When your precision pneumatic positioning systems exhibit unpredictable stick-slip behavior1, inconsistent breakaway forces, or varying friction throughout the stroke, you’re witnessing the complex friction regimes described by Stribeck curves2—a tribological3 phenomenon that can cause positioning errors of ±2-5mm and force variations of 30-50% that traditional seal analysis completely overlooks. 🎯

Stribeck curves describe the relationship between friction coefficient \( \mu \) and the dimensionless parameter \( (\eta \times N \times V)/P \), showing three distinct friction regimes: boundary lubrication (high friction, surface contact), mixed lubrication (transitional friction), and hydrodynamic lubrication (low friction, full fluid film separation).

Last week, I helped David, a precision automation engineer at a medical device manufacturer in Massachusetts, who was struggling with ±3mm positioning repeatability issues that were causing 8% of his high-value assemblies to fail quality inspection.

Table of Contents

- What Are Stribeck Curves and How Do They Apply to Pneumatic Seals?

- How Do Different Friction Regimes Affect Cylinder Performance?

- What Methods Can Characterize Seal Friction Behavior?

- How Can You Optimize Seal Design Using Stribeck Analysis?

What Are Stribeck Curves and How Do They Apply to Pneumatic Seals?

Understanding Stribeck curves is fundamental to predicting and controlling seal friction behavior. 🔬

Stribeck curves plot friction coefficient \( \mu \) versus the Stribeck parameter \( (\eta \times V)/P \), where \( \eta \) is lubricant viscosity, \( V \) is sliding velocity, and \( P \) is contact pressure, revealing three distinct lubrication regimes that determine seal friction characteristics and wear behavior in pneumatic cylinders.

Fundamental Stribeck Relationship

The Stribeck parameter is defined as:

$$

S = \frac{\eta \times V}{P}

$$

Where:

- \( \eta \) = Dynamic viscosity4 of lubricant (Pa·s)

- \( V \) = Sliding velocity (m/s)

- \( P \) = Contact pressure (Pa)

Three Friction Regimes

Boundary Lubrication (Low S):

- Characteristics: Direct surface contact, high friction

- Friction coefficient: 0.1 – 0.8 (material dependent)

- Lubrication: Molecular layers, surface films

- Wear: High, direct metal/elastomer contact

Mixed Lubrication (Medium S):

- Characteristics: Partial fluid film, variable friction

- Friction coefficient: 0.05 – 0.2 (highly variable)

- Lubrication: Combination of boundary and fluid film

- Wear: Moderate, intermittent contact

Hydrodynamic Lubrication (High S):

- Characteristics: Full fluid film separation, low friction

- Friction coefficient: 0.001 – 0.05 (viscosity dependent)

- Lubrication: Complete fluid film support

- Wear: Minimal, no surface contact

Pneumatic Seal Applications

Typical Operating Conditions:

- Velocities: 0.01 – 5.0 m/s

- Pressures: 0.1 – 1.0 MPa

- Lubricants: Compressed air moisture, seal grease

- Temperatures: -20°C to +80°C

Seal-Specific Factors:

- Contact pressure: Determined by seal design and system pressure

- Surface roughness: Affects transition between regimes

- Seal material: Elastomer properties influence friction

- Lubrication: Limited in pneumatic systems

Stribeck Curve Characteristics for Pneumatic Seals

| Regime | Stribeck Parameter | Typical μ | Cylinder Behavior |

|---|---|---|---|

| Boundary | S < 0.001 | 0.2 – 0.6 | Stick-slip, high breakaway |

| Mixed | 0.001 < S < 0.1 | 0.05 – 0.3 | Variable friction, hunting |

| Hydrodynamic | S > 0.1 | 0.01 – 0.08 | Smooth motion, low friction |

Material-Specific Behavior

NBR (Nitrile) Seals:

- Boundary friction: μ = 0.3 – 0.7

- Transition region: Broad, gradual

- Hydrodynamic potential: Limited due to elastomer properties

PTFE Seals:

- Boundary friction: μ = 0.1 – 0.3

- Transition region: Sharp, well-defined

- Hydrodynamic potential: Excellent due to low surface energy5

Polyurethane Seals:

- Boundary friction: μ = 0.2 – 0.5

- Transition region: Moderate width

- Hydrodynamic potential: Good with proper lubrication

Case Study: David’s Medical Device Application

David’s precision positioning system exhibited classic Stribeck behavior:

- Operating velocity range: 0.05 – 2.0 m/s

- System pressure: 6 bar (0.6 MPa)

- Seal material: NBR O-rings

- Observed friction: μ = 0.4 at low speeds, μ = 0.15 at high speeds

- Positioning errors: ±3mm due to friction variations

Analysis revealed the system operated across all three friction regimes during normal operation, causing unpredictable positioning behavior.

