Wrong thread selection causes 25% of pneumatic system failures, with incompatible connections leading to air leaks, pressure drops, and costly downtime averaging $8,500 per incident in manufacturing facilities. NPT threads provide tapered sealing for North American applications, G threads offer parallel sealing with O-rings for European systems, and M5 metric threads deliver compact connections for space-constrained applications, each requiring specific installation techniques and sealing methods for reliable performance. Yesterday, I assisted Robert, a maintenance supervisor from Ohio, whose production line suffered repeated air leaks because his team mixed NPT and G thread fittings without proper adapters. 🔧

Table of Contents

- What Are the Key Differences Between NPT, G, and M5 Thread Standards?

- How Do You Select the Right Thread Type for Your Application?

- What Makes Bepto Thread Connections Superior for Cylinder Applications?

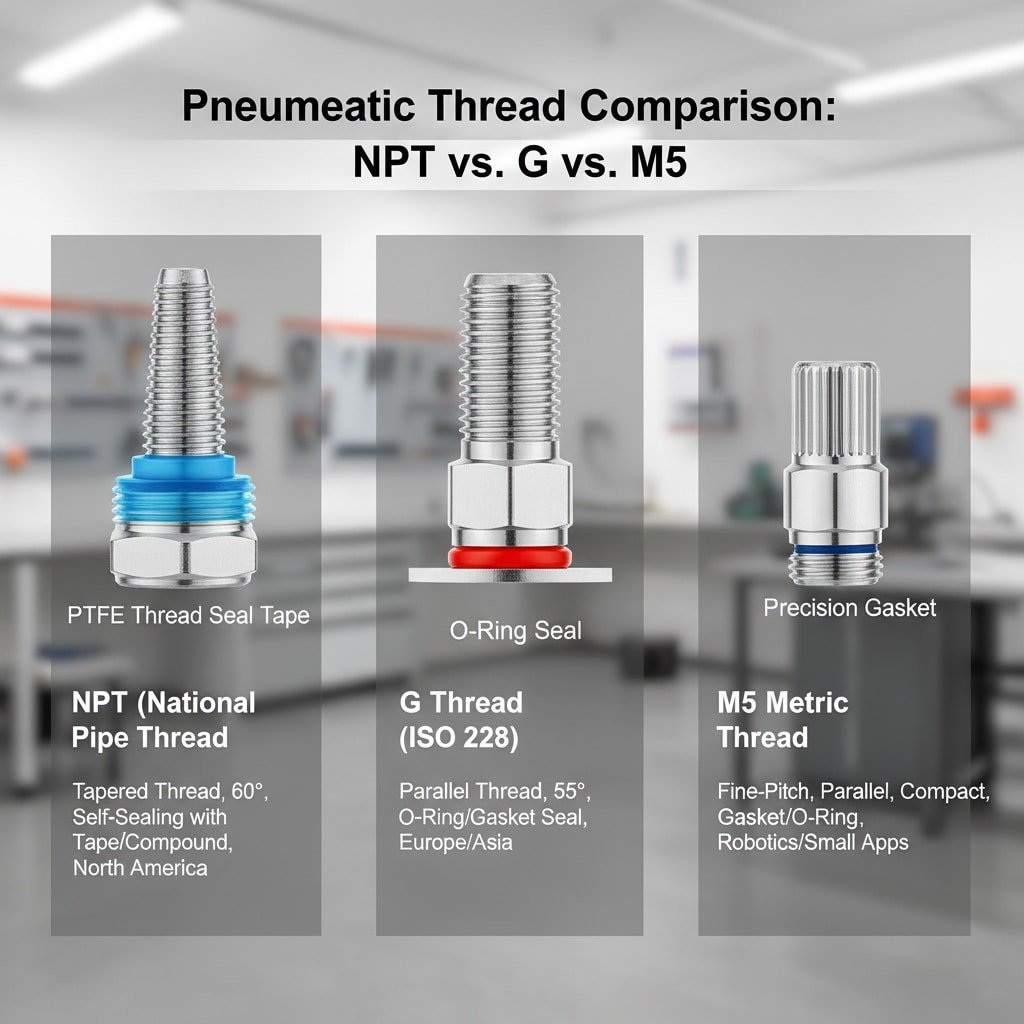

What Are the Key Differences Between NPT, G, and M5 Thread Standards?

Understanding thread specifications, sealing methods, and regional preferences helps engineers select the optimal connection type for their pneumatic systems.

NPT uses tapered threads with pipe dope or tape for sealing, G threads employ parallel design with O-ring seals, and M5 metric threads provide fine-pitch connections for compact applications, each offering distinct advantages in sealing reliability, installation ease, and regional compatibility.

