Your pneumatic system just experienced a catastrophic seal failure that shut down production for 8 hours and cost thousands in lost revenue. The root cause? Wrong seal material selection for the operating environment. Chemical attack, temperature extremes, or incompatible media can destroy even the highest-quality seals in hours rather than years. 🔥

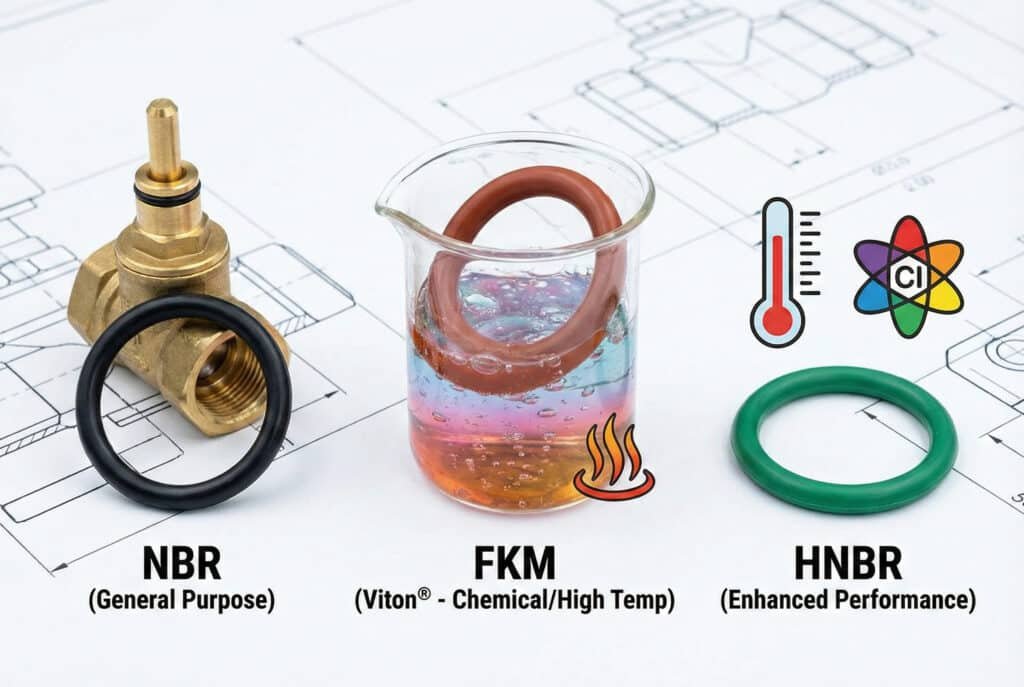

Proper valve seal material selection requires matching elastomer chemistry to operating conditions: NBR for general purpose applications, FKM (Viton®) for chemical resistance and high temperatures, and HNBR for enhanced performance across broader temperature and chemical ranges, with compatibility determined by polymer structure and additive packages.

Last month, I helped Robert, a maintenance manager at a petrochemical facility in Louisiana, solve recurring seal failures in his process gas valves that were costing $50,000 annually in downtime and replacement parts.

Table of Contents

- What Are the Fundamental Properties of Valve Seal Materials?

- How Do NBR, FKM, and HNBR Compare in Performance?

- What Determines Chemical Compatibility and How to Evaluate It?

- How Do You Select the Right Seal Material for Your Application?

What Are the Fundamental Properties of Valve Seal Materials?

