Der Mini-Pneumatikzylinder der MA-Serie verfügt über ein kompaktes, leichtes Aluminiumgehäuse, das sich ideal für Automatisierungssysteme mit begrenztem Platzangebot eignet. Er wurde für präzise lineare Bewegungen entwickelt und bietet einen reibungslosen Betrieb, eine schnelle Reaktion und eine hohe Lebensdauer. Er ist in verschiedenen Bohrungsgrößen erhältlich und eignet sich perfekt für OEM-Maschinen, Robotik und industrielle Automatisierung.

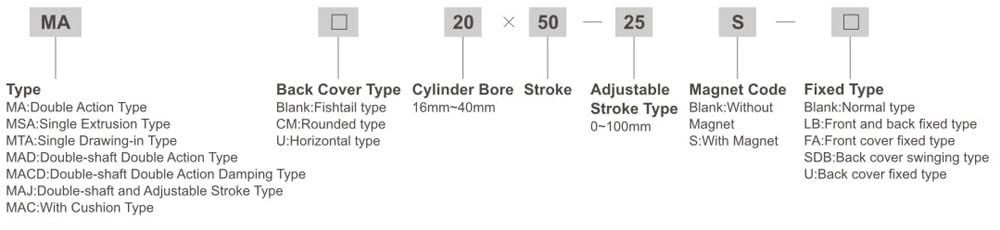

| Bohrung(mm) | 16 | 20 | 25 | 32 | 40 | |

| Bewegungsmuster | Double Action oder Single Action | |||||

| Arbeitsmedium | Luft | |||||

| Fester Typ | Normal Typ LB/Typ FA/Typ SDB/Typ U/Typ | |||||

| Betriebsspannungsbereich | 0,1~0,9MPa | |||||

| Gesicherte Druckbeständigkeit | 1,35MPa | |||||

| Betriebstemperaturbereich | -5~70℃ | |||||

| Betriebsdrehzahlbereich | 50~800mm/s | |||||

| Puffer Typ | Standard Typ | Anti-Crash-Kissen | ||||

| Dämpfung Typ | – | Verstellbares Kissen | ||||

| Größe der Rohre | M5×0.8 | G1/8″ | ||||

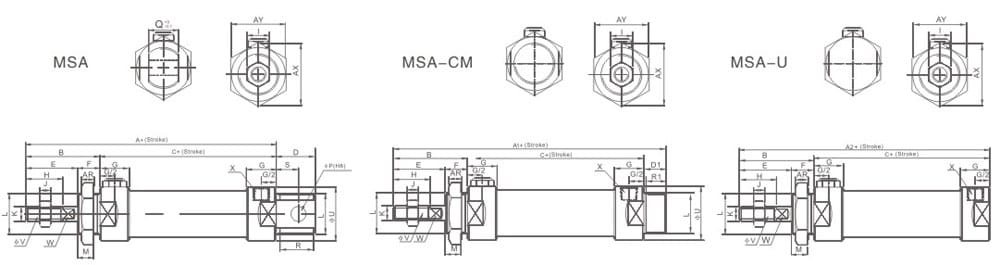

| Bohrung/Symbol | A | A1 | A2 | B | C | D | D1 | E | F | G | H | I | J | K |

| 16 | 114 | 114 | 98 | 38 | 60 | 16 | 16 | 22 | 16 | 10 | 16 | 10 | 5 | M6×1 |

| 20 | 137 | 128 | 116 | 40 | 76 | 21 | 12 | 28 | 12 | 16 | 20 | 12 | 6 | M8×1.25 |

| 25 | 141 | 134 | 120 | 44 | 76 | 21 | 14 | 30 | 14 | 16 | 22 | 17 | 6 | M10×1.25 |

| 32 | 147 | 134 | 120 | 44 | 76 | 27 | 14 | 30 | 14 | 16 | 22 | 17 | 6 | M10×1.25 |

| 40 | 149 | 136 | 122 | 46 | 76 | 27 | 14 | 32 | 14 | 16.7 | 24 | 17 | 7 | M12×1.25 |

| Bohrung/Symbol | L | M | P | Q | R | R1 | S | U | V | W | X | AR | AX | AY |

| 16 | M16×1.5 | 14 | 6 | 12 | 14 | 14 | 9 | 21 | 6 | 5 | M5 | 6 | 24 | 27.5 |

| 20 | M22×1.5 | 10 | 8 | 16 | 19 | 10 | 12 | 27 | 8 | 6 | G1/8″ | 7 | 33 | 29 |

| 25 | M22×1.5 | 12 | 8 | 16 | 19 | 12 | 12 | 30 | 10 | 8 | G1/8″ | 7 | 33 | 29 |

| 32 | M24×2.0 | 12 | 10 | 16 | 25 | 12 | 15 | 35 | 12 | 10 | G1/8″ | 8 | 37 | 32 |

| 40 | M30×2.0 | 12 | 12 | 20 | 25 | 12 | 15 | 41.6 | 16 | 14 | G1/8″ | 9 | 47 | 41 |

| Symbol | A | A1 | A2 | B | C | D | D1 | E | F | G | H | I | J | ||||

| Bohrung/Hub | 0-50 | 51-100 | 0-50 | 51-100 | 0-50 | 51-100 | 0-50 | 51-100 | |||||||||

| 16 | 114 | 139 | 128 | 153 | 98 | 123 | 38 | 60 | 85 | 16 | 16 | 22 | 16 | 10 | 16 | 10 | 5 |

| 20 | 137 | 162 | 134 | 159 | 116 | 141 | 40 | 76 | 101 | 21 | 12 | 28 | 12 | 16 | 20 | 12 | 6 |

| 25 | 141 | 166 | 134 | 159 | 120 | 145 | 44 | 76 | 101 | 21 | 14 | 30 | 14 | 16 | 22 | 17 | 6 |

| 32 | 147 | 172 | 136 | 161 | 120 | 145 | 44 | 76 | 101 | 27 | 14 | 30 | 14 | 16 | 22 | 17 | 6 |

| 40 | 149 | 174 | 122 | 144 | 122 | 147 | 46 | 76 | 101 | 27 | 14 | 32 | 14 | 22 | 24 | 17 | 7 |

| Innendurchmesser/Symbol | K | L | M | P | Q | R | R1 | S | U | V | W | X | AR | AX | AY |

