Many engineers experience premature seal failure, excessive air leakage, and inconsistent cylinder performance, unaware that poor cylinder tube surface finish is the root cause of these costly problems that can result in thousands of dollars in downtime and replacement costs.

A honed cylinder tube is a precision-machined pneumatic cylinder barrel with an ultra-smooth internal surface finish achieved through abrasive honing processes, providing optimal seal performance, reduced friction, and extended service life in rodless cylinders1 and standard pneumatic cylinders.

Yesterday, I spoke with David, a maintenance supervisor at a North Carolina textile facility, whose rodless cylinder seals were failing every six weeks instead of lasting their expected two years, costing his plant $15,000 in replacement parts and downtime before we discovered his cylinders had rough, unhoned tubes that were destroying his seals.

Table of Contents

- What Makes Honed Cylinder Tubes Different from Standard Tubes?

- How Does the Honing Process Create Superior Cylinder Performance?

- What Are the Key Benefits of Using Honed Tubes in Pneumatic Applications?

- How Do You Select and Maintain Honed Cylinder Tubes for Maximum Performance?

What Makes Honed Cylinder Tubes Different from Standard Tubes?

Honed cylinder tubes feature precision-engineered internal surfaces that provide superior performance compared to standard machined tubes in pneumatic cylinder applications.

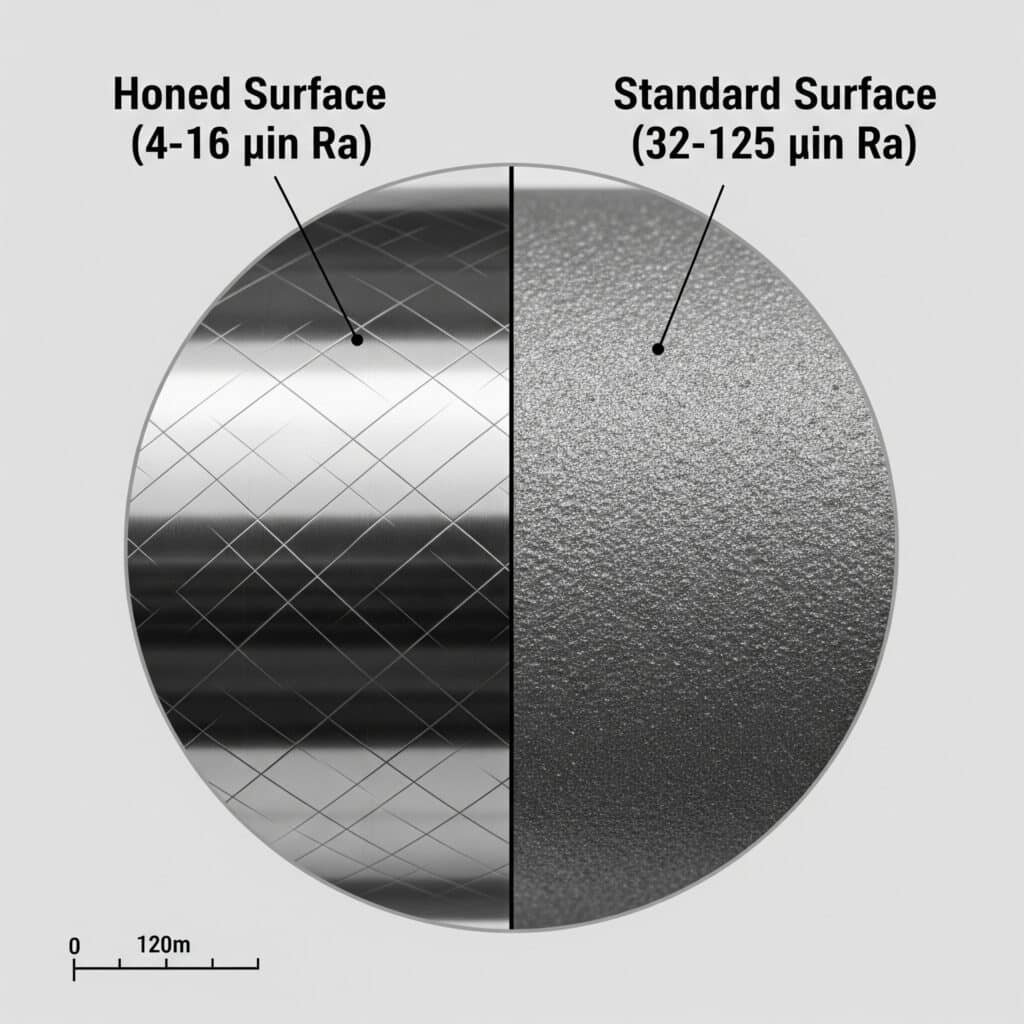

Honed cylinder tubes have mirror-smooth internal surfaces with Ra values of 4-16 microinches compared to standard tubes at 32-125 microinches, featuring controlled crosshatch patterns that retain lubrication while providing optimal sealing surfaces for extended seal life and reduced friction in rodless cylinders.

