Engineers often assume electric actuators automatically provide superior precision, leading to over-engineered solutions and unnecessary costs when pneumatic cylinders could meet positioning requirements at significantly lower investment and complexity.

Electric actuators provide superior precision with positioning accuracy to ±0.001-0.01mm and repeatability within ±0.002mm, while pneumatic cylinders typically achieve ±0.1-1.0mm accuracy, making electric systems essential for micro-positioning but pneumatic solutions adequate for most industrial positioning requirements.

Yesterday, Carlos from a Mexican electronics assembly plant discovered his expensive servo actuators were providing 50 times more precision than his application required, while Bepto rodless cylinders1 could have met his ±0.5mm positioning needs at 70% lower cost.

Table of Contents

- What Precision Levels Do Electric Actuators Actually Achieve?

- How Precise Can Pneumatic Cylinders Be in Real Applications?

- Which Applications Actually Require Ultra-High Precision Positioning?

- How Do Cost and Complexity Scale with Precision Requirements?

What Precision Levels Do Electric Actuators Actually Achieve?

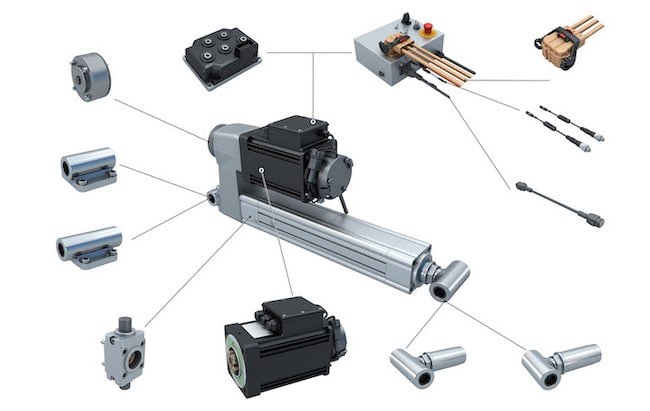

Electric actuator precision capabilities vary significantly based on system design, feedback devices, and control sophistication, with performance ranging from basic positioning to sub-micron accuracy.

High-end electric actuators achieve positioning accuracy of ±0.001-0.01mm with repeatability within ±0.002mm using servo motors and high-resolution encoders, while basic electric actuators provide ±0.1-0.5mm accuracy, comparable to precision pneumatic systems but at significantly higher cost and complexity.

Electric Actuator Precision Categories

Servo System Performance

High-precision servo actuators deliver exceptional accuracy:

- Positioning accuracy: ±0.001-0.01mm depending on system design

- Repeatability: ±0.002-0.005mm for consistent positioning

- Resolution: 0.0001-0.001mm incremental movement capability

- Stability: ±0.001-0.003mm position holding accuracy

Stepper Motor Precision

Stepper-based systems offer good precision at lower cost:

- Step resolution: 0.01-0.1mm per step depending on lead screw pitch

- Positioning accuracy: ±0.05-0.2mm with proper calibration

- Repeatability: ±0.02-0.1mm for consistent performance

- Microstepping2: Enhanced resolution through electronic subdivision

Precision Performance Comparison

Electric Actuator Precision Matrix

| Actuator Type | Positioning Accuracy | Repeatability | Resolution | Typical Cost |

|---|---|---|---|---|

| High-end servo | ±0.001-0.005mm | ±0.002mm | 0.0001mm | $3000-$8000 |

| Standard servo | ±0.01-0.05mm | ±0.005mm | 0.001mm | $1500-$4000 |

| Precision stepper | ±0.05-0.2mm | ±0.02mm | 0.01mm | $800-$2500 |

| Basic stepper | ±0.1-0.5mm | ±0.05mm | 0.05mm | $400-$1200 |

Factors Affecting Electric Actuator Precision

Mechanical Design Elements

Physical construction impacts achievable precision:

- Lead screw quality: Precision ground screws reduce backlash and error

- Bearing systems: High-precision bearings minimize play and deflection

- Structural rigidity: Stiff construction prevents deflection under load

- Thermal stability: Temperature compensation maintains accuracy

Control System Sophistication

Electronic control systems determine precision capability:

