Introduction

Are your pneumatic cylinders failing prematurely, costing you thousands in downtime? 💸 The root cause might not be poor maintenance—it could be the wrong aluminum manufacturing process. Many engineers overlook how Die-casting1 versus extrusion2 fundamentally changes the metallurgical properties of cylinder barrels, leading to catastrophic failures under pressure.

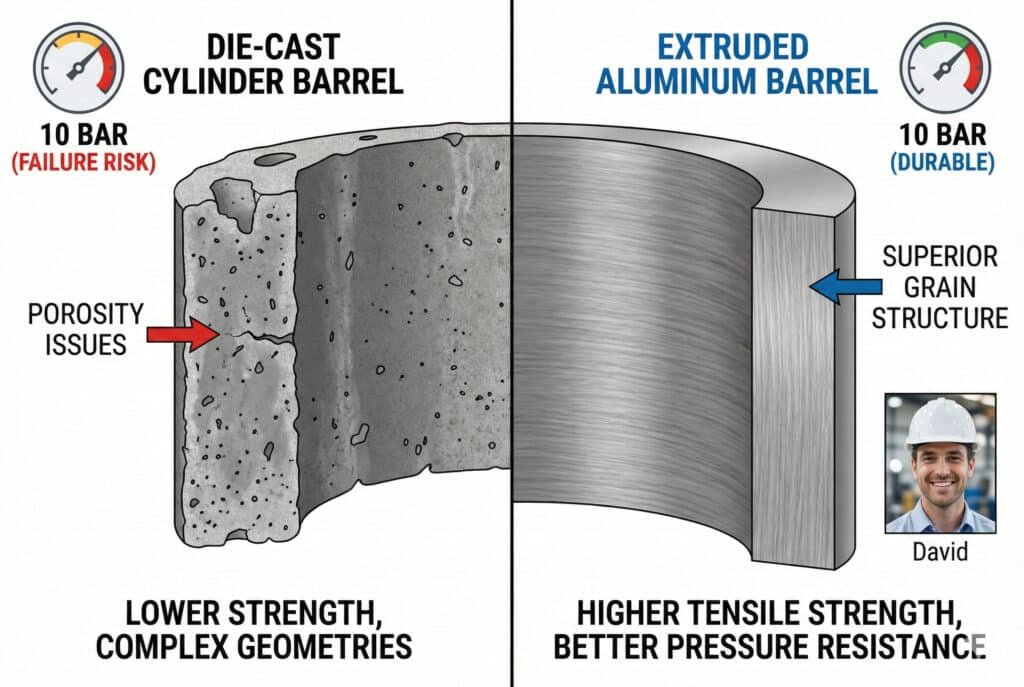

Die-cast aluminum cylinder barrels offer faster production and complex geometries but have lower strength and porosity3 issues, while extruded aluminum provides superior grain structure4, higher tensile strength, and better pressure resistance—making extrusion the preferred choice for high-performance rodless cylinders and pneumatic applications requiring durability.

I recently spoke with David, a maintenance engineer at a automotive parts plant in Michigan, who faced repeated cylinder failures every six months. His OEM supplier had switched to die-cast barrels without notification, and the porous structure couldn’t handle the 10-bar operating pressure. After we supplied him with extruded aluminum replacements from Bepto, his failure rate dropped to zero over 18 months. 🔧

Table of Contents

- What Are the Core Metallurgical Differences Between Die-Cast and Extruded Aluminum?

- How Does Manufacturing Process Affect Cylinder Barrel Performance?

- Which Aluminum Type Should You Choose for Rodless Cylinders?

- Can Die-Cast Aluminum Ever Match Extruded Performance in Pneumatic Applications?

What Are the Core Metallurgical Differences Between Die-Cast and Extruded Aluminum?

Understanding the atomic-level differences between these processes is crucial for making informed purchasing decisions. ⚛️

Die-casting involves injecting molten aluminum into molds under high pressure, creating random grain structures with potential porosity, while extrusion forces heated aluminum through dies, producing aligned grain structures with superior mechanical properties and minimal internal defects.

Grain Structure and Crystallization

The fundamental difference lies in how aluminum crystals form and align. In die-casting, rapid cooling creates a chaotic grain boundary network. The molten metal solidifies quickly against the mold walls, trapping gases and creating micro-porosity that weakens the structure.

