Chemical incompatibility destroys actuator seals within weeks instead of years, causing catastrophic failures that shut down entire production lines. Most engineers discover seal material limitations only after experiencing expensive downtime, when their “standard” seals dissolve, swell, or crack under chemical exposure.

The right seal material selection based on chemical compatibility can extend actuator service life from months to 5+ years in harsh chemical environments, with materials like FFKM (Perfluoroelastomer) offering universal chemical resistance while NBR (Nitrile) provides cost-effective solutions for hydrocarbon applications. Understanding the chemical resistance chart is crucial for preventing premature seal failure.

Just last month, I received an urgent call from a frustrated plant manager whose facility had experienced three actuator failures in two weeks, all due to seal degradation from an overlooked chemical cleaning process. This costly mistake could have been prevented with proper seal material selection. 😰

Table of Contents

- How Do Different Chemical Environments Affect Actuator Seal Performance?

- Which Seal Materials Offer the Best Chemical Resistance Properties?

- What Are the Cost vs. Performance Trade-offs in Seal Material Selection?

- How Do You Select the Right Seal Material for Your Specific Application?

How Do Different Chemical Environments Affect Actuator Seal Performance?

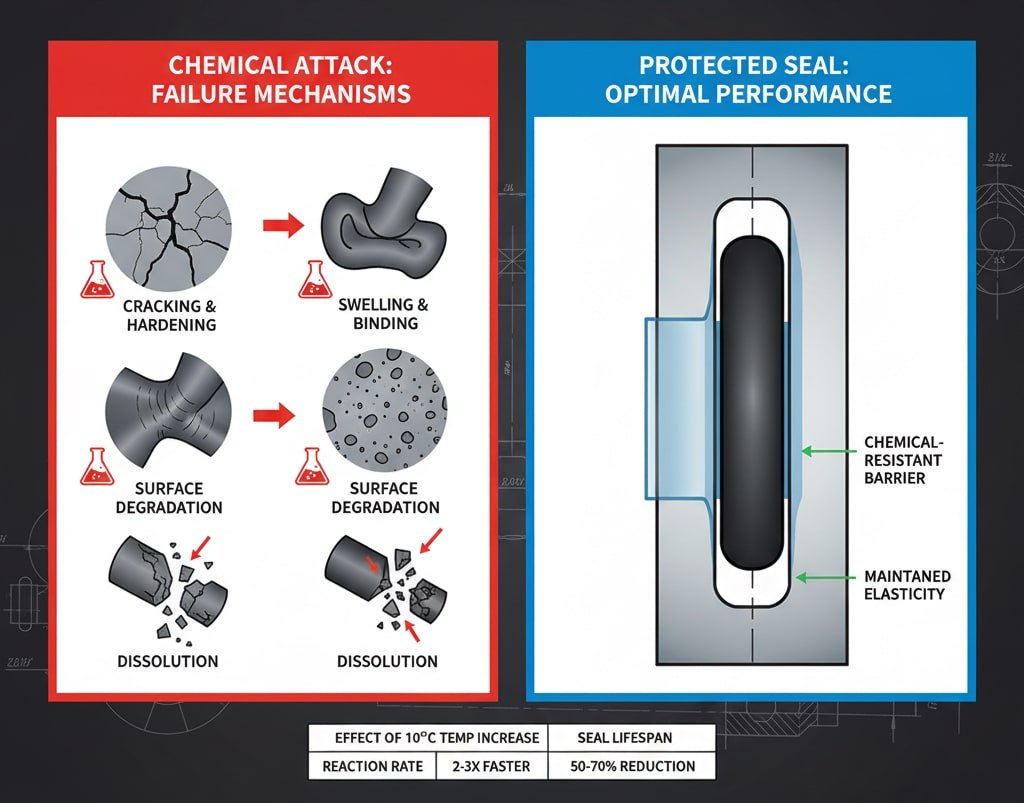

Chemical exposure creates multiple failure mechanisms in actuator seals, from immediate dissolution to gradual property degradation over time.

Chemical environments affect seals through swelling (volume increase up to 40%), hardening (durometer1 changes of 20+ points), cracking (stress fractures), and dissolution (material breakdown), with exposure temperature amplifying these effects by 2-3x for every 10°C increase.

