Introduction

“This part is only compatible with our brand.” “Using third-party components will void your warranty.” “Our proprietary design requires OEM parts.” Sound familiar? These warnings from major pneumatic manufacturers have cost industrial customers billions in unnecessary spending over the past decade. But here’s what they’re not telling you: Most of these compatibility claims are marketing fiction designed to lock you into single-source purchasing at premium prices. 😤

The truth is that 85-90% of industrial pneumatic components follow international ISO standards that ensure cross-brand compatibility—manufacturers emphasize “proprietary” features and compatibility restrictions to protect profit margins, not because genuine technical incompatibilities exist. Understanding which compatibility claims are legitimate engineering concerns versus which are pure vendor lock-in tactics can save your operation 30-50% on pneumatic procurement while actually improving supply chain resilience.

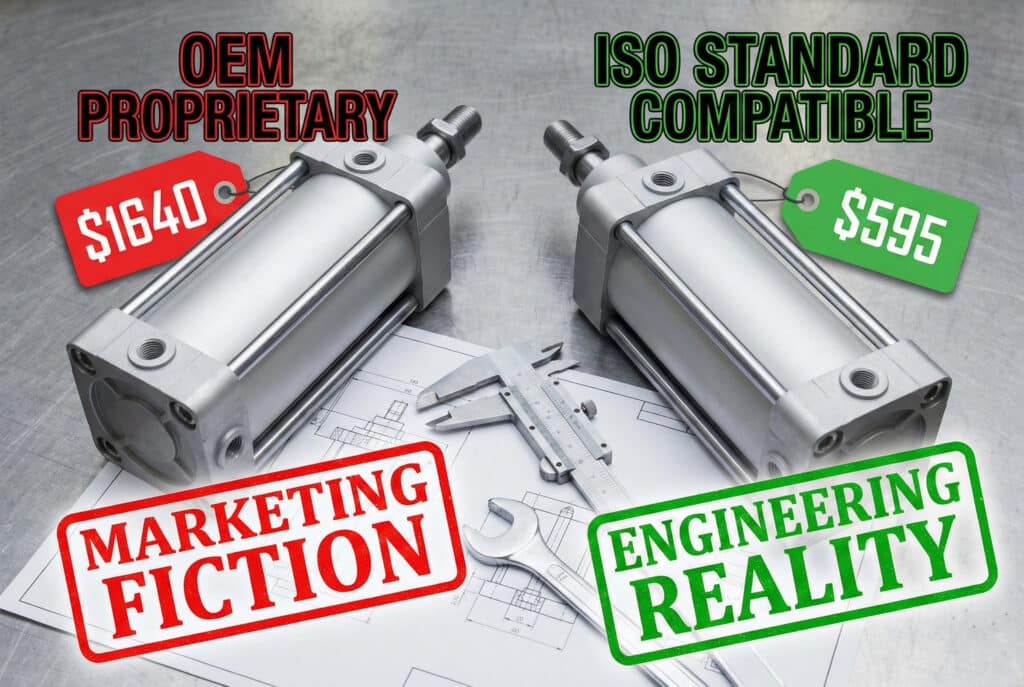

Three months ago, I received a desperate call from Michael, maintenance director at a pharmaceutical packaging plant in New Jersey. His Festo valve manifold needed a replacement cylinder, and Festo insisted only their $1,640 cylinder would work due to “proprietary mounting specifications.” Frustrated by the 8-week lead time, Michael sent me the technical drawings. Within 20 minutes, I identified that the “proprietary” mounting was actually standard ISO 15552—Festo was using industry-standard dimensions but claiming exclusivity. We supplied a compatible Bepto cylinder for $595 that installed perfectly and has run flawlessly for four months. Michael was furious—not at us, but at the years of unnecessary overspending based on false compatibility claims. 💰

Table of Contents

- What Does “Compatible” Actually Mean in Pneumatic Systems?

- Which Compatibility Claims Are Legitimate vs. Marketing Tactics?

- How Do ISO Standards Ensure Cross-Brand Compatibility?

- What Are the Hidden Costs of Believing Compatibility Myths?

- FAQs About Pneumatic Component Compatibility

What Does “Compatible” Actually Mean in Pneumatic Systems?