- Encoder resolution: Higher resolution feedback improves positioning accuracy

- Control algorithms: Advanced PID and feedforward control3 enhance performance

- Calibration systems: Automatic error compensation and mapping

- Environmental compensation: Temperature and load correction algorithms

Real-World Precision Limitations

Environmental Impact Factors

Operating conditions affect actual precision:

- Temperature variations: Thermal expansion affects mechanical components

- Vibration effects: External vibration degrades positioning accuracy

- Load variations: Changing loads affect system compliance and accuracy

- Wear progression: Component wear gradually reduces precision over time

System Integration Challenges

Complete system precision depends on multiple factors:

- Mounting accuracy: Installation precision affects overall performance

- Coupling systems: Mechanical connections introduce compliance and backlash

- Load coupling: Application loads create deflection and positioning errors

- Control system tuning: Proper parameter optimization essential for precision

Precision Measurement and Verification

Testing and Calibration Procedures

Verifying electric actuator precision requires sophisticated methods:

- Laser interferometry4: Most accurate method for position measurement

- Linear encoders: High-resolution feedback for position verification

- Dial indicators: Mechanical measurement for basic accuracy checking

- Statistical analysis: Multiple measurements for repeatability assessment

Performance Documentation Standards

Industry standards define precision measurement:

- ISO standards: International specifications for positioning accuracy

- Manufacturer specifications: Factory testing and certification procedures

- Application testing: Field verification under actual operating conditions

- Calibration intervals: Regular verification to maintain precision claims

Anna, a precision machinery designer in Switzerland, initially specified ±0.001mm servo actuators for her assembly equipment. After analyzing her actual tolerance requirements, she discovered ±0.05mm precision was adequate, allowing her to use lower-cost stepper systems that reduced her actuator budget by 60% while meeting all performance requirements.

How Precise Can Pneumatic Cylinders Be in Real Applications?

Pneumatic cylinder precision capabilities are often underestimated, with modern designs and control systems achieving surprisingly accurate positioning for many industrial applications.

Advanced pneumatic cylinders with precision controls can achieve ±0.1-0.5mm positioning accuracy and ±0.05-0.2mm repeatability, while standard cylinders provide ±0.5-2.0mm accuracy, making pneumatic systems suitable for most industrial positioning requirements at significantly lower cost than electric alternatives.

Pneumatic Precision Capabilities

Standard Cylinder Precision

Basic pneumatic cylinders achieve practical positioning accuracy:

- End position accuracy: ±0.5-2.0mm with mechanical stops

- Cushioning precision: ±0.2-1.0mm with proper speed control

- Repeatability: ±0.1-0.5mm for consistent end positioning

- Load sensitivity: ±0.5-1.5mm variation under different loads

Enhanced Precision Systems

Advanced pneumatic designs improve positioning capability:

- Servo-pneumatic systems: ±0.1-0.5mm accuracy with position feedback

- Precision regulators: ±0.05-0.2mm repeatability with pressure control

- Guided cylinders: ±0.2-0.8mm accuracy with integrated linear guides

- Multi-position systems: ±0.3-1.0mm accuracy at intermediate positions

Bepto Precision Cylinder Solutions

Rodless Cylinder Precision Advantages

Our rodless air cylinders offer enhanced accuracy:

| Cylinder Type | Positioning Accuracy | Repeatability | Stroke Range | Precision Features |

|---|---|---|---|---|

| Standard rodless | ±0.5-1.0mm | ±0.2-0.5mm | 100-6000mm | Magnetic coupling |

| Precision rodless | ±0.2-0.5mm | ±0.1-0.3mm | 100-4000mm | Linear guides |

| Servo-pneumatic | ±0.1-0.3mm | ±0.05-0.2mm | 100-2000mm | Position feedback |

| Multi-position | ±0.3-0.8mm | ±0.2-0.5mm | 100-3000mm | Intermediate stops |

Precision Enhancement Techniques

Bepto cylinders incorporate precision-improving features:

- Precision machining: Tight tolerances on critical components

- Quality seals: Low-friction seals reduce stick-slip effects

- Cushioning systems: Adjustable cushioning for consistent deceleration

- Mounting precision: Accurate mounting interfaces and alignment features

Factors Affecting Pneumatic Precision

Air System Quality Impact

Compressed air quality directly affects positioning precision:

- Pressure stability: ±0.1 bar pressure variation affects positioning ±0.2-0.5mm

- Air treatment: Proper filtration and lubrication improve consistency

- Temperature control: Stable air temperature reduces thermal effects

- Flow control: Precise speed control enhances positioning repeatability

Control System Sophistication

Basic Control Methods

Simple pneumatic controls provide adequate precision:

- Mechanical stops: Fixed end positions with ±0.2-0.5mm accuracy

- Cushioning valves: Speed control for consistent deceleration

- Pressure regulation: Force control affecting final position

- Flow restriction: Speed control for improved repeatability

Advanced Control Systems

Sophisticated pneumatic controls enhance precision:

- Position feedback: Linear sensors provide closed-loop control

- Servo valves: Proportional control for precise positioning

- Electronic controls: PLC-based systems with position algorithms

- Pressure profiling: Variable pressure for load compensation

Application-Specific Precision Requirements

Manufacturing Assembly Applications

Typical precision needs in industrial assembly:

- Component insertion: ±1-3mm accuracy usually sufficient

- Part positioning: ±0.5-2mm repeatability for most operations

- Material handling: ±2-5mm precision adequate for transfer operations

- Fixture positioning: ±0.5-1.5mm accuracy for workholding

Packaging and Material Handling

Precision requirements for packaging operations:

- Product positioning: ±1-5mm accuracy for most packaging needs

- Label application: ±0.5-2mm precision for label placement

- Conveyor transfers: ±2-10mm accuracy sufficient for material flow

- Sorting operations: ±1-3mm precision for product diversion

Precision Improvement Strategies

System Design Optimization

Maximizing pneumatic cylinder precision through design:

- Rigid mounting: Stiff mounting systems reduce deflection errors

- Load balancing: Proper load distribution improves accuracy

- Alignment precision: Accurate installation critical for performance

- Environmental control: Temperature and vibration isolation

Control System Enhancement

Improving precision through better control:

- Pressure regulation: Stable supply pressure improves repeatability

- Speed control: Consistent approach speeds enhance positioning

- Load compensation: Adjusting parameters for varying loads

- Feedback systems: Position sensors for closed-loop control

Precision Measurement and Verification

Field Testing Methods

Practical approaches to measuring pneumatic precision:

- Dial indicators: Mechanical measurement for basic accuracy assessment

- Linear scales: Optical measurement for improved accuracy

- Statistical sampling: Multiple measurements for repeatability analysis

- Load testing: Precision verification under actual operating conditions

Performance Optimization

Improving pneumatic cylinder precision through tuning:

- Cushioning adjustment: Optimizing deceleration for consistent stopping

- Pressure optimization: Finding optimal operating pressure for accuracy

- Speed tuning: Adjusting approach speeds for best repeatability

- Environmental compensation: Accounting for temperature and load variations

Miguel, who designs automated assembly equipment in Spain, achieved ±0.3mm positioning accuracy with Bepto rodless cylinders by implementing proper pressure regulation and cushioning adjustment. This precision met his assembly requirements at 65% lower cost than the servo actuators he initially considered, while providing faster cycle times and simpler maintenance.

Which Applications Actually Require Ultra-High Precision Positioning?

Understanding genuine precision requirements helps engineers avoid over-specification and select cost-effective actuator solutions that meet actual performance needs without unnecessary complexity.

True ultra-high precision (±0.01mm or better) is required in only 5-10% of industrial applications, primarily in semiconductor manufacturing, precision machining, and optical assembly, while most industrial automation operates successfully with ±0.1-1.0mm precision that pneumatic cylinders can provide cost-effectively.