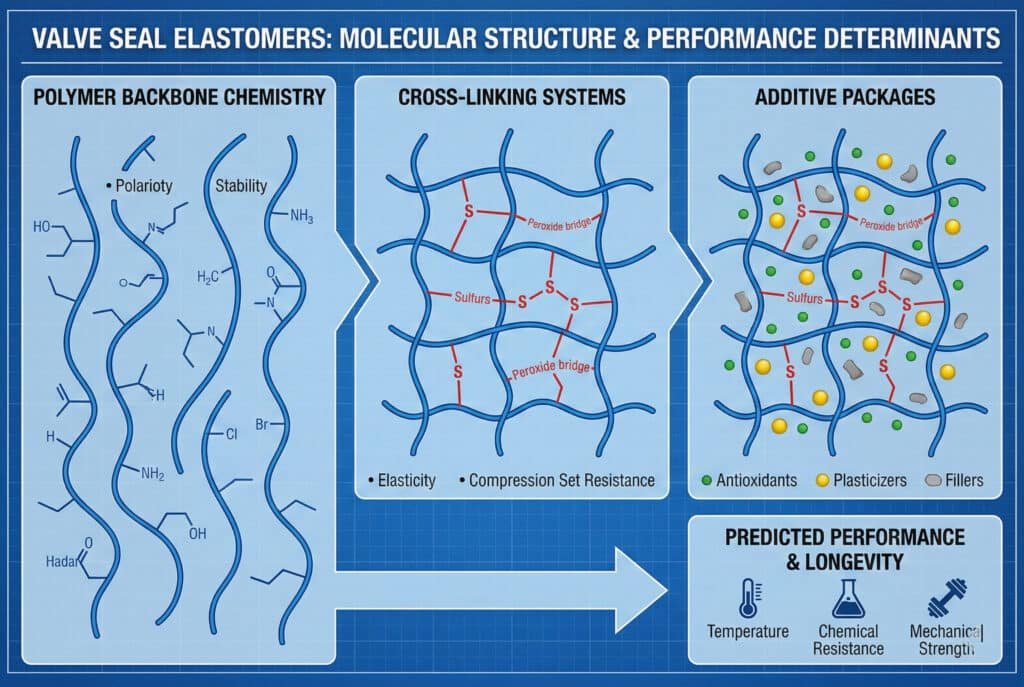

Understanding the molecular structure and fundamental properties of elastomeric seal materials is crucial for predicting performance and longevity in specific applications.

Valve seal materials are cross-linked polymers1 with specific molecular structures that determine their resistance to temperature, chemicals, compression set, and aging, with performance governed by polymer backbone chemistry, cross-linking density, and additive packages.

Polymer Backbone Chemistry

The fundamental polymer chain structure determines basic properties like flexibility, chemical resistance, and temperature stability. Different backbone chemistries provide inherently different characteristics.

Cross-Linking Systems

Cross-linking creates the three-dimensional network that gives elastomers their elastic properties. Sulfur, peroxide, and other cross-linking systems affect chemical resistance, temperature capability, and compression set resistance.

Additive Packages

Antioxidants, plasticizers, fillers, and processing aids significantly affect final seal performance. The same base polymer can have vastly different properties depending on the additive package used.

| Property Category | Impact on Performance | Key Factors | Measurement Methods |

|---|---|---|---|

| Chemical resistance | Media compatibility | Polymer polarity, cross-linking | Immersion testing, swell measurement |

| Temperature range | Operating limits | Polymer stability, additives | Heat aging, low-temp brittleness |

| Mechanical properties | Sealing force, wear | Cross-link density, fillers | Tensile, Compression set2, abrasion |

| Permeability | Gas/liquid diffusion | Molecular structure, crystallinity | Permeation rate testing |

Robert’s petrochemical plant was using standard NBR seals in hydrogen sulfide service, where the sulfur compounds were attacking the sulfur-cured NBR cross-links. We switched to our Bepto FKM seals with peroxide curing for superior chemical resistance. ⚗️

Aging and Degradation Mechanisms

Understanding how seals degrade over time—through oxidation, ozone attack, thermal degradation, or chemical attack—helps predict service life and select appropriate materials.

Environmental Stress Factors

Multiple environmental factors often act simultaneously: temperature cycling, chemical exposure, mechanical stress, and UV radiation can interact synergistically to accelerate seal degradation.

How Do NBR, FKM, and HNBR Compare in Performance?

Each major seal material family offers distinct advantages and limitations based on their molecular structure and typical formulations.