How Do Different Friction Regimes Affect Cylinder Performance?

Each friction regime creates distinct performance characteristics that directly impact cylinder behavior. ⚡

Different friction regimes affect cylinder performance through varying breakaway forces, velocity-dependent friction coefficients, and transition-induced instabilities: boundary lubrication causes stick-slip motion and high starting forces, mixed lubrication creates unpredictable friction variations, while hydrodynamic lubrication enables smooth, consistent motion.

Boundary Lubrication Effects

High Static Friction:

$$

F_{\text{static}} = \mu_{\text{static}} \times N

$$

Where \( \mu_{\text{static}} \) can be 2–3 times higher than kinetic friction.

Stick-Slip Phenomena:

- Stick phase: Static friction prevents motion

- Slip phase: Sudden acceleration when breakaway occurs

- Frequency: Typically 1-50 Hz depending on system dynamics

Performance Impacts:

- Positioning accuracy: ±1-5mm errors common

- Force variations: 200-500% between static and kinetic

- Control instability: Difficult to achieve smooth motion

- Wear acceleration: High contact stresses

Mixed Lubrication Characteristics

Variable Friction Coefficient:

$$

\mu = f(V, P, T, \text{surface conditions})

$$

Friction varies unpredictably with operating conditions.

Transition Instabilities:

- Hunting behavior: Oscillation between friction regimes

- Speed sensitivity: Small velocity changes cause large friction changes

- Pressure effects: System pressure variations affect friction

- Temperature dependence: Thermal effects on lubrication

Control Challenges:

- Unpredictable response: System behavior varies with conditions

- Tuning difficulties: Control parameters must accommodate variations

- Repeatability issues: Cycle-to-cycle variations in performance

Hydrodynamic Lubrication Benefits

Low, Consistent Friction:

$$

\mu \approx \text{constant} \times \frac{\eta \times V}{P}

$$

Friction becomes predictable and velocity-proportional.

Smooth Motion Characteristics:

- No stick-slip: Continuous motion without jerking

- Predictable forces: Friction follows known relationships

- High precision: Positioning accuracy <0.1mm achievable

- Reduced wear: Minimal surface contact

Velocity-Dependent Performance

Low Velocity Operation (<0.1 m/s):

- Regime: Primarily boundary lubrication

- Friction: High and variable (μ = 0.2-0.6)

- Motion quality: Stick-slip, jerky movement

- Applications: Positioning, clamping

Medium Velocity Operation (0.1-1.0 m/s):

- Regime: Mixed lubrication

- Friction: Moderate and variable (μ = 0.05-0.3)

- Motion quality: Transitional, some instability

- Applications: General automation

High Velocity Operation (>1.0 m/s):

- Regime: Approaching hydrodynamic

- Friction: Low and consistent (μ = 0.01-0.08)

- Motion quality: Smooth, predictable

- Applications: High-speed cycling

Force Analysis Across Regimes

| Operating Condition | Friction Regime | Friction Force | Motion Quality |

|---|---|---|---|

| Startup (V = 0) | Boundary | 400-800 N | Stick-slip |

| Low speed (V = 0.05 m/s) | Boundary/Mixed | 200-500 N | Jerky |

| Medium speed (V = 0.5 m/s) | Mixed | 100-300 N | Variable |

| High speed (V = 2.0 m/s) | Mixed/Hydrodynamic | 50-150 N | Smooth |

System Dynamic Effects

Natural Frequency Interactions:

$$

f_n = \frac{1}{2\pi} \times \sqrt{\frac{k}{m}}

$$

Where stick-slip frequencies can excite system resonances.

Control System Response:

- Boundary regime: Requires high gains, prone to instability

- Mixed regime: Difficult to tune, variable response

- Hydrodynamic regime: Stable, predictable control response

Case Study: Performance Analysis

David’s medical device system showed distinct regime-dependent behavior:

Boundary Lubrication (V < 0.1 m/s):

- Breakaway force: 650 N

- Kinetic friction: 380 N (μ = 0.42)

- Positioning error: ±2.8mm

- Motion quality: Severe stick-slip

Mixed Lubrication (0.1 < V < 0.8 m/s):

- Friction variation: 150-320 N

- Average friction: 235 N (μ = 0.26)

- Positioning error: ±1.5mm

- Motion quality: Inconsistent, hunting

Approaching Hydrodynamic (V > 0.8 m/s):

- Friction force: 85-110 N (μ = 0.12)

