Der Mini-Pneumatikzylinder der Serie CJ2 bietet ein schlankes, leichtes Design, das sich ideal für kompakte Räume eignet. Mit einem Zylinder aus Edelstahl und einer sanften Kolbenbewegung liefert er präzise lineare Bewegungen für die Automatisierung in kleinem Maßstab. Perfekt für den Einsatz in der Elektronikmontage, Robotik und leichten Industriemaschinen, wo der Platz begrenzt ist.

| Bohrung(mm) | 6 | 10 | 16 |

| Arbeitsmedium | Luft | ||

| Bewegungsmuster | Doppelt wirkend/Einfach wirkend Extrusionstyp/Einfach wirkend Einzugstyp | ||

| Gesicherte Druckbeständigkeit | 1.05Mpa(10.5kgf/cm2) | ||

| Max. Druck | 0.7Mpa(7.1kgf/cm2) | ||

| Min.druck | 0.25Mpa(2.5kgf/cm2) | 0.15Mpa(1.5kgf/cm2) | |

| Betriebstemperaturbereich | -10~+70℃ | ||

| Betriebsdrehzahlbereich | 50~750mm/s | ||

| Pufferung | Beide Seiten Gummipuffer (Standard) | ||

| Marge des Hubfehlers (mm) | +1.0 0 mm |

||

| Hafengröße | M5×0.8 | ||

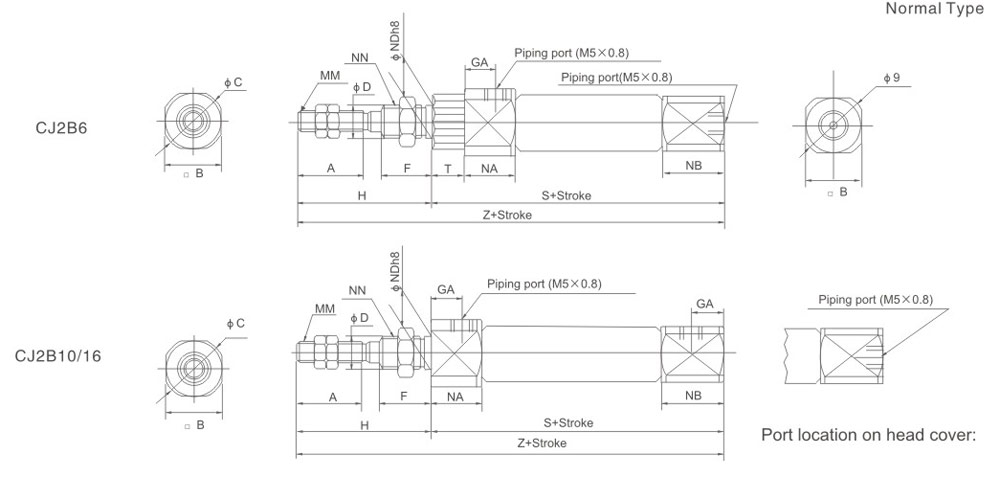

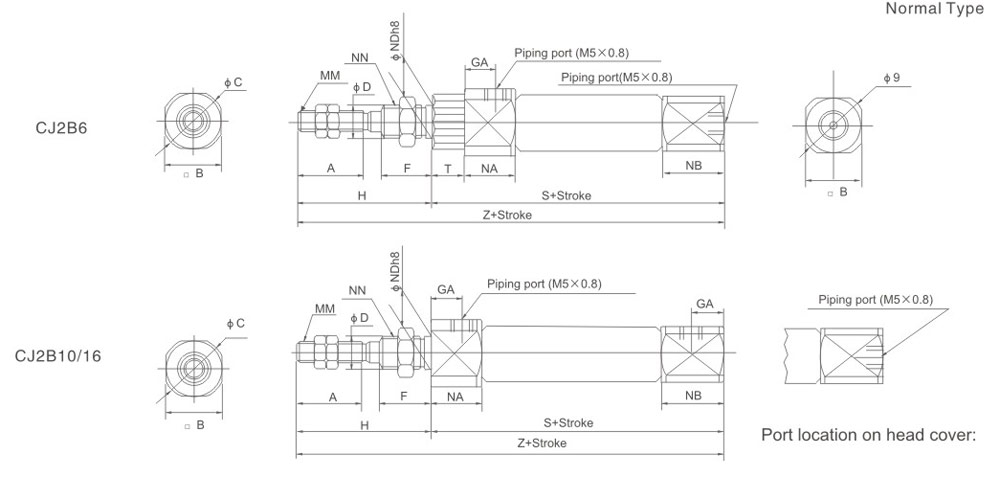

| Bohrung(mm) | A | B | C | D | F | GA | GB | H | MM | NA | NB | NDh8 | NN | S | T | Z |

