Introduction

Have you ever ordered a pneumatic component only to find the threads don’t match your existing system? 😰 This costly mistake happens daily in factories worldwide, causing delays, frustration, and unexpected expenses. Thread incompatibility can halt production lines and drain budgets faster than almost any other procurement error.

BSP, NPT, G, and R threads are the four most common thread standards used in pneumatic systems globally. BSP (British Standard Pipe1) and G threads use parallel designs, while NPT (National Pipe Thread2) and R threads feature tapered profiles. Understanding these differences is critical for ensuring leak-free connections and system compatibility.

Just last month, I spoke with David, a maintenance supervisor at a automotive parts factory in Michigan, who faced a three-day production shutdown because someone ordered NPT fittings for a system designed for BSP threads. His frustration was palpable—and completely avoidable with the right knowledge. Let me walk you through everything you need to know.

Table of Contents

- What Are BSP Threads and Where Are They Used?

- How Do NPT Threads Differ from BSP Threads?

- What Is the Difference Between G and R Thread Designations?

- Which Thread Type Should You Choose for Your Pneumatic System?

What Are BSP Threads and Where Are They Used?

Choosing the right thread standard starts with understanding your geographic market and industry conventions. 🌍

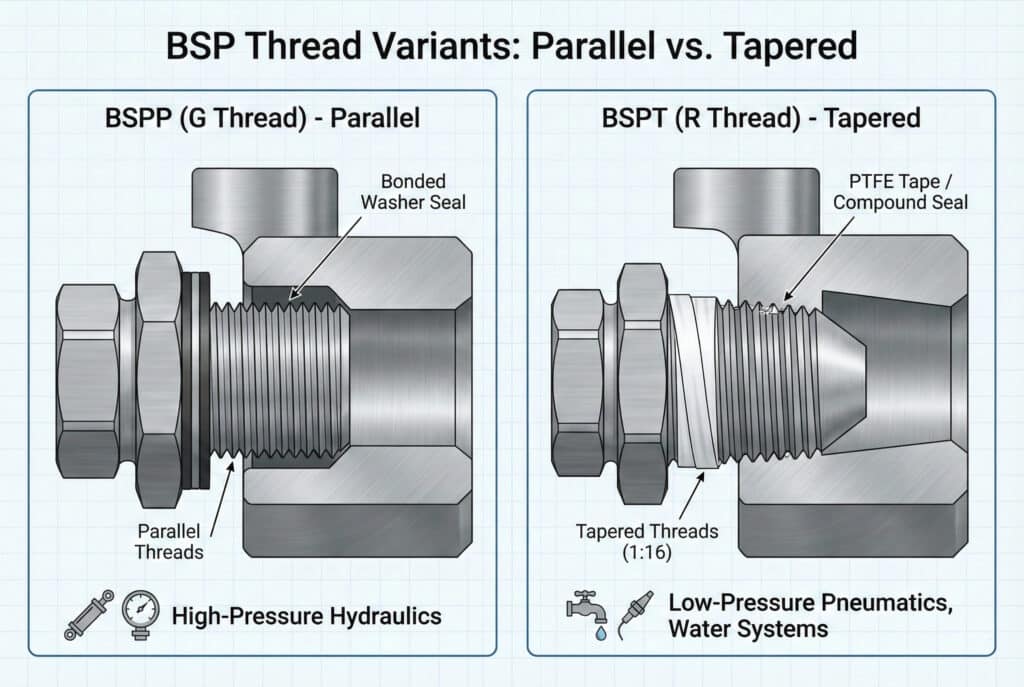

BSP (British Standard Pipe) threads are parallel threads commonly used throughout Europe, Asia, Australia, and most Commonwealth countries. They come in two variants: BSPP (parallel) for mechanical joints with sealing washers, and BSPT (tapered) for self-sealing applications in lower-pressure systems.

The History and Prevalence of BSP

BSP threads originated in the United Kingdom and became the de facto standard across the British Empire. Today, they remain dominant in international markets outside North America. At Bepto Pneumatics, approximately 70% of our rodless cylinder orders specify BSP connections—a testament to their global reach.

