Introduction

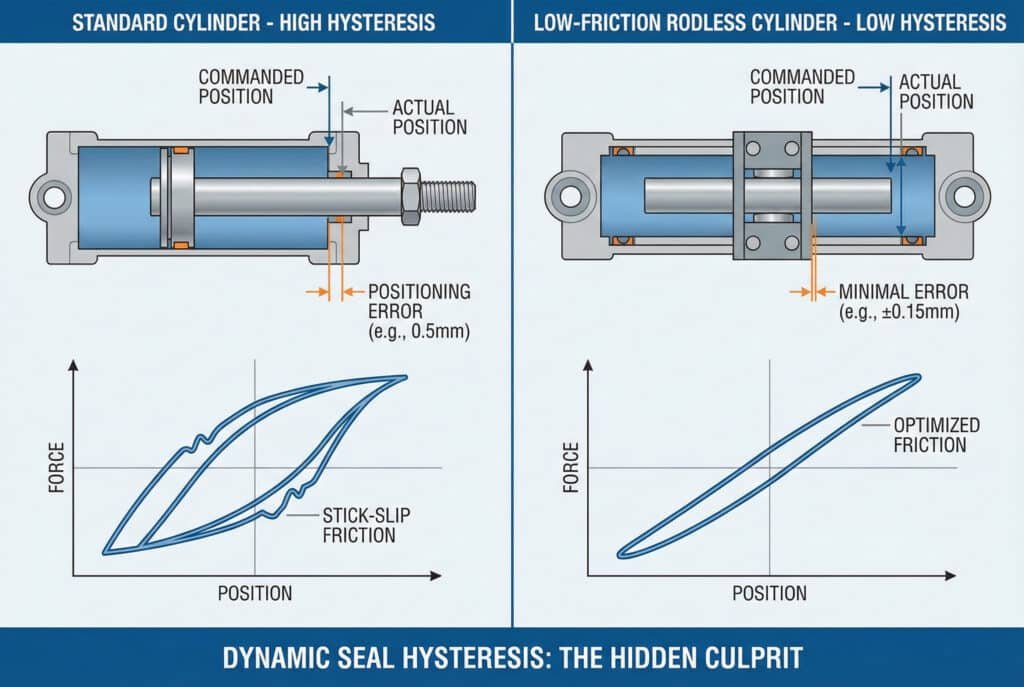

Your automated assembly line is missing placement targets by 0.5mm, and rejected parts are piling up. 🎯 You’ve calibrated the position sensors three times, but the inconsistency persists. The hidden culprit isn’t your control system—it’s dynamic seal hysteresis, a friction phenomenon that creates unpredictable positioning errors costing manufacturers thousands in scrap and rework daily.

Dynamic seal hysteresis is the friction-induced lag between commanded and actual cylinder position caused by stick-slip behavior1, breakaway force variations, and velocity-dependent friction in seal materials—this hysteresis creates positioning errors of 0.2-2.0mm in standard pneumatic cylinders, making seal design, material selection, and lubrication optimization critical for applications requiring repeatability better than ±0.5mm in precision assembly, testing, and measurement systems.

Last month, I worked with Kevin, a controls engineer at an electronics assembly plant in Illinois, who was struggling with inconsistent component placement in a pick-and-place application. His positioning errors ranged from 0.3-0.8mm despite using high-resolution encoders. After analyzing his system, we discovered that seal hysteresis in his standard cylinders was the root cause. Switching to our Bepto low-friction rodless cylinders with optimized seal geometry reduced his positioning error to ±0.15mm, cutting his reject rate by 73%. 📊

Table of Contents

- What Is Dynamic Seal Hysteresis and Why Does It Affect Positioning Accuracy?

- How Do Different Seal Designs and Materials Influence Hysteresis Behavior?

- What Are the Quantifiable Effects of Seal Hysteresis on Precision Positioning Systems?

- Which Design Strategies Minimize Seal Hysteresis in Rodless Cylinders?

What Is Dynamic Seal Hysteresis and Why Does It Affect Positioning Accuracy?