Ultra-High Precision Applications

Semiconductor Manufacturing

Chip production demands exceptional positioning accuracy:

- Wafer handling: ±0.005-0.02mm for die placement and alignment

- Wire bonding: ±0.002-0.01mm for electrical connections

- Lithography: ±0.001-0.005mm for pattern alignment

- Assembly operations: ±0.01-0.05mm for component placement

Precision Machining Operations

High-accuracy manufacturing requires tight positioning:

- CNC machining: ±0.005-0.02mm for precision part production

- Grinding operations: ±0.002-0.01mm for surface finishing

- Measurement systems: ±0.001-0.005mm for quality inspection

- Tool positioning: ±0.01-0.05mm for cutting tool placement

Applications Suitable for Pneumatic Precision

Automotive Manufacturing

Vehicle production precision requirements:

| Operation Type | Required Precision | Pneumatic Capability | Cost Advantage |

|---|---|---|---|

| Body welding | ±1-3mm | ±0.5-1.0mm | Excellent match |

| Component assembly | ±0.5-2mm | ±0.2-0.8mm | Good match |

| Material handling | ±2-5mm | ±0.5-2.0mm | Excellent match |

| Fixture positioning | ±1-2mm | ±0.3-1.0mm | Good match |

Packaging Industry Applications

Commercial packaging precision needs:

- Product positioning: ±1-5mm adequate for most package types

- Label application: ±0.5-2mm sufficient for commercial labeling

- Carton forming: ±2-10mm acceptable for packaging operations

- Palletizing: ±5-20mm adequate for automated stacking

Food and Beverage Processing

Sanitary applications with moderate precision needs:

- Product handling: ±2-10mm suitable for food processing

- Filling operations: ±1-5mm adequate for most filling systems

- Packaging: ±2-8mm sufficient for food packaging

- Conveyor systems: ±5-15mm acceptable for material transport

General Manufacturing Applications

Assembly Operations

Typical assembly precision requirements:

- Component insertion: ±1-3mm for most mechanical assemblies

- Fastener installation: ±0.5-2mm for automated fastening

- Part orientation: ±2-5mm for feeding and positioning

- Quality inspection: ±0.5-2mm for go/no-go checking

Material Handling Systems

Precision needs in material movement:

- Pick and place: ±1-5mm for most handling operations

- Sorting systems: ±2-8mm for product diversion

- Transfer mechanisms: ±3-10mm for conveyor interfaces

- Storage systems: ±5-20mm for automated warehousing

Precision Requirement Analysis Framework

Application Assessment Criteria

Determining actual precision needs:

- Product tolerances: What accuracy does the final product require?

- Process capability5: What precision can downstream processes accommodate?

- Quality standards: What positioning accuracy ensures acceptable quality?

- Cost sensitivity: How does precision requirement affect total project cost?

Over-Specification Consequences

Problems caused by excessive precision requirements:

- Unnecessary costs: 3-5x higher actuator and system costs

- Increased complexity: More sophisticated control and maintenance needs

- Extended timelines: Longer design, procurement, and commissioning periods

- Operational challenges: Higher skill requirements and maintenance costs

Cost-Benefit Analysis of Precision

Precision vs. Cost Relationship

Understanding the economic impact of precision requirements:

| Precision Level | Actuator Cost Multiplier | System Complexity | Maintenance Factor |

|---|---|---|---|

| ±1-2mm | 1.0x (baseline) | Simple | 1.0x |

| ±0.5-1mm | 1.5-2x | Moderate | 1.2-1.5x |

| ±0.1-0.5mm | 2-4x | Complex | 1.5-2.5x |

| ±0.01-0.1mm | 4-8x | Very complex | 2.5-4x |

| ±0.001-0.01mm | 8-15x | Extremely complex | 4-8x |

Alternative Precision Solutions

Mechanical Precision Enhancement

Achieving better precision without expensive actuators:

- Precision fixtures: Mechanical references improve positioning accuracy

- Guide systems: Linear guides reduce positioning errors

- Compliance systems: Flexible couplings accommodate positioning errors

- Calibration methods: Software compensation for systematic errors

Process Design Optimization

Designing processes to accommodate available precision:

- Tolerance stacking: Designing assemblies to accommodate positioning errors

- Self-aligning features: Product designs that correct positioning errors

- Process flexibility: Operations that function with wider positioning tolerances

- Quality systems: Inspection and correction rather than perfect positioning

Industry-Specific Precision Guidelines

Electronics Manufacturing

Precision requirements vary by application:

- PCB assembly: ±0.1-0.5mm for most component placement

- Connector assembly: ±0.05-0.2mm for electrical connections

- Housing assembly: ±0.5-2mm for mechanical enclosures

- Testing operations: ±0.2-1mm for automated testing

Pharmaceutical Manufacturing

Precision needs in drug production:

- Tablet handling: ±1-3mm for most pharmaceutical operations

- Packaging operations: ±0.5-2mm for blister pack formation

- Filling systems: ±0.2-1mm for liquid filling operations

- Labeling: ±0.5-2mm for pharmaceutical labeling

Sarah, who manages automation projects for a UK consumer goods manufacturer, conducted a precision audit of her production lines. She discovered that 85% of her positioning requirements were within ±1mm, allowing her to replace expensive servo systems with Bepto rodless cylinders. This change reduced her automation costs by $280,000 while maintaining all quality standards and improving system reliability.

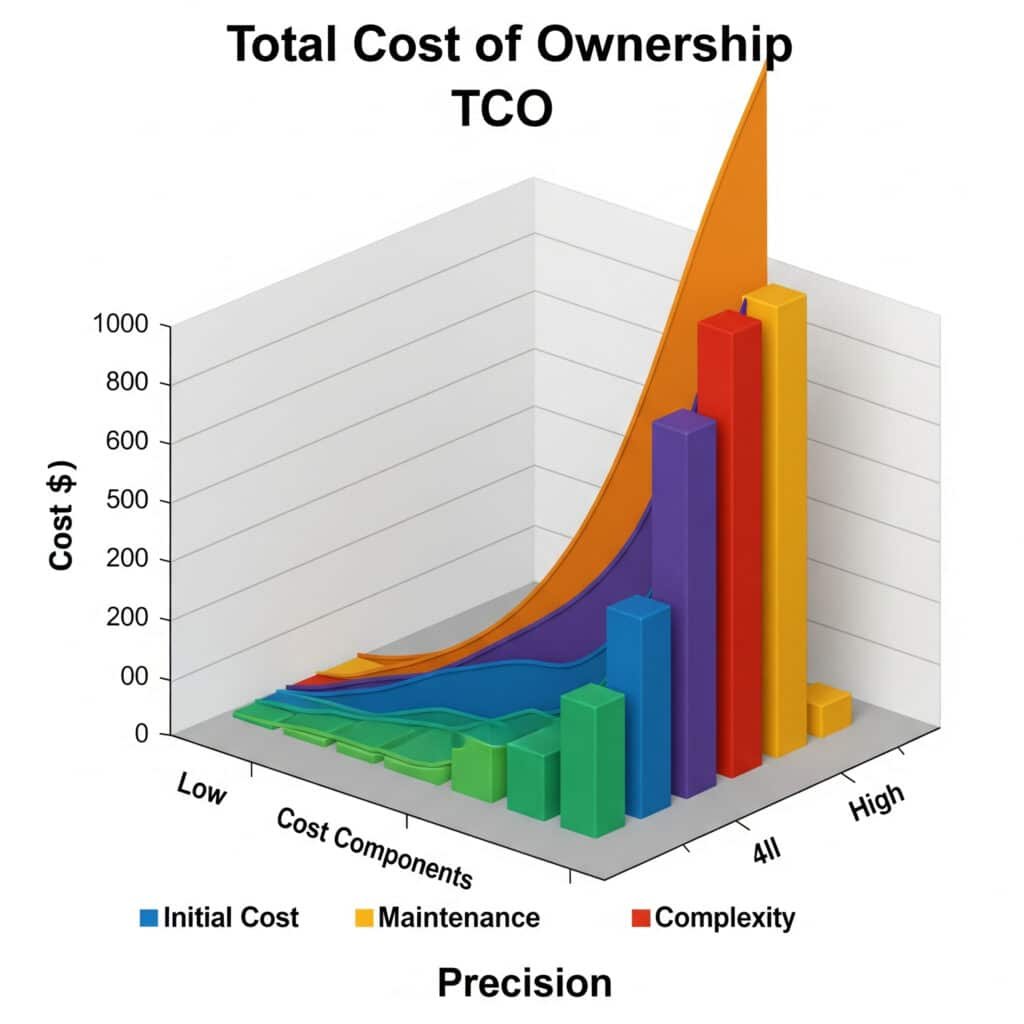

How Do Cost and Complexity Scale with Precision Requirements?