| 16 | M6×1 | M16×1.5 | 14 | 6 | 12 | 14 | 14 | 9 | 21 | 6 | 5 | M5 | 6 | 25 | 22 |

| 20 | M8×1.25 | M22×1.5 | 10 | 8 | 16 | 19 | 10 | 12 | 27 | 8 | 6 | G1/8″ | 7 | 33 | 29 |

| 25 | M10×1.25 | M22×1.5 | 12 | 8 | 16 | 19 | 12 | 12 | 30 | 10 | 8 | G1/8″ | 7 | 33 | 29 |

| 32 | M10×1.25 | M24×2.0 | 12 | 10 | 16 | 25 | 12 | 15 | 35 | 12 | 10 | G1/8″ | 8 | 37 | 32 |

| 40 | M12×1.25 | M30×2.0 | 12 | 12 | 20 | 25 | 12 | 15 | 41.6 | 16 | 14 | G1/8″ | 9 | 47 | 41 |

| Innendurchmesser/Symbol | A | A1 | B | C | E | F | G | H | I | J | K |

| 16 | 136 | 135 | 38 | 60 | 22 | 16 | 10 | 16 | 10 | 5 | M6x1 |

| 20 | 156 | 153 | 40 | 76 | 28 | 12 | 16 | 20 | 12 | 6 | M8x1.25 |

| 25 | 164 | 161 | 44 | 76 | 30 | 14 | 16 | 22 | 17 | 6 | M10x1.25 |

| 32 | 164 | 161 | 44 | 76 | 30 | 14 | 16 | 22 | 17 | 6 | M10x1.25 |

| 40 | 168 | 164 | 46 | 76 | 32 | 14 | 16.7 | 24 | 17 | 7 | M12x1.25 |

| Innendurchmesser/Symbol | L | M | U | V | W | X | AR | AX | AY | T |

| 16 | M16x1,5 | 14 | 21 | 6 | 5 | M5 | 6 | 25 | 22 | 16 |

| 20 | M22x1,5 | 10 | 29 | 9 | 6 | G1/8″ | 7 | 33 | 29 | 19 |

| 25 | M22x1,5 | 12 | 34 | 10 | 8 | G1/8″ | 7 | 33 | 29 | 19 |

| 32 | M24x1,5 | 12 | 39.5 | 12 | 10 | G1/8″ | 8 | 37 | 32 | 21 |

| 40 | M30x2.0 | 12 | 41.6 | 16 | 12 | G1/8″ | 9 | 47 | 41 | 21 |

| NEIN. | Bezeichnung | NEIN. | Bezeichnung |

| 1 | Kolbenstangenmutter | 2 | Kolbenstange |

| 3 | Dichtungsring der vorderen Abdeckung | 4 | Geöltes Lager |

| 5 | Mutter der Frontabdeckung | 6 | Titelblatt |

| 7 | Rohr aus rostfreiem Stahl | 8 | Anti-Crash-Kissen |

| 9 | Kolben | 10 | Kolben O-Ring |

| 11 | Magnet (optional) | 12 | Ring tragen |

| 13 | Dichtungskissen | 14 | Innensechskantschraube |

| 15 | Umschlag Rückseite |

| Bohrung(mm) | Standard-Hub | Max. Hub | Zulässiger Hub |

