Your production line suddenly stops because a cylinder position sensor failed to trigger. 😰 The PLC shows no signal, your machine sits idle, and every minute of downtime costs money. You replace the sensor, and everything works again—but was it really the sensor’s fault, or is the magnet in your cylinder losing strength? Making the wrong diagnosis means you’ll face the same failure again in weeks, wasting time and money on the wrong solution.

Sensor failure in pneumatic cylinders typically results from either magnetic field decay (gradual weakening of the piston magnet reducing detection range) or reed switch burnout (electrical failure of the sensor’s internal contacts from excessive current, voltage spikes, or mechanical shock). Magnetic field decay is gradual and affects all sensors on a cylinder equally, while reed switch burnout is sudden and typically affects individual sensors. Proper diagnosis requires testing magnet strength with a gauss meter and verifying reed switch electrical continuity, enabling targeted replacement of only the failed component rather than unnecessary parts.

Last month, I received a frustrated call from Steven, a maintenance manager at an automotive parts facility in Michigan. His facility had replaced 15 “failed” magnetic sensors over three months at $80 each, totaling $1,200—but failures kept occurring. When we investigated, we discovered that 12 of those sensors were actually fine; the real problem was magnetic field decay in the cylinder magnets. By misdiagnosing the root cause, Steven’s team had wasted nearly $1,000 on unnecessary sensor replacements while the actual problem went unaddressed. Once we identified and replaced the weak magnets, sensor reliability improved dramatically.

Table of Contents

- What Causes Magnetic Sensors to Fail in Pneumatic Cylinders?

- How Do You Diagnose Magnetic Field Decay vs Reed Switch Failure?

- What Testing Methods Accurately Identify the Root Cause?

- How Can You Prevent Future Sensor and Magnet Failures?

What Causes Magnetic Sensors to Fail in Pneumatic Cylinders?

Understanding failure mechanisms is essential for accurate diagnosis. 🔍

Magnetic sensor failures occur through two distinct mechanisms: magnetic field decay (demagnetization of the piston magnet from temperature exposure, mechanical shock, or time-related degradation) and reed switch electrical failure (contact welding from inductive loads, contact erosion from high switching currents, or mechanical damage from vibration). Magnetic field decay typically reduces detection range gradually over months or years, while reed switch failures are usually sudden and complete. Environmental factors including temperature extremes above 80°C, electrical noise, improper load matching, and mechanical vibration accelerate both failure modes.

Magnetic Field Decay Mechanisms

Permanent magnets in cylinder pistons can lose strength through several processes:

Thermal demagnetization:

Magnets have a maximum operating temperature (Curie temperature1)

Neodymium magnets: Typically rated to 80-150°C depending on grade

Ferrite magnets: More temperature-resistant (250°C+) but weaker initial field

Exposure above rated temperature causes permanent strength loss

Even temperatures below maximum gradually weaken magnets over time

Mechanical shock demagnetization:

- Impact or vibration can disrupt magnetic domain alignment

- Repeated cylinder hammering accelerates magnet weakening

- Drop damage during maintenance or installation

- Particularly affects neodymium magnets, which are brittle

Time-related degradation:

- All permanent magnets experience gradual flux loss over decades

- Modern rare-earth magnets lose <1% per decade under ideal conditions

- Poor-quality magnets may lose 5-10% in first few years

- Accelerated by temperature cycling and mechanical stress

Reed Switch Electrical Failures

Reed switches fail through electrical and mechanical mechanisms:

| Failure Mode | Cause | Symptoms | Typical Lifespan Impact |

|---|---|---|---|

| Contact welding | Inductive load2 switching without suppression | Sensor stuck “on,” no switching | Immediate failure |

| Contact erosion | High switching current, arcing | Intermittent operation, high resistance | 50-70% life reduction |

| Contact contamination | Hermetic seal breach, moisture ingress | Erratic switching, high resistance | 60-80% life reduction |

| Mechanical fatigue | Excessive vibration, millions of cycles | Contacts fail to close reliably | Normal wear-out |

