When production lines demand split-second precision, every millisecond counts in pneumatic valve response time. The wrong coil choice can mean the difference between seamless operation and costly downtime that impacts your bottom line. ⚡

DC solenoid coils typically offer faster response times (10-50ms) compared to AC coils (50-100ms) due to their instant magnetic field generation, making them ideal for high-speed pneumatic applications requiring precise timing control.

Last month, I spoke with Sarah, a production manager at a packaging facility in Manchester, who was struggling with timing issues in her pneumatic sorting system. Her AC-powered valves weren’t keeping up with the line speed, causing product jams and reducing throughput by 15%. 📉

Table of Contents

- What Determines Pneumatic Valve Response Time?

- How Do DC and AC Solenoid Coils Compare in Speed?

- Which Applications Benefit Most from Fast Response Times?

- What Are the Trade-offs Between DC and AC Coils?

What Determines Pneumatic Valve Response Time?

Response time isn’t just about the coil – it’s a complex dance of electromagnetic and mechanical forces. ⚙️

Pneumatic valve response time is primarily determined by coil inductance1, magnetic field strength, spring tension, and the physical mass of moving components within the valve assembly.

Key Factors Affecting Response Speed

The electromagnetic response depends heavily on the coil’s ability to generate sufficient magnetic force quickly. DC coils have a significant advantage here because they don’t need to overcome the impedance2 that AC coils face.

Coil Type Comparison:

| Factor | DC Coils | AC Coils |

|---|---|---|

| Inductance Effect | Minimal | High impedance |

| Power Consumption | Constant | Variable |

| Heat Generation | Moderate | Higher |

| Response Time | 10-50ms | 50-100ms |

Mechanical Components Impact

Beyond the electrical aspects, the valve’s mechanical design plays a crucial role. Our Bepto replacement valves are engineered with optimized spring tensions and lightweight armatures to maximize response speed regardless of coil type.

How Do DC and AC Solenoid Coils Compare in Speed?

The fundamental difference lies in how these coils generate their magnetic fields. 🔌

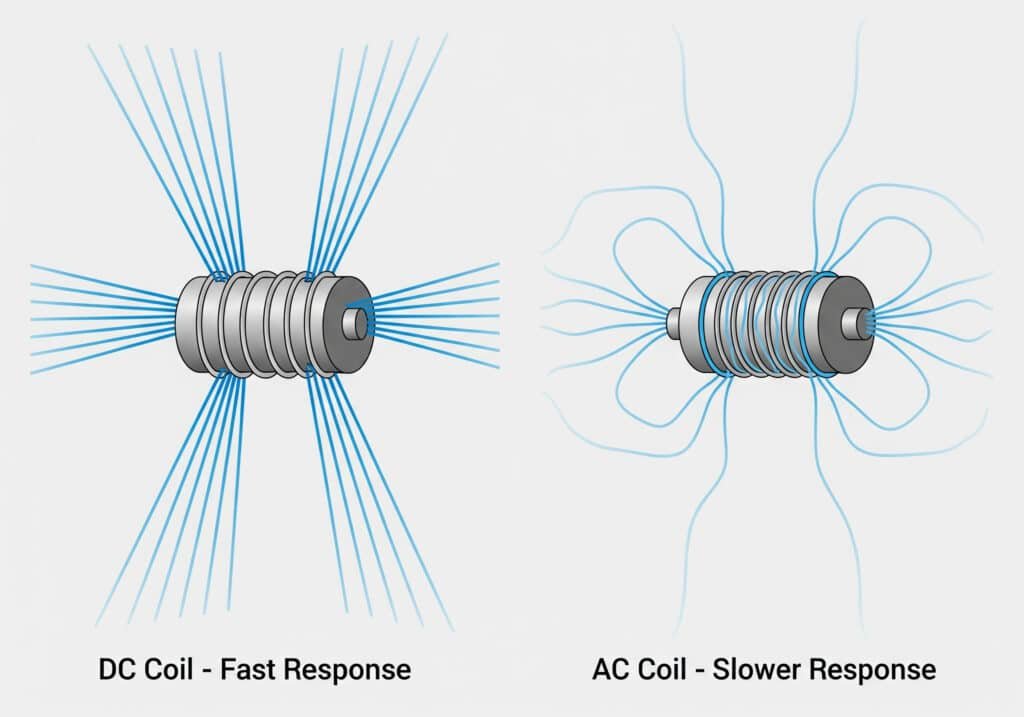

DC coils achieve faster response times because they instantly reach full magnetic strength, while AC coils must overcome inductive reactance and work with alternating magnetic fields that reduce effective force.

