When food production lines face frequent washdowns with harsh chemicals and high-pressure water, standard pneumatic cylinders quickly corrode, fail, and contaminate your products. This creates costly downtime, safety risks, and regulatory compliance nightmares that can shut down entire operations.

Stainless steel cylinders are specifically engineered for washdown environments, featuring corrosion-resistant 316L stainless steel construction, FDA-approved seals, and IP671+ protection ratings that ensure reliable performance in the harshest food production conditions while maintaining strict hygiene standards.

Last month, I spoke with Sarah, a production manager at a dairy processing facility in Wisconsin, who was struggling with cylinder failures every few weeks due to aggressive cleaning protocols. Her team was spending more time replacing corroded components than actually producing dairy products. 🥛

Table of Contents

- What Makes Stainless Steel Cylinders Essential for Food Production?

- How Do Washdown Environments Affect Standard Pneumatic Cylinders?

- Which Stainless Steel Grades Perform Best in Food Applications?

- What Are the Key Design Features for Washdown Applications?

What Makes Stainless Steel Cylinders Essential for Food Production?

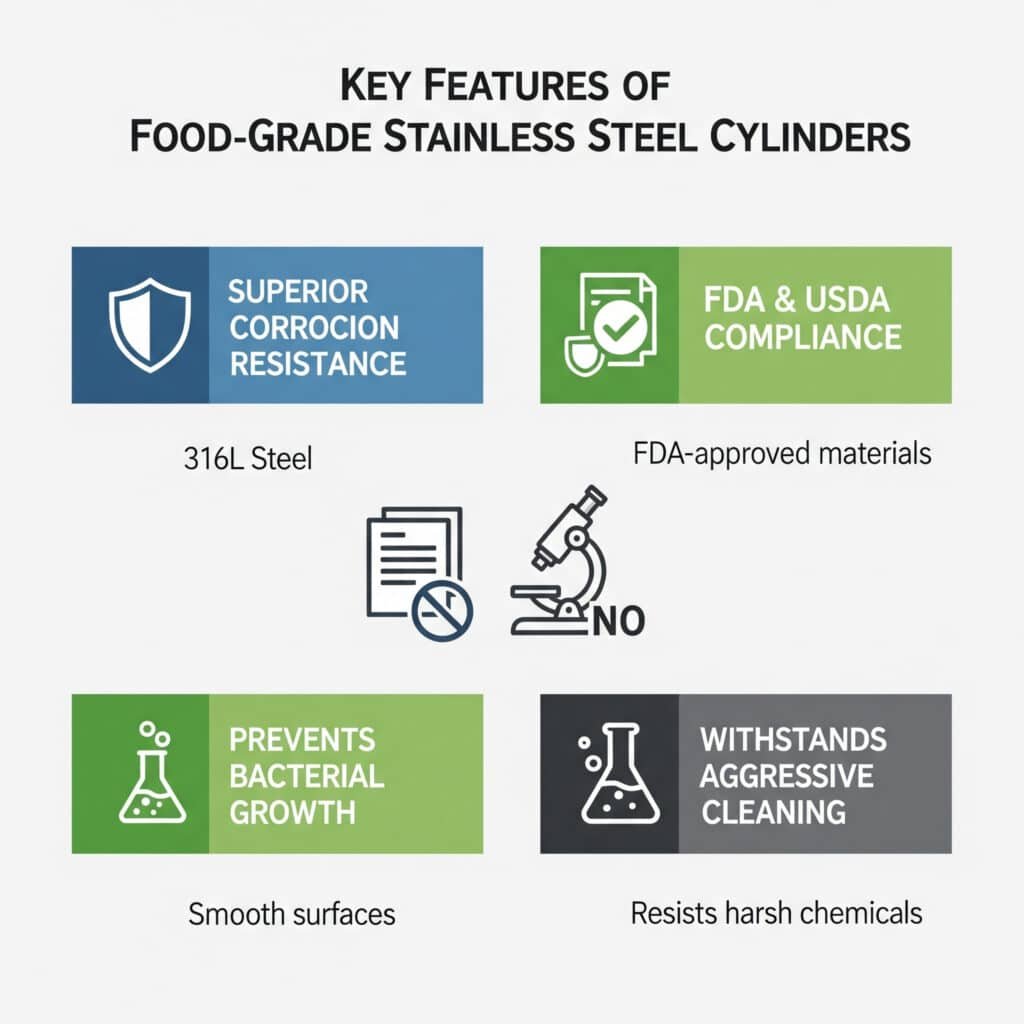

Food production environments demand the highest levels of cleanliness and contamination prevention.