Surface Finish Specifications

The internal surface finish of honed cylinder tubes is precisely controlled to achieve optimal performance characteristics. Surface roughness is measured in Ra (arithmetic average roughness)2 values, with honed tubes typically achieving 4-16 microinches Ra compared to 32-125 microinches for standard machined tubes.

This dramatic improvement in surface smoothness provides several critical advantages:

- Reduced seal wear: Smooth surfaces minimize abrasive contact

- Improved sealing: Better surface contact reduces air leakage

- Lower friction: Smoother surfaces reduce operating forces

- Enhanced lubrication retention: Controlled surface texture holds lubricants

Dimensional Accuracy Advantages

Honed tubes maintain superior dimensional accuracy throughout their length, with typical tolerances of ±0.0002 inches compared to ±0.002 inches for standard boring operations.

| Specification | Standard Tube | Honed Tube | Performance Impact |

|---|---|---|---|

| Surface Finish (Ra) | 32-125 μin | 4-16 μin | 5-10x smoother surface |

| Diameter Tolerance | ±0.002″ | ±0.0002″ | 10x better accuracy |

| Straightness | 0.005″/ft | 0.001″/ft | 5x straighter bore |

| Roundness | 0.003″ | 0.0005″ | 6x more circular |

Crosshatch Pattern Benefits

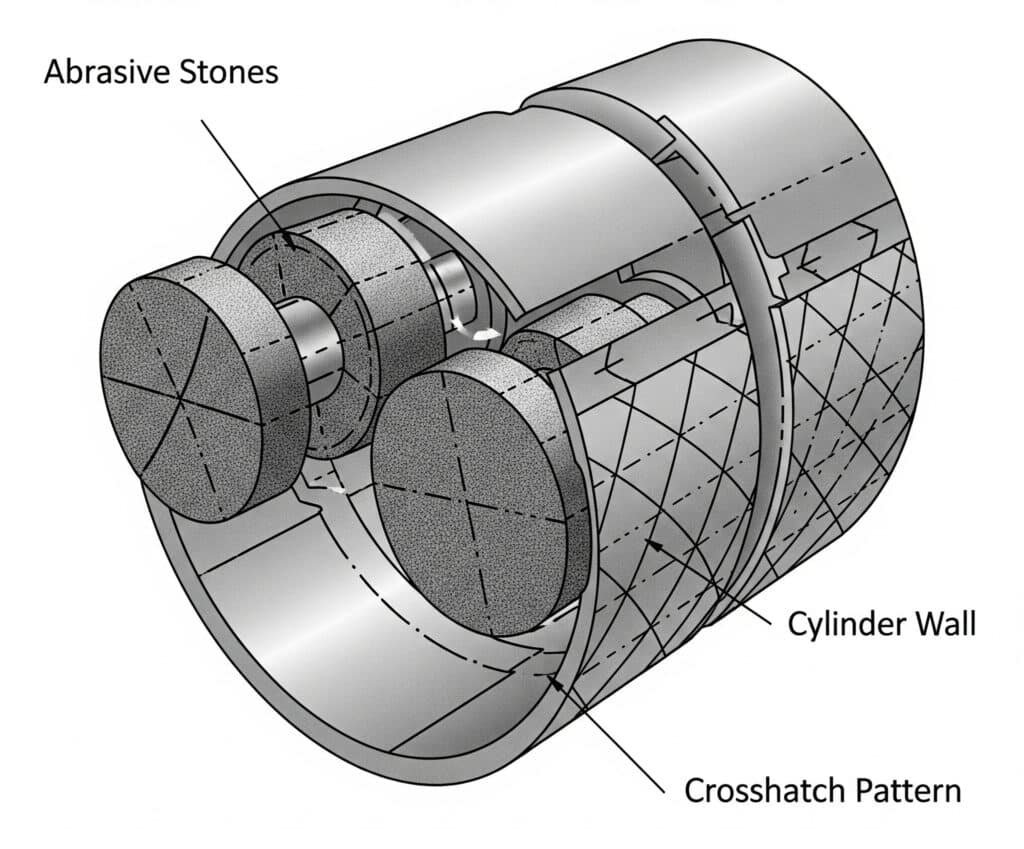

The honing process creates a controlled crosshatch pattern on the cylinder wall surface. This pattern, typically at 45-60 degree angles, serves multiple functions:

- Oil retention: Microscopic valleys hold lubricating oil

- Seal support: Provides optimal surface for seal contact

- Wear distribution: Distributes contact stress evenly

- Break-in acceleration: Reduces initial wear-in period

Material Considerations

Honed cylinder tubes are available in various materials to suit different applications:

Steel Tubes: Most common for general industrial applications, offering excellent strength and durability with proper corrosion protection.

Stainless Steel: Ideal for food processing, pharmaceutical, and corrosive environments where contamination resistance is critical.

Aluminum: Lightweight option for mobile applications, though requiring careful seal selection due to softer material properties.

At Bepto, we supply precision honed tubes for all major rodless cylinder brands, ensuring our customers receive the surface quality needed for optimal seal performance and extended service life.

How Does the Honing Process Create Superior Cylinder Performance?

The honing process uses controlled abrasive action to achieve precise internal dimensions and surface finishes that dramatically improve pneumatic cylinder performance and reliability.

Cylinder honing employs rotating abrasive stones under controlled pressure and feed rates to remove material uniformly, creating mirror-smooth surfaces with specific crosshatch patterns that optimize seal performance, reduce friction by 40-60%, and extend cylinder life by 3-5 times compared to standard machined tubes.

Honing Process Steps

The honing process involves multiple carefully controlled steps to achieve optimal results:

Step 1: Rough Honing

Initial honing removes machining marks and major surface irregularities using coarse abrasive stones (typically 220-400 grit). This step establishes basic dimensional accuracy and removes 0.003-0.005 inches of material.

Step 2: Finish Honing

Fine abrasive stones (600-1200 grit) create the final surface finish and precise dimensions. This step removes only 0.0005-0.001 inches while establishing the crosshatch pattern.

Step 3: Plateau Honing3

Final polishing with very fine stones (1500+ grit) creates the plateau finish that optimizes seal contact while maintaining oil retention valleys.

Abrasive Stone Selection

Different abrasive materials provide specific advantages for various applications:

| Stone Type | Grit Range | Applications | Surface Finish |

|---|---|---|---|

| Aluminum Oxide | 220-800 | General steel tubes | 8-32 μin Ra |

| Silicon Carbide | 400-1200 | Hard materials | 4-16 μin Ra |

| Diamond | 600-3000 | Precision finishing | 2-8 μin Ra |

| CBN (Cubic Boron Nitride)4 | 800-2000 | Hardened steels | 4-12 μin Ra |

Process Control Parameters

Achieving consistent honing results requires precise control of multiple process variables:

Spindle Speed: Typically 100-400 RPM, optimized for material and desired finish

Feed Rate: 10-50 feet per minute, controlling crosshatch angle

Stone Pressure: 50-200 PSI, determining material removal rate

Honing Oil: Cooling and lubrication, preventing thermal damage

Quality Verification Methods

Honed tubes undergo rigorous quality control to ensure specifications are met:

Surface Finish Measurement: Profilometers measure Ra, Rz, and other surface parameters

Dimensional Inspection: Coordinate measuring machines verify diameter, straightness, and roundness

Visual Inspection: Microscopic examination confirms crosshatch pattern quality

Leak Testing: Pressure testing verifies seal compatibility

Advanced Honing Techniques

Modern honing operations employ advanced techniques for superior results:

CNC Honing: Computer-controlled machines ensure consistent results and complex geometries

Servo-Controlled Pressure: Automatic adjustment maintains optimal stone pressure

Multi-Stage Processing: Sequential operations optimize each surface characteristic

Real-Time Monitoring: Continuous measurement during processing ensures quality

The precision achieved through proper honing is remarkable – we can maintain diameter tolerances within 0.0001 inches across tube lengths exceeding 20 feet, ensuring consistent seal performance throughout the entire stroke length of rodless cylinders.

What Are the Key Benefits of Using Honed Tubes in Pneumatic Applications?

Honed cylinder tubes provide significant performance improvements that translate directly into reduced operating costs, increased reliability, and enhanced system performance in pneumatic applications.