Electrical stress factors:

- Switching inductive loads (solenoid valves, relay coils) without protection

- Voltage spikes from nearby equipment

- Current exceeding reed switch rating (typically 0.5-1.0A for pneumatic sensors)

- DC loads causing contact material transfer (one contact erodes, other builds up)

I worked with Patricia, a controls engineer at a packaging plant in North Carolina, whose sensors were failing every 2-3 months. Investigation revealed her PLC outputs were switching 24VDC at 0.8A directly through the reed switches—right at the maximum rating. Adding simple flyback diodes across the inductive loads extended sensor life from 3 months to over 2 years.

Environmental Accelerators

External conditions that accelerate both failure modes:

Temperature extremes:

- High temperatures (>60°C) accelerate magnet decay exponentially

- Temperature cycling causes mechanical stress

- Cold temperatures (<0°C) can affect reed switch operation temporarily

Vibration and shock:

- Weakens magnet domain structure

- Causes reed switch contact bounce and premature wear

- Loosens sensor mounting, changing air gap

Electromagnetic interference (EMI):

- Induces false triggering in reed switches

- Can cause unexpected switching and contact wear

- Particularly problematic near welders, VFDs, or high-power motors

Contamination:

- Metal particles attracted to sensor magnets

- Moisture ingress in non-hermetic sensors

- Chemical exposure degrading sensor housing

How Do You Diagnose Magnetic Field Decay vs Reed Switch Failure?

Accurate diagnosis prevents wasting time and money on wrong solutions. 🔬

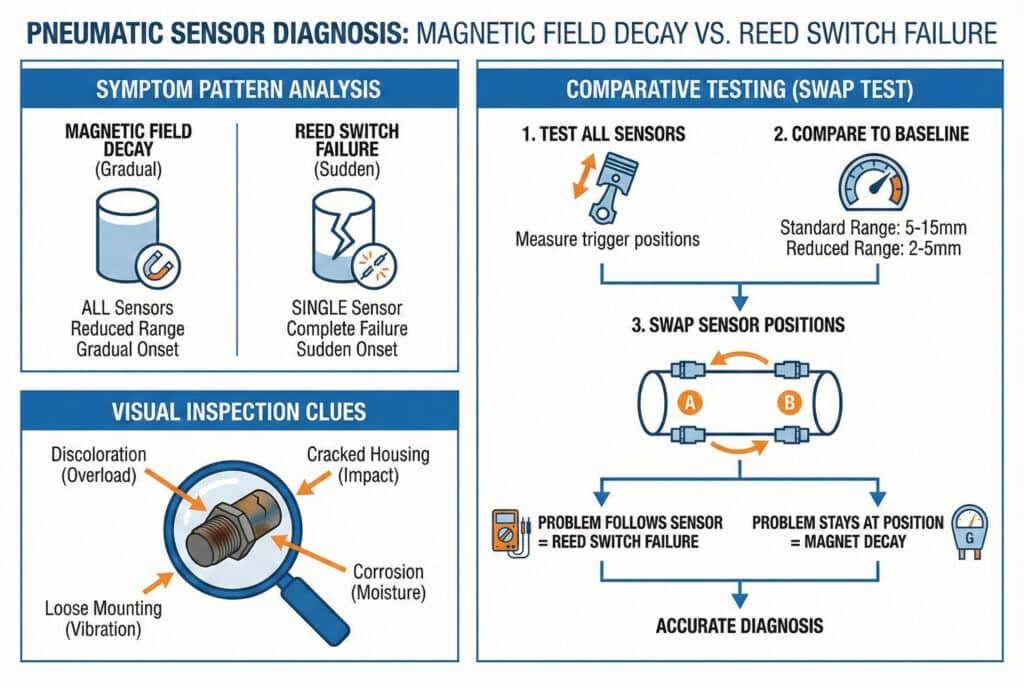

Diagnosing the failure mode requires systematic testing: magnetic field decay shows reduced detection range on all sensors equally, gradual onset over weeks/months, and magnet field strength below specification when measured with a gauss meter (typically <50% of original 800-1200 gauss). Reed switch failure shows sudden complete loss of function on individual sensors, normal detection range on working sensors, and electrical continuity failure or infinite resistance when tested with a multimeter. The key diagnostic is testing multiple sensors—if all show reduced range, suspect magnet decay; if only one fails while others work normally, suspect reed switch failure.