Extrusion, by contrast, applies directional force to heated aluminum billets. This mechanical working process aligns the grain structure longitudinally, creating what metallurgists call “fiber flow.” Think of it like the difference between tangled yarn and neatly combed fibers—the aligned structure in extruded aluminum provides predictable, superior strength characteristics.

Porosity and Internal Defects

Die-cast components typically contain 2-5% porosity by volume. These microscopic voids act as stress concentrators under cyclic loading. In our testing at Bepto, we’ve found that die-cast samples fail pressure tests at 15-20% lower thresholds than extruded equivalents.

| Property | Die-Cast Aluminum | Extruded Aluminum |

|---|---|---|

| Porosity Level | 2-5% | <0.5% |

| Tensile Strength | 180-240 MPa | 250-310 MPa |

| Yield Strength | 120-160 MPa | 200-280 MPa |

| Elongation | 2-6% | 8-15% |

| Pressure Rating | Up to 8 bar | Up to 16 bar |

Alloy Composition Constraints

Die-casting requires specific alloys (typically A380 or ADC12) with high silicon content for fluidity. These alloys sacrifice strength for castability. Extrusion works with stronger alloys like 6061-T6 or 6063-T5, which contain magnesium and silicon for age-hardening capability, delivering superior mechanical properties for cylinder applications.

How Does Manufacturing Process Affect Cylinder Barrel Performance?

The production method directly impacts how your pneumatic system performs under real-world conditions. 🏭

Manufacturing process determines wall thickness consistency, surface finish quality, and dimensional accuracy—extruded barrels maintain tighter tolerances (±0.05mm) and uniform wall thickness, while die-cast parts show variations that can compromise seal integrity and lead to premature wear in rodless cylinder applications.

Dimensional Stability Under Pressure

When compressed air cycles through a cylinder thousands of times daily, even minor dimensional inconsistencies become critical. Extruded barrels maintain their geometry because the manufacturing process work-hardens the material uniformly. Die-cast barrels can experience micro-deformation at pressure points where porosity weakens the structure.

Surface Finish and Seal Compatibility

Our rodless cylinders at Bepto use extruded barrels with Ra values below 0.8μm after honing. This mirror-like finish is achievable because extrusion creates a dense surface layer. Die-cast surfaces require extensive machining to remove the rough cast skin, and even then, subsurface porosity can emerge during operation, causing seal degradation and air leakage.

Thermal Conductivity in High-Cycle Applications

Extrusion’s aligned grain structure provides 10-15% better thermal conductivity along the barrel axis. In high-speed pneumatic applications, this helps dissipate heat from friction and compression more effectively, extending component life and maintaining consistent performance.

Which Aluminum Type Should You Choose for Rodless Cylinders?

Selecting the right material can mean the difference between reliable operation and costly failures. 🎯

For rodless cylinders operating above 6 bar or in critical applications, extruded aluminum is the only viable choice due to its superior strength-to-weight ratio, pressure resistance, and dimensional stability—die-cast aluminum should only be considered for low-pressure, non-critical applications where cost is the primary concern.

Application-Based Selection Criteria

I always advise our clients at Bepto to consider three factors: operating pressure, cycle frequency, and consequence of failure. For packaging machinery running 24/7, extruded barrels are non-negotiable. For occasional-use fixtures under 5 bar, die-cast components might suffice.

Cost vs. Lifecycle Analysis

Here’s where many purchasing managers make mistakes—they see die-cast components at 30-40% lower initial cost and jump at the savings. But when you factor in replacement frequency, downtime costs, and labor for changeouts, extruded aluminum delivers 3-5x better total cost of ownership.

Sarah, a procurement manager at a food processing plant in Ontario, learned this the hard way. She initially chose die-cast cylinders to meet budget targets, but after three failures in one year (each causing $8,000 in lost production), she switched to our extruded Bepto cylinders. Her maintenance costs dropped by 65% annually. 📊

Quality Indicators to Verify

When sourcing cylinders, demand these specifications:

- Material certification showing alloy grade (6061-T6 for extrusion)

- Pressure test reports at 1.5x rated pressure

- Dimensional inspection data with tolerance verification

- Surface finish measurements (Ra values)

At Bepto, we provide complete material traceability and test documentation with every shipment because we understand that your production line depends on reliable components.