Understanding the exponential relationship between precision requirements and system costs helps engineers make informed decisions about actuator selection and specification.

Actuator costs increase exponentially with precision requirements, with ±0.01mm systems costing 8-15 times more than ±1mm systems, while complexity, maintenance, and training costs multiply even faster, making precision specification critical for project economics and long-term success.

Cost Scaling Analysis

Actuator Cost Progression

Precision requirements drive exponential cost increases:

| Precision Level | Pneumatic Cost | Electric Cost | Cost Multiplier | Bepto Advantage |

|---|---|---|---|---|

| ±2-5mm | $100-$400 | $500-$1500 | 1.0x | 70-80% savings |

| ±1-2mm | $150-$600 | $800-$2500 | 1.5-2x | 65-75% savings |

| ±0.5-1mm | $200-$800 | $1500-$4000 | 2-3x | 60-70% savings |

| ±0.1-0.5mm | $300-$1200 | $3000-$8000 | 4-6x | Limited pneumatic |

| ±0.01-0.1mm | Not applicable | $6000-$15000 | 8-12x | Electric required |

| ±0.001-0.01mm | Not applicable | $12000-$30000 | 15-25x | Electric required |

System Complexity Escalation

Supporting Component Requirements

Precision demands increasingly sophisticated support systems:

- Basic systems: Simple valves and basic controls

- Moderate precision: Servo valves and position feedback

- High precision: Advanced controllers and environmental isolation

- Ultra-high precision: Clean rooms and vibration isolation

Control System Complexity

Precision requirements drive control sophistication:

| Precision Level | Control Complexity | Programming Hours | Maintenance Skill |

|---|---|---|---|

| ±2-5mm | Basic on/off | 1-4 hours | Mechanical |

| ±1-2mm | Simple positioning | 4-16 hours | Basic electrical |

| ±0.5-1mm | Closed-loop control | 16-40 hours | Advanced electrical |

| ±0.1-0.5mm | Servo control | 40-120 hours | Programming expert |

| ±0.01-0.1mm | Advanced servo | 120-300 hours | Specialist required |

Total Cost of Ownership Impact

Five-Year Cost Projection

Precision requirements affect all cost categories:

| Cost Category | ±2mm System | ±0.5mm System | ±0.1mm System | ±0.01mm System |

|---|---|---|---|---|

| Initial equipment | $2,000 | $8,000 | $20,000 | $50,000 |

| Installation | $500 | $2,000 | $8,000 | $20,000 |

| Training | $500 | $2,000 | $8,000 | $20,000 |

| Annual maintenance | $200 | $800 | $3,000 | $8,000 |

| 5-year total | $4,000 | $16,000 | $51,000 | $140,000 |

Environmental and Infrastructure Costs

Precision Environment Requirements

Higher precision demands controlled environments:

- Temperature control: ±0.1°C for ultra-high precision systems

- Vibration isolation: Specialized foundations and isolation systems

- Clean environments: Filtered air and contamination control

- Humidity control: Stable moisture levels for dimensional stability

Infrastructure Investment

Precision systems require supporting infrastructure:

- Power quality: Regulated power supplies and UPS systems

- Network infrastructure: High-speed communication systems

- Calibration equipment: Precision measurement and verification tools

- Maintenance facilities: Clean rooms and specialized work areas

Precision Optimization Strategies

Right-Sizing Precision Requirements

Avoiding over-specification through careful analysis:

- Tolerance analysis: Understanding actual precision needs

- Process capability: Matching precision to manufacturing requirements

- Quality systems: Using inspection rather than perfect positioning

- Design optimization: Creating products that accommodate positioning errors

Bepto Cost-Effective Solutions

Pneumatic Precision Optimization

Maximizing pneumatic cylinder precision cost-effectively:

- System design: Proper mounting and alignment for best accuracy

- Control optimization: Pressure and speed control for repeatability

- Quality components: Precision-manufactured cylinders and controls

- Application engineering: Matching cylinder capabilities to requirements

Hybrid Approaches

Combining technologies for optimal cost-performance:

- Coarse/fine positioning: Pneumatic for rapid movement, electric for precision

- Selective precision: High precision only where absolutely required

- Mechanical precision: Using fixtures and guides to enhance positioning

- Process compensation: Software correction for positioning errors

Decision Framework for Precision Selection

Precision Requirement Assessment

Systematic approach to determining actual needs:

- Product analysis: What precision does the end product require?