Let’s start by cutting through the deliberately confusing terminology manufacturers use. 🔍

True compatibility means that components can physically connect, operate safely within the same pressure/temperature parameters, and deliver specified performance without modification—this requires matching five critical specifications: mounting dimensions, port sizes and thread types, pressure ratings, flow capacity, and electrical interfaces (for smart components). Everything else—brand names, color schemes, proprietary model numbers—is marketing noise designed to obscure the fundamental interchangeability of standardized components.

The Five Pillars of True Compatibility

Let me break down what actually matters when determining if components will work together:

1. Mounting Dimensions (Physical Interface)

What it means: The bolt holes, tie-rod spacing, and mounting surface dimensions must match.

The standard: ISO 155521 (formerly ISO 6431) defines exact mounting dimensions for cylinders by bore size. If two cylinders are both ISO 15552 compliant with the same bore, they’re physically interchangeable—period.

The deception: Manufacturers call standard ISO mounting “our design” or use proprietary model numbers to obscure the fact that they’re following international standards.

Example dimensions for 40mm bore ISO 15552 cylinder:

- Mounting hole spacing: 80mm center-to-center

- Mounting hole diameter: 9mm

- Tie-rod spacing: 70mm × 70mm

- Flange thickness: 16mm

These dimensions are identical whether the cylinder is branded Festo, SMC, Parker, Norgren, or Bepto. The ISO standard exists precisely to ensure interchangeability. ✅

2. Port Sizes and Thread Types

What it means: The pneumatic connections must physically mate with your fittings and tubing.

Common standards:

- G1/8″ (BSPP): Small cylinders, pilot valves

- G1/4″ (BSPP): Most common industrial size

- G3/8″ (BSPP): Larger cylinders, high flow

- NPT threads: Common in North America

- Metric threads: M5, M7 increasingly common

The deception: Manufacturers imply their port configuration is unique when they’re using industry-standard threads.

Reality check: A G1/4″ port is a G1/4″ port. It doesn’t matter if it’s on a $2,000 Festo cylinder or a $700 Bepto cylinder—the same fitting screws into both with identical sealing performance.

3. Pressure Ratings

What it means: Components must operate safely within the same pressure range.

Standard industrial range: 1-10 bar (14.5-145 psi) for 95% of applications

The deception: Manufacturers sometimes specify narrow “recommended” pressure ranges to suggest incompatibility, even though the component safely operates across standard industrial pressures.

Example: A valve rated “6 bar operating pressure” and a cylinder rated “1-10 bar” are perfectly compatible at 6 bar. The manufacturer might claim you need their matched set, but basic engineering says otherwise.

4. Flow Capacity (Cv Value)

What it means: The valve must supply sufficient air volume to actuate the cylinder at your required speed.

The calculation: Flow requirement2 = (Piston Area × Stroke × Cycles/Min) ÷ 60

The deception: Manufacturers claim you need their “optimized” valve-cylinder combinations, when simple flow calculations prove many combinations work perfectly.

Reality: A 40mm bore cylinder requires approximately 0.15 Cv at 6 bar for 1-second actuation. Any valve meeting this Cv specification will work—regardless of brand. 📊

5. Electrical Interfaces (Smart Components)

What it means: For electronically controlled components, communication protocols must match.

Legitimate compatibility concern: IO-Link3, Profinet, EtherCAT, and other industrial protocols have genuine compatibility requirements.

The deception: Manufacturers extend this legitimate concern to suggest that even basic pneumatic components need brand matching, when 90% of cylinders have zero electronics.

Reality: A standard pneumatic cylinder has no electrical components. Claims that it must “match” your electronic valve are nonsense—the air doesn’t care about communication protocols. 🙄

What “Compatible” Doesn’t Mean

Here’s what manufacturers want you to think compatibility requires—but actually doesn’t:

❌ Same brand name: Brands are marketing constructs, not engineering requirements

❌ Same color scheme: Aesthetics have zero impact on function

❌ Same model series: Model numbers are arbitrary marketing designations

❌ Purchased together: Components don’t need to be “married” at the factory

❌ Same country of origin: Geography doesn’t affect ISO compliance

❌ Same price point: Expensive and economical components can work together perfectly

The Compatibility Verification Process

Here’s how to actually verify compatibility—without trusting manufacturer claims:

Step 1: Obtain Technical Specifications

Get dimensional drawings and specifications for both components (existing and replacement).

Step 2: Compare Critical Dimensions

Verify mounting holes, port locations, and overall envelope dimensions match.

