Have you ever experienced a sudden pneumatic system failure that brought your entire production line to a halt? You’re not alone. Even well-designed pneumatic systems can fail in unexpected ways, especially when exposed to extreme conditions or unusual operating parameters. Understanding the root causes of these failures can help you implement preventive measures before disaster strikes.

This analysis of three catastrophic pneumatic cylinder failures—magnetic coupling demagnetization in a semiconductor manufacturing environment, seal brittleness in Arctic operating conditions, and fastener loosening due to high-frequency vibration in a stamping press—reveals that seemingly minor environmental factors can cascade into complete system failures. By implementing proper condition monitoring, material selection, and fastener security protocols, these failures could have been prevented, saving hundreds of thousands of dollars in downtime and repairs.

Let’s examine these failure cases in detail to extract valuable lessons that can help you avoid similar disasters in your operations.

Table of Contents

- How Did Magnetic Coupling Demagnetization Shut Down a Semiconductor Fab?

- What Caused Catastrophic Seal Failure in Arctic Conditions?

- Why Did High-Frequency Vibration Lead to Critical Fastener Failure?

- Conclusion: Implementing Preventive Measures

- FAQs About Pneumatic Cylinder Failures

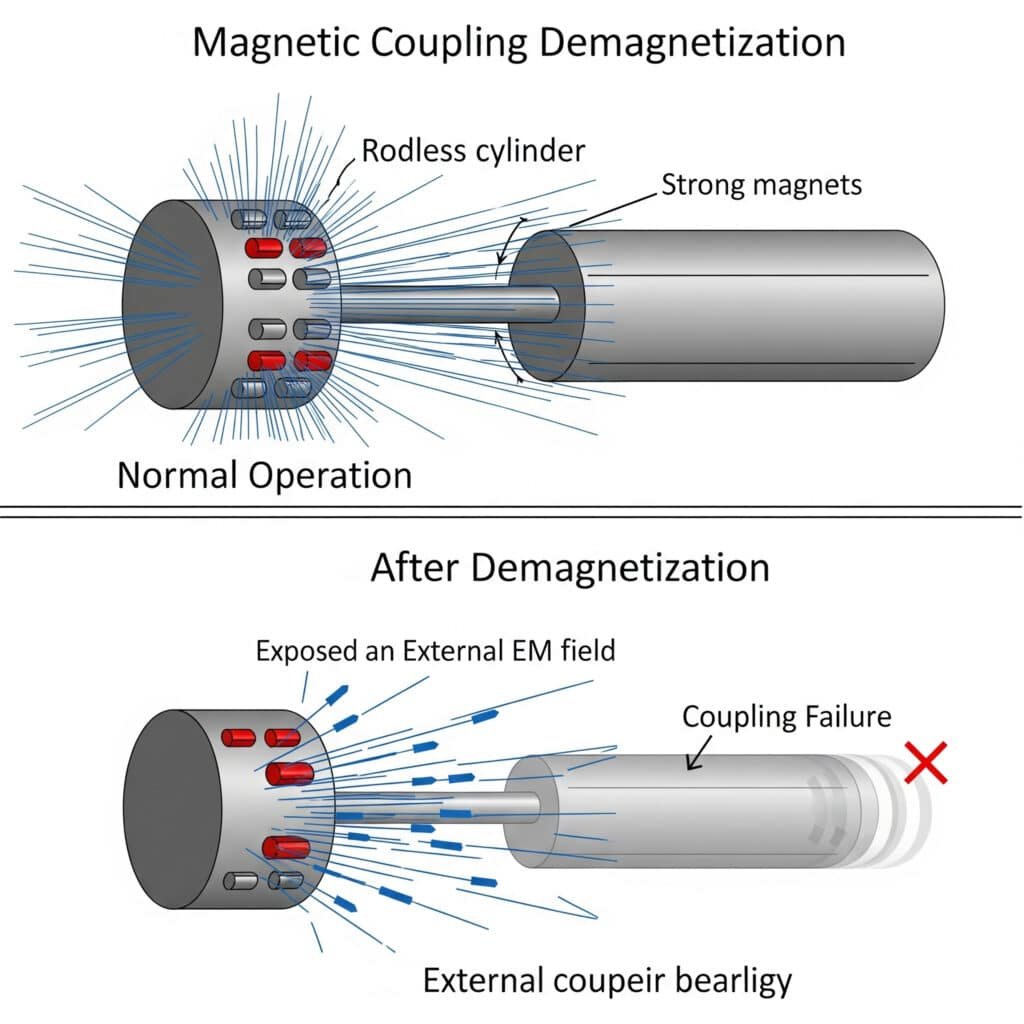

How Did Magnetic Coupling Demagnetization Shut Down a Semiconductor Fab?

A leading semiconductor manufacturer experienced a catastrophic system failure when a magnetically-coupled rodless cylinder in a wafer handling system suddenly lost positioning capability, resulting in a collision that damaged multiple $250,000 silicon wafers and caused 36 hours of production downtime.

The root cause analysis revealed that the magnetic coupling in the rodless cylinder had become partially demagnetized after exposure to an unexpected electromagnetic field generated during maintenance of nearby equipment. The gradual weakening of the magnetic field went undetected until it reached a critical threshold where the coupling could no longer maintain proper engagement under normal acceleration loads, causing the catastrophic positioning failure.

Incident Timeline and Investigation

| Time | Event | Observations | Actions Taken |

|---|---|---|---|

| Day 1, 08:30 | Maintenance begins on nearby ion implantation equipment | Normal operation of wafer handling system | Routine maintenance procedures |

| Day 1, 10:15 | Strong electromagnetic field generated during implanter troubleshooting | No immediate effect noticed | Continued maintenance |

