Engineers frequently struggle with pneumatic terminology, creating confusion during component selection and leading to costly specification errors in industrial automation projects.

Yes, all cylinders are considered actuators. Specifically, cylinders are linear actuators that convert compressed air energy into straight-line mechanical motion, making them a specialized subset of the broader actuator family that includes rotary units, grippers, and other motion-producing devices.

Last month, David from a Michigan automotive plant called us frustrated because his supplier kept referring to his “cylinder requirements” as “linear actuator specifications,” leaving him uncertain about component compatibility.

Table of Contents

- What Exactly Defines an Actuator in Pneumatic Applications?

- How Do Cylinders Fit Within the Complete Actuator Classification System?

- What Are the Key Differences Between Cylinder Types and Other Actuators?

- Why Does Understanding Actuator Classification Matter for Your System Design?

What Exactly Defines an Actuator in Pneumatic Applications?

Understanding actuator fundamentals helps engineers make informed decisions and communicate effectively with suppliers about system requirements.

An actuator is any device that converts energy into mechanical motion. In pneumatic systems, actuators transform compressed air energy into linear, rotary, or specialized movement to perform useful work in industrial applications.

Basic Actuator Operating Principles

Energy Conversion Process

All pneumatic actuators follow the same fundamental mechanism:

- Input energy: Compressed air from system pressure

- Conversion mechanism: Internal components transform air pressure into mechanical force

- Output motion: Useful mechanical movement for industrial tasks

- Control system: Solenoid Valve1 or manual controls regulate operation

Primary Motion Categories

Pneumatic actuators produce three main types of movement:

- Linear motion: Straight-line push/pull operations

- Rotary motion: Angular positioning and rotation

- Specialized motion: Gripping, clamping, or combined movements

System Integration Requirements

Essential Supporting Components

All actuators require complementary pneumatic elements:

- Air preparation: Filtration, regulation, and lubrication systems

- Connection hardware: Pneumatic fittings and tubing

- Control valves: Direction and flow control devices

- Feedback systems: Position monitoring and performance tracking

Performance Specification Parameters

Key characteristics define actuator capabilities:

- Force output: Maximum working force or torque capacity

- Operating speed: Cycle time and velocity specifications

- Travel range: Maximum stroke length or rotation angle

- Positioning accuracy: Repeatability and precision requirements

Industry Classification Standards

Professional Terminology Hierarchy

Pneumatic industry terminology follows established patterns:

- Actuator: Umbrella term for all motion-producing devices

- Linear actuator: Specific category for straight-line motion devices

- Cylinder: Common industry name for pneumatic linear actuators

- Motor: Continuous rotation pneumatic devices

How Do Cylinders Fit Within the Complete Actuator Classification System?

Cylinders represent the most common and versatile category of pneumatic actuators used across industrial automation applications.

Cylinders are linear actuators that use piston-cylinder arrangements to convert compressed air pressure into straight-line mechanical motion, accounting for approximately 75% of all pneumatic actuators installed in manufacturing facilities worldwide.

Comprehensive Linear Actuator Categories

Standard Cylinder Classifications

All cylinder variants fall under the linear actuator umbrella:

| Cylinder Type | Motion Characteristic | Typical Force Range | Primary Applications |

|---|---|---|---|

| Standard Cylinder | Rod extends/retracts | 10-5000 lbf | Push/pull operations |

| Rodless Cylinder2 | Carriage moves along body | 50-3000 lbf | Long stroke positioning |

| Mini Cylinder | Compact linear motion | 5-200 lbf | Precision applications |

| Double Rod Cylinder | Rods extend both ends | 25-2500 lbf | Balanced loading |

Construction and Design Variations

Different cylinder designs serve specific operational needs:

- Single-acting3: Air pressure extends, spring returns

- Double-acting: Pneumatic control in both directions

- Telescopic: Multiple stages for extended stroke capability

- Guided: Integrated linear guides for enhanced precision

Actuator Performance Comparison Matrix

Cylinders vs Alternative Actuator Types

| Actuator Category | Motion Type | Speed Range | Precision Level | Cost Factor |

|---|---|---|---|---|

| Standard Cylinder | Linear | High | Good | Low |

| Rodless Air Cylinder | Linear | Medium | Excellent | Medium |

| Rotary Actuator4 | Angular | Medium | Good | Medium |

| Pneumatic Gripper5 | Clamping | High | Good | Medium |

Market Distribution Analysis

Industry Usage Statistics

Based on our extensive experience supplying pneumatic components:

- Linear actuators (cylinders): 75% of total pneumatic actuator market

- Rotary actuators: 18% of industrial applications

- Specialized actuators: 7% for unique motion requirements

Application-Specific Preferences

Different industries demonstrate distinct actuator selection patterns:

- Manufacturing: Heavy reliance on standard and rodless pneumatic cylinders

- Packaging: Balanced mix of cylinders and pneumatic grippers

- Process control: Rotary actuators dominate valve automation

- Assembly operations: Mini cylinders for precision positioning

Sarah, who manages procurement for a German packaging equipment manufacturer, was initially confused when her engineering team requested “linear actuators” instead of “cylinders.” After understanding that cylinders are simply the most common type of linear actuator, she successfully sourced Bepto rodless cylinders that reduced her component costs by 40% while maintaining OEM performance standards.

What Are the Key Differences Between Cylinder Types and Other Actuators?

Understanding distinct actuator characteristics helps engineers select optimal components for specific motion requirements and performance specifications.

Cylinders produce linear motion through piston-cylinder mechanisms, rotary actuators create angular positioning via vane or gear systems, while specialized actuators like grippers provide clamping action, each optimized for different industrial automation needs.

Linear Motion Actuators (Cylinder Family)

Standard Pneumatic Cylinders

Traditional piston-rod designs for general applications:

- Single rod configuration: Most common setup for push/pull operations

- Compact designs: Space-saving solutions for confined installations

- Heavy-duty variants: Reinforced construction for demanding environments

- Custom modifications: Tailored solutions for specific requirements

Rodless Cylinder Specialties

Advanced linear actuators for extended stroke applications:

- Magnetic coupling: Sealed operation for clean room environments

- Mechanical coupling: Higher force transmission and reliability

- Integrated guidance: Built-in precision linear bearing systems

- Multi-position capability: Intermediate stopping positions available

Rotary Motion Actuators

Vane Actuator Systems

Simple rotary motion for valve control applications:

- Quarter-turn units: 90-degree valve operation

- Multi-turn capability: Extended rotation for complex positioning

- Spring return options: Fail-safe positioning for safety applications

- Adjustable angle: Variable rotation settings

Rack and Pinion Designs

High-torque rotary positioning solutions:

- Standard torque: Balanced performance for general applications

- High-torque variants: Heavy-duty industrial requirements

- Precision models: Accurate angular positioning capability

- Multi-turn options: Extended rotation range

Specialized Motion Actuators

Pneumatic Gripper Applications

Handling and clamping operations:

- Parallel jaw: Straight-line gripping motion

- Angular jaw: Pivoting clamping action

- Three-finger designs: Complex part manipulation

- Magnetic variants: Ferrous material handling

Performance Selection Guide

Application-Based Actuator Selection

| Motion Requirement | Space Constraint | Force Needed | Optimal Solution |

|---|---|---|---|

| Short linear stroke | Standard | Medium | Standard Cylinder |

| Long linear positioning | Limited | Medium-High | Rodless Cylinder |

| Rotational positioning | Standard | High torque | Rotary Actuator |

| Part gripping/handling | Compact | Variable | Pneumatic Gripper |

Bepto Competitive Advantages

Our comprehensive actuator solutions provide:

- Cost savings: 40-60% reduction compared to OEM pricing

- Fast delivery: 5-10 day shipping versus 4-12 week OEM lead times

- Technical support: Direct access to experienced pneumatic engineers

- Quality assurance: OEM-equivalent performance with comprehensive warranties

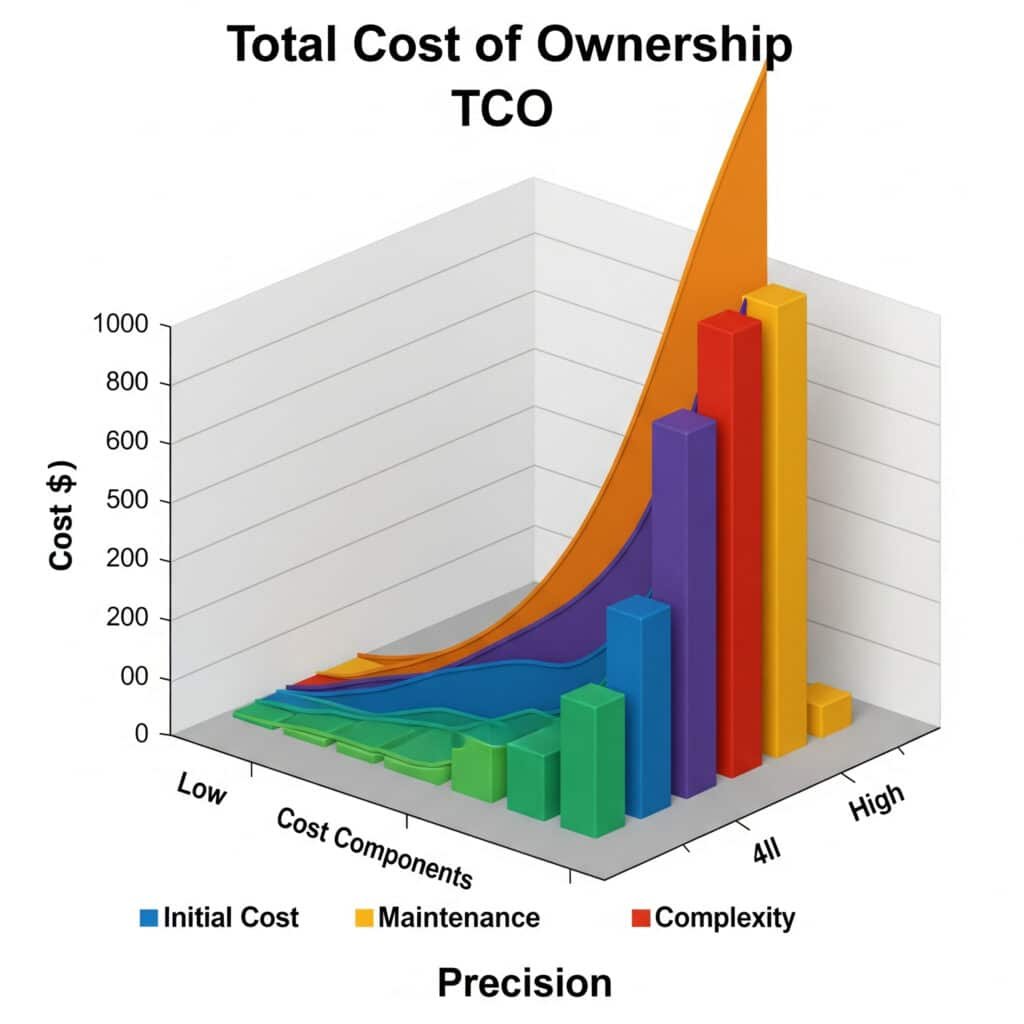

Why Does Understanding Actuator Classification Matter for Your System Design?

Proper actuator classification knowledge directly impacts component selection accuracy, system performance optimization, and long-term maintenance cost control.