Step 3: Verify Pressure Ratings

Confirm overlapping operating pressure ranges.

Step 4: Calculate Flow Requirements

Ensure valve Cv meets cylinder flow needs at your operating pressure.

Step 5: Check Thread Types

Verify port threads match your fittings (or obtain adapters).

At Bepto, we do this verification for customers free of charge. Send us your existing component specifications, and we’ll confirm compatibility within 2-4 hours—with documentation you can show your engineering team. No sales pressure, just engineering facts. 🎯

Which Compatibility Claims Are Legitimate vs. Marketing Tactics?

Not all compatibility warnings are lies—some reflect genuine engineering constraints. The trick is knowing which is which. 🕵️

Legitimate compatibility requirements include: matching communication protocols for smart components (IO-Link, fieldbus), verified seal material compatibility with your process media, proper flow matching for high-speed applications (<0.5 second cycle times), and mounting interface verification for non-ISO standard equipment. However, claims that standard ISO-compliant cylinders “only work with” specific brand valves, or that using third-party parts automatically voids warranties, are typically legal intimidation tactics without engineering basis.

Legitimate Compatibility Concerns

Let me be clear: Some compatibility requirements are real and important.

1. Electronic Communication Protocols

Claim: “This IO-Link cylinder requires our IO-Link valve for communication.”

Verdict: ✅ LEGITIMATE (with nuance)

Reality: IO-Link, Profinet, EtherCAT, and other industrial communication protocols do have compatibility requirements. However:

- The pneumatic function still works without electronic communication

- Many “smart” components use standard protocols that work across brands

- Only 5-10% of industrial cylinders have electronic interfaces

Example: A Festo IO-Link cylinder can communicate with a Bepto IO-Link valve if both follow the IO-Link specification (most do). The “proprietary” claim often refers to manufacturer-specific diagnostic features, not basic operation.

2. Extreme Environment Applications

Claim: “High-temperature applications require our matched seal materials.”

Verdict: ✅ LEGITIMATE CONCERN (but solvable)

Reality: Seal material compatibility is critical for:

- High temperatures (>80°C): Requires Viton (FKM) seals

- Chemical exposure: Requires EPDM, PTFE, or other specialized materials

- Food/pharma: Requires FDA-compliant materials

However: This doesn’t mean you need the same brand—it means you need the same seal material specification. Bepto offers Viton seals, PTFE seals, and FDA-compliant options that match OEM specifications exactly.

Translation: “You need Viton seals” = legitimate. “You need our Viton seals” = marketing. 💡

3. Ultra-High-Speed Applications

Claim: “Our valve-cylinder combination is optimized for 0.2-second cycle times.”

Verdict: ✅ LEGITIMATE (but verifiable)

Reality: Very high-speed applications (sub-0.5 second cycles) do require careful flow matching. Valve Cv, cylinder bore, stroke length, and pressure all interact.

However: This is basic engineering calculation, not brand magic. Any valve with sufficient Cv will work. The manufacturer’s “optimization” often just means they did the math for you.

Solution: Calculate required Cv, verify valve specification, test in your application. We provide flow calculation support for customers with high-speed requirements.

4. Proprietary Mounting Interfaces

Claim: “This custom machine uses proprietary mounting that requires OEM parts.”

Verdict: ✅ SOMETIMES LEGITIMATE

Reality: Some custom machinery truly uses non-standard mounting. However:

- 85% of “proprietary” mounting is actually ISO standard with custom brackets

- Custom mounting can often be adapted with simple modifications

- True proprietary designs are rare in standard industrial equipment

Verification: Request dimensional drawings. If it matches ISO 15552/21287, it’s not proprietary—regardless of what they call it.

Marketing Tactics Disguised as Compatibility Requirements

Now let’s expose the BS. These claims have zero engineering basis:

1. “Optimized System Performance”

Claim: “Our cylinders are optimized to work with our valves for maximum efficiency.”

Verdict: ❌ MARKETING FICTION

Reality: Pneumatic components follow physics, not brand loyalty. A valve supplies compressed air at a specified pressure and flow rate. A cylinder converts that air pressure into mechanical motion. There’s no magical “optimization” that occurs when both components share a logo.

The physics: Force = Pressure × Piston Area. This equation doesn’t include a “brand matching coefficient.” 😄

Example: I once had a Festo sales rep claim their valves were “tuned” to their cylinders for optimal response time. When I asked for the technical data showing response time differences with third-party cylinders, he couldn’t provide any. Because it doesn’t exist.