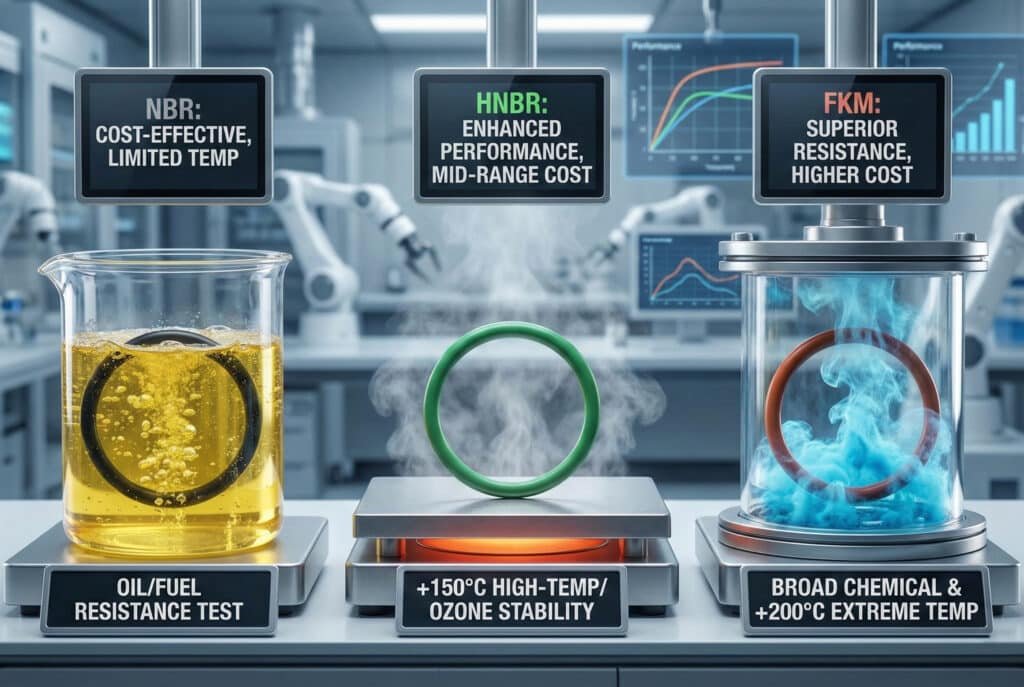

NBR (nitrile) provides excellent oil resistance and cost-effectiveness but limited temperature range, FKM (fluoroelastomer) offers superior chemical and temperature resistance at higher cost, while HNBR (hydrogenated nitrile) bridges the gap with enhanced temperature and ozone resistance.

NBR (Nitrile Butadiene Rubber) Characteristics

NBR offers excellent resistance to petroleum oils, fuels, and many hydraulic fluids. The acrylonitrile content (typically 18-50%) determines oil resistance—higher content provides better oil resistance but reduces low-temperature flexibility.

FKM (Fluoroelastomer) Properties

FKM provides exceptional chemical resistance due to the strong carbon-fluorine bonds in its backbone. It maintains properties at high temperatures and resists most chemicals except strong bases and some specialized solvents.

HNBR (Hydrogenated Nitrile) Advantages

HNBR combines the oil resistance of NBR with improved temperature stability and ozone resistance through hydrogenation3 of the polymer backbone, eliminating reactive double bonds.

| Material | Temperature Range | Chemical Resistance | Cost Factor | Typical Applications |

|---|---|---|---|---|

| NBR | -40°C to +120°C | Good oils/fuels | 1.0x | General pneumatic/hydraulic |

| HNBR | -40°C to +150°C | Excellent oils/fuels | 2.5x | Automotive, high-temp |

| FKM | -20°C to +200°C | Excellent broad spectrum | 4-6x | Chemical processing, aerospace |

Specific Grade Variations

Within each material family, different grades offer optimized properties. For example, FKM grades vary from general purpose to specialized formulations for steam, amines, or extreme temperatures.

Performance Trade-offs

No single material excels in all properties. NBR offers cost advantage but temperature limitations, FKM provides chemical resistance but higher cost and potential low-temperature brittleness, HNBR balances properties but at moderate cost increase.

I recently worked with Lisa, who manages a food processing facility in Wisconsin, where her application required both FDA compliance and steam cleaning resistance. Our HNBR seals provided the necessary approvals and temperature resistance for her sanitary valve applications. 🍎

Compound Optimization

Seal manufacturers can optimize compounds within each material family for specific applications, adjusting hardness, additive packages, and curing systems to enhance particular properties.

What Determines Chemical Compatibility and How to Evaluate It?

