Introduction

Your cylinder seals are brand new, properly installed, and rated for your application—yet air is still leaking past them. You’ve replaced seals twice in three months, but the problem persists. Your pressure holding capability is deteriorating, cycle times are slowing, and energy costs are climbing. The culprit isn’t your seals—it’s invisible damage to your cylinder bore. 🔍

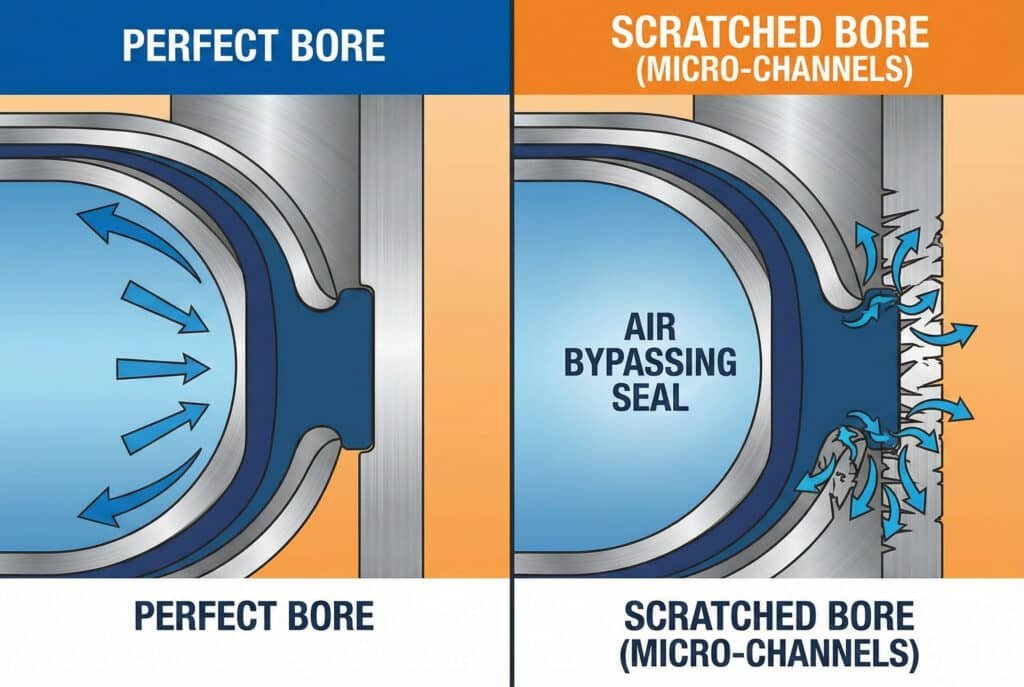

Scratched cylinder bores create micro-channels that allow pressurized air to bypass even perfect seals, with scratches as shallow as 5-10 microns (0.005-0.010mm) capable of causing measurable leakage. These leakage pathways develop from contamination ingress, improper installation, seal debris, or manufacturing defects, and can reduce seal effectiveness by 40-80% while accelerating seal wear by 300-500%, making bore condition analysis critical for diagnosing persistent leakage problems.

Two months ago, I received a frustrated call from Thomas, a maintenance manager at an automotive assembly plant in Tennessee. His production line had twelve rodless cylinders that were consuming excessive air and losing positioning accuracy. He’d replaced every seal twice with premium OEM parts, spending over $3,000, but leakage persisted within weeks. When we performed bore inspection with our specialized equipment, we discovered the real problem: contamination had scored all twelve cylinder bores with microscopic scratches that were destroying new seals within days. 🔧

Table of Contents

- What Causes Scratches and Damage in Pneumatic Cylinder Bores?

- How Do Microscopic Scratches Create Leakage Pathways?

- What Inspection Methods Detect Cylinder Bore Damage?

- How Can You Repair or Prevent Cylinder Bore Scratching?

- Conclusion

- FAQs About Cylinder Bore Damage

What Causes Scratches and Damage in Pneumatic Cylinder Bores?

