Every engineer I consult with faces the same dilemma: standard pneumatic cylinders fail prematurely in challenging environments. Whether you’re battling aggressive chemicals, tight space constraints, or precision requirements, conventional cylinders simply weren’t designed for these demanding applications. This limitation forces costly maintenance cycles, production downtime, and frustrating redesigns.

The optimal special cylinder for extreme applications combines application-specific materials that resist corrosive media, space-efficient designs that maintain performance in compact spaces, and precision-engineered components that ensure accuracy in critical operations. This specialized approach typically extends service life by 300-500% compared to standard cylinders in challenging environments.

Last month, I visited a semiconductor fabrication facility in Singapore that had been replacing standard cylinders every 3-4 weeks due to aggressive chemical exposure. After implementing our corrosion-resistant special cylinder solution with custom Hastelloy components, they’ve now operated continuously for over 8 months without a single failure. Let me show you how to achieve similar results for your challenging application.

Table of Contents

- Corrosion-Resistant Cylinder Material Comparison

- Ultra-Thin Cylinder Structure Compactness Testing

- Magnetic Coupling Rodless Cylinder Accuracy Verification

- Conclusion

- FAQs About Special Cylinders

Which Cylinder Materials Actually Survive When Exposed to Aggressive Chemicals?

Selecting the wrong material for corrosive environments is one of the most expensive mistakes I see engineers make. Either the material fails prematurely, causing expensive downtime, or they overspend on exotic alloys when more cost-effective options would suffice.