| Day 1-7 | Gradual demagnetization of rodless cylinder coupling | Occasional position errors (attributed to software) | Software recalibration |

| Day 7, 14:22 | Complete coupling failure | Wafer carrier moves uncontrolled | Emergency shutdown |

| Day 7, 14:23 | Collision with adjacent equipment | Multiple wafers damaged | Production halt |

| Day 7-9 | Investigation and repairs | Root cause identified | System restoration |

Magnetic Coupling Fundamentals

Magnetically-coupled rodless cylinders use permanent magnets to transmit force through a non-magnetic barrier, eliminating the need for dynamic seals while maintaining a hermetic separation between the internal piston and external carriage.

Critical Design Elements

Magnetic Circuit Design

– Permanent magnet material (typically NdFeB or SmCo1)

– Magnetic flux path optimization

– Pole arrangement for maximum coupling force

– Shielding considerationsCoupling Force Characteristics

– Static holding force: 200-400N (typical for semiconductor applications)

– Dynamic force transmission: 70-80% of static force

– Force-displacement curve: Non-linear with critical breakaway point

– Temperature sensitivity: -0.12% per °C (typical for NdFeB magnets)Failure Mechanisms

– Demagnetization due to external fields

– Thermal demagnetization

– Mechanical shock causing momentary decoupling

– Material degradation over time

Root Cause Analysis

The investigation revealed multiple contributing factors:

Primary Factors

Electromagnetic Interference

– Source: Ion implanter troubleshooting generated a 0.3T field

– Proximity: Field strength at cylinder location estimated at 0.15T

– Duration: Approximately 45 minutes of intermittent exposure

– Field orientation: Partially aligned with demagnetization direction of NdFeB magnetsMagnetic Material Selection

– Material: N42 grade NdFeB magnets used in coupling

– Intrinsic coercivity (Hci)2: 11 kOe (lower than alternative SmCo options)

– Operating point: Designed with insufficient margin against demagnetization

– Lack of external magnetic shieldingMonitoring Deficiencies

– No magnetic field strength monitoring

– Position error trending not implemented

– Force margin testing not part of preventive maintenance

– Lack of EMI exposure protocols during maintenance

Secondary Factors

Maintenance Procedure Gaps

– No notification of potential EMI generation

– No equipment isolation requirements

– Lack of post-maintenance verification

– Insufficient understanding of magnetic sensitivitySystem Design Weaknesses

– No redundant position verification

– Insufficient error detection capabilities

– Lack of force margin monitoring

– No magnetic field exposure indicators

Failure Reconstruction and Analysis

Through detailed analysis and laboratory testing, the failure sequence was reconstructed:

Demagnetization Progression

| Exposure Time | Estimated Field Strength | Coupling Force Reduction | Observable Effects |

|---|---|---|---|

| Initial | 0 T | 0% (350N nominal) | Normal operation |

| 15 minutes | 0.15 T intermittent | 5-8% | Undetectable in operation |

| 30 minutes | 0.15 T intermittent | 12-15% | Minor position errors at max acceleration |

| 45 minutes | 0.15 T intermittent | 18-22% | Noticeable position lag under load |

| Day 7 | Cumulative effect | 25-30% | Below critical threshold for operation |

Laboratory testing confirmed that exposure to fields of 0.15T could cause partial demagnetization of N42 NdFeB magnets when oriented unfavorably relative to the magnetization direction. The cumulative effect of multiple exposures further degraded the magnetic performance until the coupling force dropped below the minimum required for reliable operation.

Corrective Actions Implemented

Following this incident, the semiconductor manufacturer implemented several corrective actions:

Immediate Corrections

– Replaced all magnetic couplings with higher-grade SmCo magnets (Hci > 20 kOe)

– Added magnetic shielding to rodless cylinders

– Implemented EMI monitoring during maintenance activities

– Established exclusion zones during high-EMI maintenance proceduresSystem Improvements

– Added real-time magnetic coupling force monitoring

– Implemented position error trending analysis

– Installed EMI exposure indicators on sensitive equipment

– Enhanced collision detection and prevention systemsProcedural Changes

– Developed comprehensive EMI management protocols

– Implemented post-maintenance verification procedures

– Created maintenance coordination requirements

– Enhanced staff training on magnetic system vulnerabilitiesLong-term Measures

– Redesigned critical systems with redundant position verification

– Established regular magnetic coupling strength testing

– Developed predictive maintenance protocols based on coupling performance

– Created a database of EMI-sensitive components for maintenance planning

Lessons Learned

This case highlights several important lessons for pneumatic system design and maintenance:

Material Selection Considerations

– Magnetic materials must be selected with appropriate coercivity for the environment

– Cost savings on magnetic materials can lead to significant vulnerability

– Environmental exposure must be considered in material selection

– Safety margins should account for worst-case exposure scenariosMonitoring Requirements

– Subtle degradation can occur without obvious symptoms

– Trend analysis is essential for detecting gradual performance changes

– Critical parameters must be monitored directly, not inferred

– Early warning indicators should be established for key failure modesMaintenance Protocol Importance