Primary Chemical Attack Mechanisms

Understanding how chemicals damage seals helps predict failure modes:

Volume Swell and Shrinkage

- Excessive swelling: Seals bind in grooves, increasing friction

- Shrinkage effects: Loss of sealing contact pressure

- Dimensional instability: Unpredictable performance variations

- Groove damage: Swollen seals can crack housing components

Chemical Property Changes

- Hardness variation: Durometer shifts affecting flexibility

- Tensile strength loss: Reduced tear resistance under stress

- Compression set: Permanent deformation after chemical exposure

- Surface degradation: Roughening that accelerates wear

| Chemical Class | Primary Effect | Typical Damage | Time to Failure |

|---|---|---|---|

| Acids (pH <3) | Hydrolysis2 | Cracking, hardening | 1-6 months |

| Bases (pH >11) | Saponification3 | Softening, swelling | 2-8 months |

| Hydrocarbons | Swelling | Volume increase | 3-12 months |

| Oxidizers | Chain scission4 | Cracking, brittleness | 1-3 months |

Real-World Chemical Failure Case

I worked with Robert, a process engineer at a chemical processing plant in Houston, Texas. His facility’s cleaning-in-place (CIP) system used caustic solutions that were destroying standard NBR seals every 6 weeks. After switching to our Bepto actuators with EPDM seals specifically rated for alkaline environments, Robert’s maintenance intervals extended to over 2 years, saving his company $15,000 annually in replacement costs. 🧪

Which Seal Materials Offer the Best Chemical Resistance Properties?

Different elastomer families provide varying levels of chemical resistance, with specialized compounds designed for specific chemical environments.

FFKM (Perfluoroelastomer) offers the broadest chemical resistance but costs 10-20x more than standard materials, while FKM (Fluoroelastomer) provides excellent performance for most industrial chemicals at moderate cost, and specialized compounds like EPDM excel in specific applications like steam and alkaline environments.

Comprehensive Seal Material Guide

Premium Chemical Resistance Materials

FFKM (Perfluoroelastomer) – Kalrez®, Chemraz®

- Temperature range: -15°C to +327°C

- Chemical resistance: Excellent to nearly all chemicals

- Applications: Semiconductor, pharmaceutical, extreme chemical service

- Limitations: Very high cost, limited low-temperature flexibility

FKM (Fluoroelastomer) – Viton®, Fluorel®

- Temperature range: -26°C to +204°C

- Chemical resistance: Excellent for acids, hydrocarbons, oxidizers

- Applications: Chemical processing, automotive, aerospace

- Limitations: Poor performance with steam, amines, ketones

Standard Industrial Materials

EPDM (Ethylene Propylene Diene Monomer)

- Temperature range: -54°C to +149°C

- Chemical resistance: Excellent for steam, alkaline solutions

- Applications: Food processing, steam service, water treatment

- Limitations: Poor hydrocarbon resistance

NBR (Nitrile Butadiene Rubber)

- Temperature range: -40°C to +121°C

- Chemical resistance: Excellent for petroleum products

- Applications: Hydraulic systems, fuel handling, general industrial

- Limitations: Poor ozone and weather resistance

| Material | Chemical Resistance Rating | Cost Factor | Best Applications |

|---|---|---|---|

| FFKM5 | Excellent (95% chemicals) | 20x | Extreme chemical service |

| FKM | Very Good (80% chemicals) | 5x | General chemical processing |

| EPDM | Good (60% chemicals) | 2x | Steam and alkaline service |

| NBR | Fair (40% chemicals) | 1x | Hydrocarbon applications |

What Are the Cost vs. Performance Trade-offs in Seal Material Selection?

Balancing initial material costs against service life and downtime prevention requires careful analysis of total cost of ownership.

While premium seal materials cost 5-20x more initially, they often provide 3-10x longer service life in harsh chemical environments, making them cost-effective when downtime costs exceed $1,000 per hour or replacement intervals fall below 6 months with standard materials.

Total Cost of Ownership Analysis

Direct Cost Components

- Material cost: Initial seal material premium

- Labor cost: Installation and replacement time

- Downtime cost: Production losses during maintenance

- Inventory cost: Spare parts and emergency procurement

Hidden Cost Factors

- Contamination risk: Product quality issues from seal failures

- Safety concerns: Chemical exposure during emergency repairs

- Reliability impact: Unplanned maintenance disrupting schedules

- Warranty implications: Equipment damage from seal failures

Cost-Benefit Calculation Example

Consider a chemical processing application with $5,000/hour downtime costs:

| Seal Material | Initial Cost | Service Life | Annual Replacements | Total Annual Cost |

|---|---|---|---|---|

| NBR (Standard) | $50 | 3 months | 4 | $20,200 |

| FKM (Premium) | $250 | 18 months | 0.67 | $3,500 |

| FFKM (Ultra) | $1,000 | 60 months | 0.2 | $1,200 |

Calculation includes material cost + $5,000 downtime cost per replacement

I recently helped Maria, who manages a pharmaceutical manufacturing facility in New Jersey. She was hesitant about the 15x cost premium for FFKM seals until we calculated that her current seal failures were costing $30,000 annually in downtime alone. After switching to our Bepto actuators with FFKM seals, Maria eliminated unplanned maintenance and achieved full regulatory compliance. 💊

How Do You Select the Right Seal Material for Your Specific Application?