Stainless steel cylinders provide superior corrosion resistance, meet FDA regulations, prevent bacterial growth, and withstand aggressive cleaning chemicals that would destroy standard aluminum or steel cylinders within months.

Regulatory Compliance Requirements

Food processing facilities must comply with FDA, USDA, and HACCP standards2. Our stainless steel cylinders feature:

- 316L stainless steel construction for maximum corrosion resistance

- FDA-approved sealing materials3 that won’t leach chemicals

- Smooth surface finishes that prevent bacterial adhesion

- Easy-to-clean designs with minimal crevices

Contamination Prevention

Unlike standard cylinders, stainless steel units eliminate rust particles, metal flakes, and chemical residues that could contaminate food products. This is critical for maintaining product quality and avoiding costly recalls.

How Do Washdown Environments Affect Standard Pneumatic Cylinders?

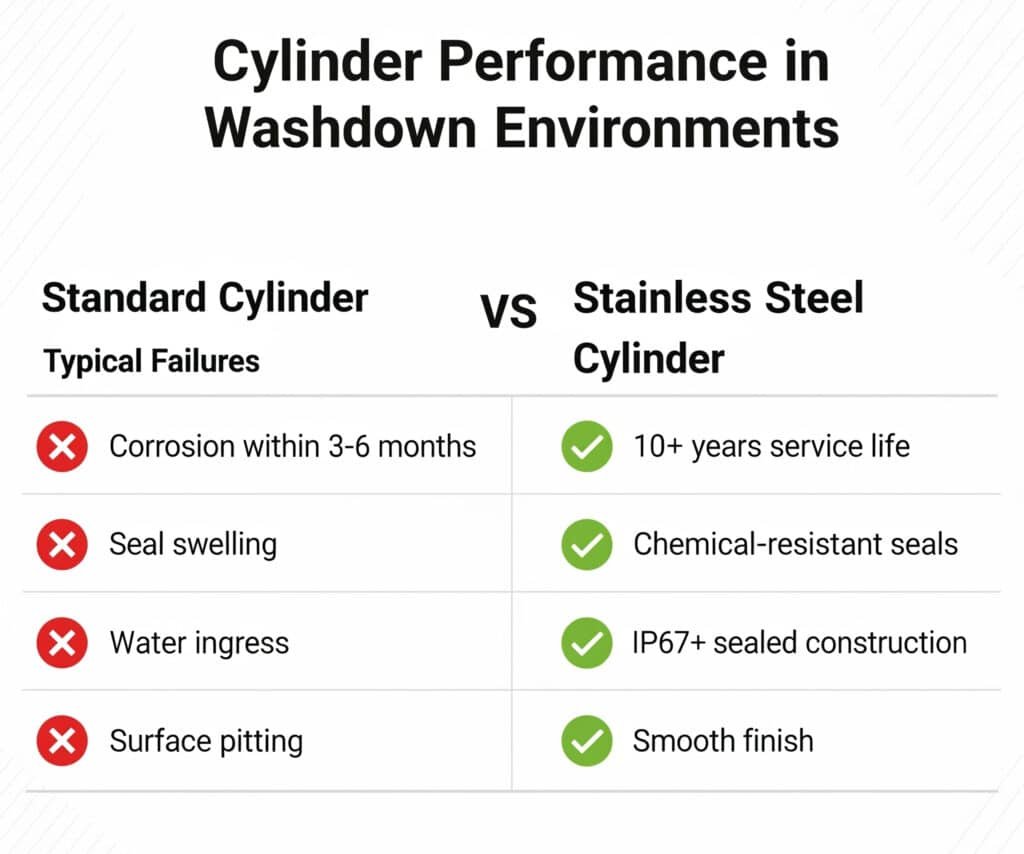

Washdown procedures in food production are notoriously harsh on equipment.