– Maintenance activities on one system can affect adjacent systems

– EMI generation should be treated as a significant hazard

– Communication between maintenance teams is essential

– Verification procedures must confirm system integrity after nearby maintenance

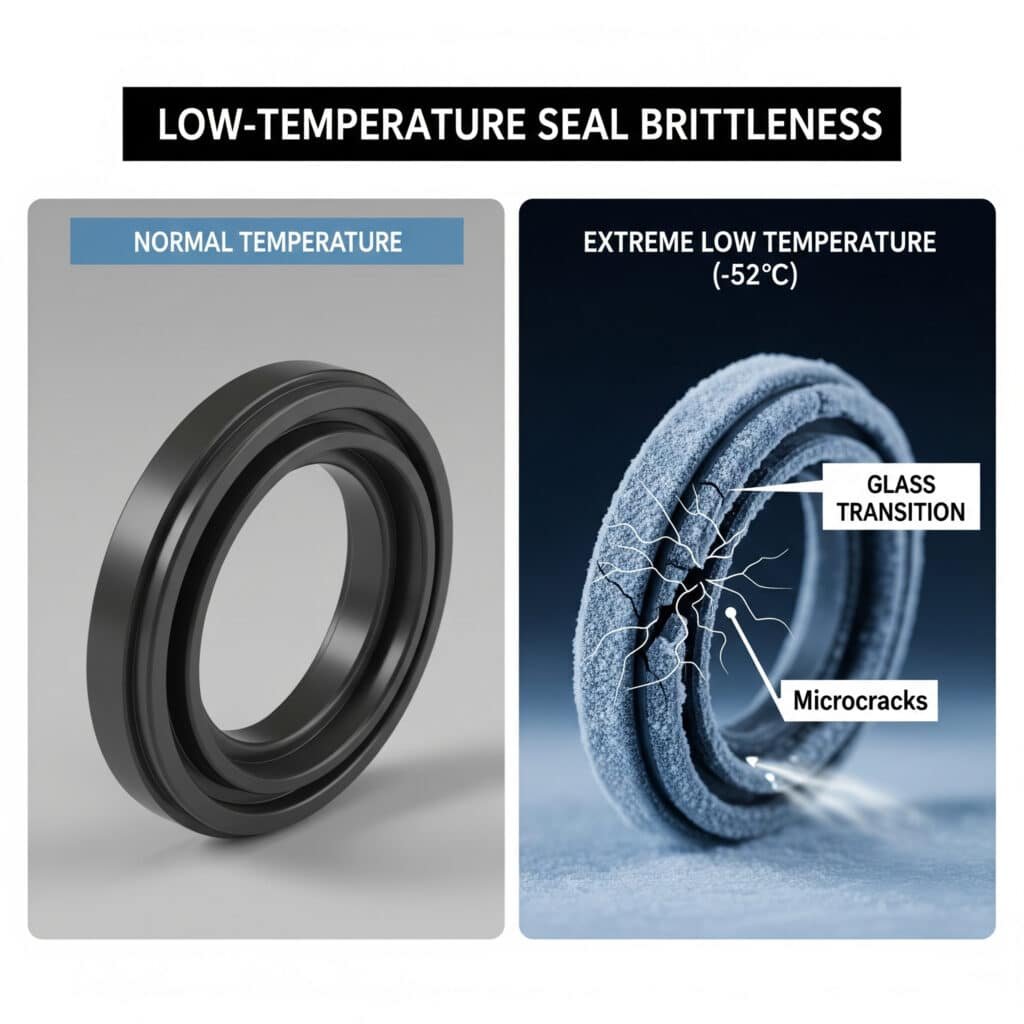

What Caused Catastrophic Seal Failure in Arctic Conditions?

An oil exploration company operating in northern Alaska experienced multiple simultaneous failures of pneumatic positioning cylinders controlling critical pipeline valves during an unexpected cold snap, resulting in an emergency shutdown that cost approximately $2.1 million in lost production.

Forensic analysis revealed that the cylinder seals had become brittle and cracked at the unexpectedly low temperatures (-52°C), well below their rated operating temperature of -40°C. The standard nitrile (NBR) seals underwent glass transition3 at these extreme temperatures, losing elasticity and developing microcracks that rapidly propagated during operation. The situation was exacerbated by inadequate cold-weather preventive maintenance procedures that failed to identify the deteriorating seal condition.

Incident Timeline and Investigation

| Time | Event | Temperature | Observations |

|---|---|---|---|

| Day 1, 18:00 | Weather forecast updated | -45°C predicted | Normal operation |

| Day 2, 02:00 | Temperature drops rapidly | -48°C | No immediate issues |

| Day 2, 06:00 | Temperature reaches minimum | -52°C | First seal failures begin |

| Day 2, 07:30 | Multiple valve actuator failures | -51°C | Emergency procedures initiated |

| Day 2, 08:15 | System shutdown completed | -50°C | Production halted |

| Day 2-4 | Investigation and repairs | -45°C to -40°C | Temporary heated enclosures installed |

Seal Material Properties and Temperature Effects

The failed seals were standard nitrile (NBR) with a manufacturer’s specified operating range of -40°C to +100°C, commonly used in industrial pneumatic applications.