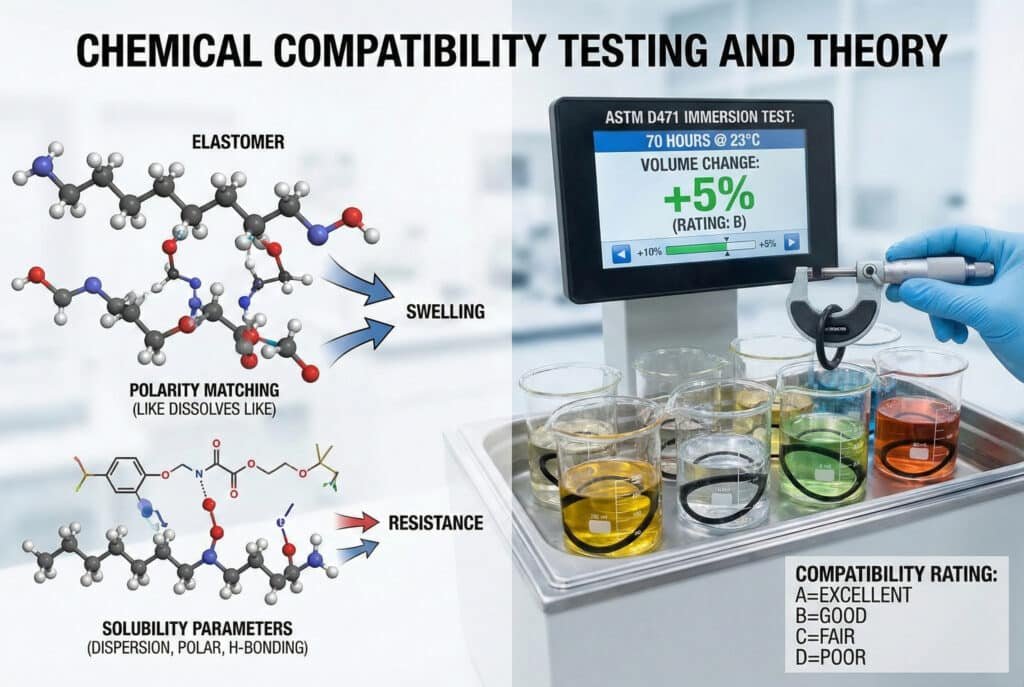

Chemical compatibility between seal materials and process media depends on molecular interactions that can be predicted and tested through established methods.

Chemical compatibility is determined by solubility parameters, polarity matching, and specific chemical reactions between the elastomer and media, evaluated through standardized immersion testing, swell measurements, and accelerated aging protocols.

Solubility Parameter Theory

Hansen solubility parameters4 predict compatibility based on dispersion forces, polar interactions, and hydrogen bonding. Materials with similar parameters tend to be compatible (and potentially problematic for seals).

Polarity and Molecular Interactions

Polar elastomers like NBR resist non-polar oils but may swell in polar solvents. Non-polar elastomers like EPDM resist polar chemicals but swell in oils. FKM’s unique structure resists both polar and non-polar media.

Chemical Attack Mechanisms

Different chemicals attack elastomers through various mechanisms: swelling (reversible), extraction of additives, chain scission, cross-link degradation, or formation of new cross-links leading to hardening.

Standardized Testing Methods

ASTM D4715 (immersion testing), ISO 1817 (liquid immersion), and ASTM D1414 (steam resistance) provide standardized methods for evaluating chemical compatibility under controlled conditions.

| Test Method | Duration | Conditions | Measurements | Applications |

|---|---|---|---|---|

| ASTM D471 | 70 hours | 23°C immersion | Volume/hardness change | General compatibility |

| Accelerated aging | 168+ hours | Elevated temperature | Multiple properties | Long-term prediction |

| Dynamic testing | Variable | Actual service conditions | Functional performance | Real-world validation |

Compatibility Rating Systems

Industry uses various rating systems (A=excellent, B=good, C=fair, D=poor) based on volume swell, hardness change, and tensile property retention after chemical exposure.

Synergistic Effects

Multiple chemicals, temperature, and stress can interact synergistically to cause compatibility problems not predicted by individual component testing, requiring system-level evaluation.