Understanding the root causes of bore damage is your first step toward preventing costly seal failures and air leakage. 🛡️

Cylinder bore scratches result primarily from four mechanisms: contamination ingress (metal particles, dust, or abrasive debris), improper seal installation (dragging hardened seal edges across the bore), catastrophic seal failure (allowing metal-to-metal contact), and manufacturing defects (inadequate surface finishing or material flaws). Even a single 50-micron particle trapped between seal and bore can create a scratch channel that compromises sealing for the cylinder’s remaining life.

Contamination-Induced Scratching

The most common cause of bore damage is external contamination that bypasses wiper seals:

- Metal particles: From worn components, machining operations, or pipe scale

- Abrasive dust: Silica, cement, mineral particles in industrial environments

- Weld splatter: From nearby welding operations

- Hardened seal debris: Fragments from deteriorated seals

Once inside the cylinder, these particles become trapped between the seal and bore surface, acting like microscopic cutting tools that score the bore with each stroke.

Installation-Related Damage

Improper installation techniques cause immediate bore damage:

- Forcing seals over sharp edges: Creates seal fragments that scratch bores

- Installing without lubrication: Causes excessive friction and galling

- Cross-threading end caps: Misaligns components, causing eccentric wear

- Using incorrect tools: Damages seal edges, creating hard particles

Seal Failure Cascade

When seals fail catastrophically, secondary damage often exceeds the original problem:

| Failure Stage | Mechanism | Bore Damage | Severity |

|---|---|---|---|

| Initial seal wear | Normal friction | Minimal polishing | Low |

| Seal hardening | Heat/chemical degradation | Light scoring | Moderate |

| Seal cracking | Material failure | Deep scratches | High |

| Complete seal loss | Metal-to-metal contact | Severe galling | Critical |

Manufacturing and Material Defects

Not all bore damage originates in the field. Manufacturing issues include:

- Inadequate honing: Surface finish exceeds Ra 0.4μm specification1

- Material inclusions: Hard particles in aluminum or steel matrix

- Corrosion pitting: From improper storage or moisture exposure

- Dimensional errors: Out-of-round bores cause uneven seal loading

In Thomas’s Tennessee facility, our analysis revealed that contamination from a nearby grinding operation had introduced aluminum oxide particles into his compressed air system. These particles—harder than the cylinder bore material—had systematically scratched all twelve bores over six months of operation. No amount of seal replacement could solve a bore damage problem. 💡

How Do Microscopic Scratches Create Leakage Pathways?

The physics of how tiny scratches defeat modern seal technology reveals why bore condition is so critical. 📊

Scratches create leakage pathways through capillary channels that allow pressurized air to flow beneath seal lips even under full compression. A scratch just 10 microns deep and 50 microns wide can pass 0.5-2.0 SCFM2 at 100 psi—equivalent to a 0.5mm hole—because the scratch length (often 100-500mm in rodless cylinders) provides an extended low-resistance pathway. Multiple scratches create parallel leakage paths that compound the problem exponentially.

The Seal-Bore Interface

Under normal conditions, pneumatic seals create an airtight barrier through:

- Material compression: Seal deforms to fill microscopic surface irregularities

- Pressure activation: System pressure forces seal against bore surface

- Surface conformity: Elastomer flows into surface texture (typically Ra 0.2-0.4μm)

This works perfectly on undamaged bores where surface irregularities are smaller than the seal’s ability to conform (typically <2 microns).

How Scratches Defeat Seals

When scratches exceed critical dimensions, seals can no longer conform:

Scratch Depth vs. Seal Conformity:

- 0-3 microns: Seal fully conforms, no leakage

- 3-8 microns: Partial conformity, minimal leakage (<0.1 SCFM)

- 8-15 microns: Poor conformity, moderate leakage (0.5-2.0 SCFM)

- 15+ microns: No conformity, severe leakage (2-10+ SCFM)

Leakage Flow Calculations

The leakage rate through a scratch follows fluid dynamics principles:

Key factors affecting flow:

- Scratch depth: Deeper scratches = exponentially higher flow

- Scratch width: Wider channels = proportionally higher flow

- Scratch length: Longer paths = lower resistance = higher flow

- Pressure differential: Higher pressure = higher driving force

For a typical scratch (10μm deep × 50μm wide × 300mm long) at 100 psi, leakage approximates 1.2 SCFM—enough to cause noticeable performance degradation.

