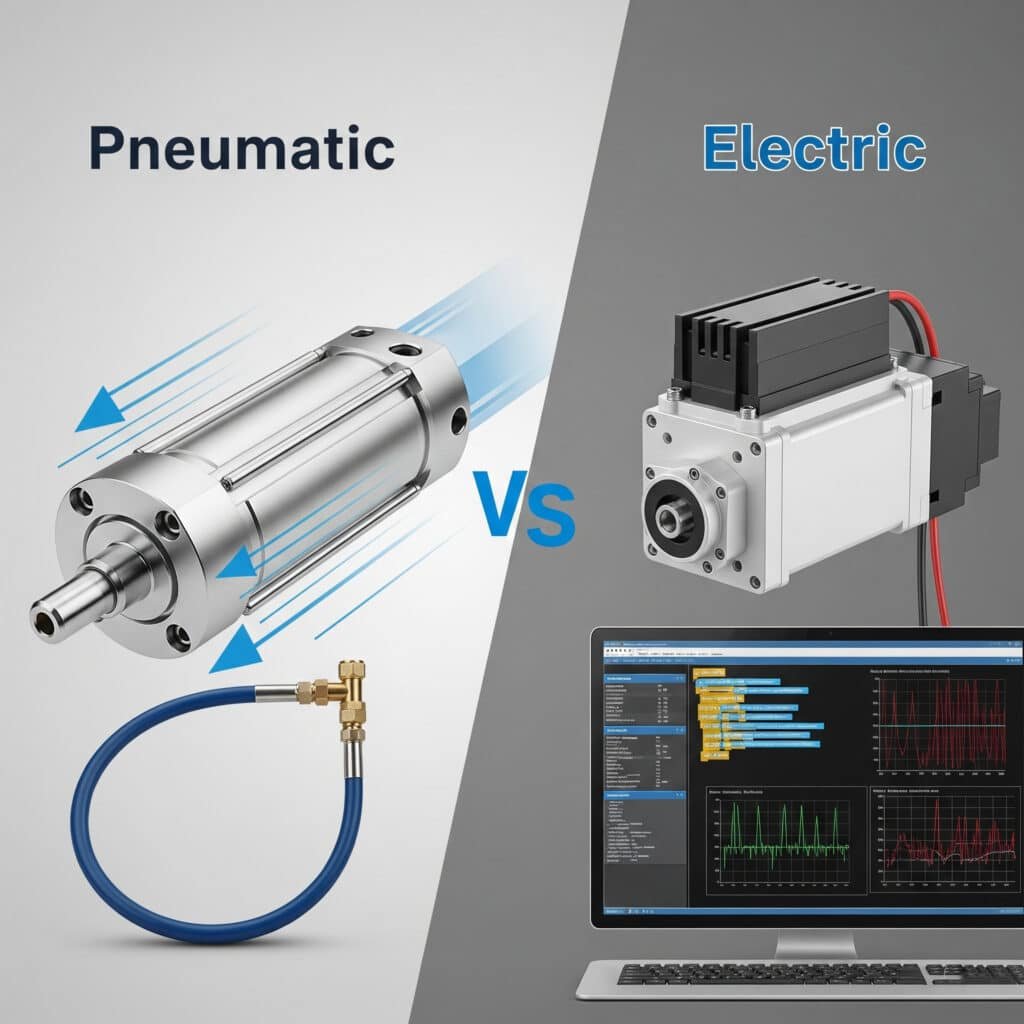

Engineers face critical decisions between pneumatic cylinders and electric actuators, with wrong choices leading to performance issues, excessive costs, and maintenance headaches in industrial automation systems.

Choose a cylinder over an electric actuator when you need high speed, explosive-proof operation, simple control, cost-effective solutions, or applications requiring high force-to-weight ratios, while electric actuators excel in precision positioning, energy efficiency, and complex motion control requirements.

Last week, Marcus from a Texas chemical processing plant called us after discovering his expensive electric actuators were failing in their hazardous environment, where our pneumatic cylinders would have been the safer, more reliable choice from the start.

