Unpredictable cylinder acceleration causes 35% of production line inefficiencies, with varying loads creating speed inconsistencies that cost manufacturers an average of $15,000 per month in reduced throughput and quality issues. Cylinder acceleration varies with load due to Newton’s second law (F=ma)1, where constant pneumatic force must overcome increasing mass and friction, requiring precise pressure control and cylinder sizing to maintain consistent performance across different load conditions. Last month, I helped David, a production engineer from Michigan, whose packaging line was experiencing erratic speeds that damaged products when loads varied from 5 to 50 pounds. 🔧

Table of Contents

- How Does Load Mass Affect Cylinder Acceleration Physics?

- What Role Does Friction Play in Variable Load Performance?

- How Can Bepto Rodless Cylinders Optimize Performance with Varying Loads?

How Does Load Mass Affect Cylinder Acceleration Physics?

Understanding the fundamental physics relationship between force, mass, and acceleration reveals why cylinder performance changes with different loads.

Load mass directly affects cylinder acceleration through Newton’s second law (F=ma), where increasing load mass reduces acceleration proportionally when pneumatic force remains constant, requiring higher pressures or larger cylinder bores to maintain consistent performance across varying load conditions.

Cylinder Theoretical Force Calculator

Calculate the theoretical push and pull force of a cylinder

Input Parameters

Theoretical Force

Newton’s Second Law in Pneumatic Systems

The fundamental equation F = ma governs all cylinder acceleration behavior. In pneumatic systems, force comes from air pressure acting on piston area, while mass includes both the load and moving cylinder components.

Force Calculation:

- F = P × A (Pressure × Piston Area)

- Available force decreases with back pressure2

- Effective force = Supply pressure – Return pressure resistance

Mass Components:

- External load mass (primary variable)

- Piston and rod assembly mass

- Attached tooling and fixtures

- Fluid mass in cylinder chambers

Load Impact Analysis

| Load Mass | Required Force | Acceleration (at 80 PSI) | Performance Impact |

|---|---|---|---|

| 10 lbs | 45 N | 4.5 m/s² | Optimal speed |

| 25 lbs | 112 N | 1.8 m/s² | Moderate reduction |

| 50 lbs | 224 N | 0.9 m/s² | Significant slowdown |

| 100 lbs | 448 N | 0.45 m/s² | Poor performance |

Acceleration Curve Characteristics

Light Loads (Under 20 lbs):

- Rapid initial acceleration

- Quick approach to maximum velocity

- Minimal pressure requirements

- Potential for overshooting target positions

Heavy Loads (Over 50 lbs):

- Slow initial acceleration

- Extended time to reach working speed

- High pressure requirements

- Better position control but reduced throughput

David’s packaging line perfectly illustrated this physics challenge. His cylinders needed to handle products ranging from lightweight boxes (5 lbs) to heavy components (50 lbs). Light loads accelerated too quickly, causing positioning errors, while heavy loads moved too slowly, creating bottlenecks. We solved this by implementing variable pressure control and optimizing his rodless cylinder selection! 📦

What Role Does Friction Play in Variable Load Performance?