Symptom Pattern Analysis

Different failure modes create distinctive symptom patterns:

Magnetic field decay indicators:

- Multiple sensors on same cylinder show reduced range

- Sensors must be positioned closer to detect piston

- Gradual onset—detection becomes less reliable over time

- Affects both extend and retract sensors equally

- Problem persists even with new sensors installed

Reed switch failure indicators:

- Single sensor fails while others work normally

- Complete loss of signal (not intermittent initially)

- Sudden onset—sensor worked fine, then stopped

- Problem resolved by replacing specific sensor

- May affect only extend OR retract sensor, not both

Visual Inspection Clues

Physical examination provides important diagnostic information:

Sensor inspection:

- Discoloration or melting: Indicates electrical overload or heat damage

- Cracked housing: Mechanical damage or impact

- Corrosion on terminals: Moisture ingress or chemical exposure

- Loose mounting: Vibration damage, increased air gap

Cylinder inspection:

- Piston position indicator (if present) shows magnet location

- Impact damage to piston: May indicate shock demagnetization

- Temperature indicators: Thermal labels show if overheating occurred

Comparative Testing Method

Test multiple sensors to identify patterns:

Step 1: Test all sensors on affected cylinder

- Move piston slowly through full stroke

- Note exact position where each sensor triggers

- Measure distance from sensor to piston at trigger point

- Document which sensors work and which don’t

Step 2: Compare to baseline specifications

- Standard detection range: 5-15mm depending on sensor type

- Reduced range (2-5mm): Indicates weak magnet or sensor issue

- No detection: Complete failure of sensor or magnet

Step 3: Swap sensor positions

- Move a “failed” sensor to a working position

- Move a working sensor to the “failed” position

- If problem follows the sensor: Reed switch failure

- If problem stays with position: Magnet decay or mounting issue

Steven’s automotive facility used this swap test and discovered that sensors worked fine when moved to different positions—proving the magnets were weak, not the sensors.

What Testing Methods Accurately Identify the Root Cause?

Proper testing tools eliminate guesswork and confirm diagnosis. 🔧

Accurate diagnosis requires three key tests: magnetic field strength measurement using a gauss meter or magnetometer (healthy cylinder magnets should read 800-1200 gauss at the sensor mounting surface, with readings below 400 gauss indicating significant decay), electrical continuity testing of reed switches using a multimeter (healthy switches show <1 ohm resistance when closed and infinite resistance when open), and functional range testing by measuring the maximum air gap distance at which sensors reliably trigger (typically 5-15mm for standard sensors, with reduced range indicating magnet weakness). At Bepto Pneumatics, our rodless cylinders use high-grade neodymium magnets and we provide field strength specifications to enable accurate diagnostic testing.

Magnetic Field Strength Testing

Use a gauss meter3 to measure magnet strength quantitatively:

Equipment needed:

- Gauss meter or magnetometer ($50-500 depending on accuracy)

- Non-magnetic spacers (plastic or brass) for air gap testing

- Documentation of original magnet specifications

Testing procedure:

Direct contact measurement:

- Place gauss meter probe against cylinder body at sensor location

- Move piston to align magnet with probe

- Record maximum reading

- Compare to specification (typically 800-1200 gauss)

Air gap measurement:

- Use non-magnetic spacers to create known distances (5mm, 10mm, 15mm)