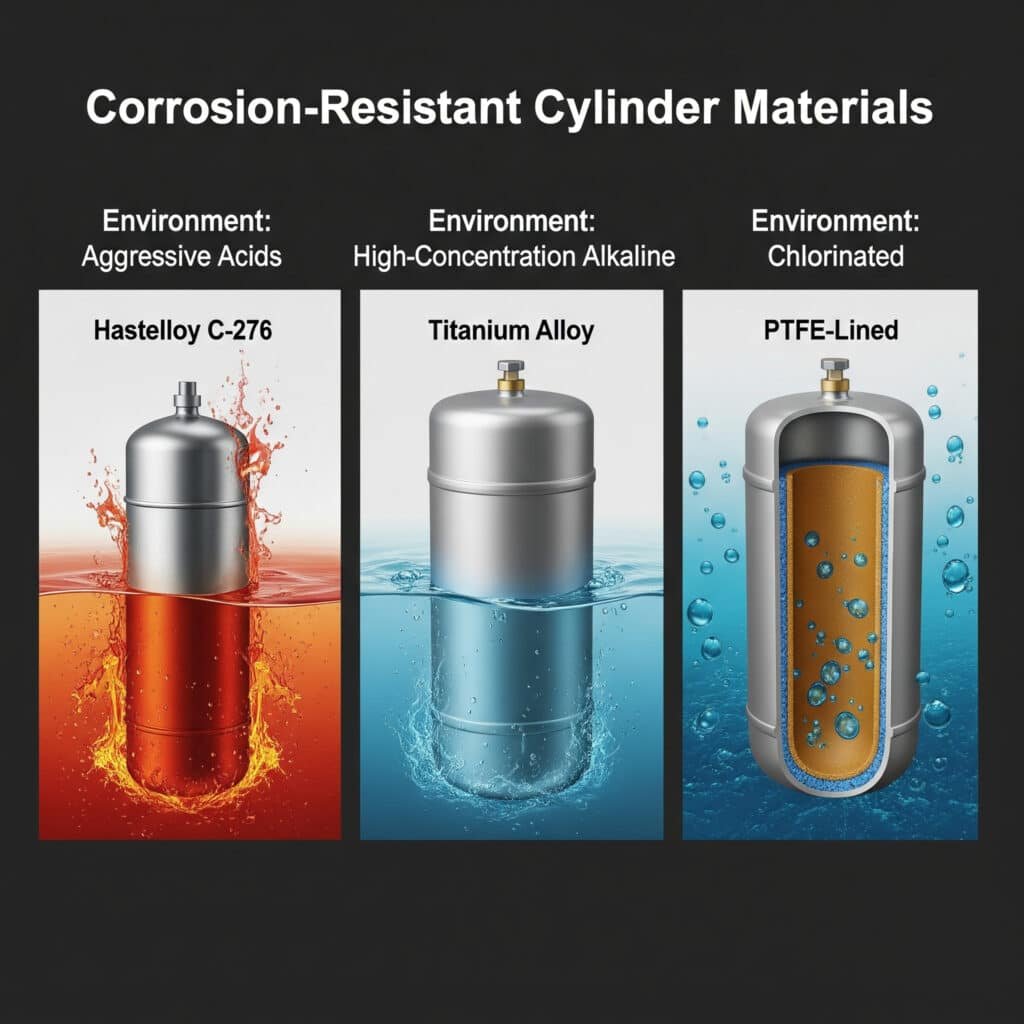

The optimal corrosion-resistant cylinder material depends on your specific chemical environment, operating temperature, and pressure requirements. For most aggressive acid environments, Hastelloy C-2761 provides superior performance, while high-concentration alkaline applications are better served by titanium alloys. For chlorinated environments, specialized PTFE-lined cylinders offer the best combination of performance and cost-effectiveness.

Comprehensive Material Comparison for Corrosive Environments

After analyzing hundreds of special cylinder applications in corrosive environments, I’ve compiled this comparison of material performance:

| Material | Acid Resistance | Alkaline Resistance | Chloride Resistance | Temperature Range | Relative Cost | Best Applications |

|---|---|---|---|---|---|---|

| 316L Stainless Steel | Moderate | Good | Poor | -40°C to 260°C | 1x (baseline) | Mild food acids, dilute chemicals |

| Hastelloy C-276 | Excellent | Good | Excellent | -120°C to 450°C | 5-7x | Concentrated acids, mixed chemicals |

| Titanium Grade 2 | Good | Excellent | Very Good | -60°C to 350°C | 3-4x | Chlorinated environments, seawater |

| Monel 400 | Good | Moderate | Excellent | -60°C to 540°C | 4-5x | Hydrofluoric acid, fluoride salts |

| PTFE-lined | Excellent | Excellent | Excellent | -20°C to 150°C | 2-3x | Broad chemical compatibility |

| PVDF | Very Good | Good | Excellent | -30°C to 120°C | 1.5-2x | General chemical processing |

| Alloy 20 | Very Good | Good | Good | -50°C to 300°C | 3-4x | Sulfuric acid applications |

| Zirconium 702 | Excellent | Excellent | Good | -60°C to 400°C | 8-10x | Hot concentrated acids |

Material Selection Framework for Corrosive Applications

When helping clients select the right material for their corrosive environment, I use this decision framework:

Step 1: Chemical Environment Analysis

Start by thoroughly analyzing your specific chemical environment:

- Chemical Composition: Identify all chemicals present, including trace components

- Concentration Levels: Determine maximum concentrations expected

- Temperature Range: Establish minimum and maximum operating temperatures

- Pressure Requirements: Define operating pressure and any pressure spikes

- Exposure Pattern: Continuous immersion vs. intermittent exposure

Step 2: Material Compatibility Evaluation

Match your environment to material capabilities:

Acidic Environments

For acidic applications, consider these specialized options:

Sulfuric Acid (H₂SO₄)

– Concentrations <50%: 316L stainless steel often sufficient

– Concentrations 50-80%: Alloy 20 or Hastelloy B-3

– Concentrations >80%: Hastelloy C-276 or PTFE-linedHydrochloric Acid (HCl)

– Any concentration: Hastelloy C-276, PTFE-lined, or tantalum for extreme cases

– Avoid most metals; even “resistant” alloys can fail quicklyNitric Acid (HNO₃)

– Concentrations <30%: 316L stainless steel

– Concentrations 30-70%: Titanium Grade 2

– Concentrations >70%: Zirconium 702

Alkaline Environments

For alkaline applications:

Sodium Hydroxide (NaOH)

– Concentrations <30%: 316L stainless steel

– Concentrations 30-70%: Nickel 200/201

– Concentrations >70%: Titanium (with caution on temperature)Potassium Hydroxide (KOH)

– Similar to NaOH, but more aggressive at higher temperatures

– Consider Nickel 200/201 or Hastelloy C-276

Chlorinated Environments

For chloride-containing environments:

Seawater/Brine

– Titanium Grade 2 or Super Duplex stainless steel

– For higher temperatures: Hastelloy C-276Chlorine Gas/Hypochlorite

– PTFE-lined cylinders

– For high pressure: Titanium with special seals

Step 3: Component-Specific Selection

Different cylinder components may require different materials:

| Component | Material Considerations | Special Requirements |

|---|---|---|

| Cylinder Body | Primary corrosion barrier | Consider pressure rating impact |

| Piston Rod | Exposed to both media and atmosphere | May need coating or composite structure |

| Seals | Chemical compatibility critical | Temperature limits often lower than metals |

| End Caps | May need same resistance as body | Thread compatibility with body material |

| Fasteners | Galvanic corrosion risk | Often need higher grade than body |

Case Study: Chemical Processing Plant Solution

A chemical processing plant in Germany was experiencing repeated failures of their pneumatic cylinders in a phosphoric acid environment. Standard stainless steel cylinders were lasting only 2-3 weeks before seal failure and pitting corrosion rendered them unusable.

Their specific environment included:

- 65% phosphoric acid

- Operating temperatures of 40-60°C

- Occasional splashing (not continuous immersion)

- 6 bar operating pressure

After analyzing their application, we recommended a specialized cylinder with:

- Hastelloy C-276 cylinder body and rod

- Modified PTFE composite seals

- Protected vent pathways to prevent acid ingress

- Special rod wiper design to remove acid residue

Results after implementation:

- Cylinder service life extended from 2-3 weeks to over 12 months

- Maintenance costs reduced by 87%

- Production uptime improved by 4.3%

- Total ROI achieved in less than 5 months despite 4.5x higher initial cylinder cost

Implementation Considerations for Corrosion-Resistant Cylinders

When implementing corrosion-resistant special cylinders, consider these critical factors:

Material Certification Requirements

Ensure proper material verification:

- Require material test certificates (MTCs)

- Consider PMI (Positive Material Identification)2 testing for critical applications

- Verify correct material grade, not just material type

Surface Treatment Options

Surface treatments can enhance corrosion resistance:

- Electropolishing for stainless steels (improves passive layer)

- PTFE coating for additional chemical barrier

- Specialized anodizing for aluminum components

- Passivation treatments for specific alloys

Seal Selection for Corrosive Environments

Seals often fail before metal components:

- FFKM (Perfluoroelastomer) for broadest chemical resistance

- Modified PTFE compounds for specific chemicals

- Consider composite seals with chemical-resistant facing

- Evaluate temperature limits carefully

Maintenance Protocols

Develop specific maintenance procedures:

- Regular inspection schedules based on exposure severity

- Proper cleaning procedures that won’t damage materials

- Seal replacement intervals based on material and exposure

- Documentation of material performance for future reference

How Compact Can Pneumatic Cylinders Get While Maintaining Performance?

Space constraints are increasingly challenging in modern machinery design. Engineers are forced to compromise between performance and size, often resulting in underpowered actuators or redesigned machinery.

Ultra-thin pneumatic cylinders can achieve profile heights as low as 8mm while maintaining performance through optimized internal flow paths, reinforced body designs, and specialized seal geometries. The most effective compact cylinders deliver 85-95% of the force of conventional designs while occupying less than 40% of the space.

Compactness Performance Metrics for Special Cylinders

When evaluating ultra-thin cylinders, these key metrics determine real-world performance:

| Performance Metric | Standard Cylinder | Ultra-Thin Cylinder | Impact on Application |

|---|---|---|---|

| Profile Height | 25-40mm | 8-15mm | Critical for space-constrained applications |

| Force Output Ratio | 100% (baseline) | 85-95% | Minor force reduction acceptable in most applications |

| Lateral Load Capacity | High | Moderate to Low | May require guide systems in some applications |

| Cycle Life | 10+ million cycles | 5-8 million cycles | Acceptable trade-off for many applications |

| Flow Efficiency | High | Moderate | May require higher operating pressure |

| Seal Wear Rate | Low | Moderate | More frequent maintenance may be necessary |

Design Innovations for Ultra-Thin Cylinders

The most effective ultra-thin cylinders incorporate these innovative design elements:

Optimized Body Structures

Advanced structural designs maintain strength with minimal material:

Reinforced Extrusion Profiles

Ultra-thin aluminum extrusions with internal ribbing provide maximum strength-to-weight ratio while minimizing height. Critical stress points are reinforced without increasing overall dimensions.Composite Body Materials

High-strength composite materials like glass-fiber reinforced polymers offer excellent rigidity with reduced weight and profile. These materials can be molded into complex shapes that would be difficult to machine from metal.Asymmetric Stress Distribution

Unlike conventional symmetric cylinder designs, advanced ultra-thin cylinders use asymmetric body structures that place more material precisely where stress analysis shows it’s needed.