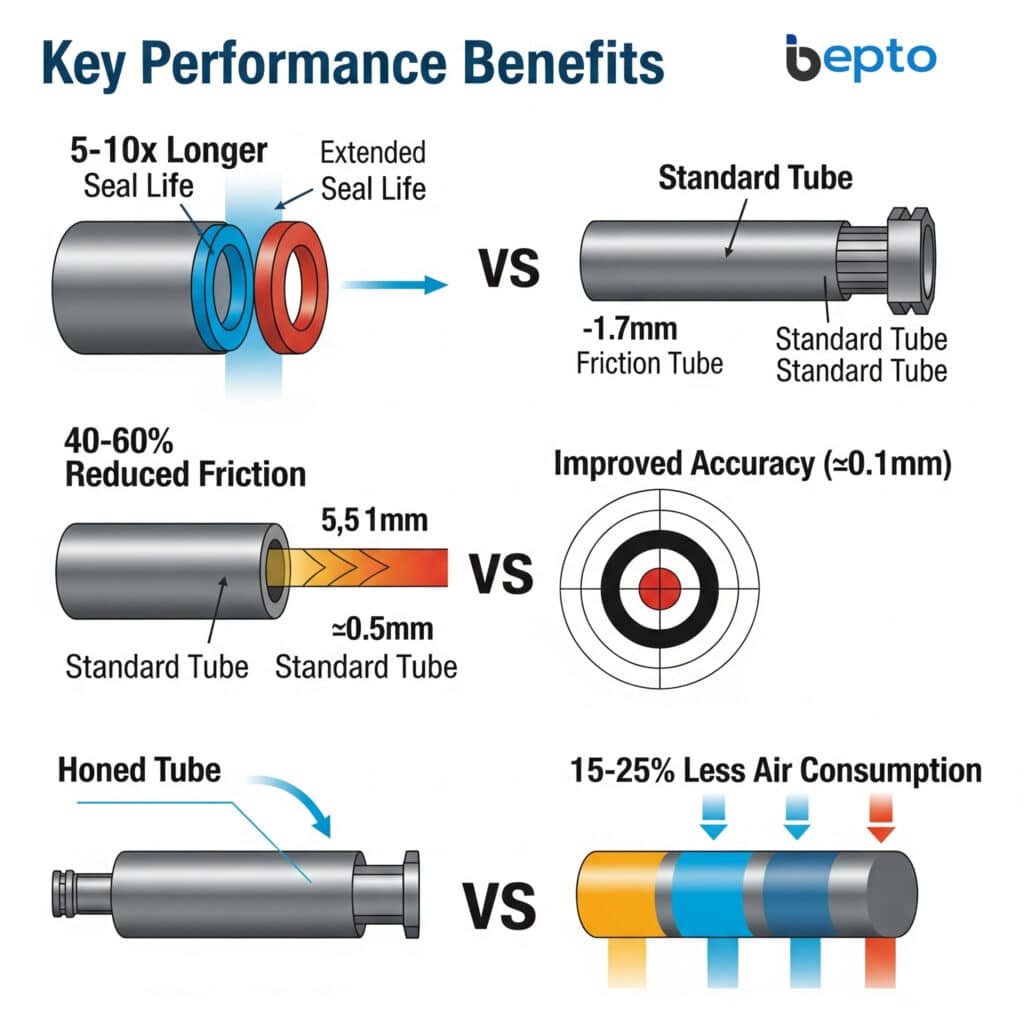

Honed tubes deliver 5-10 times longer seal life, reduce friction by 40-60%, eliminate stick-slip motion, improve positioning accuracy to ±0.1mm, and reduce air consumption by 15-25% compared to standard machined tubes, resulting in substantial cost savings and improved productivity in rodless cylinder applications.

Extended Seal Life

The smooth surface finish of honed tubes dramatically reduces seal wear, extending service life by 5-10 times compared to rough machined surfaces. This improvement results from:

Reduced Abrasive Wear: Mirror-smooth surfaces eliminate microscopic cutting action that destroys seals in rough tubes.

Optimal Seal Contact: Consistent surface finish ensures even pressure distribution across the seal contact area.

Improved Heat Dissipation: Smooth surfaces reduce friction heating that accelerates seal degradation.

Better Lubrication Retention: Controlled crosshatch patterns hold lubricating films that protect seals.