Understanding the physics of friction-induced positioning errors is essential for achieving precision in automated systems. 🔬

Dynamic seal hysteresis occurs when friction forces vary non-linearly with velocity and direction, creating a lag between input pressure and output position—the hysteresis loop width (difference between extending and retracting force-displacement curves) typically measures 5-15% of total stroke force in standard cylinders, causing position-dependent errors that compound in closed-loop systems and prevent achievement of sub-millimeter repeatability without compensation algorithms or low-friction seal designs.

The Mechanics of Seal Friction Hysteresis

Think of seal hysteresis like the difference between pushing a heavy box across a floor versus pulling it back. The friction isn’t the same in both directions due to surface interactions, material deformation, and directional effects. In pneumatic seals, this asymmetry is even more pronounced.

When a cylinder extends, the seal lip is compressed against the barrel in one direction. When it retracts, the seal deforms differently, creating different friction characteristics. This creates a hysteresis loop—a graphical representation showing that the force required to move the cylinder depends not just on position, but also on direction and velocity history.

Stick-Slip Phenomenon and Breakaway Forces

The most problematic aspect of seal hysteresis is stick-slip behavior. At rest, seals develop stiction2 that’s 20-50% higher than dynamic friction during motion. When pressure builds to overcome this breakaway force, the cylinder suddenly “jumps” forward, overshooting the target position.

This stick-slip creates a sawtooth motion profile instead of smooth movement. In precision positioning, this manifests as:

- Overshoot when starting from rest

- Settling oscillations around the target position

- Direction-dependent positioning errors (different final positions when approaching from opposite directions)

At Bepto, we’ve measured breakaway forces in standard cylinders ranging from 15-35N for a 40mm bore cylinder, while our optimized low-friction designs reduce this to 5-12N—a 60-70% reduction that dramatically improves positioning consistency.

Why Control Systems Can’t Fully Compensate

Many engineers assume that closed-loop position control with feedback can eliminate hysteresis effects. While feedback helps, it can’t completely overcome the fundamental physics. The control system sees the position error and applies correction, but the hysteresis creates:

Dead zones: Small position errors that don’t generate enough force to overcome stiction

Limit cycles: Oscillations around the target as the system alternately overcomes and releases friction

Velocity-dependent errors: Different positioning accuracy at different approach speeds

I’ve consulted on dozens of projects where engineers spent months tuning PID controllers, only to discover that the fundamental limitation was seal friction hysteresis that no amount of software tuning could eliminate. The solution requires addressing the mechanical source—the seals themselves.

How Do Different Seal Designs and Materials Influence Hysteresis Behavior?

Seal geometry and material properties fundamentally determine hysteresis magnitude and positioning performance. ⚙️

Seal hysteresis varies dramatically by design: U-cup seals with aggressive lip angles create 40-60N hysteresis force in 50mm bore cylinders, while optimized low-friction designs with shallow lip angles and PTFE materials reduce hysteresis to 10-20N—material selection (polyurethane vs. PTFE vs. rubber) affects both static-to-dynamic friction ratio (1.3-2.0x) and velocity-dependent friction behavior, with PTFE offering the most consistent friction characteristics across velocity ranges for precision positioning applications.

Seal Geometry and Contact Pressure Distribution

The seal lip angle and contact width directly determine friction force and hysteresis magnitude. Traditional U-cup seals use 15-25° lip angles to ensure reliable sealing, but this creates high contact pressure and friction.

Standard U-cup seal (25° lip angle):

- High contact pressure (2-4 MPa)

- Excellent sealing reliability

- High friction force (40-60N for 50mm bore)

- Large hysteresis loop (±0.5-1.0mm positioning error)

Low-friction optimized seal (8-12° lip angle):

- Moderate contact pressure (0.8-1.5 MPa)

- Good sealing with proper surface finish

- Low friction force (10-20N for 50mm bore)

- Small hysteresis loop (±0.1-0.3mm positioning error)

At Bepto, we’ve developed proprietary seal profiles that balance sealing reliability with minimal friction. Our rodless cylinders use multi-lip designs where the primary seal handles pressure containment while secondary low-friction elements minimize hysteresis.