- Process capability: What can downstream processes accommodate?

- Quality impact: How does positioning error affect final quality?

- Cost sensitivity: What precision level optimizes total project cost?

Technology Selection Matrix

Choosing optimal actuator technology based on precision needs:

| Precision Requirement | Recommended Technology | Cost Optimization | Performance Trade-offs |

|---|---|---|---|

| ±5-10mm | Standard pneumatic | Lowest cost | Basic positioning |

| ±1-3mm | Precision pneumatic | Good value | Moderate precision |

| ±0.3-1mm | Advanced pneumatic | Balanced cost | Good precision |

| ±0.1-0.3mm | Basic electric | Higher cost | Excellent precision |

| ±0.01-0.1mm | Servo electric | High cost | Superior precision |

| <±0.01mm | Ultra-precision electric | Extreme cost | Ultimate precision |

Return on Investment Analysis

Precision Investment Justification

Determining when high precision pays for itself:

- Quality improvement: Reduced scrap and rework costs

- Process capability: Enabling new products or processes

- Competitive advantage: Market differentiation through precision

- Automation benefits: Reduced labor and improved consistency

Cost-Benefit Optimization

Finding the optimal precision level:

- Marginal cost analysis: Cost of each precision increment

- Quality impact assessment: Benefit of improved positioning

- Risk evaluation: Cost of positioning errors versus precision investment

- Long-term considerations: Technology evolution and obsolescence

James, a project engineer at a German automotive supplier, initially specified ±0.1mm servo actuators for his assembly line based on drawing tolerances. After conducting a process capability study, he discovered ±0.5mm positioning was adequate, allowing him to use Bepto rodless cylinders that reduced his project cost from $180,000 to $65,000 while meeting all production requirements and improving cycle times by 25%.

Conclusion

Electric actuators provide superior precision (±0.001-0.01mm) essential for specialized applications, while pneumatic cylinders offer adequate precision (±0.1-1.0mm) for most industrial needs at significantly lower cost and complexity, making precision requirement analysis critical for optimal actuator selection.

FAQs About Precision in Cylinders vs Electric Actuators

Q: Can pneumatic cylinders achieve sub-millimeter positioning accuracy?

Yes, advanced pneumatic cylinders with precision controls can achieve ±0.1-0.5mm positioning accuracy, which is adequate for most industrial applications and significantly more cost-effective than electric actuators providing unnecessary ultra-high precision.

Q: What percentage of industrial applications actually require ultra-high precision?

Only 5-10% of industrial applications truly require precision better than ±0.1mm, with most manufacturing, packaging, and assembly operations functioning successfully with ±0.5-2.0mm positioning accuracy that pneumatic systems provide cost-effectively.

Q: How much more do high-precision electric actuators cost compared to pneumatic cylinders?

High-precision electric actuators (±0.01mm) cost 8-15 times more than equivalent pneumatic cylinders (±0.5mm), with total system costs including installation, programming, and maintenance often 10-20 times higher.

Q: Do rodless cylinders provide better precision than standard cylinders?

Yes, rodless air cylinders typically offer ±0.2-0.8mm positioning accuracy compared to ±0.5-2.0mm for standard cylinders, due to their guided design and reduced side loading, making them excellent for long-stroke precision applications.

Q: Can I improve pneumatic cylinder precision without switching to electric actuators?

Yes, pneumatic precision can be enhanced through proper pressure regulation, speed control, mechanical guides, position feedback systems, and careful system design, often achieving adequate precision at fraction of electric actuator costs.

-

Discover the design, types, and operational advantages of rodless pneumatic cylinders in industrial automation. ↩

-

Learn how microstepping works to increase the resolution and smooth the motion of a stepper motor. ↩

-

Explore the principles of Proportional-Integral-Derivative (PID) controllers, a common and powerful feedback control loop mechanism. ↩

-

Understand the physics behind laser interferometry and its application as a high-precision measurement tool in science and engineering. ↩

-

Learn about process capability analysis, a statistical tool used to determine if a manufacturing process is capable of producing parts within specified limits. ↩