The Accelerated Wear Cycle

Scratched bores create a vicious cycle of accelerating damage:

- Initial scratch creates localized leakage pathway

- Leakage flow carries additional contamination into the scratch

- Contamination acts as abrasive, widening and deepening the scratch

- Seal edges concentrate stress at scratch boundaries, accelerating seal wear

- Worn seal allows more contamination ingress, further damaging the bore

This cycle explains why Thomas’s seals were failing within 2-3 weeks after replacement despite being premium quality parts. The damaged bores were destroying new seals faster than normal wear mechanisms. 🔄

Multiple Scratch Interactions

When multiple scratches exist (common in contaminated environments), leakage compounds:

| Number of Scratches | Individual Leakage | Combined Leakage | Seal Life Reduction |

|---|---|---|---|

| 1 scratch | 1.0 SCFM | 1.0 SCFM | -40% |

| 2-3 scratches | 0.8 SCFM each | 2.0-2.5 SCFM | -65% |

| 4-6 scratches | 0.6 SCFM each | 3.0-4.0 SCFM | -80% |

| 7+ scratches | Variable | 5.0+ SCFM | -90%+ |

Thomas’s worst cylinder had eleven distinct scratch channels, creating a combined leakage rate exceeding 8 SCFM at 90 psi—making effective sealing virtually impossible regardless of seal quality.

What Inspection Methods Detect Cylinder Bore Damage?

Early detection of bore damage prevents costly seal replacement cycles and identifies cylinders requiring repair or replacement. 🔬

Effective bore inspection combines visual examination (using borescopes or direct observation), tactile assessment (running fingernails or plastic gauges across the surface), surface roughness measurement (using profilometers3 to measure Ra values), and pressure decay testing4 (quantifying leakage rates). Professional inspection should detect scratches deeper than 5 microns and assess whether damage is repairable through honing or requires cylinder replacement.

Visual Inspection Techniques

The first line of defense is careful visual examination:

Basic Visual Methods:

- Direct observation: Remove end caps and inspect with good lighting

- Borescope inspection: For assembled cylinders or long bores

- Magnification: 10-30x magnification reveals micro-scratches

- Contrast enhancement: Light oil coating makes scratches visible

What to look for:

- Longitudinal scratches (parallel to rod/piston travel)

- Circumferential scoring (perpendicular to travel direction)

- Discoloration indicating heat damage or corrosion

- Pitting or material removal

Tactile Assessment

Experienced technicians can detect scratches by feel:

- Fingernail test: Run fingernail perpendicular to bore axis—catches indicate scratches

- Plastic gauge: Soft plastic strips detect scratches without causing damage

- Cotton swab test: Fibers catch on scratch edges

- Seal lip test: Gently drag a spare seal lip across surface

Critical: Never use metal tools for tactile assessment—they can create new scratches.

Quantitative Measurement Methods

For precise assessment, use measurement equipment:

| Method | Measures | Detection Limit | Cost | Best For |

|---|---|---|---|---|

| Surface profilometer | Ra, Rz values | 0.1 microns | $$$$ | Lab analysis |

| Portable roughness tester | Ra values | 0.5 microns | $$$ | Field inspection |

| Bore gauge | Diameter variation | 2 microns | $$ | Dimensional check |

| Pressure decay test | Leakage rate | 0.1 SCFM | $ | Functional test |

| Bepto inspection kit | Visual + tactile | 5 microns | $ | Field diagnosis |

The Bepto Bore Inspection Protocol

When customers report persistent seal failures, we provide a systematic inspection process:

Step 1: Pressure Decay Test (5 minutes)

- Pressurize cylinder to operating pressure

- Isolate and monitor pressure for 5 minutes

- Calculate decay rate (should be <2% for healthy cylinder)