| 6 | 15 | 12 | 14 | 3 | 8 | 14.5 | – | 28 | M3×0.5 | 16 | 7 | 6 | M6×1.0 | 49 | 3 | 77 |

| 10 | 15 | 12 | 14 | 4 | 8 | 8 | 5 | 28 | M4×0.7 | 12.5 | 9.5 | 8 | M8×1.0 | 46 | – | 74 |

| 16 | 15 | 18 | 20 | 5 | 8 | 8 | 5 | 28 | M5×0.8 | 12.5 | 9.5 | 10 | M10×1.0 | 47 | – | 75 |

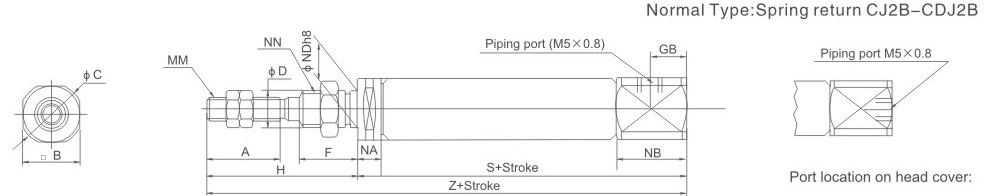

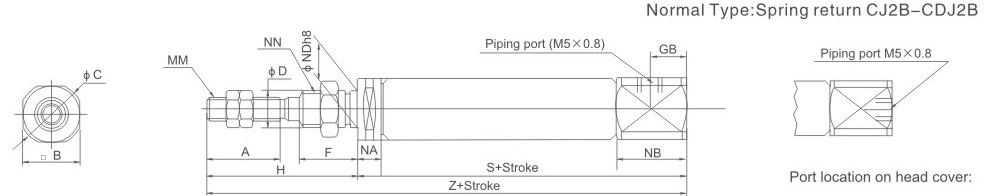

| Bohrung (mm) |

A | B | C | D | F | GB | H | MM | NA | NB | NB b8 | *S | |||||||

| 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | ||||||||||||

| 6 | 15 | 8 | 19 | 3 | 8 | – | 28 | M3×0.5 | 3 | 7 | 6 0 | 34.5 (39.5) | 43.5 (48.5) | 47.5 (52.5) | 61.5 (66.5) | – | – | – | – |

| 10 | 15 | 12 | 14 | 4 | 8 | 5 | 28 | M4×0.7 | 5.5 | 9.5 | 8 0 | 45.5 | 53 | 65 | 77 | – | – | – | – |

| 16 | 15 | 18 | 20 | 5 | 8 | 5 | 28 | M5×0.8 | 5.5 | 9.5 | 10 0 | 45.5 | 54 | 66 | 78 | 84 | 108 | 126 | 138 |

| Bohrung (mm) |

*S | *Z | ||||||||||||||

| 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | |

| 6 | 46.5 (51.5) | 55.5 (60.5) | 59.5 (60.5) | 73.5 (78.5) | – | – | – | – | 74.5 (79.5) | 83.5 (88.5) | 87.5 (92.5) | 101.5 (106.5) | – | – | – | – |

| 10 | 48.5 | 56 | 68 | 80 | – | – | – | – | 76.5 | 84 | 96 | 108 | – | – | – | – |

| 16 | 48.5 | 57 | 69 | 81 | 87 | 111 | 129 | 141 | 76.5 | 85 | 97 | 109 | 115 | 139 | 157 | 169 |