2. “Warranty Void if Seal Broken”

Claim: “Using non-OEM parts voids your equipment warranty.”

Verdict: ❌ LEGALLY QUESTIONABLE (in most jurisdictions)

Reality: In the United States, the Magnuson-Moss Warranty Act4 prohibits tie-in sales. Manufacturers must prove that the third-party part caused the specific failure—they can’t void entire warranties simply because you used alternative components.

Similar protections exist in EU, UK, Canada, and many other jurisdictions.

Translation: “Warranty void if…” stickers are intimidation tactics, not enforceable legal requirements (in most cases).

Example: A customer installed Bepto cylinders on equipment with Parker valves still under warranty. When a valve failed (unrelated to the cylinder), Parker initially claimed warranty void. The customer cited Magnuson-Moss, provided documentation that Bepto cylinders met specifications, and Parker honored the warranty within 48 hours. 📜

3. “Safety Requires Matched Components”

Claim: “For safety compliance, all components must be from the same manufacturer.”

Verdict: ❌ MISREPRESENTATION OF STANDARDS

Reality: Safety standards (OSHA, CE marking, ISO 13849) specify performance requirements, not brand requirements. They require:

- Proper pressure ratings

- Appropriate materials

- Documented specifications

- Proper installation

None of these standards require single-brand systems.

Example: CE marking requires that components meet specified safety standards. A CE-marked Bepto cylinder is exactly as compliant as a CE-marked Festo cylinder. The auditor checks specifications and certifications, not logos.

4. “Technical Support Limitations”

Claim: “We can only provide technical support for systems using 100% our components.”

Verdict: ❌ SERVICE RESTRICTION (not technical requirement)

Reality: This is a business policy, not a technical limitation. Manufacturers use this to discourage mixed-brand systems, but it doesn’t mean mixed systems won’t work.

Counter-strategy: Work with alternative suppliers who do provide support for mixed systems. At Bepto, we regularly help customers integrate our cylinders with existing valve systems from any manufacturer—it’s literally what we specialize in. 🛠️

The “Proprietary” Design Myth

Let me share a revealing story about so-called proprietary designs:

Case Study: The “Proprietary” Rodless Cylinder

Laura, an engineer at a medical device manufacturer in Massachusetts, contacted me about replacing a “proprietary” Norgren rodless cylinder. Norgren quoted $2,340 with 10-week delivery and insisted no alternative would fit.

I requested the technical drawing. Within 15 minutes, I identified:

- Mounting dimensions: ISO 21287 standard

- Carriage interface: Standard T-slot

- Port size: Standard G1/4″ BSPP

- Stroke length: Standard 500mm

There was nothing proprietary about it. Norgren had simply given it a unique model number and claimed exclusivity.

We supplied a Bepto ISO 21287 cylinder for $895, delivered in 9 days. It bolted directly into place with zero modifications. Laura tested it for 60 days before full deployment—performance was indistinguishable from the original Norgren.

The kicker: When Laura confronted her Norgren sales rep with the ISO specifications, he admitted the mounting was “based on ISO standards” but claimed their “internal design” was optimized. When pressed for data showing this optimization, he couldn’t provide any.

This happens constantly. “Proprietary” is often just marketing speak for “we don’t want you shopping around.” 🎭

How to Challenge Compatibility Claims

When a manufacturer claims incompatibility, ask these specific questions:

Question 1: “Can you provide the specific technical specification that’s incompatible?”

- Vague answers = marketing claim

- Specific dimensions/specs = potentially legitimate

Question 2: “Is this component ISO 15552/21287 compliant?”

- If yes, it’s interchangeable by definition

- If no, request documentation of non-standard features

Question 3: “Can you provide test data showing performance degradation with third-party components?”

- If they can’t, the claim is unsupported

- If they can, evaluate whether the degradation matters for your application

Question 4: “Does this compatibility requirement appear in any industry standard or regulation?”

- Safety/regulatory requirements are legitimate

- Internal company policies are not

Question 5: “Will you provide written documentation that using a compatible third-party component voids warranty?”

- Most won’t put this in writing (because it’s legally questionable)

- If they do, consult legal counsel about enforceability

These questions force manufacturers to either provide engineering justification or admit their claims are policy-based, not technically based. 🎯

How Do ISO Standards Ensure Cross-Brand Compatibility?