Step 2: Visual Inspection (10 minutes)

- Disassemble and clean bore thoroughly

- Inspect under bright light with magnification

- Document scratch locations and orientations

Step 3: Tactile Assessment (5 minutes)

- Use fingernail test at multiple locations

- Run plastic gauge through full bore length

- Assess scratch depth and distribution

Step 4: Decision Matrix

- Minor scratches (<5μm): Monitor, may continue service

- Moderate scratches (5-15μm): Consider honing/repair

- Severe scratches (>15μm): Replace cylinder or bore

For Thomas’s Tennessee facility, we performed complete inspections on all twelve cylinders in under four hours, documenting damage severity and providing repair recommendations for each unit. Eight cylinders were repairable through honing; four required replacement. 📋

How Can You Repair or Prevent Cylinder Bore Scratching?

Prevention is always preferable to repair, but when damage occurs, several restoration options exist. ⚙️

Minor bore scratches (5-15 microns deep) can often be removed through precision honing5, restoring surface finish to Ra 0.2-0.4μm specifications and extending cylinder life by 2-5 years. Severe damage (>15 microns) typically requires cylinder replacement or professional resleeving. Prevention strategies include high-efficiency filtration (5-micron or better), proper wiper seal maintenance, contamination-resistant seal materials, and regular bore inspection schedules—reducing bore damage incidents by 80-90% compared to reactive maintenance approaches.

Bore Honing and Restoration

For repairable damage, precision honing can restore bore surfaces:

Honing Process:

- Assessment: Measure scratch depth and bore dimensions

- Material removal: Remove 10-25 microns to eliminate scratches

- Surface finishing: Achieve Ra 0.2-0.4μm surface finish

- Dimensional verification: Confirm bore diameter within tolerance

- Cleaning: Remove all honing debris before reassembly

Honing Limitations:

- Maximum material removal: 0.05-0.10mm (limited by seal groove dimensions)

- Cannot repair severe galling or material loss

- Requires specialized equipment and expertise

- Not economical for small-bore cylinders (<25mm)

Replacement vs. Repair Decision Matrix

| Damage Severity | Cylinder Value | Recommended Action | Typical Cost | Bepto Solution |

|---|---|---|---|---|

| Minor (<5μm) | Any | Continue service, monitor | $0 | Inspection kit |

| Moderate (5-15μm) | >$500 | Professional honing | $150-400 | Honing service |

| Severe (>15μm) | >$1000 | Resleeving | $400-800 | Partner referral |

| Severe (>15μm) | <$1000 | Replace cylinder | $300-900 | Bepto replacement |

Prevention Strategies

The most cost-effective approach is preventing bore damage:

1. Filtration Improvements:

- Install 5-micron or better air filtration

- Add point-of-use filters at critical cylinders

- Maintain filter elements on schedule

- Monitor filter differential pressure

2. Wiper Seal Optimization:

- Use multi-lip wiper designs for high-contamination environments

- Inspect and replace wipers at 50% of piston seal interval

- Consider polyurethane wipers for abrasive conditions

- Install protective bellows on exposed rods

3. Installation Best Practices:

- Always use seal installation sleeves

- Lubricate all seals during installation

- Inspect bores before seal installation

- Train maintenance staff on proper procedures

4. Monitoring and Inspection:

- Quarterly bore inspections in critical applications

- Monthly pressure decay testing

- Track seal replacement intervals (declining intervals indicate bore issues)

- Document contamination sources and implement controls

The Bepto Comprehensive Approach

When we worked with Thomas in Tennessee, we didn’t just identify the problem—we implemented a complete solution:

Immediate Actions:

- Honed eight repairable cylinders (completed in 3 days)

- Supplied four Bepto replacement cylinders (40% less than OEM)

- Installed upgraded wiper seals on all units

- Provided installation training for maintenance team

Long-Term Prevention:

- Identified grinding operation as contamination source

- Recommended air filtration upgrades (5-micron filters installed)

- Established quarterly bore inspection schedule

- Supplied Bepto inspection kits for in-house monitoring

Results after 6 months:

- Zero bore damage incidents

- Seal life extended from 3 weeks to 14+ months

- Air consumption reduced by 18%

- Annual savings: $47,000 in seals, downtime, and energy costs 💰

At Bepto, we don’t just sell replacement parts—we solve the underlying problems that cause premature failures. Our technical team has decades of experience diagnosing and preventing cylinder bore damage in rodless cylinders and standard pneumatic systems.