Innovative Piston Designs

Conventional piston designs waste valuable space:

Oval Piston Geometry

Rather than traditional circular pistons, oval or rectangular piston designs maximize the force-generating area while minimizing height. Special seal designs accommodate these non-traditional shapes.Integrated Bearing Surfaces

By incorporating bearing surfaces directly into the piston design, separate guide systems can be eliminated, saving precious space without compromising performance.Multi-Chamber Configurations

Some advanced designs use multiple smaller chambers rather than a single large chamber, allowing for thinner overall profiles while maintaining force output.

Flow Path Engineering

Internal flow restrictions often limit compact cylinder performance:

Optimized Port Locations

Strategic positioning of air ports to minimize flow path length and maximize effective area despite space constraints.Internal Flow Channel Design

Computer-optimized flow channels reduce pressure drops that typically plague compact designs. CFD (Computational Fluid Dynamics)3 analysis identifies and eliminates restriction points.Specialized Valve Integration

Direct integration of valve functions into the cylinder body eliminates external plumbing and reduces flow restrictions.

Compactness Testing Methodology

To properly evaluate ultra-thin cylinder performance, I recommend this comprehensive testing approach:

Dimensional Efficiency Testing

Measure the true space efficiency:

Force-to-Height Ratio (FHR)

Calculate force output divided by profile height. Higher values indicate better spatial efficiency. FHR = Force Output (N) ÷ Profile Height (mm)Volume Utilization Factor (VUF)

Determine how efficiently the cylinder converts its total volume into work. VUF = Force Output (N) × Stroke Length (mm) ÷ Total Volume (mm³)Installation Envelope Analysis

Evaluate the total space required including mounting hardware and connections, not just the cylinder body itself.

Performance Under Constraint Testing

Evaluate how the compact design performs in real-world conditions:

Constrained Installation Testing

Mount the cylinder in the actual space-constrained environment to verify fit and function.Heat Dissipation Evaluation

Measure operating temperature during continuous cycling. Compact designs often have less surface area for heat dissipation.Side Load Capacity Assessment

Apply graduated side loads to determine the practical limits before binding occurs.Pressure-Force Linearity

Test force output across the pressure range to identify any non-linear behavior that might affect application performance.

Case Study: Semiconductor Equipment Application

A semiconductor equipment manufacturer in Taiwan needed an extremely thin pneumatic actuator for a wafer handling system. Their space constraint was severe – no more than 12mm in height – while still requiring 120N of force with a 50mm stroke.

Standard cylinders meeting the force requirement had minimum heights of 25-30mm, making them completely unsuitable. After evaluating several special cylinder options, we developed a custom ultra-thin solution with:

- 11.5mm total height profile

- Oval piston design with 20mm effective width

- Reinforced aluminum body with internal ribbing

- Specialized low-friction seals with modified geometry

- Integrated flow channels optimized via CFD analysis

Performance results:

- 135N force output at 6 bar (exceeding requirements)

- Full 50mm stroke in the constrained space

- Cycle time of 0.4 seconds (meeting speed requirements)

- Validated life expectancy of 7+ million cycles

- Operating temperature increase of only 15°C above ambient during continuous operation

The customer was able to maintain their compact equipment design without compromising performance, avoiding a costly complete redesign of their wafer handling system.