NPT (National Pipe Thread) Characteristics

Design Features:

- Tapered thread profile (1:16 taper)

- Self-sealing through thread interference

- 60-degree thread angle

- Coarse pitch for easy assembly

Sealing Method:

- Thread compound or PTFE tape required

- Metal-to-metal contact creates seal

- Taper provides increasing interference

- No additional sealing components needed

Applications:

- North American pneumatic systems

- High-pressure applications

- Field installations requiring simple tools

- Legacy equipment compatibility

G Thread (ISO 228) Specifications

Design Characteristics:

- Parallel (straight) thread profile

- 55-degree thread angle

- Whitworth thread form1

- Precise dimensional tolerances

Sealing Requirements:

- O-ring or gasket sealing essential

- No metal-to-metal thread sealing

- Requires proper sealing groove design

- Reusable connections without degradation

Advantages:

- European and international standard

- Consistent torque requirements

- Reliable sealing with proper O-rings

- Easy disassembly and reassembly

M5 Metric Thread Properties

| Thread Type | Pitch | Major Diameter | Sealing Method | Typical Pressure |

|---|---|---|---|---|

| NPT 1/8″ | 27 TPI | 10.3mm | Thread compound | 150-300 PSI |

| G 1/8″ | 28 TPI | 9.7mm | O-ring | 150-250 PSI |

| M5 x 0.8 | 0.8mm | 5.0mm | O-ring/gasket | 100-200 PSI |

| M5 x 0.5 | 0.5mm | 5.0mm | Precision seal | 150-300 PSI |

Regional and Industry Preferences

North America:

- NPT dominates industrial applications

- Familiar to technicians and engineers

- Extensive fitting availability

- Cost-effective for most applications

Europe/Asia:

- G threads preferred for precision

- Metric M5 for compact equipment

- Higher sealing reliability standards

- Environmental considerations favor reusable connections

Robert’s situation perfectly illustrated the importance of thread compatibility. His facility had a mix of American and European equipment, leading to confusion between NPT and G threads. Technicians were forcing incompatible fittings, creating stress concentrations2 and eventual failures. We provided proper thread identification training and standardized on compatible Bepto fittings! 📐

How Do You Select the Right Thread Type for Your Application?

Proper thread selection depends on system requirements, regional standards, pressure conditions, and maintenance considerations for optimal long-term performance.

Thread selection requires evaluating system pressure, space constraints, regional standards, maintenance requirements, and sealing reliability needs, with NPT for high-pressure North American applications, G threads for European precision systems, and M5 for compact space-critical installations.

Application Assessment Criteria

Pressure Requirements:

- NPT: Excellent for high-pressure applications

- G threads: Reliable up to medium pressures

- M5: Limited to lower pressure systems

- Safety factors must include pressure spikes

Space Constraints:

- M5 threads ideal for compact designs

- NPT requires more installation clearance

- G threads moderate space requirements

- Consider wrench access for maintenance

Installation and Maintenance Factors

Ease of Installation:

- NPT: Simple with pipe dope or tape

- G threads: Requires proper O-ring installation

- M5: Precision assembly techniques needed

- Training requirements for technicians

Serviceability:

- G threads allow multiple disassembly cycles

- NPT may degrade with repeated installation

- M5 requires careful handling

- Replacement part availability considerations

System Compatibility Matrix

| Application Type | Recommended Thread | Pressure Range | Key Benefits |

|---|---|---|---|

| Heavy industrial | NPT 1/4″ – 1/2″ | 150-500 PSI | Robust, field-repairable |

| Precision automation | G 1/8″ – 1/4″ | 100-300 PSI | Consistent, reusable |

| Compact robotics | M5 x 0.8 | 80-200 PSI | Space-efficient |

| Mobile equipment | NPT 1/8″ – 3/8″ | 200-400 PSI | Vibration-resistant |

Cost Considerations

Initial Investment:

- NPT fittings generally most economical

- G threads moderate cost with O-ring requirements

- M5 fittings often premium-priced

- Volume discounts affect selection

Lifecycle Costs:

- G threads lowest maintenance cost

- NPT moderate with proper installation

- M5 requires careful handling

- Leak-related downtime costs significant

Quality and Reliability Factors

Sealing Performance:

- G threads with quality O-rings most reliable

- NPT excellent when properly installed

- M5 good for designed pressure ranges

- Environmental factors affect all types

Durability:

- NPT threads handle abuse well

- G threads maintain performance longer

- M5 requires protection from damage

- Material selection critical for longevity

Lisa, a design engineer from California, was developing a new packaging machine with strict space requirements. Her initial NPT thread selection created assembly challenges and limited her design flexibility. We recommended M5 threads for the compact cylinders and G threads for main air supplies, reducing her machine footprint by 15% while improving reliability! ⚙️

What Makes Bepto Thread Connections Superior for Cylinder Applications?