Systematic seal material selection requires evaluating chemical exposure, operating conditions, and performance requirements through a structured decision process.

Proper seal material selection follows a four-step process: identify all chemical exposures including cleaning agents, determine operating temperature and pressure ranges, evaluate required service life and replacement costs, then cross-reference chemical compatibility charts to select the optimal material balance of performance and cost.

Systematic Selection Process

Step 1: Chemical Environment Assessment

- Primary chemicals: Main process fluids and gases

- Secondary exposures: Cleaning agents, sanitizers, maintenance chemicals

- Concentration levels: Dilute vs. concentrated solutions

- Exposure duration: Continuous vs. intermittent contact

Step 2: Operating Condition Analysis

- Temperature extremes: Maximum and minimum operating temperatures

- Pressure requirements: Static and dynamic pressure loads

- Cycle frequency: Actuator stroke cycles per hour/day

- Environmental factors: UV exposure, ozone, weather conditions

Step 3: Performance Requirements

- Service life targets: Acceptable replacement intervals

- Leakage tolerance: Internal vs. external sealing requirements

- Friction considerations: Smooth operation vs. stick-slip behavior

- Regulatory compliance: FDA, USP, or other industry standards

Selection Decision Matrix

| Priority Factor | Weight | NBR | EPDM | FKM | FFKM |

|---|---|---|---|---|---|

| Chemical resistance | 40% | 2 | 3 | 4 | 5 |

| Temperature range | 20% | 3 | 4 | 4 | 5 |

| Cost effectiveness | 25% | 5 | 4 | 2 | 1 |

| Availability | 15% | 5 | 4 | 3 | 2 |

| Weighted Score | 3.15 | 3.6 | 3.2 | 3.4 |

Scoring: 1=Poor, 2=Fair, 3=Good, 4=Very Good, 5=Excellent

Expert Consultation Benefits

At Bepto Pneumatics, our technical team provides free chemical compatibility analysis and seal material recommendations. We maintain extensive chemical resistance databases and can provide custom seal solutions for unique applications. Our replacement actuators come with optimized seal materials that often outperform original equipment specifications. 🔬

Conclusion

Proper seal material selection based on chemical compatibility is essential for reliable actuator performance and cost-effective operation in industrial environments.

FAQs About Actuator Seal Chemical Compatibility

Q: How do I test seal compatibility with new chemicals in my process?

A: Conduct immersion testing with seal samples in your actual process chemicals at operating temperature for 7-30 days, measuring volume swell, hardness change, and visual degradation before full implementation.

Q: Can I upgrade existing actuators with better seal materials?

A: Yes, most actuators can be retrofitted with upgraded seal materials during routine maintenance. Our technical team can specify compatible premium seals for your existing equipment.

Q: What’s the difference between static and dynamic chemical resistance?

A: Dynamic applications (moving seals) typically show 2-3x faster degradation due to mechanical stress combined with chemical exposure. Always specify dynamic service when selecting seal materials.

Q: How do cleaning chemicals affect seal selection?

A: Cleaning agents often represent the harshest chemical exposure in food, pharmaceutical, and semiconductor applications. Always include CIP/SIP chemicals in your compatibility analysis, not just process fluids.

Q: Are Bepto actuator seals compatible with existing OEM specifications?

A: Yes, our actuators maintain dimensional compatibility while offering upgraded seal materials optimized for your specific chemical environment, often providing superior performance compared to standard OEM seals at competitive pricing.

-

Understand the durometer scale, the standard method for measuring the indentation hardness of materials like rubber and plastic. ↩

-

Learn about hydrolysis, a chemical reaction where water is used to break down the bonds of a particular substance. ↩

-

Explore the chemical process of saponification, a reaction that involves the base-induced breakdown of an ester into an alcohol and a carboxylate. ↩

-

Discover the definition of polymer chain scission, a process that degrades polymers by breaking the bonds of their main chain. ↩

-

Review the technical properties of Perfluoroelastomers (FFKM), known for their exceptional chemical and thermal resistance. ↩