Performance Comparison Data

| Performance Metric | Standard Tube | Honed Tube | Improvement Factor |

|---|---|---|---|

| Seal Life | 6-12 months | 3-5 years | 5-10x longer |

| Friction Coefficient | 0.15-0.25 | 0.05-0.10 | 50-60% reduction |

| Air Leakage Rate | 2-5 SCFH | 0.1-0.5 SCFH | 90% reduction |

| Positioning Accuracy | ±2-5mm | ±0.1-0.5mm | 10x improvement |

| Break-in Period | 500-1000 cycles | 50-100 cycles | 90% reduction |

Friction Reduction Benefits

Honed surfaces reduce friction by 40-60%, providing multiple operational advantages:

Lower Operating Pressures: Reduced friction allows operation at lower system pressures, saving energy and reducing component stress.

Smoother Motion: Elimination of stick-slip5 behavior provides consistent, smooth cylinder movement essential for precision applications.

Faster Cycle Times: Reduced friction enables higher operating speeds without compromising accuracy or increasing wear.

Energy Savings: Lower friction translates directly to reduced compressed air consumption, typically 15-25% savings.

Improved System Reliability

The superior performance characteristics of honed tubes contribute to overall system reliability:

Consistent Performance: Uniform surface finish ensures predictable operation throughout the service life.

Reduced Maintenance: Longer seal life and reduced wear minimize maintenance requirements and associated downtime.

Better Contamination Resistance: Smooth surfaces are easier to clean and less likely to trap contaminants.

Temperature Stability: Reduced friction heating improves performance consistency across temperature ranges.

Economic Benefits Analysis

The investment in honed tubes typically pays for itself within 6-18 months through various cost savings:

Reduced Seal Replacement Costs: With seals lasting 5-10 times longer, replacement part costs drop dramatically.

Decreased Downtime: Fewer seal failures mean less production interruption and associated costs.

Lower Energy Consumption: Reduced friction and air leakage decrease compressed air system operating costs.

Extended Equipment Life: Reduced wear on all system components extends overall equipment service life.

Maria, who manages a packaging line at a German food processing facility, shared her experience with our honed tube upgrade: “After switching to Bepto’s honed tubes in our rodless cylinders, our seal replacement frequency dropped from monthly to once every two years. The $3,500 investment in honed tubes has saved us over $18,000 annually in parts and downtime costs, plus our positioning accuracy improved so much that we eliminated 95% of our packaging defects.”

How Do You Select and Maintain Honed Cylinder Tubes for Maximum Performance?

Proper selection and maintenance of honed cylinder tubes ensures optimal performance, maximum service life, and the best return on investment for your pneumatic system applications.

Honed tube selection requires matching surface finish specifications (4-16 μin Ra), material compatibility, dimensional accuracy requirements, and environmental conditions to your application, while maintenance involves proper lubrication, contamination control, regular inspection, and following manufacturer guidelines to achieve maximum performance and service life.

Selection Criteria Analysis

Choosing the right honed tube requires careful consideration of multiple factors specific to your application:

Surface Finish Requirements: Match the Ra value to your seal specifications and performance needs. General industrial applications typically use 8-16 μin Ra, while precision applications may require 4-8 μin Ra.

Material Selection: Choose tube material based on operating environment, pressure requirements, and compatibility with system fluids and seals.

Dimensional Specifications: Ensure proper bore diameter, wall thickness, and length specifications match your cylinder design requirements.

Environmental Considerations: Consider temperature range, corrosive exposure, and contamination levels that may affect material selection and surface treatments.

Application-Specific Selection Guide

| Application Type | Recommended Ra | Material Choice | Special Considerations |

|---|---|---|---|

| General Industrial | 8-16 μin | Carbon Steel | Standard honing adequate |

| Food Processing | 4-8 μin | Stainless Steel | FDA-compliant materials |

| High Precision | 4-6 μin | Steel/Stainless | Tight dimensional tolerances |

| Outdoor/Marine | 8-12 μin | Stainless Steel | Corrosion resistance critical |

| High Temperature | 6-12 μin | Special Alloys | Heat-resistant materials |

Proper Installation Practices

Correct installation is crucial for achieving optimal performance from honed tubes:

Handling Precautions: Use protective covers during transport and installation to prevent surface damage. Even minor scratches can compromise seal performance.

Cleanliness Requirements: Thoroughly clean tubes before installation using appropriate solvents and lint-free cloths. Any contamination can cause premature seal failure.

Alignment Verification: Ensure proper alignment during installation to prevent binding and uneven wear patterns that can damage the honed surface.

Seal Compatibility: Verify that seals are compatible with the honed surface finish and properly sized for optimal contact pressure.