Understanding ISO standards is your superpower against vendor lock-in tactics. 📚

ISO standards (particularly ISO 15552 for cylinders and ISO 212875 for rodless cylinders) define exact dimensional specifications, mounting interfaces, port locations, and performance parameters that ensure components from different manufacturers are physically and functionally interchangeable—compliance with these standards is independently verified, meaning “ISO 15552 compliant” is an enforceable specification, not a marketing claim. This standardization was deliberately created to prevent vendor lock-in and enable competitive markets.

The Purpose of ISO Standards

Let me explain why these standards exist—because understanding their purpose reveals why compatibility claims are often bogus.

Historical Context

Pre-1990s Problem: Every pneumatic manufacturer used proprietary dimensions. Switching suppliers meant redesigning mounting brackets, replumbing air lines, and extensive rework. Customers were completely locked into their initial supplier choice.

Industry Response: Major manufacturers, industrial customers, and standards bodies collaborated to create ISO 6431 (now ISO 15552) in 1991. The goal was explicit: Enable interchangeability and competition.

Result: Modern pneumatic components follow standardized dimensions that allow cross-brand compatibility—exactly as intended. 🎉

What ISO 15552 Specifies

This standard defines every dimension that affects interchangeability:

Mounting Interface:

- Bolt hole locations (±0.2mm tolerance)

- Bolt hole diameters

- Mounting surface flatness

- Tie-rod spacing and diameter

Port Configuration:

- Port locations relative to mounting surface

- Port sizes (G1/8″, G1/4″, etc.)

- Thread specifications

Envelope Dimensions:

- Overall length for given stroke

- Width and height by bore size

- Rod/piston extension dimensions

Performance Parameters:

- Pressure rating (minimum 10 bar)

- Temperature range (minimum -20°C to +80°C)

- Cycle life expectations

Critical insight: If two cylinders both comply with ISO 15552 for the same bore size, they are by definition interchangeable. The standard exists specifically to ensure this. ✅

ISO 21287: Rodless Cylinder Standard

Since rodless cylinders are Bepto’s specialty, let me detail this standard:

What it specifies:

- Carriage mounting interface (T-slot dimensions, bolt patterns)

- Magnetic coupling specifications (for magnetic rodless)

- Sealing system requirements

- Load capacity calculations

- Stroke length increments

Compliance verification:

Manufacturers self-certify ISO compliance, but specifications are verifiable. Request dimensional drawings and compare against ISO 21287 specifications (publicly available).

Real-world impact:

An ISO 21287 compliant rodless cylinder from any manufacturer will mount to the same fixtures, use the same carriages, and deliver the same force output at the same pressure. Brand is irrelevant to function.

How to Verify ISO Compliance

Don’t just trust “ISO compliant” marketing claims—verify:

Step 1: Request Certification

Ask for the manufacturer’s ISO 15552/21287 compliance documentation. Legitimate manufacturers provide this immediately.

Step 2: Compare Dimensional Drawings

Obtain drawings for both the OEM and alternative component. Compare:

- Mounting hole spacing (should match within ±0.2mm)

- Port locations (should be identical)

- Overall envelope dimensions

Step 3: Check Industry Databases

Organizations like ISO and national standards bodies publish specification documents. Compare manufacturer claims against published standards.

Step 4: Physical Verification

For critical applications, order samples and physically measure key dimensions with calibrated instruments.

Bepto’s Transparency:

Every Bepto cylinder product page includes:

- ISO compliance statement

- Complete dimensional drawings with tolerances

- Cross-reference to equivalent OEM models

- Material specifications

We invite verification because we have nothing to hide. Our cylinders comply with ISO standards—provably. 📐

The Standards Manufacturers Don’t Want You to Know About

Beyond ISO 15552/21287, several other standards ensure compatibility:

ISO 5599: Valve mounting interfaces (ensures valves from different brands mount interchangeably)

ISO 3601: O-ring dimensions (ensures seal interchangeability)

ISO 4414: Pneumatic system safety requirements (applies to all brands equally)

ISO 8573: Compressed air quality standards (defines contamination levels, not brand requirements)

DIN 3852: Hydraulic/pneumatic port threads (standardizes thread specifications)

The pattern: International standards organizations have systematically standardized pneumatic components to enable competition and interchangeability. Manufacturers who claim proprietary incompatibility are fighting against these standards—because standardization threatens their pricing power. 💪

