Pneumatic Grippers | Enable Precise Grasping, Holding & Placing to Boost Automation Efficiency. Explore our diverse range of pneumatic grippers, including parallel and angular types. As key end-of-arm tooling for robots and automated systems, they provide reliable gripping force and high repeatability for your pick-and-place, assembly, and material handling tasks. Equip your robot now.

Need products for your project?

We understand sourcing can be challenging.

Fill out the form with your specific items – don’t hesitate to list even unique or hard-to-find components – submit your inquiry, and get the precisely tailored solutions you’re looking for! Forget generic offerings; we specialize in understanding your exact needs and delivering results that fit like a glove

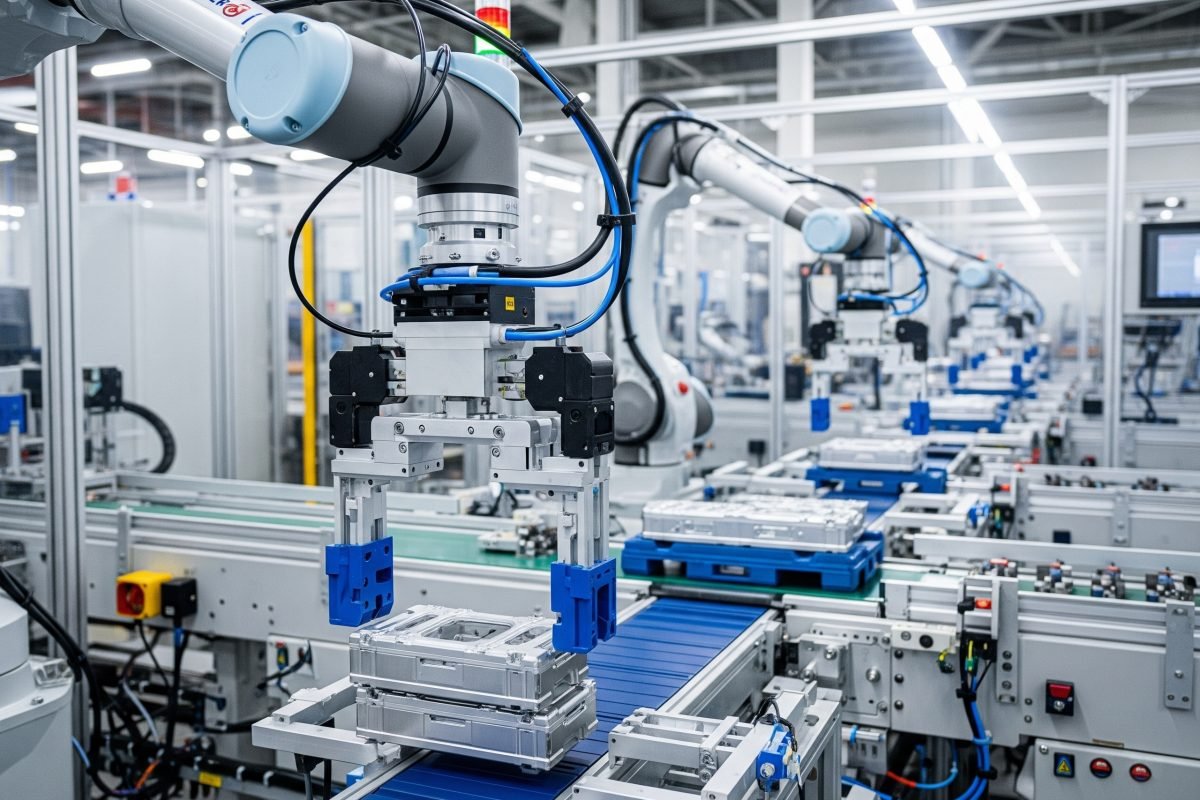

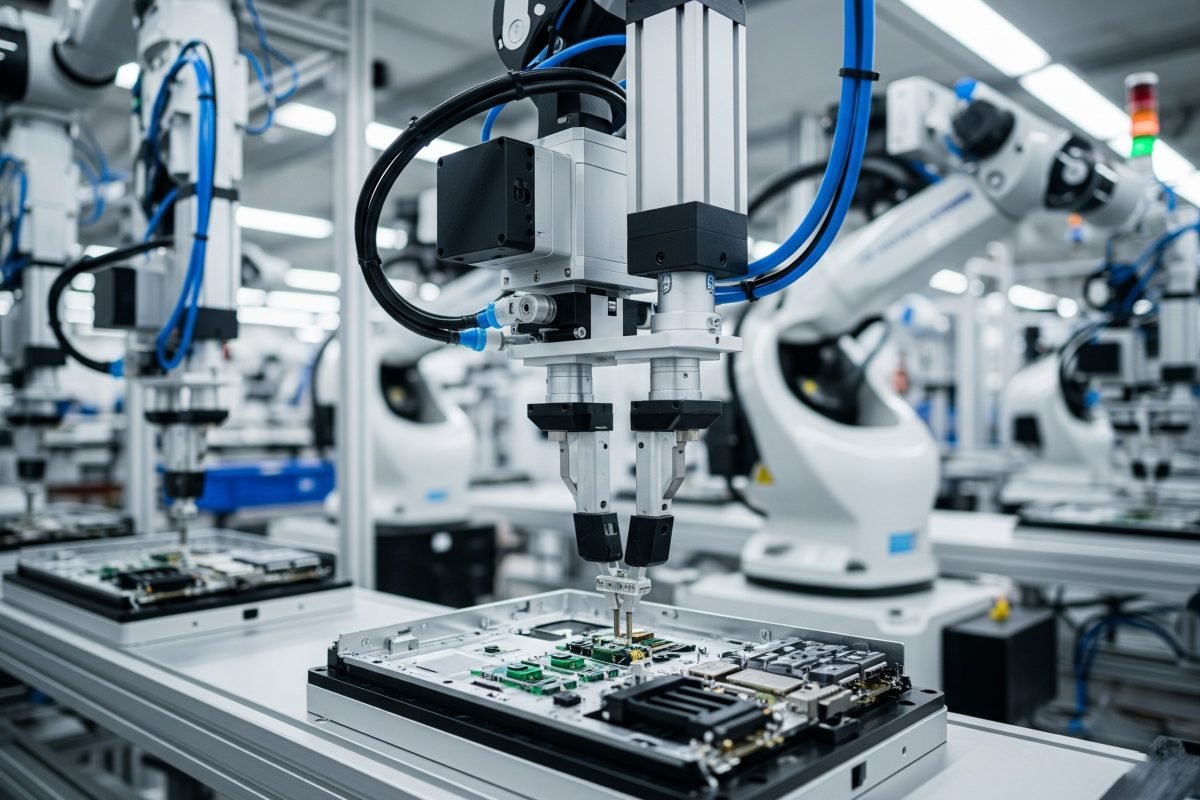

Our pneumatic gripper series provides reliable and precise workpiece gripping and handling capabilities for your automated production lines. Whether for delicate small parts or irregular objects, our diverse gripper products can meet your specific needs, helping to boost production efficiency and automation levels.

High repeat positioning accuracy ensures stable and reliable gripping and placement of workpieces, suitable for precision assembly and handling tasks.

Optimized air circuit design and lightweight construction enable fast opening and closing actions, shortening production cycles and improving overall efficiency.

Offering parallel, angular, three-finger, four-finger, and other gripping methods and specifications to adapt to workpieces of different shapes, sizes, and materials.

Fingers open and close in parallel, providing stable gripping force and high repeat positioning accuracy. Suitable for most standard workpiece gripping and positioning tasks.

Fingers open and close angularly around a pivot point. Compact structure, large opening angle, suitable for limited spaces or applications requiring a wide jaw opening.