Standard aluminum and carbon steel cylinders experience rapid corrosion, seal degradation, and mechanical failure when exposed to high-pressure water, sanitizing chemicals, and temperature fluctuations typical in food processing washdown cycles.

Common Failure Modes

| Standard Cylinders | Stainless Steel Cylinders |

|---|---|

| Corrosion within 3-6 months | 10+ years service life |

| Seal swelling from chemicals | Chemical-resistant seals |

| Water ingress through ports | IP67+ sealed construction |

| Surface pitting and flaking | Smooth, non-porous finish |

Remember Sarah from Wisconsin? Her facility was using standard aluminum cylinders that failed every 2-3 months. After switching to our Bepto stainless steel rodless cylinders, she’s now running 18 months without a single replacement. The initial investment paid for itself in just six months through reduced maintenance costs and eliminated downtime. ⚡

Chemical Compatibility Issues

Food-grade sanitizers like peracetic acid, chlorine dioxide, and quaternary ammonium compounds are extremely corrosive to standard materials but have minimal impact on 316L stainless steel.

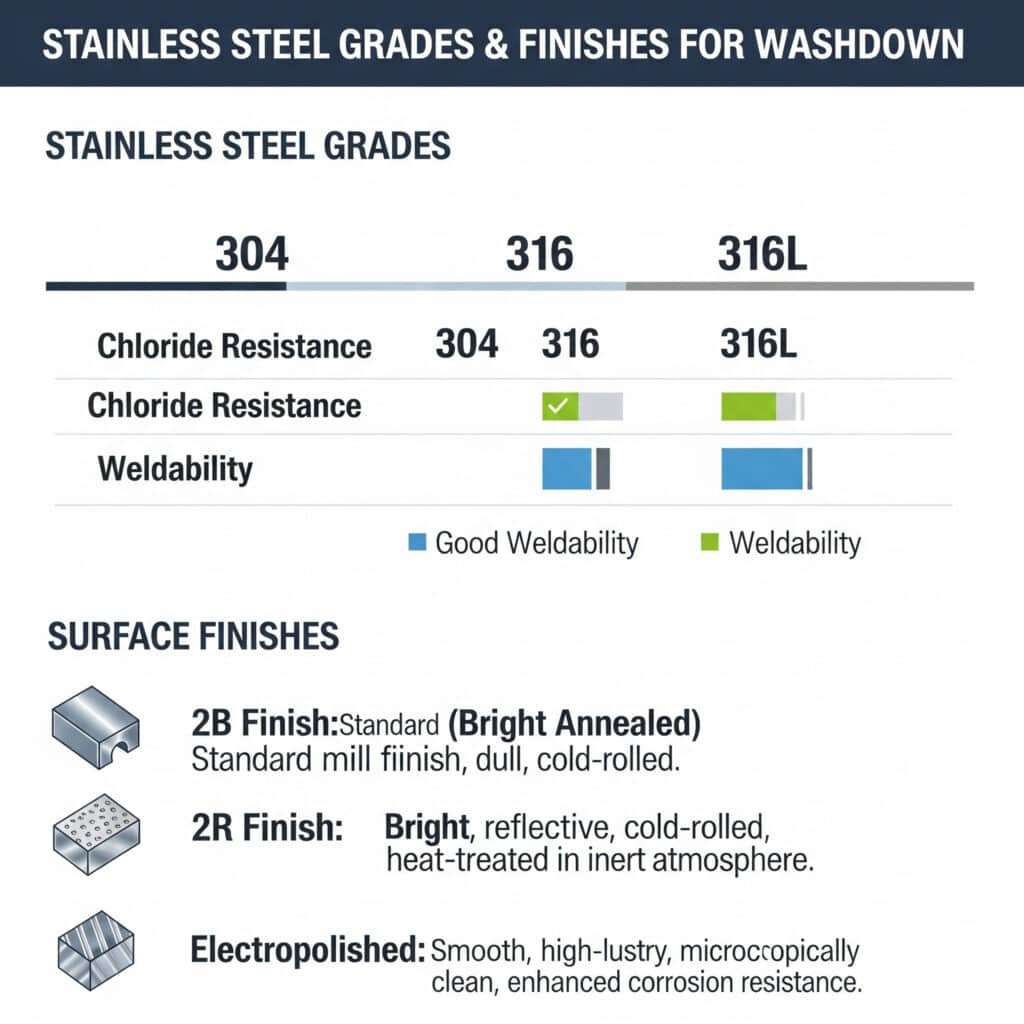

Which Stainless Steel Grades Perform Best in Food Applications?