- Positioning error: ±0.3mm

- Motion quality: Smooth, predictable

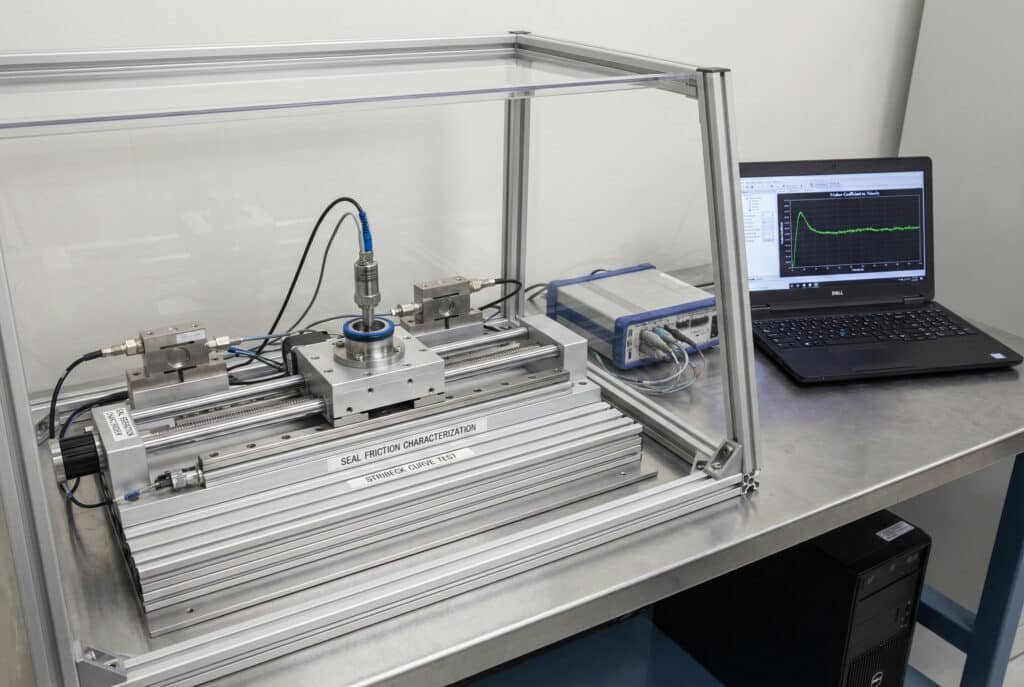

What Methods Can Characterize Seal Friction Behavior?

Accurate characterization of seal friction requires systematic testing across the full range of operating conditions. 📊

Characterize seal friction behavior using tribometer testing to measure friction vs. velocity relationships, pressure variation testing to determine contact pressure effects, temperature cycling to assess thermal influences, and long-term wear testing to track friction evolution over seal life.

Laboratory Testing Methods

Tribometer Testing:

- Linear tribometers: Reciprocating motion simulation

- Rotary tribometers: Continuous sliding measurement

- Pneumatic tribometers: Actual operating condition simulation

- Environmental control: Temperature, humidity, pressure variation

Test Parameters:

- Velocity range: 0.001 – 10 m/s (logarithmic steps)

- Pressure range: 0.1 – 2.0 MPa

- Temperature range: -20°C to +80°C

- Duration: 10⁶ – 10⁸ cycles for wear assessment

Field Testing Approaches

In-Situ Measurement:

- Force sensors: Load cells to measure friction forces

- Position feedback: High-resolution encoders

- Pressure monitoring: System pressure variations

- Temperature measurement: Seal operating temperature

Data Acquisition Requirements:

- Sampling rate: 1-10 kHz for dynamic phenomena

- Resolution: 0.1% of full scale for force measurement

- Synchronization: Coordinated measurement of all parameters

- Duration: Multiple operating cycles for statistical analysis

Stribeck Curve Generation

Data Processing Steps:

- Calculate Stribeck parameter: \( S = (\eta \times V) / P \)

- Determine friction coefficient: \( \mu = F_{\text{friction}} / F_{\text{normal}} \)

- Plot relationship: \( \mu \) vs. \( S \) on log-log scale

- Identify regimes: Boundary, mixed, hydrodynamic regions

- Curve fitting: Mathematical models for each regime

Mathematical Models:

Boundary regime: \( \mu = \mu_b \) (constant)

Mixed regime: \( \mu = a \times S^{-b} + c \)

Hydrodynamic regime: \( \mu = d \times S + e \)

Testing Equipment and Setup

| Equipment | Measurement | Accuracy | Application |

|---|---|---|---|

| Load cells | Force | ±0.1% FS | Friction measurement |

| Linear encoders | Position | ±1 μm | Velocity calculation |

| Pressure transducers | Pressure | ±0.25% FS | Contact pressure |

| Thermocouples | Temperature | ±0.5°C | Thermal effects |

Environmental Testing

Temperature Effects:

- Viscosity changes: η varies with temperature

- Material properties: Elastomer modulus temperature dependence

- Thermal expansion: Affects contact pressures

- Lubrication effectiveness: Temperature-dependent film formation

Humidity Effects:

- Moisture lubrication: Water vapor as lubricant in pneumatic systems

- Material swelling: Elastomer dimensional changes

- Corrosion effects: Surface condition changes

Wear Assessment

Friction Evolution:

- Break-in period: Initial high friction reduction

- Steady-state: Stable friction characteristics

- Wear-out: Increasing friction due to surface degradation

Surface Analysis:

- Profilometry: Surface roughness changes

- Microscopy: Wear pattern analysis

- Chemical analysis: Surface composition changes

Case Study: David’s System Characterization

Testing Protocol:

- Velocity range: 0.01 – 3.0 m/s

- Pressure levels: 2, 4, 6, 8 bar

- Temperature range: 10°C – 50°C

- Test duration: 10⁵ cycles per condition

Key Findings:

- Boundary/mixed transition: S = 0.003

- Mixed/hydrodynamic transition: S = 0.08

- Temperature sensitivity: 15% friction increase per 10°C

- Pressure effects: Minimal above 4 bar

Stribeck Parameters:

- Boundary friction: \( \mu_b = 0.45 \)

- Mixed regime: \( \mu = 0.12 \times S^{-0.3} + 0.08 \)

- Hydrodynamic: \( \mu = 0.02 \times S + 0.015 \)

How Can You Optimize Seal Design Using Stribeck Analysis?

Stribeck analysis enables targeted seal optimization for specific operating conditions and performance requirements. 🎯

Optimize seal design using Stribeck analysis by selecting materials and geometries that promote desired friction regimes, designing surface textures that enhance lubrication, choosing seal configurations that minimize contact pressure, and implementing lubrication strategies that shift operation toward hydrodynamic conditions.

Material Selection Strategy

Low-Friction Materials:

- PTFE compounds: Excellent boundary lubrication properties

- Polyurethane: Good mixed lubrication characteristics

- Specialized elastomers: Modified surface properties

- Composite seals: Multiple materials optimized for different regimes

Surface Treatment Options:

- Fluoropolymer coatings: Reduce boundary friction

- Plasma treatments: Modify surface energy

- Micro-texturing: Create lubrication reservoirs

- Chemical modifications: Alter tribological properties

Geometric Optimization

Contact Pressure Reduction:

- Wider contact areas: Distribute load over larger area

- Optimized seal profiles: Reduce stress concentrations

- Pressure balancing: Minimize net contact forces

- Progressive engagement: Gradual load application

Lubrication Enhancement:

- Micro-grooves: Channel lubricant to contact zone

- Surface texturing: Create hydrodynamic lift

- Reservoir design: Store lubricant for boundary conditions

- Flow optimization: Enhance lubricant circulation

Design Strategies by Operating Regime

| Target Regime | Design Approach | Key Features | Applications |

|---|---|---|---|

| Boundary | Low-friction materials | PTFE, surface treatments | Low-speed positioning |

| Mixed | Optimized geometry | Reduced contact pressure | General automation |

| Hydrodynamic | Enhanced lubrication | Surface texturing, grooves | High-speed operation |

Advanced Seal Technologies

Multi-Material Seals:

- Composite construction: Different materials for different functions

- Graduated properties: Varying characteristics across seal

- Hybrid designs: Combine elastomer and PTFE elements

- Functionally graded: Properties optimized by location

Adaptive Sealing Systems:

- Variable geometry: Adjust to operating conditions

- Active lubrication: Controlled lubricant delivery

- Smart materials: Respond to environmental changes

- Integrated sensors: Monitor friction in real-time

Bepto’s Stribeck-Optimized Solutions

At Bepto Pneumatics, we apply Stribeck analysis to develop application-specific seal solutions:

Design Process:

- Operating condition analysis: Map customer requirements to Stribeck regimes

- Material selection: Choose optimal materials for target regimes

- Geometric optimization: Design for desired friction characteristics

- Testing validation: Verify performance across operating range

Performance Results:

- Friction reduction: 60-80% improvement in target regimes

- Positioning accuracy: ±0.1mm achievable in optimized systems

- Seal life extension: 3-5x improvement through reduced wear

- Control stability: Predictable friction enables better control

Implementation Strategy for David’s Application

Phase 1: Immediate Improvements (Week 1-2)