BSPP vs. BSPT: Understanding the Variants

The BSP family includes two critical subtypes:

| Feature | BSPP (G Thread) | BSPT (R Thread) |

|---|---|---|

| Profile | Parallel | Tapered (1:16) |

| Sealing Method | Bonded washer or O-ring | Thread compound or PTFE tape3 |

| Common Applications | Hydraulics, high-pressure pneumatics | Low-pressure pneumatics, water systems |

| Designation Example | G 1/4 | R 1/4 or BSPT 1/4 |

Real-World Application

I remember working with Sarah, a procurement manager for a packaging machinery company in Manchester, England. She was consistently ordering BSPT fittings when her German-made equipment required BSPP. The result? Persistent minor leaks that degraded system efficiency by nearly 15%. Once we identified the issue and switched her to proper BSPP fittings with bonded washers, her air consumption dropped significantly. 💰

How Do NPT Threads Differ from BSP Threads?

Understanding NPT is essential if you’re supplying equipment to North American markets or working with US-manufactured components.

NPT (National Pipe Thread) is a tapered thread standard predominantly used in the United States and Canada. Unlike BSP’s 55-degree thread angle, NPT features a 60-degree angle and a 1:16 taper, creating a wedging seal when tightened with thread sealant or PTFE tape.

Critical Dimensional Differences

The incompatibility between NPT and BSP isn’t just about taper versus parallel—the fundamental geometry differs:

| Specification | NPT | BSP |

|---|---|---|

| Thread Angle | 60° | 55° |

| Thread Form | Tapered (1:16) | Parallel (BSPP) or Tapered (BSPT) |

| Pitch | Different for same nominal size | ISO 228-14 standard |

| Sealing | Metal-to-metal via taper | Washer/O-ring (BSPP) or taper (BSPT) |

Why You Cannot Mix NPT and BSP

This is perhaps the most important lesson I share with clients: NPT and BSP threads are NOT interchangeable, even if they seem close in size. The different thread angles mean they won’t mate properly. Forcing them together creates cross-threading, leaks, and potential safety hazards.

The North American Market Reality

At our company, we maintain separate inventory specifically for NPT-threaded rodless cylinders destined for US and Canadian customers. While this adds complexity, it’s absolutely necessary. We’ve seen too many cases where well-intentioned engineers tried to “make it work” with mixed threads—the result is always problematic. 🔧

What Is the Difference Between G and R Thread Designations?

Thread nomenclature can be confusing, but understanding these designations prevents costly ordering mistakes.

G threads are parallel BSP threads (BSPP) designated under ISO 228-1 standard, while R threads are tapered BSP threads (BSPT) designated under ISO 7-15 standard. The letter indicates the profile: G for parallel (from German “Gewinde”), R for tapered (from “Rp” for internal tapered threads).

Decoding the Designation System

Here’s how to read thread callouts correctly:

G Thread Examples:

- G 1/4 = Parallel external thread, 1/4 inch nominal

- G 1/2 = Parallel external thread, 1/2 inch nominal

R Thread Examples:

- R 1/4 = Tapered external thread, 1/4 inch nominal

- Rc 1/4 = Tapered internal thread, 1/4 inch nominal

- Rp 1/4 = Parallel internal thread (to mate with R external)

The Confusion Factor

Many engineers use “BSP” generically without specifying parallel or tapered. This ambiguity causes problems. When customers contact us, I always ask: “Do you need G or R threads?” This simple clarification saves weeks of back-and-forth. ✅

International Standards Alignment

| Old Designation | Modern ISO Designation | Type |

|---|---|---|

| BSPP | G (ISO 228-1) | Parallel |

| BSPT | R (ISO 7-1) | Tapered external |

| BSPT internal | Rc (ISO 7-1) | Tapered internal |

| BSPP internal for R | Rp (ISO 7-1) | Parallel internal |

Which Thread Type Should You Choose for Your Pneumatic System?