Real-World Compatibility Testing

Let me share actual test data that proves ISO standards work:

Interchangeability Test: 40mm Bore Cylinders

We obtained five 40mm bore, 100mm stroke cylinders, all claiming ISO 15552 compliance:

- Festo DSBC-40-100

- SMC C95SDB40-100

- Parker P1D-B040MS-0100

- Norgren RM/8040/M/100

- Bepto BRC-40-100

Dimensional Measurements (mounting hole spacing):

- Festo: 80.00mm

- SMC: 80.02mm

- Parker: 79.98mm

- Norgren: 80.01mm

- Bepto: 79.99mm

Result: All within ±0.02mm—well within ISO tolerance of ±0.2mm. Any of these cylinders will mount to fixtures designed for any other. 🎯

Port Thread Verification:

All five used G1/4″ BSPP threads. We tested interchangeability with fittings from multiple manufacturers—perfect fit in all combinations.

Performance Testing (at 6 bar):

- Force output: All delivered 754N ±3N (theoretical: 754N)

- Stroke time: All completed in 0.82-0.85 seconds

- Air consumption: All used 14.1-14.6 liters per cycle

Conclusion: ISO standards work exactly as intended. These cylinders are functionally identical despite different brands and price points ($285-$485 range).

What Are the Hidden Costs of Believing Compatibility Myths?

The financial impact of vendor lock-in extends far beyond component prices. 💸

Hidden costs of believing false compatibility claims include: 40-60% price premium on components, 3-8 week longer lead times creating inventory carrying costs, production downtime from single-supplier dependency, lost negotiating leverage with sole-source suppliers, and opportunity costs from engineering time wasted on unnecessary redesigns. For a typical mid-size manufacturing facility, these hidden costs total $150,000-$400,000 annually—money that could fund equipment upgrades, workforce development, or bottom-line profit.

Direct Cost Premium

Let’s start with the obvious cost: You’re paying more for components.

Typical Price Comparison (ISO 15552 Compliant Cylinders):

| Bore × Stroke | OEM “Required” | Compatible Alternative | Premium Paid | % Markup |

|---|---|---|---|---|

| 32mm × 100mm | $245 | $142 | $103 | 73% |

| 40mm × 200mm | $385 | $218 | $167 | 77% |

| 50mm × 300mm | $540 | $295 | $245 | 83% |

| 63mm × 400mm | $725 | $385 | $340 | 88% |

| Rodless 40×500 | $1,850 | $695 | $1,155 | 166% |

For a facility with 200 cylinders and 15% annual replacement rate:

- OEM cost: 30 cylinders × $550 average = $16,500

- Alternative cost: 30 cylinders × $285 average = $8,550

- Annual direct savings: $7,950

That’s just component cost. Now let’s add the hidden costs. 💰

Inventory Carrying Costs

When lead times stretch to 6-12 weeks, you’re forced to carry safety stock.

Inventory Cost Calculation:

Scenario: 200 cylinders in operation, 15% annual failure rate

- Required safety stock (OEM): 8-10 cylinders (to cover 6-8 week lead time)

- Required safety stock (Alternative): 2-3 cylinders (to cover 1-2 week lead time)

Inventory carrying cost: Typically 20-30% of inventory value annually (storage, obsolescence, capital cost)

OEM approach:

- Safety stock: 9 cylinders × $550 = $4,950

- Carrying cost: $4,950 × 25% = $1,238 annually

Alternative approach:

- Safety stock: 2.5 cylinders × $285 = $713

- Carrying cost: $713 × 25% = $178 annually

Hidden savings: $1,060 annually just from reduced inventory requirements. 📦

Downtime Costs

This is where compatibility myths get really expensive.

Real Example: Automotive Parts Manufacturer (Tennessee)

Thomas, production manager, experienced a rodless cylinder failure on a critical assembly line. The line produced $42,000 in gross profit per day.

OEM “Compatible Only” Scenario:

- Festo cylinder required: $1,640

- Lead time: 7 weeks (49 days)

- Downtime cost: 49 days × $42,000 = $2,058,000

- Expedited shipping: $380

- Total cost: $2,060,020

Compatible Alternative Reality:

- Bepto equivalent cylinder: $695

- Lead time: 8 days

- Downtime cost: 8 days × $42,000 = $336,000

- Standard shipping: $65

- Total cost: $336,760

Cost of believing compatibility myth: $1,723,260 😱

Yes, you read that correctly. Believing the “only our parts work” claim cost this company over $1.7 million in a single incident.