Not all stainless steel grades are suitable for food production environments.

316L stainless steel offers the optimal combination of corrosion resistance, low carbon content for weldability, and molybdenum content that provides superior protection against chloride-induced pitting in washdown applications.

Material Grade Comparison

- 304 Stainless Steel: Good for mild environments but susceptible to chloride corrosion

- 316 Stainless Steel: Better corrosion resistance with molybdenum addition

- 316L Stainless Steel: Low carbon version prevents carbide precipitation4, ideal for welding

Surface Finish Specifications

We provide various surface finishes depending on your application:

- 2B Finish: Standard mill finish for general applications

- 2R Finish: Reflective finish for enhanced cleanability

- Electropolished: Ultra-smooth surface for pharmaceutical-grade applications

What Are the Key Design Features for Washdown Applications?

Proper design is crucial for washdown environment success.

Key features include IP67+ ingress protection, sloped surfaces for drainage, quick-disconnect fittings, removable cushioning for cleaning access, and sealed bearing systems that prevent water and chemical infiltration while maintaining smooth operation.

Essential Design Elements

Ingress Protection

Our cylinders feature IP67 or higher ratings, ensuring complete protection against high-pressure washdown procedures.

Drainage Design

Sloped surfaces and drain holes prevent water accumulation that could harbor bacteria or cause corrosion in crevices.

Accessible Components

Quick-release cushioning and easily removable end caps allow thorough cleaning and inspection without complete disassembly.

I recently worked with Tom, an engineer at a meat processing plant in Nebraska, who needed cylinders that could handle daily CIP (Clean-in-Place)5 cycles. Our custom-designed stainless steel rodless cylinders with enhanced sealing and drainage features have been running flawlessly for over two years, significantly improving his plant’s efficiency and compliance scores. 🏭

Conclusion

Investing in properly designed stainless steel cylinders is essential for any food production facility serious about maintaining hygiene standards, reducing maintenance costs, and ensuring regulatory compliance.

FAQs About Stainless Steel Cylinders for Food Production

Q: How much more do stainless steel cylinders cost compared to standard units?

A: Stainless steel cylinders typically cost 40-60% more initially, but their 5-10x longer service life and reduced maintenance make them more economical long-term.

Q: Can stainless steel cylinders handle steam sterilization?

A: Yes, our 316L stainless steel cylinders can withstand steam sterilization up to 250°F (121°C) with appropriate high-temperature seals and proper design considerations.

Q: What’s the typical lead time for custom stainless steel cylinders?

A: We maintain inventory of common sizes and can ship standard configurations within 3-5 business days, while custom designs typically require 2-3 weeks for manufacturing.

Q: Do you provide validation documentation for FDA compliance?

A: Absolutely! We provide complete material certifications, surface finish documentation, and validation packages to support your FDA and HACCP compliance requirements.

Q: How do I determine the right IP rating for my washdown application?

A: IP67 is suitable for most food processing environments, while IP69K is recommended for high-temperature, high-pressure washdown applications like those found in dairy and beverage processing.

-

Review the official International Electrotechnical Commission standard that defines the Ingress Protection (IP) rating system. ↩

-

Learn about the Hazard Analysis and Critical Control Point system for managing food safety from the U.S. Food and Drug Administration. ↩

-

Explore the U.S. FDA regulations for substances intended for use in contact with food. ↩

-

Understand this metallurgical phenomenon and why low-carbon (“L” grade) stainless steels are essential for corrosion resistance after welding. ↩

-

Discover the principles of CIP, an automated method of cleaning the interior surfaces of pipes, vessels, and equipment without disassembly. ↩