DC Coil Advantages

DC solenoid coils provide consistent, instant magnetic force. When voltage is applied, the magnetic field reaches maximum strength immediately, allowing for rapid valve actuation. This makes them perfect for applications requiring precise timing.

AC Coil Characteristics

AC coils face the challenge of alternating current, which creates a fluctuating magnetic field. The coil must overcome its own inductance, and the magnetic force varies with the AC waveform3, resulting in slower overall response times.

Remember Sarah from Manchester? After switching to DC-powered Bepto valves, her sorting system’s response time improved by 60%, eliminating the product jams and actually increasing throughput by 12% above original targets. The investment paid for itself in just three weeks! 💰

Which Applications Benefit Most from Fast Response Times?

Not every pneumatic application demands lightning-fast response, but some industries can’t compromise on speed. 🏃♂️

High-speed packaging, precision assembly, automotive manufacturing, and semiconductor production benefit most from fast pneumatic valve response times, where delays can cause quality issues or production bottlenecks.

Critical Speed Applications

Packaging Industry: Filling, capping, and labeling operations running at high speeds require valves that can keep pace with conveyor systems moving hundreds of units per minute.

Assembly Lines: Pick-and-place operations4, especially in electronics manufacturing, need precise timing to avoid component damage or misplacement.

Automotive Production: Paint spraying, welding sequences, and parts handling all depend on split-second timing for quality and safety.

What Are the Trade-offs Between DC and AC Coils?

Speed isn’t the only consideration when choosing between DC and AC solenoid coils. 🤔

While DC coils offer superior speed, AC coils provide better power efficiency, lower heat generation during continuous operation, and simpler integration with standard industrial power systems.

Cost and Infrastructure Considerations

Power Supply Requirements:

| Aspect | DC System | AC System |

|---|---|---|

| Power Supply Cost | Higher (requires conversion) | Lower (direct connection) |

| Wiring Complexity | Moderate | Simple |

| Maintenance | Lower | Higher |

| Energy Efficiency | Better control | Standard |

Long-term Performance

AC coils typically have longer service life in continuous-duty applications5 because they naturally cool during each AC cycle. However, for intermittent high-speed operations, DC coils often prove more reliable due to their consistent performance characteristics.

At Bepto, we stock both DC and AC versions of our most popular valve models, allowing our customers to choose the optimal solution for their specific applications without compromising on quality or delivery speed.

Conclusion

Choosing between DC and AC solenoid coils ultimately depends on balancing response speed requirements with operational considerations and costs. 🎯

FAQs About Pneumatic Valve Response Time

Q: Can I retrofit my existing AC valves with DC coils?

A: In most cases, yes, but you’ll need to ensure your power supply and control systems are compatible with DC operation. Our technical team can help evaluate your specific setup.

Q: Do faster response times always mean better performance?

A: Not necessarily – the response time should match your application requirements. Unnecessarily fast valves can sometimes cause system instability or excessive wear.

Q: How much faster are DC coils compared to AC coils?

A: DC coils typically respond 2-5 times faster than AC coils, with response times of 10-50ms versus 50-100ms for AC coils.

Q: Are DC solenoid valves more expensive to operate?

A: Initial setup costs may be higher due to power supply requirements, but DC valves often provide better energy efficiency and longer service life in high-cycle applications.

Q: What’s the fastest pneumatic valve response time available?

A: High-performance DC solenoid valves can achieve response times as low as 5-10ms, though most industrial applications work well with 20-30ms response times.

-

Understand the principle of inductance and how it affects the flow of current in AC and DC circuits. ↩

-

Learn about electrical impedance, the measure of the opposition that a circuit presents to a current when a voltage is applied. ↩

-

See a visual and technical explanation of an AC sine wave, including its key characteristics like frequency and amplitude. ↩

-

Discover how pick-and-place automation is used for high-speed assembly in the electronics and manufacturing industries. ↩

-

Learn the difference between continuous and intermittent duty cycle ratings for solenoid coils. ↩