Table of Contents

- What Are the Key Performance Differences Between Cylinders and Electric Actuators?

- Which Applications Favor Pneumatic Cylinders Over Electric Solutions?

- How Do Cost Factors Compare Between Cylinder and Electric Actuator Systems?

- What Environmental and Safety Considerations Should Guide Your Actuator Choice?

What Are the Key Performance Differences Between Cylinders and Electric Actuators?

Understanding fundamental performance characteristics helps engineers make informed decisions based on specific application requirements and system constraints.

Pneumatic cylinders deliver superior speed, force-to-weight ratios, and simplicity, while electric actuators provide precise positioning, energy efficiency, and programmable motion profiles, with each technology optimized for different industrial automation needs.

Speed and Response Characteristics

Pneumatic Cylinder Advantages

Compressed air systems excel in high-speed applications:

- Rapid acceleration: Near-instantaneous response to control signals

- High cycle rates: Up to 1000+ cycles per minute capability

- Consistent speed: Maintains velocity under varying loads

- Simple speed control: Basic flow control valve adjustments

Electric Actuator Characteristics

Electric systems offer different speed profiles:

- Variable speed: Programmable acceleration and deceleration curves

- Precise control: Exact velocity matching and synchronization

- Load compensation: Automatic speed adjustment for varying loads

- Complex profiles: Multi-segment motion patterns

Force and Power Comparison

Pneumatic Force Capabilities

Cylinders provide excellent force characteristics:

| Cylinder Type | Force Range | Power-to-Weight1 | Typical Applications |

|---|---|---|---|

| Standard Cylinder | 10-5000 lbf | Excellent | Heavy lifting, clamping |

| Rodless Cylinder2 | 50-3000 lbf | Very Good | Long stroke positioning |

| Mini Cylinder | 5-200 lbf | Good | Precision assembly |

| Heavy Duty | 100-10000+ lbf | Excellent | Industrial pressing |

Electric Actuator Force Profile

Electric systems show different force characteristics:

- Consistent torque: Uniform force throughout stroke

- Programmable limits: Software-controlled force restrictions

- Feedback control: Real-time force monitoring and adjustment

- Lower power-to-weight: Generally heavier for equivalent force

Control System Complexity

Pneumatic Simplicity

Cylinder control systems remain straightforward:

- Basic components: Solenoid Valve3, pressure regulator, flow controls

- Simple wiring: Minimal electrical connections required

- Reliable operation: Fewer electronic components to fail

- Easy troubleshooting: Visual and audible diagnostic capabilities

Electric System Sophistication

Electric actuators require complex control systems:

- Advanced controllers: Programmable logic and motion control

- Sensor integration: Position, velocity, and force feedback

- Communication protocols: Network connectivity and data exchange

- Software maintenance: Regular updates and programming changes

Maintenance and Reliability Factors

Pneumatic Maintenance Requirements

Cylinder systems need basic maintenance:

- Air quality: Proper filtration and lubrication

- Seal replacement: Periodic seal and gasket service

- Simple diagnostics: Visual inspection and pressure testing

- Field repair: Most maintenance performed on-site

Electric Actuator Maintenance

Electric systems require specialized maintenance:

- Electronic diagnostics: Computer-based troubleshooting tools

- Motor service: Brush replacement and bearing maintenance

- Software updates: Periodic programming and calibration

- Specialized repair: Factory service often required

Which Applications Favor Pneumatic Cylinders Over Electric Solutions?

Specific industrial applications and operating conditions make pneumatic cylinders the superior choice over electric actuators for optimal performance and reliability.

Pneumatic cylinders excel in high-speed repetitive operations, hazardous environments, simple on/off positioning, heavy-duty applications, and situations requiring explosion-proof operation, while offering superior cost-effectiveness for basic automation tasks.