- Measure field strength at each distance

- Plot decay curve

- Compare to expected values

Interpretation:

- >80% of specification: Magnet healthy

- 50-80% of specification: Magnet weakening, monitor closely

- <50% of specification: Magnet failed, replacement needed

Reed Switch Electrical Testing

Use a multimeter to verify reed switch function:

Testing procedure:

- Continuity test (sensor disconnected):

- Set multimeter to resistance (Ω) mode

- Disconnect sensor from circuit

- Measure resistance between sensor terminals

- Bring magnet close to sensor to activate reed switch

- Record resistance with and without magnet

Expected results:

- Without magnet: Infinite resistance (open circuit)

- With magnet: <1 ohm resistance (closed circuit)

- Inconsistent readings: Intermittent failure

- Always low resistance: Contacts welded closed

- Always high resistance: Contacts failed open

- In-circuit voltage test:

- Reconnect sensor to circuit

- Measure voltage across sensor terminals

- Activate sensor with magnet

- Voltage should drop to near zero when activated

| Test Result | Diagnosis | Action Required |

|---|---|---|

| Normal switching | Reed switch functional | Check magnet strength |

| Always open | Reed switch failed open | Replace sensor |

| Always closed | Contacts welded | Replace sensor |

| Intermittent | Contact erosion or contamination | Replace sensor |

| High resistance when closed | Contact degradation | Replace sensor soon |

Functional Range Testing

Measure actual detection distance to assess system health:

Testing procedure:

- Mount sensor on adjustable fixture or use spacers

- Move piston to sensor location

- Gradually increase distance between sensor and cylinder

- Note maximum distance where sensor still triggers reliably

- Compare to specification and other sensors on same cylinder

Interpretation guidelines:

- Standard sensors: 5-15mm typical range

- High-sensitivity sensors: 15-25mm range

- Reduced range uniformly on all sensors: Weak magnet

- Reduced range on one sensor only: Sensor issue

- No detection even at zero gap: Complete failure (sensor or magnet)

Advanced Diagnostic Techniques

For critical applications or persistent problems:

Oscilloscope testing:

- Observe sensor output waveform

- Clean switching indicates healthy reed switch

- Bounce or noise indicates contact degradation

- Useful for intermittent failures

Thermal imaging:

- Identify hot spots indicating electrical resistance

- Detect overheating from excessive current

- Locate sources of thermal demagnetization

Vibration analysis:

- Measure vibration levels at sensor mounting

- Correlate with sensor failure rates

- Identify mechanical issues causing premature wear

How Can You Prevent Future Sensor and Magnet Failures?

Prevention strategies save time and money while improving reliability. 🛡️

Preventing sensor and magnet failures requires addressing root causes: protect reed switches from electrical stress using flyback diodes or RC snubbers across inductive loads, limit switching current to 50-70% of sensor rating, use solid-state sensors for high-cycle or harsh applications, prevent magnet demagnetization by avoiding temperature extremes above 80°C, minimizing mechanical shock through proper cushioning, and selecting appropriate magnet grades for the application. Regular preventive maintenance including annual magnet strength testing and sensor range verification enables early detection before failures cause downtime. At Bepto Pneumatics, we use high-grade temperature-resistant magnets and provide comprehensive sensor protection guidelines.

Electrical Protection for Reed Switches

Implement circuit protection to extend sensor life:

Flyback diode protection:

Install flyback diode4 across inductive loads (1N4007 or equivalent)

Cathode to positive, anode to negative

Suppresses voltage spikes from coil de-energization

Extends reed switch life 5-10x

Cost: <$0.50 per diode

RC snubber networks:

- Resistor-capacitor network across sensor contacts

- Typical values: 100Ω resistor + 0.1μF capacitor

- Reduces contact arcing

- Particularly effective for DC loads

Current limiting:

- Ensure load current <70% of sensor rating

- Use relay or solid-state switch for high-current loads

- Typical sensor rating: 0.5-1.0A maximum

- Recommended operating current: 0.3-0.7A

Patricia’s packaging plant implemented flyback diodes across all solenoid valve coils driven by sensor outputs. The $50 investment in diodes eliminated sensor failures that had been costing $1,200 annually in replacements and downtime.