Material Property Effects on Friction Behavior

Different seal materials exhibit vastly different friction characteristics and hysteresis behavior:

| Seal Material | Static/Dynamic Friction Ratio | Velocity Sensitivity | Hysteresis Force (50mm bore) | Best Application |

|---|---|---|---|---|

| NBR (Nitrile) | 1.8-2.0x | High | 45-65N | Low-cost, non-precision |

| Polyurethane | 1.5-1.8x | Moderate | 30-50N | General industrial |

| PTFE (Virgin) | 1.2-1.4x | Low | 8-15N | Precision positioning |

| Filled PTFE | 1.3-1.5x | Low | 12-20N | Balanced performance |

| Graphite-filled PU | 1.4-1.6x | Moderate-Low | 20-35N | Cost-effective precision |

PTFE’s molecular structure creates remarkably consistent friction across velocity ranges. Unlike elastomers that exhibit strong velocity-dependent friction (friction increases with speed), PTFE maintains nearly constant friction from 1mm/s to 1000mm/s—critical for predictable positioning.

The Stribeck Curve and Lubrication Regimes

Seal friction behavior follows the Stribeck curve3, which describes three lubrication regimes:

Boundary lubrication (very low velocity):

- Metal-to-metal contact through lubricant film

- Highest friction

- Dominant at positioning velocities (<10mm/s)

Mixed lubrication (moderate velocity):

- Partial lubricant film support

- Transitional friction behavior

- Most positioning applications operate here

Hydrodynamic lubrication (high velocity):

- Full lubricant film separation

- Lowest friction

- Rarely achieved in pneumatic cylinders

The width of the boundary lubrication regime determines positioning hysteresis. Materials with better boundary lubrication properties (PTFE, graphite-filled compounds) maintain lower friction at positioning speeds, reducing hysteresis.

Temperature Effects on Hysteresis

Seal friction isn’t constant with temperature—it changes significantly as systems warm up during operation. Standard polyurethane seals show 30-40% friction reduction from 20°C to 60°C, creating positioning drift as the system temperature stabilizes.

I worked with Sarah, a test equipment engineer in Michigan, whose precision measurement system showed different positioning accuracy in the morning versus afternoon. Her standard cylinder seals were temperature-sensitive, causing 0.4mm positioning variation as the system warmed up. We replaced them with temperature-stable Bepto cylinders using PTFE seals, and her positioning consistency improved to ±0.12mm regardless of operating temperature. 🌡️

What Are the Quantifiable Effects of Seal Hysteresis on Precision Positioning Systems?

Understanding the numerical impact of hysteresis helps you specify appropriate cylinder technology for your accuracy requirements. 📈

Seal hysteresis creates quantifiable positioning errors: standard cylinders with 40-50N hysteresis force exhibit ±0.5-1.2mm repeatability at 8 bar pressure, while low-friction designs with 10-15N hysteresis achieve ±0.1-0.3mm repeatability—these errors scale with stroke length (0.1-0.2% of stroke typical), pressure variations (±10% pressure creates ±0.15mm position change), and approach direction (bidirectional repeatability 2-3x worse than unidirectional), making hysteresis the limiting factor in applications requiring better than ±0.5mm accuracy.

Positioning Error Magnitude and Scaling

The relationship between hysteresis force and positioning error follows a predictable pattern. For a given cylinder bore and operating pressure, the positioning error scales approximately linearly with hysteresis force:

Position Error ≈ (Hysteresis Force / Pneumatic Force) × Stroke Length

For a 50mm bore cylinder at 8 bar (effective force ≈ 1570N) with 400mm stroke:

- 40N hysteresis: Error ≈ (40/1570) × 400mm = 10.2mm potential error

- Actual error with damping: ±0.6-1.0mm (system damping reduces theoretical maximum)

This explains why larger bore cylinders often show better relative positioning accuracy—the pneumatic force increases with bore area (D²), while seal friction increases roughly with bore diameter (D), giving a favorable scaling relationship.