Understanding actuator classification ensures correct component specification, enables effective supplier communication, facilitates maintenance planning, and helps identify significant cost-saving opportunities through strategic component selection and sourcing.

Specification Accuracy Benefits

Avoiding Costly Selection Errors

Correct classification prevents expensive mistakes:

- Motion type mismatch: Linear versus rotary requirement confusion

- Performance gaps: Inadequate force, speed, or precision specifications

- Integration problems: Mounting and connection compatibility issues

- System conflicts: Component interaction and control complications

Enhanced Supplier Communication

Clear terminology improves procurement efficiency:

- Technical discussions: Precise component identification and specification

- Quote accuracy: Correct pricing and delivery information

- Order fulfillment: Right components shipped on first attempt

- Support quality: More effective technical assistance and troubleshooting

Cost Optimization Strategies

Bepto Value Proposition Comparison

| Benefit Category | Traditional OEM | Bepto Approach | Your Advantage |

|---|---|---|---|

| Component pricing | Premium rates | 40-60% savings | Significant cost reduction |

| Delivery timeline | 4-12 weeks | 5-10 days | Faster project completion |

| Technical support | Multi-tier system | Direct engineer access | Superior problem resolution |

| Customization | Limited flexibility | Adaptable solutions | Optimized performance |

Maintenance Planning Advantages

Classification knowledge improves operational efficiency:

- Inventory management: Stock appropriate replacement components

- Service scheduling: Plan maintenance based on actuator requirements

- Troubleshooting: Faster problem identification and resolution

- Upgrade strategies: Better long-term replacement planning

System Integration Excellence

Component Compatibility Optimization

Proper classification enables superior system design:

- Air preparation: Correctly sized filtration and regulation systems

- Control integration: Appropriate solenoid valve selection and sizing

- Connection planning: Proper pneumatic fittings and tubing specification

- Safety systems: Correct manual valve placement and emergency controls

Tom, a maintenance supervisor at an Ohio manufacturing facility, reduced his pneumatic maintenance costs by 35% after learning proper actuator classification. This knowledge helped him identify compatible Bepto replacement components that met his technical specifications while significantly reducing procurement expenses and inventory complexity.

Conclusion

All cylinders are indeed actuators—specifically linear actuators that convert compressed air into straight-line motion, representing the largest and most versatile category within the comprehensive pneumatic actuator family.

FAQs About Cylinders and Actuators

Q: Can I use “cylinder” and “linear actuator” terms interchangeably?

Yes, in pneumatic systems these terms are functionally interchangeable since cylinders represent the most common type of linear actuator used in industrial applications.

Q: What makes rodless cylinders different from standard cylinder actuators?

Rodless air cylinders are linear actuators designed for long-stroke applications, providing extended travel capability in compact installations while maintaining the same basic pneumatic operating principles as standard cylinders.

Q: Are pneumatic grippers considered actuators or specialized tools?

Pneumatic grippers are specialized actuators designed specifically for clamping and handling operations, converting compressed air energy into controlled gripping motion for material handling applications.

Q: How do rotary actuators differ from cylinder-type linear actuators?

Rotary actuators convert compressed air energy into angular or rotational motion for valve control and positioning, while cylinders produce straight-line linear motion for push/pull operations.

Q: Does actuator classification affect replacement part compatibility and sourcing?

Yes, understanding proper actuator classification helps identify compatible replacement components and alternative suppliers, enabling significant cost savings while maintaining system performance and reliability standards.

-

Explore the operating principles of solenoid valves and how they are used to direct compressed air flow to control pneumatic actuators. ↩

-

Discover the design, types, and operational advantages of rodless pneumatic cylinders in industrial automation. ↩

-

Understand the key operational differences between single-acting and double-acting pneumatic cylinders. ↩

-

Learn about the mechanics of pneumatic rotary actuators and how they convert compressed air energy into rotational motion. ↩

-

Explore the different types of pneumatic grippers, such as parallel and angular designs, used in robotics and automation. ↩