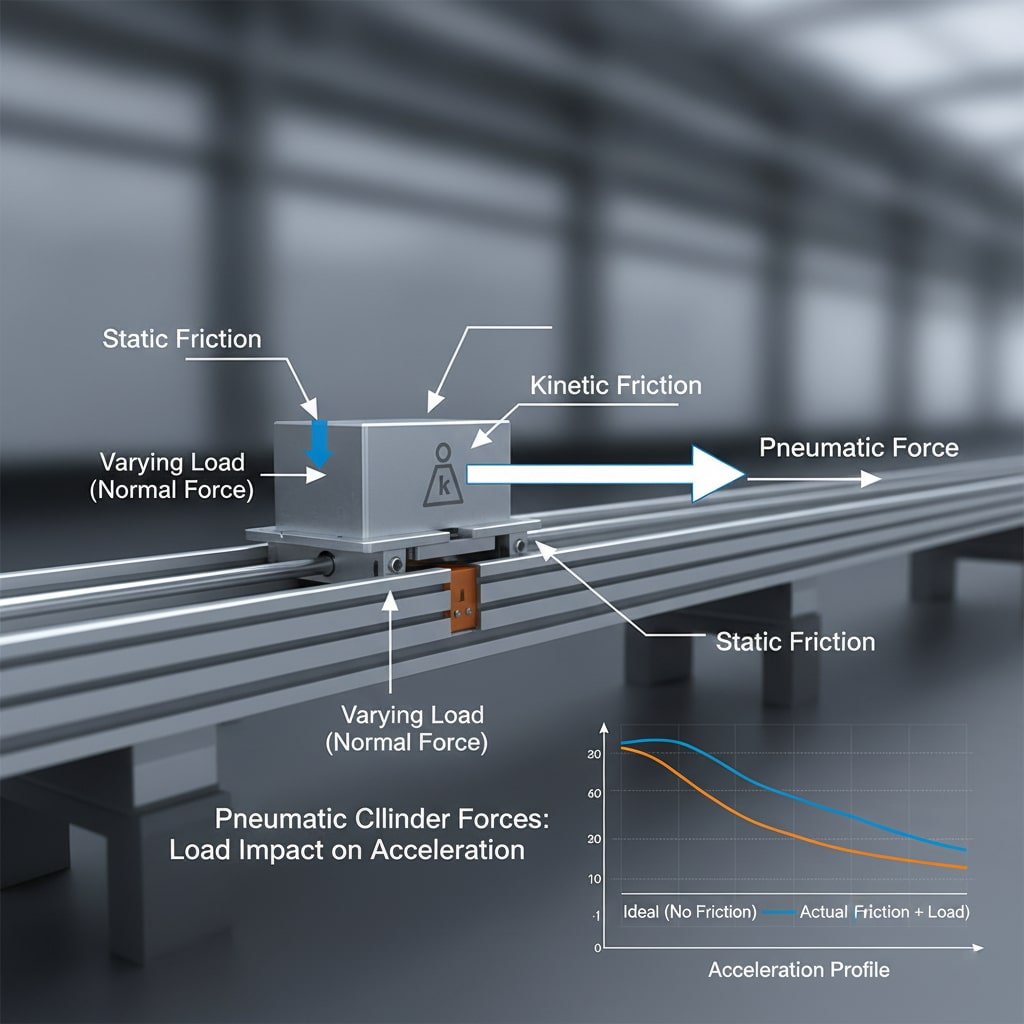

Friction forces significantly impact cylinder acceleration, especially when combined with varying loads that change the normal forces in the system.

Friction affects cylinder acceleration by creating opposing forces that vary with load weight, contact surfaces, and motion characteristics, requiring additional pneumatic force to overcome static friction at startup and kinetic friction during movement, particularly in rodless cylinders with external load contact.

Types of Friction in Cylinder Systems

- Initial force required to start movement

- Typically 1.5-2x higher than kinetic friction

- Varies with load normal force

- Critical for acceleration calculations

Kinetic Friction (Running):

- Continuous resistance during movement

- Generally constant at steady speeds

- Affected by surface conditions and lubrication

- Determines steady-state force requirements

Friction Force Calculations

Basic Friction Formula:

- F_friction = μ × N (Coefficient × Normal Force)

- Normal force increases with load weight

- Different coefficients for static vs. kinetic conditions

Load-Dependent Friction:

- Heavier loads create higher normal forces

- Increased friction requires more pneumatic force

- Compounds the mass-related acceleration reduction

- Creates non-linear performance curves

Friction Mitigation Strategies

| Strategy | Application | Friction Reduction | Load Capacity Impact |

|---|---|---|---|

| Low-friction seals | All cylinders | 30-50% | Minimal |

| External guides | Heavy loads | 60-80% | Significant improvement |

| Air cushioning | High-speed apps | 20-40% | Speed optimization |

| Lubrication systems | Continuous duty | 40-70% | Extended life |

Rodless Cylinder Advantages

Reduced Friction Sources:

- No rod seal friction

- Optimized internal sealing

- External load support options

- Better alignment capabilities

Performance Benefits:

- More consistent acceleration across load ranges

- Reduced stiction4 effects

- Better speed control

- Lower pressure requirements

Sarah, a machine designer from Texas, was struggling with inconsistent cycle times on her assembly equipment. Varying product weights from 15 to 75 pounds created unpredictable friction loads that standard cylinders couldn’t handle efficiently. Our Bepto rodless cylinders with integrated linear guides5 eliminated the friction variables, delivering consistent 2.5-second cycle times regardless of load weight! ⚙️

How Can Bepto Rodless Cylinders Optimize Performance with Varying Loads?