Critical Material Transitions

| Material | Glass Transition Temperature | Brittleness Temperature | Recommended Min. Operating Temp. | Actual Operating Range |

|---|---|---|---|---|

| Standard NBR (failed seals) | -35°C to -20°C | -40°C | -30°C | -40°C to +100°C (manufacturer spec) |

| Low-temp NBR | -45°C to -35°C | -50°C | -40°C | -40°C to +85°C |

| HNBR | -30°C to -15°C | -35°C | -25°C | -25°C to +150°C |

| FKM (Viton) | -20°C to -10°C | -25°C | -15°C | -15°C to +200°C |

| Silicone | -65°C to -55°C | -70°C | -55°C | -55°C to +175°C |

| PTFE | -73°C (crystalline transition) | Not applicable | -70°C | -70°C to +250°C |

Failure Analysis Findings

Detailed examination of the failed seals revealed multiple issues:

Primary Failure Mechanisms

Material Glass Transition

– NBR polymer chains lost mobility below glass transition temperature

– Material hardness increased from Shore A 70 to Shore A 90+

– Elasticity reduced by approximately 95%

– Compression set recovery dropped to near-zeroMicrocrack Formation and Propagation

– Initial microcracks formed at high-stress regions (seal lips, corners)

– Crack propagation accelerated during dynamic movement

– Brittle fracture mechanics dominated failure mode

– Crack networks created leak paths through seal cross-sectionSeal Geometry Effects

– Sharp corners in seal design created stress concentration points

– Insufficient gland volume prevented thermal contraction accommodation

– Excessive compression in static condition increased brittleness impact

– Inadequate support allowed excessive deformation under pressureLubricant Contribution

– Standard pneumatic lubricant became highly viscous at low temperature

– Lubricant stiffening increased friction and mechanical stress

– Inadequate lubrication distribution due to viscosity increase

– Possible lubricant crystallization creating abrasive conditions

Material Analysis Results

Laboratory testing of the failed seals confirmed:

Physical Property Changes

– Shore A hardness: Increased from 70 (room temperature) to 92 (-52°C)

– Elongation at break: Decreased from 350% to <30%

– Compression set: Increased from 15% to >80%

– Tensile strength: Decreased by approximately 40%Microscopic Examination

– Extensive microcrack networks throughout seal cross-section

– Brittle fracture surfaces with minimal deformation

– Evidence of material embrittlement at molecular level

– Crystalline regions formed in normally amorphous polymer structureChemical Analysis

– No evidence of chemical degradation or attack

– Normal aging indicators within expected range

– No contamination detected

– Polymer composition matched specifications

Root Cause Analysis

The investigation identified several contributing factors:

Primary Factors

Material Selection Inadequacy

– NBR seals specified based on standard catalog ratings

– Temperature rating margin inadequate for Arctic conditions

– No consideration of glass transition effects

– Cost considerations prioritized over environmental extremesMaintenance Program Deficiencies

– No specific cold-weather inspection protocols

– Seal condition not monitored for temperature-related degradation

– No hardness testing included in maintenance procedures

– Inadequate spares strategy for extreme weather eventsSystem Design Limitations

– No heating provision for critical pneumatic components

– Insufficient insulation for thermal protection

– Exposed installation location with maximum cold exposure

– No temperature monitoring at component level

Secondary Factors

Operational Practices

– Continued operation despite approaching temperature limits

– No operational adjustments for extreme cold (reduced cycling, etc.)

– Inadequate response to weather forecast

– Limited operator awareness of temperature-related failure risksRisk Assessment Gaps

– Extreme cold scenario not adequately addressed in FMEA

– Over-reliance on manufacturer specifications

– Insufficient testing under actual environmental conditions

– Lack of industry experience sharing on cold-weather failures

Corrective Actions Implemented

Following this incident, the company implemented comprehensive improvements:

Immediate Corrections

– Replaced all seals with silicone compounds rated to -60°C

– Installed heated enclosures for critical valve actuators

– Implemented component-level temperature monitoring

– Developed emergency procedures for extreme cold eventsSystem Improvements

– Redesigned seal glands to accommodate thermal contraction

– Modified seal geometry to eliminate stress concentration points

– Selected low-temperature lubricants rated to -60°C

– Added redundant actuation systems for critical valvesProcedural Changes

– Established temperature-based maintenance protocols

– Implemented seal hardness testing during cold weather

– Created pre-winter preparation procedures

– Developed operational limitations based on temperatureLong-term Measures

– Conducted comprehensive cold-weather vulnerability assessment

– Established material testing program for Arctic conditions

– Developed enhanced specifications for extreme environment components

– Created knowledge-sharing program with other Arctic operators

Lessons Learned

This case highlights several important considerations for cold-weather pneumatic applications:

Material Selection Criticality

– Manufacturer temperature ratings often include minimal safety margins

– Glass transition temperature is more relevant than absolute minimum rating

– Material properties change dramatically near transition temperatures

– Application-specific testing is essential for critical componentsDesign for Environmental Extremes

– Worst-case scenarios must include appropriate safety margins

– Thermal protection should be integrated into system design

– Component-level monitoring is essential for early detection

– Redundancy becomes more critical in extreme environmentsMaintenance Adaptation Requirements

– Standard maintenance procedures may be inadequate for extreme conditions

– Condition monitoring must adapt to environmental challenges

– Preventive replacement strategies should consider environmental stressors

– Specialized inspection techniques may be required for extreme environments

Why Did High-Frequency Vibration Lead to Critical Fastener Failure?

A high-speed metal stamping operation experienced a catastrophic failure when a pneumatic cylinder detached from its mounting bracket during operation, causing significant damage to the press and resulting in 4 days of production downtime with repair costs exceeding $380,000.

The investigation determined that high-frequency vibration4 (175-220 Hz) generated by the stamping operation had caused systematic loosening of the cylinder mounting bolts despite the presence of standard lock washers. Metallurgical analysis revealed that the vibration created cyclic relative movement between the bolt threads and mounting surfaces, gradually overcoming the locking features and allowing the fasteners to rotate loose over approximately 2.3 million press cycles.

Incident Timeline and Investigation

| Time | Event | Cycle Count | Observations |

|---|---|---|---|

| Installation | New cylinder mounted | 0 | Proper torque applied (65 Nm) |

| Week 1-6 | Normal operation | 0-1.5M cycles | No visible issues |

| Week 7 | Maintenance inspection | 1.7M cycles | No loosening detected visually |

| Week 8, Day 3 | Operator reports noise | 2.1M cycles | Maintenance scheduled for weekend |

| Week 8, Day 5 | Catastrophic failure | 2.3M cycles | Cylinder detachment during operation |

| Week 8-9 | Investigation and repairs | N/A | Root cause analysis conducted |

Vibration and Fastener Dynamics

The stamping press operated at 180 strokes per minute (3 Hz), but the impact of the stamping operation generated high-frequency vibration components:

Vibration Characteristics

| Frequency Component | Amplitude | Source | Effect on Fasteners |

|---|---|---|---|

| 3 Hz | 0.8g | Basic press cycle | Minimal loosening potential |

| 15-40 Hz | 1.2-1.5g | Machine structural resonance | Moderate loosening potential |

| 175-220 Hz | 3.5-4.2g | Stamping impact | Severe loosening potential |

| 350-500 Hz | 0.5-0.8g | Harmonics | Moderate loosening potential |

Fastener System Analysis

The failed mounting system used M12 class 8.8 bolts with split lock washers, tightened to 65 Nm:

Fastener Configuration

| Component | Specification | Condition After Failure | Design Limitation |

|---|---|---|---|

| Bolts | M12 x 1.75, Class 8.8 | Thread wear, no deformation | Insufficient preload retention |

| Lock Washers | Split ring, spring steel | Partially flattened, reduced tension | Inadequate for high-frequency vibration |

| Mounting Holes | 13mm clearance holes | Elongation from movement | Excessive clearance |

| Mounting Surface | Machined steel | Fretting corrosion5 visible | Insufficient friction |

| Thread Engagement | 18mm (1.5 × diameter) | Adequate | Not a contributing factor |

Failure Mechanism Investigation

Detailed analysis revealed a classic vibration-induced loosening process:

Loosening Progression

Initial Condition

– Proper preload applied (approximately 45 kN)