Such as three-finger or four-finger grippers, better suited for gripping cylindrical or irregularly shaped workpieces, providing more stable gripping.

Grippers developed for specific industries or applications, such as long-stroke grippers, high-force grippers, high-temperature resistant grippers, cleanroom-compatible grippers, etc.

Utilizing precision linear guides or high-quality bearings to ensure smooth finger movement, minimal play, and high repeat positioning accuracy.

Employing efficient transmission mechanisms like wedges, levers, or rack and pinions to convert cylinder thrust into stable and reliable gripping force.

Providing standardized mounting interfaces for fingers, allowing users to quickly customize or replace fingers based on actual workpiece shape and size.

Most models offer optional magnetic switches for detecting gripper open/close status, facilitating automated closed-loop control.

The maximum force the gripper can exert at a specific air pressure; select based on workpiece weight and friction coefficient.

The maximum distance or angle the fingers open and close; must be larger than the workpiece size.

The gripper’s accuracy in repeatedly gripping the same position; crucial for precision applications.

The maximum number of open/close cycles the gripper can complete per minute.

The air pressure range within which the gripper operates normally.

Expected number of cycles or time under rated conditions.

Affects gripper strength, durability, and impact on robot payload.

E.g., temperature range, protection rating, suitability for cleanrooms.

For detailed parameters, please refer to individual product manuals or consult our technical experts.

As robot end-effectors, widely used for material loading/unloading, sorting, and palletizing on automated production lines.

For precision assembly and positioning of electronic components, automotive parts, small appliances, etc.