Design Considerations for Ultra-Thin Cylinder Applications

When implementing ultra-thin cylinders in your application, consider these critical factors:

Mounting and Alignment

Compact cylinders are more sensitive to mounting issues:

- Ensure perfectly parallel mounting surfaces

- Consider integrated mounting features to save additional space

- Use precision alignment methods during installation

- Evaluate thermal expansion effects on alignment

Pressure and Force Management

Optimize the pneumatic system for compact cylinders:

- Consider operating at higher pressures to maintain force output

- Implement pressure regulation specific to the compact cylinder

- Verify force requirements throughout the stroke

- Account for seal friction variations that affect net force

Guiding and Support

Many ultra-thin designs have reduced side load capacity:

- Evaluate need for external guide systems

- Consider integrated guide options where space permits

- Minimize moment loads through proper load positioning

- Implement precision stops to prevent over-travel stress

Maintenance Accessibility

Plan for maintenance despite tight spaces:

- Design for seal replacement without complete disassembly

- Create access pathways for inspection

- Consider built-in wear indicators

- Document special maintenance procedures for technicians

How Accurate Are Magnetic Coupling Rodless Cylinders in High-Precision Applications?

Rodless cylinder accuracy is critical for many precision applications, yet many engineers struggle with inconsistent performance and premature failures when standard products are pushed beyond their design limits.

Magnetic coupling rodless cylinders can achieve positioning accuracy4 of ±0.05mm and repeatability of ±0.02mm when properly specified and implemented. The highest precision models incorporate precision-ground internal bearing surfaces, temperature-compensated magnetic couplings, and advanced sealing systems that maintain performance over millions of cycles.

Accuracy Performance Metrics for Magnetic Coupling Cylinders

After testing hundreds of rodless cylinder configurations, I’ve compiled these critical performance metrics:

| Performance Metric | Standard Grade | Precision Grade | Ultra-Precision Grade | Impact on Application |

|---|---|---|---|---|

| Positioning Accuracy | ±0.25mm | ±0.10mm | ±0.05mm | Critical for alignment applications |

| Repeatability | ±0.10mm | ±0.05mm | ±0.02mm | Determines process consistency |

| Straightness of Travel | 0.2mm/m | 0.1mm/m | 0.05mm/m | Affects parallel motion requirements |

| Magnetic Coupling Strength | 80-120N | 120-200N | 200-350N | Determines maximum acceleration |

| Velocity Fluctuation | ±10% | ±5% | ±2% | Critical for smooth motion applications |

| Temperature Stability | ±0.15mm/10°C | ±0.08mm/10°C | ±0.03mm/10°C | Important for varying environments |

Design Factors Affecting Rodless Cylinder Accuracy

The precision of magnetic coupling rodless cylinders depends on these key design elements:

Bearing System Design

The internal guidance system is critical for accuracy:

Bearing Type Selection

The choice between ball bearings, roller bearings, or plain bearings significantly impacts precision. Precision-ground ball bearing systems typically provide the best combination of accuracy and load capacity.Bearing Preload Optimization

Proper preload eliminates play without excessive friction. Advanced designs use adjustable preload mechanisms that can be fine-tuned for the application.Bearing Rail Precision

The straightness, flatness, and parallelism of the bearing rails directly affect motion quality. Ultra-precision cylinders use rails ground to tolerances of 0.01mm or better.

Magnetic Coupling Design

The magnetic interface determines many performance characteristics:

Magnetic Circuit Optimization

Advanced magnetic designs use finite element analysis to optimize the magnetic circuit, providing maximum coupling force with minimum piston weight.Magnetic Material Selection

The choice of magnetic materials affects temperature stability and long-term performance. Neodymium magnets with specific temperature compensation formulations provide the best stability.Coupling Gap Control

The precision of the gap between internal and external magnets is critical. High-precision cylinders maintain gap tolerances of ±0.02mm or better.

Sealing System Effectiveness

Sealing affects both performance and longevity:

Seal Design Optimization

Advanced sealing systems balance sealing effectiveness with minimal friction. Specialized lip seals or composite seals often provide the best performance.Contamination Resistance

Precision cylinders require excellent contamination protection. Multi-stage sealing systems with primary and secondary seals offer the best protection.Friction Consistency

Variations in seal friction cause velocity fluctuations. The most precise cylinders use seals specifically designed for consistent friction characteristics.

Accuracy Verification Methodology

To properly validate rodless cylinder accuracy for precision applications, I recommend this comprehensive testing protocol:

Static Accuracy Testing

Measure fundamental positioning capabilities:

Multi-Point Positioning Test

Measure positioning accuracy at multiple points throughout the stroke (minimum 10 points) using a precision measurement system (laser interferometer or digital indicator).Repeatability Testing

Perform repeated approaches to the same position from both directions (minimum 25 cycles) and measure the variation.Load Impact Assessment

Evaluate positioning accuracy under different load conditions (no load, 25%, 50%, 75%, and 100% of rated load).