– Lock washer compressed with adequate tension

– Static friction sufficient to prevent rotation

– Thread friction distributed across engaged threadsEarly Stage Degradation

– High-frequency vibration causes microscopic transverse movement

– Transverse movement creates momentary preload reduction

– Momentary preload reduction allows minute thread rotation

– Lock washer tension gradually decreasesProgressive Loosening

– Accumulated micro-rotation reduces preload

– Reduced preload increases transverse movement amplitude

– Increased movement accelerates loosening rate

– Lock washer effectiveness diminishes as flattening occursFinal Failure

– Preload drops below critical threshold

– Gross movement begins between joined components

– Rapid final loosening occurs

– Complete fastener disengagement

Root Cause Analysis

The investigation identified several contributing factors:

Primary Factors

Inadequate Fastener Selection

– Split lock washers ineffective against high-frequency vibration

– No secondary locking mechanism implemented

– Insufficient preload for vibration environment

– Reliance on friction-based locking onlyVibration Characteristics

– High-frequency components exceeded lock washer capability

– Transverse vibration aligned with loosening direction

– Resonance amplification at mounting location

– Continuous operation without vibration monitoringMaintenance Program Deficiencies

– Visual-only inspection insufficient to detect early loosening

– No torque verification during maintenance

– Inadequate vibration monitoring program

– No predictive maintenance for fastener systems

Secondary Factors

Design Limitations

– Cylinder mounting location subjected to maximum vibration

– Insufficient structural dampening

– No vibration isolation implemented

– Mounting bracket design amplified vibrationInstallation Practices

– No thread locking compound used

– Standard torque applied without vibration consideration

– No witness marks for visual loosening detection

– Inconsistent torque application procedure

Laboratory Testing and Verification

To confirm the failure mechanism, laboratory testing was conducted:

Test Results

| Test Condition | Loosening Onset | Complete Loosening | Observations |

|---|---|---|---|

| Standard configuration (as failed) | 15,000-20,000 cycles | 45,000-55,000 cycles | Progressive loosening pattern matched field failure |

| With thread locking compound | >200,000 cycles | Not reached in test | Significant improvement, some preload loss |

| With Nord-Lock washers | >500,000 cycles | Not reached in test | Minimal preload loss |

| With prevailing torque nuts | >500,000 cycles | Not reached in test | Consistent preload maintenance |

| With safety wire | >100,000 cycles | 350,000-400,000 cycles | Delayed but eventual failure |

Corrective Actions Implemented

Following this incident, the company implemented comprehensive improvements:

Immediate Corrections

– Replaced all cylinder mounting fasteners with Nord-Lock washers

– Applied medium-strength thread locking compound

– Increased fastener size to M16 (greater preload capacity)

– Implemented torque-plus-angle tightening methodSystem Improvements

– Added vibration isolation mounts for cylinders

– Redesigned mounting brackets for increased stiffness

– Implemented dual fastening systems for critical components

– Added witness marks for visual loosening detectionProcedural Changes

– Established regular torque verification program

– Implemented vibration monitoring at critical locations

– Created specific fastener inspection protocols

– Developed comprehensive fastener selection guidelinesLong-term Measures

– Conducted vibration analysis of all pneumatic systems

– Established fastener database with application-specific selections

– Implemented ultrasonic bolt tension monitoring for critical fasteners

– Developed training program on vibration-resistant fastening

Lessons Learned

This case highlights several important considerations for pneumatic systems in high-vibration environments:

Fastener Selection Criticality

– Standard lock washers are ineffective against high-frequency vibration

– Proper locking mechanisms must be matched to vibration characteristics

– Preload alone is insufficient for vibration resistance

– Redundant locking methods should be considered for critical applicationsVibration Management Requirements

– High-frequency components are often overlooked in vibration analysis

– Transverse vibration is particularly dangerous for threaded fasteners

– Vibration isolation should be considered for sensitive components

– Resonance effects can amplify vibration at specific locationsInspection and Maintenance Considerations

– Visual inspection alone cannot detect early-stage loosening

– Torque verification is essential for vibration-exposed fasteners

– Witness marks provide simple but effective monitoring

– Predictive technologies (ultrasonic, thermal) can detect loosening before failure

Conclusion: Implementing Preventive Measures

These three case studies highlight how seemingly minor environmental factors—electromagnetic fields, extreme temperatures, and high-frequency vibration—can lead to catastrophic failures in pneumatic systems. By understanding these failure mechanisms, engineers and maintenance professionals can implement effective preventive measures.