Conclusion

Cylinder bore condition is the hidden factor in seal performance and system reliability. Microscopic scratches create leakage pathways that defeat even the best seals, making bore inspection and maintenance as critical as seal selection. Whether through prevention, early detection, or professional restoration, protecting your cylinder bores delivers dramatic improvements in seal life, system efficiency, and total cost of ownership. At Bepto, we provide the expertise, tools, and solutions to keep your pneumatic systems running at peak performance. 🎯

FAQs About Cylinder Bore Damage

How deep does a scratch need to be before it causes seal leakage?

Scratches deeper than 5-8 microns (0.005-0.008mm) typically exceed seal conformity limits and begin causing measurable air leakage, with leakage rates increasing exponentially as scratch depth increases beyond 10 microns. For reference, a human hair is approximately 70 microns in diameter, so damaging scratches are often invisible to the naked eye. This is why proper inspection with magnification and measurement tools is essential for diagnosing persistent leakage problems.

Can you repair a scratched cylinder bore, or must you replace the entire cylinder?

Minor to moderate scratches (5-15 microns deep) can usually be removed through precision honing, restoring the bore to like-new condition for $150-400, while severe damage (>15 microns) typically requires cylinder replacement. The repair decision depends on scratch depth, cylinder value, and bore material. At Bepto, we offer bore inspection services to determine repairability and can provide cost-effective replacement cylinders when repair isn’t economical—often at 30-40% less than OEM prices.

What’s the best way to prevent cylinder bore scratches in contaminated environments?

Implementing 5-micron air filtration, using multi-lip polyurethane wiper seals, installing protective bellows on exposed rods, and conducting quarterly bore inspections reduces bore damage incidents by 80-90% even in heavily contaminated environments. The key is creating multiple barriers against contamination ingress and detecting problems early before minor scratches become severe damage. Investment in prevention is typically 5-10 times more cost-effective than dealing with repeated seal failures and eventual cylinder replacement.

How can you tell if bore damage or seal failure is causing air leakage?

If new seals fail within weeks or months (rather than lasting 12-24+ months), if multiple seal brands fail similarly, or if leakage resumes immediately after seal replacement, bore damage is the likely culprit rather than seal quality. Perform a simple test: install new seals and immediately conduct a pressure decay test. If leakage is present with brand-new seals properly installed, bore damage is confirmed. Bepto provides inspection kits and technical support to help diagnose the root cause of persistent leakage problems.

Are rodless cylinders more susceptible to bore damage than standard cylinders?

Yes, rodless cylinders are generally more vulnerable to bore damage because their external carriage design exposes the bore to environmental contamination, and their longer stroke lengths provide more opportunities for particle ingress and scratch propagation. The external sealing band or magnetic coupling area is particularly susceptible. This makes high-quality wiper seals, proper filtration, and regular bore inspection even more critical for rodless cylinder applications. At Bepto, we specialize in rodless cylinder seal solutions specifically engineered to minimize bore wear and maximize service life in challenging applications.

-

Learn more about surface roughness parameters and how Ra (Arithmetical Mean Height) quantifies texture in precision engineering. ↩

-

Understand the definition of Standard Cubic Feet per Minute (SCFM) and how it differs from actual flow rates in pneumatic systems. ↩

-

Explore how stylus and optical profilometers measure microscopic surface texture and roughness variations. ↩

-

Read a detailed explanation of the pressure decay testing method used to quantify leak rates in sealed components. ↩

-

Discover the mechanics of the honing process used to improve geometric form and surface texture in metal cylinders. ↩