptoms:

- Jerky or stuttering motion during cycles

- Slow response to control signals

- Inconsistent speeds between extension and retraction

- Failure to reach programmed end positions

- Excessive vibration during operation

Pressure and Force Issues

| Warning Sign | Possible Cause | Urgency Level |

|---|---|---|

| Pressure drops | Internal leakage | High |

| Reduced force output | Seal wear | Medium |

| Erratic pressure readings | Control valve issues | High |

| Slow pressure buildup | Supply restrictions | Medium |

Environmental and Safety Concerns

Temperature Monitoring

- Excessive heat generation indicates internal friction

- Cold spots may suggest inadequate lubrication

- Temperature fluctuations can cause seal problems

- Thermal expansion affects positioning accuracy

Contamination Detection

- Oil contamination in exhaust air streams

- Metallic particles indicating internal wear

- Water accumulation from condensation issues

- Chemical residue from process contamination

What Documentation Systems Optimize Maintenance Efficiency?

Comprehensive documentation enables predictive maintenance and optimizes resource allocation.

Effective maintenance documentation includes digital maintenance logs, performance trend tracking, parts inventory management, failure analysis records, and cost tracking systems that enable data-driven decisions and reduce overall maintenance expenses by 25-35%.

Digital Maintenance Records

Essential Data Points

Track these key metrics for each rodless cylinder:

- Installation date and initial performance baseline

- Operating hours and cycle count accumulation

- Maintenance activities with dates and procedures performed

- Parts replaced including part numbers and suppliers

- Performance trends showing degradation over time

Maintenance Scheduling Systems

- Calendar-based schedules for routine inspections

- Hour-based triggers for lubrication and service

- Condition-based alerts from monitoring systems

- Predictive algorithms using historical data patterns

Cost Analysis and Optimization

Financial Tracking Benefits

- Maintenance cost per cylinder per year

- Downtime expenses associated with failures

- Parts cost trends and supplier comparisons

- Labor efficiency metrics for different procedures

- Total cost of ownership3 calculations

Performance Benchmarking

Compare your results against industry standards:

- Mean time between failures4 (MTBF) tracking

- Maintenance cost as percentage of replacement value

- Energy efficiency improvements from proper maintenance

- Overall equipment effectiveness5 (OEE) improvements

At Bepto, we provide comprehensive maintenance support including detailed service manuals, technical training programs, and genuine replacement parts to help facility managers maximize their rodless cylinder investments. Our preventive maintenance approach has helped hundreds of facilities reduce unplanned downtime by over 80%. 🎯

Conclusion

Implementing systematic rodless cylinder maintenance through daily inspections, proper lubrication schedules, early warning recognition, and comprehensive documentation transforms reactive repair costs into predictable maintenance investments while maximizing equipment reliability and production uptime.

FAQs About Rodless Cylinder Maintenance

Q: How often should I perform complete rodless cylinder maintenance?

Complete maintenance should occur every 1500-2000 operating hours under normal conditions, with more frequent service required for high-speed or heavy-duty applications, harsh environments, or when performance monitoring indicates declining efficiency.

Q: What’s the most common cause of premature rodless cylinder failure?

Inadequate lubrication accounts for approximately 60% of premature failures, followed by contamination damage and improper installation, making regular lubrication and environmental protection the most critical maintenance priorities.

Q: Can I use generic lubricants instead of manufacturer-specified products?

Generic lubricants may cause seal compatibility issues and void warranties, so always use manufacturer-approved products that match your specific operating conditions, temperature range, and chemical exposure requirements for optimal performance.

Q: How do I know when seals need replacement before they fail completely?

Monitor for gradual performance degradation, slight air leakage at exhaust ports, increased cycle times, reduced force output, and visible oil traces around seal areas as early indicators requiring seal replacement.

Q: What documentation should I keep for warranty and insurance purposes?

Maintain detailed records of installation dates, maintenance schedules, service performed, parts replaced, operating conditions, and any modifications made, as this documentation supports warranty claims and demonstrates due diligence for insurance coverage.

-

Learn about the core principles of a preventive maintenance strategy and its benefits over reactive approaches. ↩

-

Understand the NSF standards and requirements for lubricants used in food and beverage processing environments. ↩

-

Explore how the TCO model provides a comprehensive financial assessment of an asset over its entire lifecycle. ↩

-

Discover how this key reliability metric is calculated and used to predict equipment uptime. ↩

-

Learn the methodology behind OEE, a critical metric for measuring manufacturing productivity. ↩