Can Die-Cast Aluminum Ever Match Extruded Performance in Pneumatic Applications?

This is the question I hear most often from cost-conscious engineers. 🤔

Despite advances in die-casting technology like vacuum-assisted processes and hot isostatic pressing (HIP)5, die-cast aluminum cannot achieve the grain structure alignment and mechanical properties of extruded material for high-pressure pneumatic cylinders—the physics of solidification versus plastic deformation creates fundamental limitations that post-processing cannot fully overcome.

Advanced Die-Casting Techniques

Modern vacuum die-casting reduces porosity to 1-2%, and HIP treatment can close internal voids through high-temperature compression. These processes narrow the performance gap but add 40-60% to production costs, eliminating the primary advantage of die-casting while still falling short of extruded properties.

Hybrid Approaches and Niche Applications

Some manufacturers use die-cast end caps with extruded barrels—a reasonable compromise for certain designs. Die-casting excels at creating complex mounting features and integrated manifolds that would require extensive machining on extruded stock. We occasionally recommend this hybrid approach at Bepto for custom applications where geometry complexity justifies it.

The Future of Aluminum Cylinder Manufacturing

Emerging technologies like additive manufacturing (3D printing) of aluminum may eventually offer the geometric freedom of casting with properties approaching extrusion. However, for production volumes and cost-effectiveness in 2025, extrusion remains the gold standard for pneumatic cylinder barrels, especially in rodless cylinder designs where the entire barrel length must withstand internal pressure without external rod support.

Conclusion

The metallurgical differences between die-cast and extruded aluminum aren’t just academic—they directly impact your operational reliability and bottom line. For critical pneumatic applications, especially rodless cylinders, extruded aluminum’s superior grain structure, minimal porosity, and consistent mechanical properties make it the clear choice. At Bepto, we exclusively use extruded 6061-T6 aluminum for our cylinder barrels because we’ve seen firsthand how this decision prevents the costly failures that plague die-cast alternatives. 🛡️

FAQs About Aluminum Cylinder Barrels

Q: Can I visually identify whether a cylinder barrel is die-cast or extruded?

Extruded barrels show longitudinal machining marks and consistent wall thickness, while die-cast parts often have parting lines, ejector pin marks, and slight surface texture variations. However, definitive identification requires material certification documentation from the manufacturer, which we always provide at Bepto.

Q: How much pressure difference can I expect between die-cast and extruded cylinder barrels?

Extruded aluminum cylinders typically handle 10-16 bar working pressure, while die-cast equivalents max out at 6-8 bar safely. The 50-100% pressure rating difference stems from porosity and grain structure variations that affect burst strength and fatigue resistance under cyclic loading.

Q: Does the aluminum type affect compatibility with different seal materials?

Yes—extruded barrels’ superior surface finish (Ra <0.8μm) works optimally with all seal types including polyurethane, NBR, and PTFE. Die-cast surfaces may cause premature wear on softer seals due to microscopic surface irregularities and potential subsurface porosity emergence during operation.

Q: Are there environmental or recycling differences between die-cast and extruded aluminum?

Both aluminum types are fully recyclable with similar energy requirements. However, extruded cylinders’ longer service life (typically 3-5x longer) means fewer replacements and lower overall environmental impact when considering the complete lifecycle from raw material extraction through disposal.

Q: Can post-machining improve die-cast aluminum to match extruded performance?

Surface machining improves finish and dimensional accuracy but cannot alter the internal grain structure or eliminate subsurface porosity. While machining helps, the fundamental metallurgical differences remain—you cannot machine away the random crystallization pattern created during the casting solidification process.

-

Explore the technical process of high-pressure aluminum die casting and its industrial applications. ↩

-

Learn how the extrusion process creates high-strength aluminum profiles for structural engineering. ↩

-

View detailed technical reports on how porosity affects the structural integrity of cast metals. ↩

-

Understand the relationship between metal grain orientation and the final strength of components. ↩

-

Discover how Hot Isostatic Pressing is used to eliminate internal defects and densify metallic components. ↩