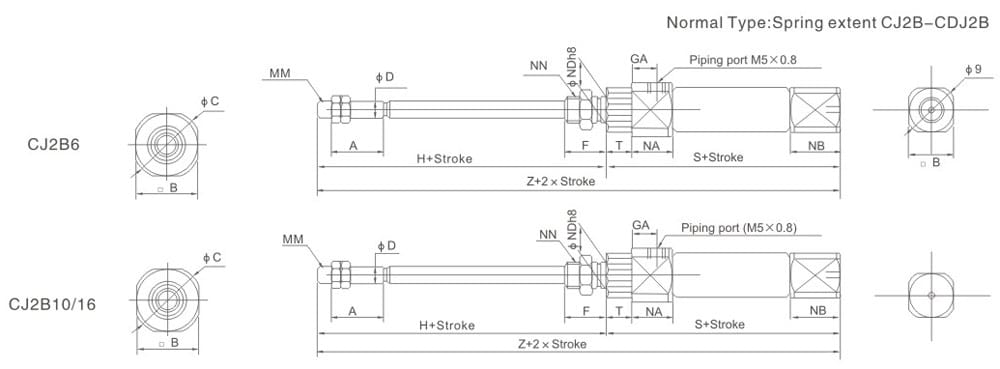

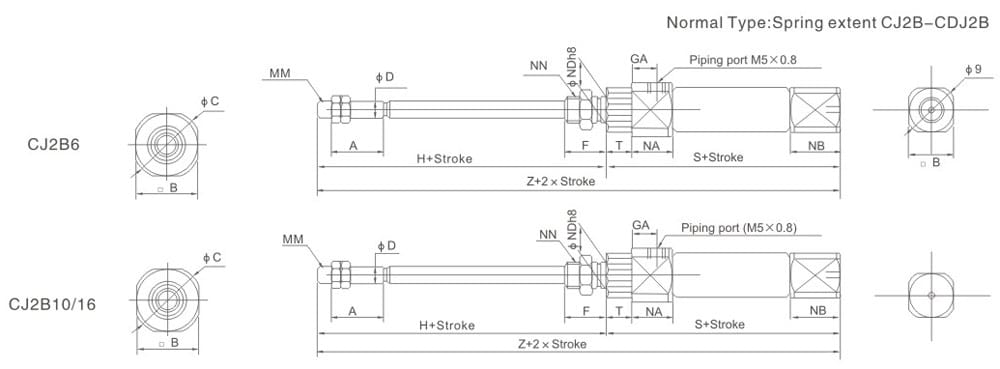

| Bohrung(mm) | A | B | C | D | F | GA | GB | H | MM | NA | NB | NDh8 | NN | S | T | Z |

| 6 | 15 | 12 | 14 | 3 | 8 | 14.5 | – | 28 | M3×0.5 | 16 | 7 | 6 | M6×1.0 | 49 | 3 | 77 |

| 10 | 15 | 12 | 14 | 4 | 8 | 8 | 5 | 28 | M4×0.7 | 12.5 | 9.5 | 8 | M8×1.0 | 46 | – | 74 |

| 16 | 15 | 18 | 20 | 5 | 8 | 8 | 5 | 28 | M5×0.8 | 12.5 | 9.5 | 10 | M10×1.0 | 47 | – | 75 |

| Bohrung (mm) |

A | B | C | D | F | GB | H | MM | NA | NB | NB b8 | *S | |||||||

| 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | ||||||||||||

| 6 | 15 | 8 | 19 | 3 | 8 | – | 28 | M3×0.5 | 3 | 7 | 6 0 | 34.5 (39.5) | 43.5 (48.5) | 47.5 (52.5) | 61.5 (66.5) | – | – | – | – |

| 10 | 15 | 12 | 14 | 4 | 8 | 5 | 28 | M4×0.7 | 5.5 | 9.5 | 8 0 | 45.5 | 53 | 65 | 77 | – | – | – | – |

| 16 | 15 | 18 | 20 | 5 | 8 | 5 | 28 | M5×0.8 | 5.5 | 9.5 | 10 0 | 45.5 | 54 | 66 | 78 | 84 | 108 | 126 | 138 |

| Bohrung (mm) |

*S | *Z | ||||||||||||||

| 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | |

| 6 | 46.5 (51.5) | 55.5 (60.5) | 59.5 (60.5) | 73.5 (78.5) | – | – | – | – | 74.5 (79.5) | 83.5 (88.5) | 87.5 (92.5) | 101.5 (106.5) | – | – | – | – |

| 10 | 48.5 | 56 | 68 | 80 | – | – | – | – | 76.5 | 84 | 96 | 108 | – | – | – | – |

| 16 | 48.5 | 57 | 69 | 81 | 87 | 111 | 129 | 141 | 76.5 | 85 | 97 | 109 | 115 | 139 | 157 | 169 |