| 16 | 25 50 75 80 100 125 160 175 200 | 300 | 500 |

| 20 | 25 50 75 80 100 125 160 175 200 250 300 | 500 | 650 |

| 25 | 25 50 75 80 100 125 160 175 200 250 300 350 400 450 500 | 500 | 650 |

| 32 | 25 50 75 80 100 125 160 175 200 250 300 350 400 450 500 | 500 | 650 |

| 40 | 25 50 75 80 100 125 160 175 200 250 300 350 400 450 500 | 500 | 650 |

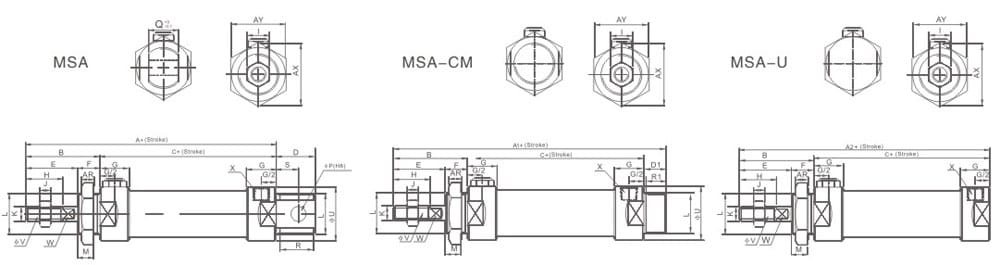

| Bohrung/Symbol | A | A1 | A2 | B | C | D | D1 | E | F | G | H | I | J | K |

| 16 | 114 | 114 | 98 | 38 | 60 | 16 | 16 | 22 | 16 | 10 | 16 | 10 | 5 | M6×1 |

| 20 | 137 | 128 | 116 | 40 | 76 | 21 | 12 | 28 | 12 | 16 | 20 | 12 | 6 | M8×1.25 |

| 25 | 141 | 134 | 120 | 44 | 76 | 21 | 14 | 30 | 14 | 16 | 22 | 17 | 6 | M10×1.25 |

| 32 | 147 | 134 | 120 | 44 | 76 | 27 | 14 | 30 | 14 | 16 | 22 | 17 | 6 | M10×1.25 |

| 40 | 149 | 136 | 122 | 46 | 76 | 27 | 14 | 32 | 14 | 16.7 | 24 | 17 | 7 | M12×1.25 |

| Bohrung/Symbol | L | M | P | Q | R | R1 | S | U | V | W | X | AR | AX | AY |

| 16 | M16×1.5 | 14 | 6 | 12 | 14 | 14 | 9 | 21 | 6 | 5 | M5 | 6 | 24 | 27.5 |

| 20 | M22×1.5 | 10 | 8 | 16 | 19 | 10 | 12 | 27 | 8 | 6 | G1/8″ | 7 | 33 | 29 |

| 25 | M22×1.5 | 12 | 8 | 16 | 19 | 12 | 12 | 30 | 10 | 8 | G1/8″ | 7 | 33 | 29 |

| 32 | M24×2.0 | 12 | 10 | 16 | 25 | 12 | 15 | 35 | 12 | 10 | G1/8″ | 8 | 37 | 32 |

| 40 | M30×2.0 | 12 | 12 | 20 | 25 | 12 | 15 | 41.6 | 16 | 14 | G1/8″ | 9 | 47 | 41 |

| Symbol | A | A1 | A2 | B | C | D | D1 | E | F | G | H | I | J | ||||

| Bohrung/Hub | 0-50 | 51-100 | 0-50 | 51-100 | 0-50 | 51-100 | 0-50 | 51-100 | |||||||||

| 16 | 114 | 139 | 128 | 153 | 98 | 123 | 38 | 60 | 85 | 16 | 16 | 22 | 16 | 10 | 16 | 10 | 5 |

| 20 | 137 | 162 | 134 | 159 | 116 | 141 | 40 | 76 | 101 | 21 | 12 | 28 | 12 | 16 | 20 | 12 | 6 |