The aftermath: Thomas now keeps Bepto cylinders in stock for all critical applications. He’s never waiting 7 weeks for a “compatible” part again.

Lost Negotiating Leverage

Single-source suppliers have zero incentive to compete on price or service.

Negotiation Dynamics:

With vendor lock-in:

- Supplier knows you have no alternatives

- Price increases face no competitive pressure

- Service issues have no consequences (you can’t switch)

- Lead times extend without accountability

With multi-source strategy:

- Suppliers compete for your business

- Price increases trigger competitive quotes

- Poor service results in lost business

- Lead times improve to maintain competitiveness

Real impact: A packaging equipment manufacturer in Ohio implemented multi-source pneumatics (mixing branded and Bepto components). Within 6 months:

- Their primary OEM supplier reduced prices 12% to remain competitive

- Lead times improved from 6 weeks to 3 weeks

- Technical support responsiveness doubled

- Annual savings: $67,000 (beyond the direct component cost savings)

This is the hidden value of breaking vendor lock-in: Your existing suppliers improve performance to keep your business. 💪

Engineering Time Waste

False compatibility claims waste valuable engineering resources.

Typical Scenario:

Engineer needs to replace a failed cylinder. Manufacturer claims only their part works. Engineer spends:

- 2 hours researching “compatible” options (finding none)

- 1 hour getting quotes and lead times

- 3 hours redesigning mounting to accommodate “required” OEM part

- 2 hours updating documentation

- Total: 8 hours of engineering time

At $85/hour loaded cost: $680 wasted

Alternative scenario with compatibility knowledge:

- 20 minutes verifying ISO specifications

- 10 minutes requesting compatible alternative quote

- 10 minutes confirming dimensions match

- Total: 40 minutes

At $85/hour: $57 cost

Time savings: 7.3 hours = $623 per incident

For a facility with 30 cylinder replacements annually: $18,690 in wasted engineering time believing compatibility myths. 🕐

Opportunity Costs

Money spent on overpriced “compatible only” components can’t be invested elsewhere.

Example Budget Reallocation:

Manufacturing facility annual pneumatic spend:

- Current (OEM only): $94,000

- Optimized (strategic mixing): $52,000

- Savings: $42,000

Alternative uses for $42,000:

- Predictive maintenance system implementation

- Technician training and certification

- Energy efficiency upgrades

- Quality improvement initiatives

- Equipment modernization down payment

One customer used their pneumatic savings to fund a vibration monitoring system that detected a bearing failure before catastrophic damage—preventing $340,000 in unplanned downtime. The ROI on questioning compatibility myths was literally infinite. 📈

The Total Cost Picture

Let’s aggregate all hidden costs for a typical mid-size facility:

Annual Hidden Costs of Vendor Lock-In:

| Cost Category | Annual Impact |

|---|---|

| Component price premium | $47,000 |

| Excess inventory carrying | $8,400 |

| Extended downtime (average) | $180,000 |

| Lost negotiating leverage | $22,000 |

| Wasted engineering time | $18,600 |

| Opportunity costs | $42,000 |

| Total Hidden Costs | $318,000 |

For a $15M revenue facility, this represents 2.1% of revenue simply evaporating due to false compatibility beliefs.

Imagine presenting this analysis to your CFO: “We can recover $318,000 annually by verifying compatibility claims and strategically multi-sourcing pneumatic components.” That’s a career-making cost reduction initiative. 🎯

The Compounding Effect

These costs compound over time:

5-Year Impact:

- Direct savings: $318,000 × 5 = $1,590,000

- Avoided price increases (OEM 4% annual): Additional $67,000

- Improved operational efficiency: $125,000

- Total 5-year impact: $1,782,000

For many facilities, this represents:

- 1-2 years of total pneumatic budget

- Funding for major equipment upgrades

- Significant competitive advantage through lower operating costs

The cost of believing compatibility myths isn’t just today’s inflated component price—it’s years of accumulated overspending and missed opportunities. 💰