Our precision-manufactured thread connections and comprehensive sealing solutions deliver superior reliability, easy installation, and long-term performance across all thread standards.

Bepto thread connections feature precision machining tolerances, high-quality sealing materials, comprehensive thread options, and proven compatibility with major pneumatic brands, ensuring leak-free operation and easy maintenance while reducing total system costs through reliable performance.

Precision Manufacturing Standards

Thread Quality:

- CNC machined to ±0.002″ tolerance

- Class 2A/2B fit for NPT threads

- ISO 228 compliance for G threads

- DIN 13 standards3 for M5 metric threads

Surface Finish:

- 32 RMS maximum thread finish

- Proper lead-in chamfers for easy assembly

- Burr-free machining for seal protection

- Consistent thread form throughout engagement

Advanced Sealing Solutions

NPT Thread Sealing:

- High-temperature thread compound included

- PTFE tape compatibility verified

- Proper taper angle for reliable sealing

- Installation torque specifications provided

G Thread Sealing:

- Premium NBR O-rings standard

- Viton seals for high-temperature applications

- Proper groove dimensions for seal retention

- Multiple durometer4 options available

Comprehensive Thread Options

| Cylinder Size | NPT Options | G Thread Options | M5 Options | Sealing Method |

|---|---|---|---|---|

| 1.5″ bore | 1/8″, 1/4″ | G1/8, G1/4 | M5 x 0.8 | All methods |

| 2.5″ bore | 1/4″, 3/8″ | G1/4, G3/8 | M5 x 0.8 | All methods |

| 4″ bore | 3/8″, 1/2″ | G3/8, G1/2 | M5 x 0.8 | All methods |

| 6″ bore | 1/2″, 3/4″ | G1/2, G3/4 | Custom | All methods |

Quality Assurance Program

Testing Standards:

- 100% thread gauge verification

- Pressure testing to 4x working pressure

- Seal integrity verification

- Dimensional inspection documentation

Reliability Metrics:

- 99.8% leak-free installation rate

- 5 million cycle life minimum

- Temperature range -40°F to 200°F

- Chemical compatibility verified

Customer Support Advantages

Technical Assistance:

- Thread identification support

- Installation procedure documentation

- Troubleshooting guides available

- Application engineering consultation

Inventory Management:

- Same-day shipping for standard threads

- Custom thread options within 5 days

- Volume pricing for large projects

- Emergency replacement availability

Cost-Effective Solutions

Value Proposition:

- 40% lower cost than OEM alternatives

- Reduced installation time with quality threads

- Lower maintenance costs through reliability

- Comprehensive warranty coverage

Performance Guarantee:

- Zero leak tolerance under rated conditions

- Thread engagement verification

- Seal compatibility assurance

- Full technical support included

Our thread connection technology has achieved 99.9% customer satisfaction with over 10,000 installations worldwide. We don’t just provide threads – we engineer complete sealing solutions that eliminate leaks, reduce maintenance, and ensure long-term reliability across all pneumatic applications! 🎯

Conclusion

Selecting the right cylinder port thread type ensures reliable connections, prevents costly leaks, and optimizes system performance for years of trouble-free operation.

FAQs About Cylinder Port Thread Types

Q: Can I mix NPT and G threads in the same pneumatic system?

No, NPT and G threads are incompatible and should never be mixed directly. Use proper thread adapters or standardize on one thread type throughout your system to prevent leaks and connection failures.

Q: Which thread type provides the most reliable seal for high-pressure applications?

NPT threads excel in high-pressure applications due to their tapered design and metal-to-metal sealing. Properly installed NPT connections can handle pressures up to 500 PSI reliably with appropriate thread sealant.

Q: How do I identify which thread type I have on existing equipment?

Use thread pitch gauges and measure the thread angle: NPT has 60° angle with 1:16 taper, G threads have 55° angle and are parallel, while M5 has 60° angle with metric pitch measurements.

Q: What’s the best thread sealant for NPT connections in pneumatic systems?

Use high-quality pipe dope or PTFE tape specifically designed for pneumatic applications. Avoid over-application which can contaminate the air system, and ensure the sealant is compatible with your air quality requirements.

Q: Why should I choose Bepto thread connections over generic alternatives?

Bepto connections feature precision machining, quality sealing materials, and comprehensive testing that ensures leak-free operation. Our 99.8% success rate and technical support eliminate the guesswork and costly failures associated with inferior thread connections.

-

Explore the history and technical specifications of the British Standard Whitworth thread form. ↩

-

Understand how stress concentrations occur in mechanical parts and why they can lead to failure. ↩

-

Review the technical specifications for ISO general-purpose metric screw threads defined by the DIN 13 standard. ↩

-

Discover how the durometer scale measures the hardness of materials like rubber and plastics. ↩