| 25 | 141 | 166 | 134 | 159 | 120 | 145 | 44 | 76 | 101 | 21 | 14 | 30 | 14 | 16 | 22 | 17 | 6 |

| 32 | 147 | 172 | 136 | 161 | 120 | 145 | 44 | 76 | 101 | 27 | 14 | 30 | 14 | 16 | 22 | 17 | 6 |

| 40 | 149 | 174 | 122 | 144 | 122 | 147 | 46 | 76 | 101 | 27 | 14 | 32 | 14 | 22 | 24 | 17 | 7 |

| Innendurchmesser/Symbol | K | L | M | P | Q | R | R1 | S | U | V | W | X | AR | AX | AY |

| 16 | M6×1 | M16×1.5 | 14 | 6 | 12 | 14 | 14 | 9 | 21 | 6 | 5 | M5 | 6 | 25 | 22 |

| 20 | M8×1.25 | M22×1.5 | 10 | 8 | 16 | 19 | 10 | 12 | 27 | 8 | 6 | G1/8″ | 7 | 33 | 29 |

| 25 | M10×1.25 | M22×1.5 | 12 | 8 | 16 | 19 | 12 | 12 | 30 | 10 | 8 | G1/8″ | 7 | 33 | 29 |

| 32 | M10×1.25 | M24×2.0 | 12 | 10 | 16 | 25 | 12 | 15 | 35 | 12 | 10 | G1/8″ | 8 | 37 | 32 |

| 40 | M12×1.25 | M30×2.0 | 12 | 12 | 20 | 25 | 12 | 15 | 41.6 | 16 | 14 | G1/8″ | 9 | 47 | 41 |

| Innendurchmesser/Symbol | A | A1 | B | C | E | F | G | H | I | J | K |

| 16 | 136 | 135 | 38 | 60 | 22 | 16 | 10 | 16 | 10 | 5 | M6x1 |

| 20 | 156 | 153 | 40 | 76 | 28 | 12 | 16 | 20 | 12 | 6 | M8x1.25 |

| 25 | 164 | 161 | 44 | 76 | 30 | 14 | 16 | 22 | 17 | 6 | M10x1.25 |

| 32 | 164 | 161 | 44 | 76 | 30 | 14 | 16 | 22 | 17 | 6 | M10x1.25 |

| 40 | 168 | 164 | 46 | 76 | 32 | 14 | 16.7 | 24 | 17 | 7 | M12x1.25 |

| Innendurchmesser/Symbol | L | M | U | V | W | X | AR | AX | AY | T |

| 16 | M16x1,5 | 14 | 21 | 6 | 5 | M5 | 6 | 25 | 22 | 16 |

| 20 | M22x1,5 | 10 | 29 | 9 | 6 | G1/8″ | 7 | 33 | 29 | 19 |

| 25 | M22x1,5 | 12 | 34 | 10 | 8 | G1/8″ | 7 | 33 | 29 | 19 |

| 32 | M24x1,5 | 12 | 39.5 | 12 | 10 | G1/8″ | 8 | 37 | 32 | 21 |

| 40 | M30x2.0 | 12 | 41.6 | 16 | 12 | G1/8″ | 9 | 47 | 41 | 21 |

| NEIN. | Bezeichnung | NEIN. | Bezeichnung |

| 1 | Kolbenstangenmutter | 2 | Kolbenstange |

| 3 | Dichtungsring der vorderen Abdeckung | 4 | Geöltes Lager |

| 5 | Mutter der Frontabdeckung | 6 | Titelblatt |

| 7 | Rohr aus rostfreiem Stahl | 8 | Anti-Crash-Kissen |

| 9 | Kolben | 10 | Kolben O-Ring |

| 11 | Magnet (optional) | 12 | Ring tragen |

| 13 | Dichtungskissen | 14 | Innensechskantschraube |

| 15 | Umschlag Rückseite |

| Bohrung(mm) | Standard-Hub | Max. Hub | Zulässiger Hub |

| 16 | 25 50 75 80 100 125 160 175 200 | 300 | 500 |

| 20 | 25 50 75 80 100 125 160 175 200 250 300 | 500 | 650 |

| 25 | 25 50 75 80 100 125 160 175 200 250 300 350 400 450 500 | 500 | 650 |

| 32 | 25 50 75 80 100 125 160 175 200 250 300 350 400 450 500 | 500 | 650 |

| 40 | 25 50 75 80 100 125 160 175 200 250 300 350 400 450 500 | 500 | 650 |