Maintenance Best Practices

Proper maintenance maximizes the benefits of honed tubes:

Lubrication Management: Use appropriate pneumatic lubricants at recommended rates. Over-lubrication can attract contaminants, while under-lubrication increases wear.

Filtration Systems: Maintain proper air filtration to prevent contamination from reaching the honed surfaces. Typical requirements are 5-micron filtration with coalescing capability.

Regular Inspection: Perform visual inspections during scheduled maintenance to identify potential issues before they cause major problems.

Performance Monitoring: Track cycle counts, seal replacement frequency, and performance parameters to optimize maintenance schedules.

Troubleshooting Common Issues

Address common problems to maintain optimal performance:

| Problem | Symptoms | Likely Cause | Solution |

|---|---|---|---|

| Premature seal wear | Frequent seal replacement | Contamination or misalignment | Improve filtration, check alignment |

| Excessive friction | High operating pressure | Surface damage or poor lubrication | Inspect surface, adjust lubrication |

| Air leakage | Pressure loss, slow operation | Seal damage or improper installation | Replace seals, verify installation |

| Inconsistent motion | Jerky or erratic movement | Surface contamination | Clean and re-lubricate system |

Quality Verification Methods

Ensure your honed tubes meet specifications through proper verification:

Surface Finish Testing: Use calibrated profilometers to verify Ra values meet specifications.

Dimensional Inspection: Measure critical dimensions including bore diameter, straightness, and roundness.

Visual Inspection: Examine crosshatch pattern quality and surface condition using appropriate magnification.

Performance Testing: Conduct operational tests to verify seal compatibility and friction characteristics.

Replacement and Upgrade Considerations

Plan for tube replacement and system upgrades:

Service Life Indicators: Monitor performance degradation indicators such as increased friction, air consumption, or positioning errors.

Upgrade Opportunities: Consider upgrading to higher-quality honed tubes during scheduled maintenance to improve system performance.

Compatibility Verification: Ensure replacement tubes maintain compatibility with existing seals and system components.

Documentation: Maintain records of tube specifications, installation dates, and performance history for optimal maintenance planning.

At Bepto, we provide comprehensive support for honed tube selection and application. Our engineering team analyzes your specific requirements and recommends the optimal tube specifications to maximize performance and service life in your rodless cylinder applications, backed by our extensive experience in pneumatic system optimization.

Conclusion

Honed cylinder tubes provide superior surface finish and dimensional accuracy that dramatically improve seal life, reduce friction, and enhance overall pneumatic system performance, making them essential for reliable rodless cylinder operation and cost-effective maintenance.

FAQs About Honed Cylinder Tubes

Q: What’s the difference between honed and standard machined cylinder tubes?

Honed tubes have mirror-smooth internal surfaces (4-16 μin Ra) with controlled crosshatch patterns compared to standard tubes (32-125 μin Ra), providing 5-10 times longer seal life, 40-60% friction reduction, and significantly better sealing performance in pneumatic applications.

Q: How much do honed cylinder tubes cost compared to standard tubes?

Honed tubes typically cost 30-50% more than standard machined tubes initially, but the investment pays for itself within 6-18 months through extended seal life, reduced maintenance costs, and improved energy efficiency in most industrial applications.

Q: Can I retrofit my existing cylinders with honed tubes?

Yes, existing cylinders can often be retrofitted with honed tubes, though you’ll need to verify dimensional compatibility and may need to replace seals with ones designed for honed surface finishes to achieve optimal performance benefits.

Q: What maintenance do honed cylinder tubes require?

Honed tubes require proper lubrication, clean filtered air (5-micron filtration recommended), regular visual inspection for surface damage, and protection from contamination to maintain their superior performance characteristics throughout their service life.

Q: How long do honed cylinder tubes last compared to standard tubes?

Honed tubes typically provide 3-5 times longer service life than standard tubes due to reduced wear, better seal compatibility, and superior surface durability, often lasting 5-10 years in properly maintained pneumatic systems versus 1-2 years for standard tubes.

-

Discover the design, types, and operational advantages of rodless pneumatic cylinders in industrial automation. ↩

-

Learn about Ra (Roughness average), a key parameter used to measure and specify the texture or smoothness of a surface. ↩

-

Explore the process of plateau honing and how it creates a superior bearing surface with excellent lubrication retention. ↩

-

Understand the properties of Cubic Boron Nitride (CBN), a superabrasive material used for precision grinding and finishing of hard metals. ↩

-

Learn about the stick-slip phenomenon, a form of spontaneous jerking motion that can occur while two objects are sliding over each other. ↩