Our Bepto technical team maintains an extensive chemical compatibility database and provides application-specific testing services to ensure optimal seal material selection for challenging environments. 🧪

Real-World vs Laboratory Conditions

Laboratory compatibility testing may not fully represent actual service conditions with temperature cycling, mechanical stress, contamination, and chemical mixtures, requiring careful interpretation of test results.

How Do You Select the Right Seal Material for Your Application?

Systematic seal material selection requires evaluating all operating conditions, performance requirements, and economic factors to optimize long-term system performance.

Effective seal material selection follows a systematic process: define operating conditions (temperature, pressure, media), identify critical performance requirements, evaluate material options against compatibility databases, consider economic factors, and validate selection through testing when necessary.

Operating Condition Analysis

Document all operating conditions: temperature range (including transients), pressure levels, chemical media (including cleaning agents), mechanical stresses, and environmental factors like ozone or UV exposure.

Performance Requirement Prioritization

Identify critical performance requirements: sealing effectiveness, service life expectations, maintenance intervals, safety considerations, and regulatory compliance needs (FDA, USP Class VI, etc.).

Material Screening Process

Use compatibility databases and manufacturer recommendations to screen suitable materials, eliminating obviously incompatible options and identifying candidates for detailed evaluation.

Economic Analysis

Consider total cost of ownership: initial material cost, installation labor, maintenance frequency, downtime costs, and replacement part availability over the expected system life.

| Selection Factor | Weight | NBR | HNBR | FKM | Decision Impact |

|---|---|---|---|---|---|

| Chemical compatibility | High | Good | Good | Excellent | Primary screening |

| Temperature capability | Medium | Limited | Good | Excellent | Secondary factor |

| Cost considerations | Medium | Excellent | Good | Poor | Economic balance |

| Availability/lead time | Low | Excellent | Good | Good | Practical consideration |

Testing and Validation

For critical applications or uncertain conditions, conduct application-specific testing: compatibility testing with actual media, accelerated aging, or field trials to validate material selection.

Supplier Technical Support

Work with seal manufacturers who provide technical support, compatibility databases, custom compounds, and application engineering assistance to optimize material selection.

Our Bepto engineering team provides comprehensive seal material selection support, including custom compound development for unique applications and extensive compatibility testing capabilities. 🎯

Documentation and Standardization

Document material selection rationale and establish standard material specifications for similar applications to ensure consistency and facilitate future maintenance and replacement.

Continuous Improvement

Monitor seal performance in service, document failure modes and root causes, and continuously refine material selection criteria based on actual field experience and new material developments.

Proper seal material selection is critical for pneumatic system reliability, requiring systematic evaluation of operating conditions, material properties, and economic factors to optimize long-term performance.

FAQs About Valve Seal Materials and Chemical Compatibility

Q: Can I use NBR seals in all pneumatic applications?

NBR works well for general compressed air and many pneumatic applications, but may not be suitable for high temperatures, ozone exposure, or certain chemical environments where HNBR or FKM would be better choices.

Q: How do I know if my current seal material is compatible with a new chemical?

Consult chemical compatibility charts, contact the seal manufacturer, or conduct compatibility testing with the specific chemical and seal material combination under your operating conditions.

Q: Why do seals fail even when compatibility charts show they should work?

Compatibility charts show general guidance, but actual performance depends on specific compound formulations, operating conditions, synergistic effects, and quality of the seal installation.

Q: Is it worth paying extra for FKM seals in standard air applications?

Generally no—NBR or HNBR provides adequate performance for standard compressed air at much lower cost. FKM is justified only when its superior chemical or temperature resistance is needed.

Q: How often should valve seals be replaced preventively?

Replacement intervals depend on material, operating conditions, and criticality. Monitor seal performance and establish replacement schedules based on actual service experience rather than arbitrary time intervals.

-

Understand the fundamental chemical structure that gives elastomeric materials their elastic memory and sealing capability. ↩

-

Learn how this critical measure determines a seal’s ability to maintain its sealing force over time under continuous stress. ↩

-

Discover the process used to convert NBR to HNBR, eliminating reactive double bonds and improving high-temperature and ozone resistance. ↩

-

Explore the advanced modeling system used by chemists to predict swelling and compatibility between elastomers and solvents. ↩

-

Consult the specific standard procedure used to measure the changes in mass, volume, and hardness of seals after liquid exposure. ↩