- Seal material upgrade: PTFE-lined seals for low friction

- Lubrication enhancement: Specialized seal grease application

- Operating parameter optimization: Adjust velocities to avoid mixed regime

- Control system tuning: Compensate for known friction characteristics

Phase 2: Design Optimization (Month 1-2)

- Custom seal development: Application-specific seal design

- Surface treatments: Low-friction coatings on cylinder bores

- Geometric modifications: Optimize seal contact geometry

- Lubrication system: Integrated lubrication delivery

Phase 3: Advanced Solutions (Month 3-6)

- Smart sealing system: Adaptive friction control

- Real-time monitoring: Friction feedback for control optimization

- Predictive maintenance: Seal condition monitoring

- Continuous improvement: Ongoing optimization based on performance data

Results and Performance Improvement

David’s Implementation Results:

- Positioning accuracy: Improved from ±3mm to ±0.2mm

- Friction consistency: 85% reduction in friction variation

- Breakaway force: Reduced from 650N to 180N

- Quality improvement: Defect rate reduced from 8% to 0.3%

- Cycle time: 25% faster due to smoother motion

Cost-Benefit Analysis

Implementation Costs:

- Seal upgrades: $12,000

- Surface treatments: $8,000

- Control system modifications: $15,000

- Testing and validation: $5,000

- Total investment: $40,000

Annual Benefits:

- Quality improvement: $180,000 (reduced defects)

- Productivity increase: $45,000 (faster cycles)

- Maintenance reduction: $18,000 (longer seal life)

- Energy savings: $8,000 (reduced friction)

- Total annual benefit: $251,000

ROI Analysis:

- Payback period: 1.9 months

- 10-year NPV: $2.1 million

- Internal rate of return: 485%

Monitoring and Continuous Improvement

Performance Tracking:

- Friction monitoring: Continuous measurement of seal friction

- Positioning accuracy: Statistical process control of positioning

- Wear assessment: Regular seal condition evaluation

- Performance trending: Long-term optimization opportunities

Optimization Opportunities:

- Seasonal adjustments: Account for temperature and humidity effects

- Load optimization: Adjust for varying production requirements

- Technology upgrades: Implement new seal technologies

- Best practices: Share successful optimization techniques

The key to successful Stribeck-based optimization lies in understanding that friction is not a fixed property but a system characteristic that can be engineered and controlled through proper seal design and operating condition management. 💪

FAQs About Stribeck Curves and Pneumatic Seal Friction

What is the typical Stribeck parameter range for pneumatic cylinder seals?

Pneumatic cylinder seals typically operate with Stribeck parameters between 0.001 and 0.1, spanning boundary and mixed lubrication regimes. Pure hydrodynamic lubrication (S > 0.1) is rare in pneumatic systems due to limited lubrication and relatively low velocities.

How does seal material affect the shape of the Stribeck curve?

Different seal materials produce distinctly different Stribeck curves: PTFE seals show sharp transitions and low boundary friction (μ = 0.1-0.3), while elastomer seals exhibit gradual transitions and higher boundary friction (μ = 0.3-0.7). The mixed lubrication region width also varies significantly between materials.

Can you shift a seal’s operating regime through design changes?

Yes, seal operating regime can be shifted through several approaches: reducing contact pressure moves toward hydrodynamic conditions, improving lubrication increases the Stribeck parameter, and surface texturing can enhance fluid film formation. However, the fundamental velocity and pressure constraints of the application limit the achievable range.

Why do pneumatic systems rarely achieve true hydrodynamic lubrication?

Pneumatic systems typically lack sufficient lubrication (only moisture and minimal seal grease), operate at moderate velocities, and have relatively high contact pressures, keeping Stribeck parameters below 0.1. True hydrodynamic lubrication requires continuous lubricant supply and higher velocity-to-pressure ratios.

How do rodless cylinders compare to rod cylinders in terms of Stribeck behavior?

Rodless cylinders often have more sealing elements but can be designed with optimized seal geometries and better lubrication access. They may exhibit slightly different Stribeck characteristics due to different seal loading patterns, but the fundamental friction regimes remain the same. The key advantage is design flexibility for friction optimization.

-

Understand the mechanics of the stick-slip phenomenon (jerking motion) and how it disrupts precision control. ↩

-

Explore the fundamental principles of the Stribeck curve to better predict friction regimes. ↩

-

Learn about tribology, the science of interacting surfaces in relative motion, including friction, wear, and lubrication. ↩

-

Review the technical definition of dynamic viscosity and its role in calculating the Stribeck parameter. ↩

-

Discover how low surface energy in materials like PTFE reduces adhesion and friction. ↩