Selecting the optimal thread standard depends on multiple factors beyond just geographic location. 🤔

Choose NPT threads for North American markets and equipment, G (BSPP) threads for high-pressure applications requiring reliable sealing with O-rings or washers, and R (BSPT) threads for lower-pressure systems where tapered self-sealing is acceptable. Always match your existing system’s thread standard unless you’re implementing adapters.

Decision Matrix for Thread Selection

Consider these factors when specifying threads for your pneumatic components:

Geographic Considerations

- North America: Default to NPT unless equipment specifies otherwise

- Europe, Asia, Australia: Default to BSP (G or R depending on application)

- Global equipment: Verify manufacturer specifications carefully

Application Pressure Levels

- High pressure (>10 bar): Prefer G threads with proper O-ring sealing

- Medium pressure (5-10 bar): Either G or R acceptable with appropriate sealing

- Low pressure (<5 bar): R threads often sufficient and more economical

Assembly and Maintenance Requirements

G threads offer advantages for systems requiring frequent disassembly. The parallel design with replaceable sealing washers means you can reassemble connections multiple times without degradation. R and NPT tapered threads, by contrast, may require fresh sealant each time and can wear with repeated assembly cycles.

The Bepto Pneumatics Approach

At our company, we stock rodless cylinders in all major thread configurations. When customers are replacing existing cylinders from brands like SMC, Festo, or Parker, we carefully match not just the bore size and stroke length, but also the exact thread specification. This attention to detail is why our replacement cylinders achieve true plug-and-play compatibility—saving our customers both time and money. 💡

When to Use Thread Adapters

Sometimes you inherit mixed systems or need to integrate equipment from different regions. Quality thread adapters can bridge NPT-to-BSP connections, but they add potential leak points and cost. We recommend adapters only as temporary solutions or when system redesign isn’t feasible.

Conclusion

Understanding thread types isn’t just technical knowledge—it’s a business necessity that directly impacts your bottom line, system reliability, and operational efficiency. Whether you’re specifying G, R, BSP, or NPT threads, precision matters. 🎯

FAQs About Pneumatic Thread Standards

Can I use NPT fittings with BSP threads?

No, NPT and BSP threads are fundamentally incompatible due to different thread angles (60° vs. 55°) and should never be forced together. Attempting to mix these standards results in cross-threading, leaks, and potential system failure. Always use proper thread adapters if you must connect different standards, though matching threads is always the superior solution.

What does the “G” stand for in G thread designation?

The “G” designation comes from the German word “Gewinde” (meaning thread) and indicates a parallel BSP thread under ISO 228-1 standard. This nomenclature is used internationally to clearly distinguish parallel threads from tapered R threads, eliminating the ambiguity of older “BSP” terminology.

How do I identify which thread type I currently have?

Use a thread pitch gauge to measure threads per inch, check for taper using a straight edge, and measure the thread angle if possible. NPT threads show visible taper and 60° angles, while G threads are perfectly parallel with 55° angles. When in doubt, consult the original equipment documentation or contact the manufacturer—we at Bepto Pneumatics help customers identify threads daily.

Why do European and American systems use different thread standards?

Thread standards evolved independently based on historical industrial development and national standardization efforts in the 19th and early 20th centuries. The British Empire standardized on BSP threads, while the United States developed NPT threads. These standards became entrenched in their respective markets and remain dominant today despite globalization efforts.

Are metric threads different from BSP and NPT?

Yes, metric threads (like M10x1.0) use millimeter-based sizing and different thread profiles entirely, adding another layer of complexity to pneumatic system design. Metric threads are increasingly common in modern equipment, particularly from European and Asian manufacturers. At Bepto Pneumatics, we offer metric thread options on our rodless cylinders to accommodate this growing demand. 🔩

-

Comprehensive background on the history and technical specifications of British Standard Pipe threads. ↩

-

Technical details regarding American National Standard Pipe Thread standards and their specific tapers. ↩

-

A guide on how Polytetrafluoroethylene (Teflon) tape functions as a thread sealant and lubricant. ↩

-

The official international standard document specifying requirements for non-sealing pipe threads. ↩

-

The official international standard detailing dimensions for pipe threads where pressure-tight joints are made on the threads. ↩