Magnet Protection Strategies

Preserve magnet strength throughout cylinder life:

Temperature management:

- Keep operating temperature below magnet rating (typically 80°C for standard grade)

- Use high-temperature magnet grades for hot environments (150°C+ rated)

- Provide cooling or heat shielding if necessary

- Monitor temperature in critical applications

Shock and vibration reduction:

- Implement proper cylinder cushioning to prevent hammering

- Use vibration isolation mounts in high-vibration environments

- Avoid dropping or impacting cylinders during handling

- Secure all mounting hardware to prevent loosening

Quality magnet selection:

- Specify high-grade neodymium (N42 or better) for long life

- Consider samarium-cobalt for high-temperature applications

- Verify magnet specifications from cylinder supplier

- Test magnet strength on new cylinders to establish baseline

Sensor Selection and Upgrade Options

Choose appropriate sensor technology for your application:

| Sensor Type | Advantages | Disadvantages | Best Applications |

|---|---|---|---|

| Reed switch (standard) | Low cost ($15-30), simple, reliable | Limited life (10-20M operations), electrical sensitivity | General industrial, moderate cycling |

| Reed switch (protected) | Better electrical protection, longer life | Slightly higher cost ($25-40) | High-cycle applications, inductive loads |

| Solid-state (Hall effect5) | Very long life (100M+ operations), no contacts | Higher cost ($40-80), requires power | High-cycle, harsh environments |

| Magnetoresistive | Precise positioning, long life | Highest cost ($60-120), complex | Precision applications, positioning |

Upgrade decision factors:

- Cycle frequency >100 cycles/hour: Consider solid-state

- Harsh electrical environment: Use solid-state or protected reed

- High reliability requirement: Invest in solid-state

- Cost-sensitive application: Standard reed with proper protection

Preventive Maintenance Program

Implement regular testing to catch problems early:

Monthly inspections:

- Visual check of sensor mounting and wiring

- Listen for unusual cylinder operation (hammering, etc.)

- Review any intermittent sensor issues

Quarterly testing:

- Functional range test on critical cylinders

- Document detection distances

- Compare to baseline measurements

- Investigate any 20% reduction in range

Annual comprehensive testing:

- Gauss meter testing of magnet strength on critical cylinders

- Electrical testing of sensors showing any issues

- Replace magnets showing >30% strength loss

- Replace sensors showing degraded performance

Documentation and trending:

- Record all test results with dates and cylinder identification

- Plot trends over time

- Identify patterns correlating with failures

- Adjust maintenance intervals based on data

Cost-Benefit Analysis

Quantify the value of prevention versus reactive replacement:

Steven’s automotive facility analysis:

Previous approach: Replace sensors on failure

- 15 sensors replaced in 3 months = $1,200

- 8 hours downtime = $6,400 (at $800/hour)

- Total cost: $7,600 per quarter

Prevention program implemented:

- Initial testing and magnet replacement: $800

- Flyback diodes and circuit protection: $200

- Quarterly testing program: $400/quarter

- Sensor failures reduced by 85%

- Total first-quarter cost: $1,400

- Ongoing quarterly cost: $600

- Annual savings: >$20,000

ROI calculation:

- Implementation cost: $1,000

- Annual savings: $20,000+

- Payback period: <3 weeks

- Additional benefits: Reduced downtime, improved reliability, better planning

Best Practices Summary

Key recommendations for maximum sensor and magnet reliability:

- Always use electrical protection on reed switch sensors switching inductive loads

- Test magnet strength on new cylinders to establish baseline

- Monitor temperature in applications approaching magnet limits

- Implement cushioning to prevent mechanical shock

- Use appropriate sensor technology for your application demands

- Establish testing program to detect degradation early

- Document everything to identify patterns and trends

- Choose quality components from reputable suppliers like Bepto Pneumatics

At Bepto Pneumatics, our rodless cylinders come standard with high-grade neodymium magnets rated for extended life, and we provide detailed sensor selection guidance and protection recommendations. We also offer field strength testing services and can supply replacement magnets with documented specifications, ensuring you have the data needed for effective preventive maintenance.