Key Preventive Strategies

Enhanced Material Selection

– Select materials with appropriate properties for the actual operating environment

– Consider worst-case scenarios in material specifications

– Implement safety margins beyond manufacturer ratings

– Validate material performance through application-specific testingImproved Monitoring Systems

– Implement condition monitoring for critical parameters

– Establish trend analysis to detect gradual degradation

– Utilize predictive technologies for early failure detection

– Monitor environmental conditions at the component levelComprehensive Maintenance Protocols

– Develop environment-specific maintenance procedures

– Implement regular verification of critical components

– Establish clear acceptance criteria for continued operation

– Create response protocols for environmental extremesRobust Design Practices

– Design for environmental extremes with appropriate margins

– Implement redundancy for critical functions

– Consider failure modes beyond normal operating conditions

– Validate designs through testing under actual conditions

By applying these lessons learned, pneumatic system designers and maintenance professionals can significantly improve reliability and prevent costly failures, even in the most challenging operating environments.

FAQs About Pneumatic Cylinder Failures

How often should magnetic couplings be tested for field strength?

For non-critical applications, annual testing is typically sufficient. For critical applications, especially in environments where electromagnetic fields may be present, quarterly testing is recommended. Any maintenance activities involving electrical equipment within 5 meters of magnetic couplings should trigger additional verification testing. Implementing simple field strength indicators that change color when exposed to potentially damaging fields can provide continuous monitoring between formal tests.

What seal materials are best for extreme low-temperature applications?

For extreme low-temperature applications (below -40°C), silicone, PTFE, or specially formulated low-temperature elastomers like LTFE (Low Temperature Fluoroelastomer) are recommended. Silicone maintains flexibility down to approximately -55°C, while PTFE remains functional to -70°C. For the most extreme conditions, custom compounds like perfluoroelastomers with special plasticizers can function below -65°C. Always verify the glass transition temperature (Tg) rather than relying solely on the manufacturer’s stated minimum temperature rating, and implement a safety margin of at least 10°C below the expected minimum temperature.

What are the most effective fastener locking methods for high-vibration environments?

For high-vibration environments, mechanical locking systems that don’t rely solely on friction are most effective. Nord-Lock washers, which use wedge-locking principles, provide excellent resistance to vibration loosening. Prevailing torque nuts (with nylon inserts or deformed threads) also perform well. For critical applications, a combination approach using both mechanical locking (Nord-Lock washers) and chemical locking (medium-strength threadlocker) provides the highest reliability. Safety wire is effective for fasteners that aren’t frequently removed, while tab washers can be appropriate for lower-vibration applications. Standard split lock washers should never be relied upon in high-vibration environments.

-

Provides a technical comparison of Neodymium (NdFeB) and Samarium-Cobalt (SmCo) rare-earth magnets, detailing their differences in magnetic strength, temperature stability, and resistance to demagnetization. ↩

-

Explains the concept of intrinsic coercivity (Hci), a material’s inherent ability to resist demagnetization from an external magnetic field, which is a critical parameter for magnet selection in high-EMI environments. ↩

-

Offers a scientific explanation of the glass transition temperature (Tg), the point at which an amorphous polymer changes from a hard, glassy state to a soft, rubbery state, which is crucial for determining a seal’s low-temperature performance limit. ↩

-

Describes the mechanics of how transverse vibration can cause threaded fasteners to self-loosen, often referencing the Junker test, a standard method for evaluating the security of bolted joints under dynamic loads. ↩

-

Details the mechanism of fretting corrosion, a form of wear and corrosion damage that occurs at the interface of two contacting surfaces subjected to minute, repetitive rubbing movements, often caused by vibration. ↩