High-Speed Automation Applications

Manufacturing Assembly Lines

Rapid cycle operations favor pneumatic solutions:

- Pick and place: Fast part transfer and positioning

- Stamping operations: High-speed pressing and forming

- Packaging machinery: Rapid product handling and sealing

- Sorting systems: Quick diverting and routing operations

Material Handling Systems

Pneumatic cylinders dominate material movement:

- Conveyor transfers: Product pushing and positioning

- Gate operations: Fast opening and closing cycles

- Lifting mechanisms: Rapid vertical positioning

- Clamping systems: Quick workpiece securing

Simple Positioning Requirements

Basic On/Off Operations

Applications requiring simple extend/retract motion:

- Door and gate control: Basic opening and closing

- Safety barriers: Emergency stop and blocking systems

- Tool positioning: Simple in/out movements

- Part ejection: Finished product removal

Two-Position Applications

Systems needing only start and end positions:

- Valve actuation: Open/close control without intermediate positions

- Brake systems: Engage/disengage operations

- Clamp mechanisms: Secure/release functions

- Diverter gates: Route selection operations

Heavy-Duty Industrial Applications

High-Force Requirements

Pneumatic cylinders excel in demanding applications:

| Application Type | Force Requirement | Cylinder Advantage | Alternative Cost |

|---|---|---|---|

| Industrial pressing | 1000-5000 lbf | Simple, reliable | 3-5x electric cost |

| Heavy lifting | 500-3000 lbf | Excellent power/weight | Complex electric system |

| Clamping operations | 200-2000 lbf | Fast response | Slower electric response |

| Forming operations | 1000-8000 lbf | Consistent force | Variable electric torque |

Harsh Environment Operations

Extreme Temperature Conditions

Pneumatic systems handle temperature extremes:

- High temperature: Air systems operate in extreme heat

- Low temperature: Compressed air functions in freezing conditions

- Temperature cycling: Pneumatic components handle thermal stress

- Thermal expansion: Air systems accommodate dimensional changes

Contaminated Environments

Cylinders perform reliably in dirty conditions:

- Dust and debris: Sealed pneumatic systems resist contamination

- Moisture exposure: Proper air treatment prevents corrosion

- Chemical exposure: Appropriate materials resist chemical attack

- Washdown environments: Sealed cylinders handle cleaning procedures

Cost-Sensitive Applications

Budget-Conscious Projects

Pneumatic solutions offer economic advantages:

- Lower initial cost: Cylinders cost 50-70% less than equivalent electric

- Simple installation: Reduced setup and commissioning time

- Minimal training: Operators quickly understand pneumatic systems

- Standard components: Common parts reduce inventory costs

Anna, who manages automation projects for a UK food processing company, chose Bepto rodless cylinders over electric actuators for her new packaging line. The pneumatic solution provided the required 200 cycles per minute at 40% lower cost, with simpler maintenance that her existing staff could handle without additional training.

How Do Cost Factors Compare Between Cylinder and Electric Actuator Systems?

Total cost of ownership analysis reveals significant differences between pneumatic and electric actuator systems across initial investment, operating costs, and maintenance expenses.

Pneumatic cylinders typically cost 50-70% less initially than electric actuators, with lower installation complexity and maintenance requirements, while electric systems may offer energy savings in specific applications but require higher upfront investment and specialized support.

Initial Investment Comparison

Pneumatic System Costs

Cylinder-based systems require minimal initial investment:

- Component costs: Basic cylinders, valves, and fittings

- Installation simplicity: Standard pneumatic connections

- Control system: Simple solenoid valve and basic controls

- Supporting equipment: Air compressor and treatment units

Electric Actuator Investment

Electric systems demand higher upfront costs:

- Actuator pricing: 2-3x cost of equivalent pneumatic cylinder

- Controller requirements: Sophisticated motion control systems

- Installation complexity: Specialized electrical and programming work

- Support infrastructure: Power supplies and communication networks

Bepto Cost Advantage Analysis

Pneumatic Component Pricing Comparison

| Component Type | Bepto Price | OEM Price | Electric Alternative | Your Savings |

|---|---|---|---|---|

| Standard Cylinder | $85-$450 | $150-$750 | $400-$1200 | 60-75% |

| Rodless Air Cylinder | $180-$850 | $300-$1400 | $800-$2500 | 65-80% |

| Mini Cylinder | $45-$200 | $80-$350 | $300-$800 | 70-85% |

| Complete System | $500-$2000 | $800-$3500 | $2000-$8000 | 60-75% |

Operating Cost Analysis

Energy Consumption Factors

Different energy profiles affect long-term costs:

- Pneumatic efficiency: Air compressor energy consumption

- Electric efficiency: Direct electrical power usage

- Duty cycle impact: Continuous vs. intermittent operation effects

- Load variations: Energy consumption under different conditions

Maintenance Cost Comparison

Long-term service expenses vary significantly:

| Maintenance Category | Pneumatic Cylinder | Electric Actuator | Cost Difference |

|---|---|---|---|

| Routine service | $50-$150/year | $200-$500/year | 75% savings |

| Parts replacement | $25-$100/service | $150-$800/service | 60-85% savings |

| Specialized service | Minimal | $500-$2000/year | 90%+ savings |

| Training requirements | Basic | Specialized | Significant savings |

System Integration Costs

Installation and Commissioning

Setup costs differ substantially:

- Pneumatic installation: Standard fittings and connections

- Electric installation: Specialized wiring and programming

- Commissioning time: Hours vs. days for complex electric systems

- Training requirements: Minimal vs. extensive for electric systems

Long-Term Support Costs

Ongoing support expenses vary:

- Pneumatic support: Local technicians and standard parts

- Electric support: Specialized service and proprietary components

- Upgrade costs: Simple pneumatic vs. complex electric modifications

- Obsolescence risk: Standard pneumatic vs. proprietary electric components

Return on Investment Analysis

Payback Period Calculations

Different applications show varying payback periods:

- High-speed applications: Pneumatic advantage in 6-12 months

- Simple positioning: Immediate pneumatic cost advantage

- Heavy-duty operations: Pneumatic savings apparent immediately

- Complex motion: Electric systems may justify higher costs

Total Cost of Ownership

Five-year cost analysis typically favors pneumatics:

- Initial investment: 50-70% pneumatic advantage

- Operating costs: Variable based on duty cycle and energy costs

- Maintenance expenses: 60-80% pneumatic advantage

- Upgrade flexibility: Pneumatic systems easier to modify

What Environmental and Safety Considerations Should Guide Your Actuator Choice?

Environmental conditions and safety requirements often determine the optimal actuator technology choice, with each offering distinct advantages in specific operating conditions.

Pneumatic cylinders provide inherent explosion-proof operation, temperature tolerance, and contamination resistance, while electric actuators offer precise control and energy efficiency, making environmental factors and safety requirements critical selection criteria.

Hazardous Environment Applications

Explosion-Proof Requirements

Pneumatic systems excel in dangerous atmospheres:

- Intrinsically safe4: No electrical sparks or heat generation

- Hazardous area ratings: Suitable for explosive gas and dust environments

- Chemical compatibility: Appropriate materials resist chemical attack

- Fire safety: No ignition sources in pneumatic operation

Safety System Integration

Pneumatic cylinders enhance overall safety:

- Fail-safe operation: Spring return and air pressure loss protection

- Emergency stops: Immediate response to safety signals

- Manual override: Mechanical backup operation capability

- Visible operation: Clear indication of actuator position and status

Environmental Tolerance Factors

Temperature Extremes

Pneumatic systems handle harsh temperature conditions:

| Environmental Factor | Pneumatic Capability | Electric Limitation | Application Advantage |

|---|---|---|---|

| High temperature | -40°F to +200°F | Limited by electronics | Foundries, heat treating |

| Low temperature | Operates to -40°F | Battery/motor issues | Cold storage, outdoor |

| Thermal cycling | Excellent tolerance | Electronic stress | Varying conditions |

| Humidity | Sealed operation | Electrical concerns | Wet environments |

Contamination Resistance

Cylinders perform reliably in dirty environments:

- Dust protection: Sealed designs prevent particle ingress

- Washdown capability: Food-grade and pharmaceutical applications

- Chemical resistance: Appropriate seal materials and coatings

- Vibration tolerance: Mechanical systems handle shock and vibration

Regulatory Compliance Considerations

Industry Standards

Different industries favor specific technologies:

- Food and beverage: Pneumatic systems meet sanitary requirements

- Pharmaceutical: Clean operation and validation requirements

- Chemical processing: Explosion-proof and chemical compatibility

- Mining and oil: Harsh environment and safety requirements

Certification Requirements

Compliance factors influence technology choice:

- ATEX certification5: European explosion-proof requirements

- UL listings: North American safety standards

- FDA compliance: Food contact and pharmaceutical applications

- ISO standards: International quality and safety requirements

Energy and Sustainability Factors

Environmental Impact Analysis

Long-term environmental considerations:

- Energy efficiency: Electric systems may offer advantages in continuous operation

- Carbon footprint: Depends on local electricity generation methods

- Recyclability: Pneumatic components generally more recyclable

- Service life: Pneumatic systems often provide longer operational life

Compressed Air Infrastructure

Existing air systems influence decisions:

- Available capacity: Utilize existing compressed air systems

- Quality requirements: Air treatment and filtration needs

- Distribution systems: Piping and connection infrastructure

- Backup systems: Redundancy and emergency operation capability

Application-Specific Selection Guide

Decision Matrix for Technology Selection

| Application Requirement | Favor Pneumatic | Favor Electric | Key Consideration |

|---|---|---|---|

| Explosion-proof operation | ✓ | ✗ | Safety critical |

| High-speed cycles | ✓ | ✗ | Performance requirement |

| Precise positioning | ✗ | ✓ | Accuracy critical |

| Simple on/off operation | ✓ | ✗ | Cost and simplicity |

| Complex motion profiles | ✗ | ✓ | Sophistication needed |

| Harsh environments | ✓ | ✗ | Reliability critical |

James, a project engineer at a German chemical plant, initially specified electric actuators for a new reactor system. After consulting with our team about the explosive atmosphere requirements, he switched to Bepto rodless cylinders that provided the necessary safety certification at 60% lower cost, with faster delivery and simpler installation in their hazardous environment.

Conclusion

Choose pneumatic cylinders when you need high speed, explosion-proof operation, simple control, cost-effectiveness, or harsh environment capability, while electric actuators excel in precision positioning and complex motion control applications.

FAQs About Cylinder vs Electric Actuator Selection

Q: Are pneumatic cylinders always faster than electric actuators?

Yes, pneumatic cylinders typically achieve faster speeds and response times due to compressed air’s rapid expansion, making them ideal for high-speed repetitive operations where electric actuators may be too slow.

Q: Which technology offers better precision – cylinders or electric actuators?

Electric actuators provide superior precision with programmable positioning and feedback control, while pneumatic cylinders excel in simple two-position applications but offer limited intermediate positioning accuracy.

Q: How do maintenance costs compare between pneumatic and electric systems?

Pneumatic cylinders typically require 60-80% lower maintenance costs due to simpler components, standard parts availability, and basic service requirements compared to complex electric actuator systems.

Q: Can rodless cylinders compete with electric actuators for long-stroke applications?

Yes, rodless air cylinders often outperform electric actuators in long-stroke applications by providing faster speeds, higher force capability, and significantly lower costs while maintaining reliable operation.

Q: What safety advantages do pneumatic cylinders offer over electric actuators?

Pneumatic cylinders provide inherent explosion-proof operation, fail-safe spring return capability, and no electrical ignition sources, making them safer for hazardous environments and critical safety applications.

-

Understand the power-to-weight ratio, a key performance metric used in engineering to compare the output of different devices or engines. ↩

-

Learn about the design, types, and operational advantages of rodless pneumatic cylinders in industrial automation. ↩

-

Explore the operating principles of solenoid valves and how they are used to direct compressed air flow to control pneumatic actuators. ↩

-

Discover the concept of intrinsic safety, a design technique applied to electrical equipment for safe use in hazardous locations. ↩

-

Learn about the ATEX directives, the European Union regulations that define the requirements for equipment used in potentially explosive atmospheres. ↩