Conclusion

Accurate diagnosis of sensor failures—distinguishing magnetic field decay from reed switch burnout—enables targeted solutions that save money, reduce downtime, and improve long-term reliability. 💪

FAQs About Sensor and Magnet Failures

Q: Can a weak magnet be recharged, or must it be replaced?

While magnets can theoretically be re-magnetized, it’s not practical for pneumatic cylinder applications. The process requires specialized equipment, complete cylinder disassembly, and often doesn’t restore full strength if thermal or mechanical damage caused the demagnetization. Replacement is more reliable and cost-effective—a new magnet costs $20-50 and guarantees full field strength, while attempting to recharge a magnet risks incomplete restoration and repeated failures. At Bepto Pneumatics, we stock replacement magnets for our rodless cylinders and can provide them with documented field strength specifications.

Q: How long should magnetic sensors and magnets last in typical applications?

Under proper operating conditions, high-quality neodymium magnets should maintain >90% field strength for 20+ years, while reed switch sensors typically last 10-20 million operations (about 2-5 years in moderate-cycle applications). However, adverse conditions dramatically reduce life: temperatures above 80°C can cut magnet life to 2-5 years, while electrical stress without protection can destroy reed switches in months. Solid-state sensors last 100+ million operations, making them cost-effective for high-cycle applications despite higher initial cost. The key is matching component quality and technology to your specific application demands.

Q: Why do some sensors fail immediately after installation?

Immediate sensor failures typically result from installation errors or incompatible specifications. Common causes include: incorrect voltage rating (using 12V sensor on 24V circuit), excessive switching current (sensor rated 0.5A but switching 1A load), reversed polarity on polarized sensors, mechanical damage during installation, or contamination introduced during assembly. Always verify sensor specifications match your circuit, use proper electrical protection, handle sensors carefully, and test functionality immediately after installation before putting equipment into production.

Q: Can I use higher-sensitivity sensors to compensate for weak magnets?

While high-sensitivity sensors can temporarily compensate for weak magnets, this is not a reliable long-term solution. The weak magnet will continue degrading, eventually falling below even the high-sensitivity sensor’s detection threshold. Additionally, high-sensitivity sensors are more prone to false triggering from stray magnetic fields or nearby ferrous materials. The correct approach is replacing the weak magnet to restore proper field strength, then using appropriately-rated sensors. This ensures reliable operation and prevents the cascading problems that weak magnets cause, including reduced positioning accuracy and intermittent failures.

Q: Should I replace all sensors when one fails, or just the failed unit?

Replace only the failed sensor unless testing reveals systemic issues. If diagnosis shows reed switch failure (sudden, single sensor, electrical test confirms), replace just that sensor. However, if magnet testing reveals field decay, consider the magnet’s condition: if strength is <50% of specification, replace the magnet and test all sensors; if 50-80%, monitor closely and plan replacement soon. If multiple sensors fail within a short period, investigate root causes (electrical stress, vibration, temperature) before replacing components, or you’ll face repeated failures. This targeted approach minimizes cost while ensuring reliability.

-

Learn the physics behind how temperature limits affect permanent magnet strength and performance. ↩

-

Understand why switching inductive components like solenoids creates damaging voltage spikes. ↩

-

Discover how gauss meters measure magnetic flux density for accurate diagnostic testing. ↩

-

See how flyback diodes protect sensitive switches from high-voltage inductive kickback. ↩

-

Compare the solid-state operation of Hall effect sensors against mechanical reed switches. ↩