Dynamic Performance Testing

Evaluate motion quality during operation:

Velocity Consistency Measurement

Use high-speed position sensing to calculate velocity throughout the stroke and measure variations.Acceleration Capability Testing

Determine maximum acceleration before magnetic decoupling occurs.Vibration Analysis

Measure vibration characteristics during motion to identify resonances or motion irregularities.Settling Time Evaluation

Measure the time required to settle within the final position tolerance after movement.

Environmental Influence Testing

Assess performance under varying conditions:

Temperature Sensitivity Testing

Measure positioning accuracy across the operating temperature range.Duty Cycle Impact

Evaluate accuracy changes during continuous operation as temperature increases.Contamination Resistance Validation

Test accuracy before and after exposure to application-specific contaminants.

Case Study: Medical Device Manufacturing Application

A medical device manufacturer in Switzerland needed an extremely precise rodless cylinder for an automated assembly system for implantable devices. Their requirements included:

- Positioning accuracy of ±0.05mm or better

- Repeatability of ±0.02mm

- Stroke length of 400mm

- Clean room compatibility (ISO Class 6)

- Continuous operation capability (24/7)

After evaluating several options, we recommended an ultra-precision magnetic coupling rodless cylinder with these features:

- Precision-ground stainless steel bearing rails

- Ceramic-hybrid bearing system with optimized preload

- Temperature-compensated rare earth magnetic circuit

- Multi-stage sealing system with PTFE primary seals

- Specialized low-particle-emission lubricants

Verification testing showed:

- Positioning accuracy of ±0.038mm across full stroke

- Repeatability of ±0.012mm under all load conditions

- Straightness of travel within 0.04mm over the entire length

- Velocity consistency of ±1.8% at all speeds

- No measurable accuracy degradation after 5 million cycles

The customer was able to achieve their demanding assembly tolerances consistently, reducing reject rates from 3.2% to 0.4% and improving overall production efficiency by 14%.

Implementation Best Practices for High-Precision Applications

For achieving maximum accuracy with magnetic coupling rodless cylinders:

Mounting and Installation

Proper mounting is critical for maintaining accuracy:

- Use precision-machined mounting surfaces (flatness within 0.02mm)

- Implement three-point mounting to prevent distortion

- Apply consistent torque to mounting fasteners

- Consider thermal expansion effects in mounting design

Environmental Controls

Control these environmental factors:

- Maintain consistent operating temperature (±2°C if possible)

- Protect from direct sunlight or radiant heat sources

- Control humidity to prevent condensation

- Shield from electromagnetic interference for sensitive applications

Motion Control Integration

Optimize the control system for precision:

- Use proportional valves for velocity control

- Implement closed-loop positioning with external feedback when possible

- Consider servo-pneumatic control5 for ultimate precision

- Optimize acceleration/deceleration profiles to prevent overshooting

Maintenance for Precision

Develop a precision-focused maintenance protocol:

- Regular accuracy verification measurements

- Scheduled seal replacement before performance degradation

- Precision cleaning procedures

- Proper lubrication with application-specific lubricants

Advanced Applications for Precision Rodless Cylinders

The exceptional accuracy of modern magnetic coupling rodless cylinders enables these demanding applications:

Automated Optical Inspection

High-precision rodless cylinders are ideal for camera positioning in inspection systems:

- Smooth motion prevents image blur

- Precise positioning ensures consistent image capture

- Repeatability ensures comparable images for analysis

- Non-contact magnetic coupling eliminates vibration

Laboratory Automation

Life science applications benefit from these features:

- Clean operation for sensitive environments

- Precise sample positioning

- Repeatable process execution

- Compact design for space-constrained labs

Semiconductor Manufacturing

Ultra-precision models excel in semiconductor applications:

- Sub-micron repeatability for critical processes

- Clean operation compatible with cleanroom requirements

- Stable performance in temperature-controlled environments

- Long service life with minimal maintenance

Conclusion

Selecting the right special cylinder for extreme applications requires careful consideration of your specific requirements. For corrosive environments, choosing the appropriate material based on your chemical exposure is critical. In space-constrained applications, ultra-thin cylinders with optimized designs can provide the necessary force in minimal space. For precision requirements, high-accuracy magnetic coupling rodless cylinders deliver the positioning performance needed for demanding applications.