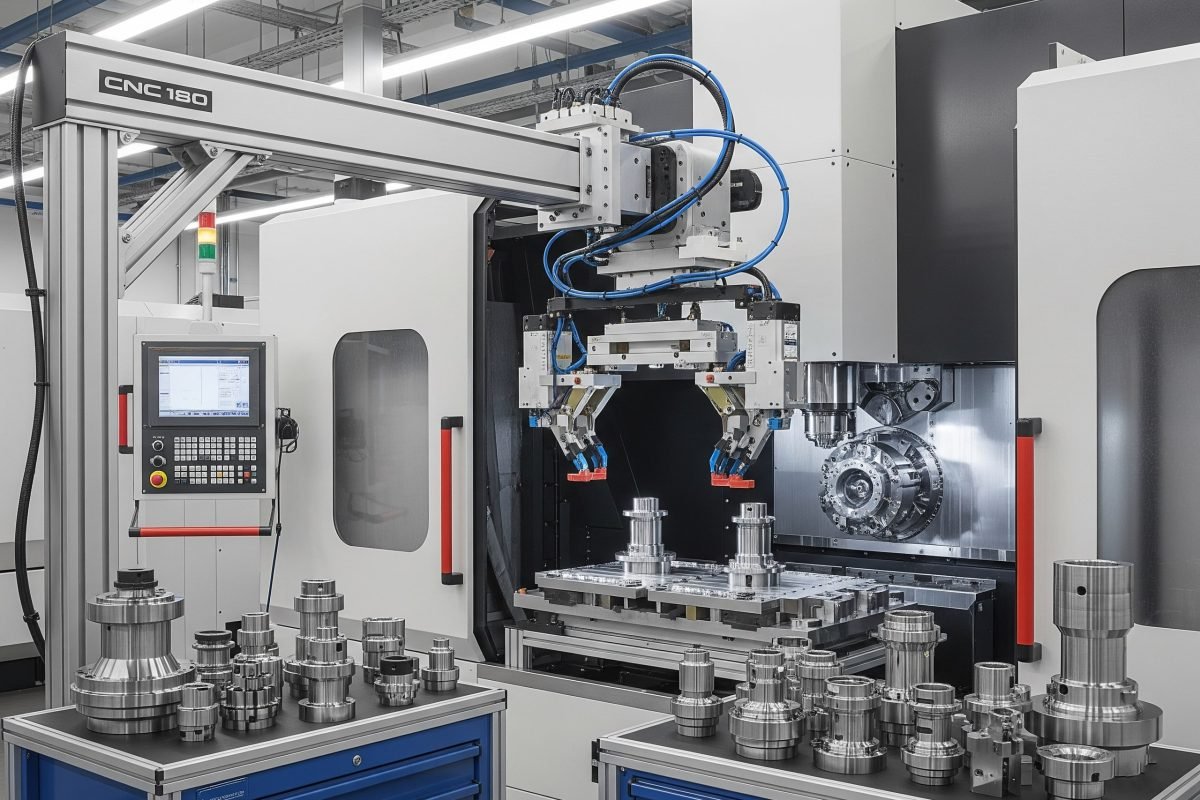

Used with robotic arms or gantry robots for automated loading, unloading, and transfer of machined parts.

For gripping bottles, boxes, bags, and other packaging materials; also for case erecting, packing, and sealing operations.

Quickly and stably removing molded plastic or metal parts from molds.

For gripping and transferring test tubes, petri dishes, and other labware; also for sample handling.

Correct installation and regular maintenance are key to the long-term, efficient, and reliable operation of pneumatic grippers.

Choosing the right gripper type mainly depends on the workpiece’s shape, size, weight, material, and gripping method:

Also consider factors like gripping force, stroke, repeat accuracy, and operating environment.

The gripping force is the force exerted by the fingers on the workpiece at a specific air pressure. When selecting gripping force, consider:

A simplified estimation (for friction grip, lifting vertically): Single jaw gripping force F ≥ (m × g × S) / (n × μ), where g is gravitational acceleration.

For actual selection, it’s recommended to consult the gripping force charts in our product catalogs (gripping force often varies with gripping point position) and consult our technical staff for precise calculations and recommendations based on your specific conditions.

Yes, the fingers (jaw attachments) of pneumatic grippers can usually be customized according to the shape, size, and material of the workpiece being handled.

Standard gripper bodies typically provide one or more standardized mounting interfaces (like threaded holes, dowel pin holes) allowing users to design and fabricate custom fingers. We can also assist in designing and manufacturing custom fingers based on customer-provided workpiece drawings or samples.

When customizing fingers, consider:

To improve stability and accuracy:

Yes, most pneumatic grippers’ moving parts (like guides, carriages, gear-rack mechanisms) require periodic lubrication to reduce wear, ensure smooth motion, and extend service life. However, some small or specially designed grippers might use self-lubricating materials or long-life grease, extending maintenance intervals.

Lubrication method and frequency:

Clean off old grease and dirt before applying new lubricant. Incorrect lubricant or over/under-lubrication can adversely affect gripper performance. Always follow the manufacturer’s maintenance guidelines.

With a diverse selection, high precision, and reliable performance, our pneumatic gripper series provides robust support for your automated gripping tasks. Explore our products now, or contact our pneumatic expert team for professional selection advice and customized solutions.