Our advanced rodless cylinder technology provides superior load handling capabilities and consistent performance across wide weight ranges through intelligent design and precision engineering.

Bepto rodless cylinders optimize variable load performance through larger bore sizes, integrated load support systems, advanced sealing technology, and customizable pressure control options that maintain consistent acceleration and speed regardless of load variations, delivering reliable automation performance.

Advanced Design Features

Large Bore Capabilities:

- Higher force output for heavy loads

- Better force-to-weight ratios

- Consistent performance across load ranges

- Reduced pressure requirements

Integrated Load Support:

- External linear guides eliminate side loading

- Reduced friction from proper load distribution

- Better alignment under varying loads

- Extended service life

Performance Optimization Solutions

| Load Range | Recommended Bore | Pressure Setting | Expected Performance |

|---|---|---|---|

| 5-20 lbs | 2.5″ | 60-80 PSI | Consistent 3 m/s |

| 20-50 lbs | 4″ | 80-100 PSI | Stable 2.5 m/s |

| 50-100 lbs | 6″ | 100-120 PSI | Reliable 2 m/s |

| 100+ lbs | 8″ | 120+ PSI | Controlled 1.5 m/s |

Customization Options

Pressure Control Systems:

- Variable pressure regulators

- Load-sensing pressure adjustment

- Programmable pressure profiles

- Automatic compensation systems

Speed Control Features:

- Flow control valves for consistent speeds

- Cushioning systems for smooth stops

- Acceleration ramps for gentle starts

- Position feedback for precise control

Cost-Effective Solutions

Bepto Advantages:

- 40% lower cost than OEM alternatives

- Same-day shipping for standard configurations

- Custom solutions within 5 business days

- Comprehensive technical support

Performance Guarantees:

- Consistent ±5% speed variation across load ranges

- 2 million cycle life minimum

- Temperature stability from -10°F to 180°F

- Full compatibility with existing systems

Our rodless cylinder technology has helped over 500 customers solve variable load challenges, achieving 95% performance consistency and reducing cycle time variations by 80%. We don’t just sell cylinders – we engineer complete motion solutions that deliver predictable performance regardless of load variations! 🎯

Conclusion

Understanding cylinder acceleration physics with varying loads enables proper system design and component selection for consistent automation performance.

FAQs About Cylinder Acceleration with Varying Loads

Q: Why does my cylinder slow down significantly with heavier loads?

Heavier loads require more force to achieve the same acceleration due to Newton’s second law (F=ma). Your cylinder may need higher pressure, larger bore size, or reduced friction to maintain consistent performance across different load weights.

Q: How can I calculate the right cylinder size for varying loads?

Calculate maximum required force using F = ma for your heaviest load, add friction forces, then divide by your available pressure to determine minimum piston area. Always include a 25-50% safety factor for reliable operation.

Q: What’s the best way to maintain consistent speeds with different load weights?

Use variable pressure control, flow control valves, or servo-pneumatic systems that automatically adjust based on load conditions. Rodless cylinders with integrated guides also provide more consistent performance across load ranges.

Q: Can Bepto rodless cylinders handle rapid load changes during operation?

Yes, our rodless cylinders with advanced control systems can adapt to load changes within milliseconds using pressure feedback and flow control. This makes them ideal for applications with varying product weights or changing process conditions.

Q: How do Bepto solutions compare to expensive servo systems for variable load applications?

Bepto pneumatic solutions provide 80% of servo performance at 30% of the cost, with simpler maintenance and higher reliability. For most industrial applications, our advanced pneumatic control delivers the precision you need without servo complexity.

-

Learn the fundamental principles of Newton’s second law and how it relates force, mass, and acceleration. ↩

-

Understand how back pressure is created in pneumatic circuits and its impact on system performance. ↩

-

Explore the difference between static (breakaway) and kinetic friction and the forces required to overcome them. ↩

-

Read about the phenomenon of “stiction” and how it affects the initial movement of mechanical components. ↩

-

Discover the design and function of linear guides and their role in providing precise, low-friction motion. ↩