By properly matching special cylinder specifications to your application requirements, you can achieve dramatic improvements in service life, performance, and reliability compared to standard cylinders that weren’t designed for these challenging conditions.

FAQs About Special Cylinders

How much longer do corrosion-resistant special cylinders last compared to standard models?

In aggressive chemical environments, properly specified corrosion-resistant cylinders typically last 5-10 times longer than standard stainless steel cylinders. For example, in concentrated acid applications, a Hastelloy C-276 cylinder often provides 1-2 years of service where a 316L stainless cylinder might fail in 4-6 weeks. The exact improvement depends on the specific chemicals, concentrations, temperature, and duty cycle.

What is the force trade-off when selecting ultra-thin pneumatic cylinders?

Ultra-thin pneumatic cylinders typically deliver 85-95% of the force of conventional cylinders with equivalent bore diameter. This slight reduction occurs due to increased seal friction relative to piston area and reduced effective pressure area from structural reinforcements. For most applications, this small force reduction can be compensated by increasing operating pressure by 0.5-1 bar or selecting a slightly larger bore size.

How does temperature affect the accuracy of magnetic coupling rodless cylinders?

Temperature significantly impacts the accuracy of magnetic coupling rodless cylinders through three mechanisms: thermal expansion of the cylinder body (typically 0.01-0.02mm/°C over the length), changes in magnetic coupling strength (approximately 0.1%/°C for standard magnets), and variations in seal friction. High-precision cylinders use temperature-compensated magnetic materials and thermally stable construction to reduce these effects to less than 0.03mm over a 10°C temperature change.

Can special cylinders with exotic materials be repaired, or must they be replaced when damaged?

Most special cylinders with exotic materials can be repaired rather than replaced, offering significant cost savings. Typical repairs include seal replacement, bearing service, and minor surface reconditioning. However, major structural damage often requires replacement due to the specialized manufacturing processes and materials. Establishing a relationship with a cylinder manufacturer that offers repair services for special cylinders can reduce lifetime costs by 60-70% compared to full replacement.

What is the cost premium for special cylinders compared to standard models?

The cost premium for special cylinders varies significantly based on the specific requirements. Corrosion-resistant models typically cost 2-7 times more than standard cylinders, depending on the material (with exotic alloys like Hastelloy and titanium at the higher end). Ultra-thin designs generally carry a 1.5-3x premium, while high-precision rodless cylinders may cost 2-4 times more than standard accuracy versions. Despite this higher initial cost, the total cost of ownership is often lower due to extended service life and reduced downtime.

How do you prevent galvanic corrosion when using dissimilar metals in special cylinder applications?

Preventing galvanic corrosion in special cylinders requires several strategies: electrical isolation between dissimilar metals using non-conductive bushings or gaskets, selecting compatible metals with minimal potential difference in the galvanic series, applying protective coatings to create barriers between metals, using sacrificial anodes in extremely corrosive environments, and ensuring proper drainage to prevent electrolyte pooling. For critical applications, regular inspection of potential galvanic corrosion sites should be included in maintenance protocols.

-

Provides detailed technical data on Hastelloy C-276, a nickel-molybdenum-chromium superalloy known for its exceptional resistance to a wide range of corrosive environments, particularly aggressive acids. ↩

-

Explains Positive Material Identification (PMI), a set of non-destructive testing methods, such as X-ray fluorescence (XRF), used to verify the chemical composition and alloy grade of metallic materials to ensure compliance with specifications. ↩

-

Offers an overview of Computational Fluid Dynamics (CFD), a powerful simulation tool that uses numerical analysis to model and visualize fluid flow, heat transfer, and associated phenomena, which is used to optimize internal designs. ↩

-

Describes the fundamental difference between accuracy (the closeness of a measurement to a true value) and repeatability (the closeness of agreement between successive measurements), which are key concepts in precision engineering. ↩

-

Details the principles of servo-pneumatics, an advanced motion control technology that combines the high force and speed of pneumatics with the precision of a closed-loop servo controller, enabling precise position and force control. ↩