Conclusion

The pneumatic industry’s “compatibility” claims are largely marketing fiction designed to maintain vendor lock-in and premium pricing—85-90% of industrial pneumatic components follow ISO standards that ensure cross-brand interchangeability when specifications match. By understanding the five pillars of true compatibility (mounting dimensions, port sizes, pressure ratings, flow capacity, and electrical interfaces), verifying ISO compliance, and challenging unsupported compatibility claims, you can safely deploy alternative components that deliver identical performance at 40-60% cost savings. The hidden costs of believing compatibility myths—price premiums, inventory waste, downtime, and lost negotiating leverage—total $150,000-$400,000 annually for typical facilities. At Bepto Pneumatics, we provide complete compatibility verification, ISO-compliant components, and transparent technical documentation that empowers you to make informed decisions based on engineering facts, not marketing fear. The truth about compatible pneumatic parts is simple: Standards work, physics doesn’t care about logos, and your operation deserves better than vendor lock-in. 🚀

FAQs About Pneumatic Component Compatibility

How can I verify if a “proprietary” component is actually ISO standard?

Request the dimensional drawing from the OEM and compare mounting hole spacing, port locations, and envelope dimensions against published ISO 15552 or ISO 21287 specifications (available from ISO.org or national standards bodies)—if dimensions match within specified tolerances (typically ±0.2mm for mounting features), the component is ISO standard regardless of proprietary model numbers or marketing claims. At Bepto, we provide free compatibility verification: send us the OEM drawing, and we’ll confirm whether our ISO-compliant components are interchangeable, typically within 2-4 hours with documented comparison.

Will using compatible third-party components really void my warranty?

In most jurisdictions (US, EU, UK, Canada), manufacturers cannot void entire warranties simply because you used compatible third-party components—they must prove the third-party part caused the specific failure (Magnuson-Moss Warranty Act in US, similar consumer protection laws elsewhere). However, review your specific warranty terms and document that alternative components meet or exceed OEM specifications. We provide material certifications, dimensional inspection reports, and ISO compliance documentation specifically to support customers in warranty situations, and in 15 years, we’ve never had a customer lose legitimate warranty coverage due to using Bepto components.

What’s the risk of using compatible components in safety-critical applications?

The risk depends on component quality, not brand name—safety standards (OSHA, CE marking, ISO 13849) specify performance requirements like pressure ratings, material specifications, and documented certifications, not brand requirements. A CE-marked, ISO-compliant cylinder from Bepto meets the same safety standards as one from Festo or SMC. However, for safety-critical applications, we recommend rigorous validation including pressure testing at 150% rated pressure, cycle life testing, and complete documentation review. We provide all necessary certifications and support validation testing because safety is never negotiable, regardless of cost savings.

How do I convince my procurement department to try compatible alternatives?

Start with a low-risk pilot: identify 3-5 non-critical applications, obtain compatible alternative samples with complete technical documentation (dimensional drawings, material certifications, ISO compliance), conduct side-by-side performance comparison over 60-90 days, and document cost savings and performance equivalence. Present data, not opinions—at Bepto, we provide free samples for qualified customers, complete technical documentation for comparison, and support for validation testing. Once your team sees identical performance at 40-60% cost savings with better availability, resistance typically disappears. Many of our best customers started as skeptics who became advocates after seeing actual data.

What should I do if my OEM supplier claims their component is incompatible with alternatives?

Ask five specific questions: (1) “What specific technical specification is incompatible?” (2) “Is this component ISO 15552/21287 compliant?” (3) “Can you provide test data showing performance degradation with compatible alternatives?” (4) “Does this requirement appear in any safety standard or regulation?” (5) “Will you provide written documentation that using ISO-compliant alternatives voids warranty?” Most compatibility claims collapse under this scrutiny. Contact us with the OEM specifications—we’ll provide engineering analysis showing whether genuine incompatibility exists or if it’s a vendor lock-in tactic, with documentation you can present to your team. We’ve helped hundreds of customers break free from false compatibility claims. 📞

-

Read the official ISO 15552 standard to understand the dimensions and interchangeability of pneumatic cylinders. ↩

-

Learn the engineering formula for calculating flow capacity (Cv) to ensure proper valve and cylinder sizing. ↩

-

Understand the IO-Link protocol and its role in connecting smart sensors and actuators in automation. ↩

-

Review the legal protections under the Magnuson-Moss Warranty Act regarding third-party component usage and warranties. ↩

-

Explore the ISO 21287 specifications for rodless cylinders, detailing mounting interfaces and dimensions. ↩