Bidirectional vs. Unidirectional Repeatability

One of the most important specifications for precision positioning is bidirectional repeatability—the ability to return to the same position when approaching from opposite directions. Hysteresis directly determines this specification:

Unidirectional repeatability (always approaching from same direction):

- Standard cylinder: ±0.3-0.6mm

- Low-friction cylinder: ±0.1-0.2mm

- Bepto precision rodless: ±0.05-0.15mm

Bidirectional repeatability (approaching from either direction):

- Standard cylinder: ±0.8-1.5mm (2-3x worse)

- Low-friction cylinder: ±0.2-0.4mm (2x worse)

- Bepto precision rodless: ±0.1-0.25mm (1.5-2x worse)

The bidirectional penalty comes directly from hysteresis—the position depends on approach direction due to friction asymmetry. Applications requiring bidirectional accuracy must specify cylinders with minimal hysteresis.

Pressure Sensitivity and Force Balance

Positioning accuracy also depends on pressure stability. Hysteresis creates a “dead band” where small pressure changes don’t produce motion because they don’t overcome static friction. This dead band width is:

Dead Band Pressure ≈ Breakaway Force / Piston Area

For a 50mm bore cylinder (area ≈ 1963mm²) with 25N breakaway force:

Dead Band ≈ 25N / 1963mm² = 0.013 MPa = 0.13 bar

This means pressure variations below 0.13 bar won’t produce motion—the cylinder “sticks” in position. For precision positioning, this creates:

- Pressure regulation requirements: Need ±0.05 bar or better for consistent positioning

- Resolution limitations: Can’t achieve positioning resolution better than dead band equivalent

- Settling time issues: System oscillates within dead band before settling

Real-World Application Requirements

Different applications have different tolerance for hysteresis-induced errors:

High-precision applications (±0.1-0.2mm required):

- Electronics assembly and testing

- Optical component positioning

- Precision measurement and inspection

- Solution: PTFE seal systems, low-friction designs, closed-loop control

Medium-precision applications (±0.3-0.5mm acceptable):

- General assembly operations

- Material handling with tight tolerances

- Packaging and labeling

- Solution: Optimized polyurethane seals, quality standard cylinders

Low-precision applications (±1.0mm+ acceptable):

- Bulk material handling

- Clamping and fixturing

- General automation

- Solution: Standard cylinders adequate

At Bepto, we help customers match cylinder technology to their actual requirements. Over-specifying precision cylinders wastes money, while under-specifying causes quality problems and rework costs.

Which Design Strategies Minimize Seal Hysteresis in Rodless Cylinders?

Achieving precision positioning requires integrated design approaches that address friction at every level. 🎯

Minimizing seal hysteresis requires multi-faceted design strategies: optimized seal lip geometry with 8-12° contact angles, PTFE or filled-PTFE materials with static/dynamic friction ratios below 1.4x, precision-honed barrel surfaces (Ra 0.2-0.4μm) to support boundary lubrication, synthetic lubricants with appropriate viscosity (ISO VG 32-68), and mechanical design features like guided carriages and preload adjustment—in rodless cylinders, dual-seal configurations with pressure balancing further reduce net friction force while maintaining sealing integrity.

Optimized Seal Profile Engineering

At Bepto, we’ve invested heavily in seal profile optimization using finite element analysis and empirical testing. Our precision seal profiles incorporate:

Shallow lip angles (8-12° vs. standard 20-25°):

- Reduces contact pressure by 40-60%

- Maintains sealing through precise surface finish requirements

- Requires Ra 0.3-0.5μm barrel finish (vs. Ra 0.8-1.2μm for standard)

Multi-lip configurations:

- Primary seal: Pressure containment (moderate friction acceptable)

- Secondary seal: Low-friction wiper (minimal contact pressure)

- Tertiary seal: Contamination exclusion (external)

Pressure-balanced designs:

- Opposing seal lips with pressure equalization

- Net friction force reduced by 30-50%

- Particularly effective in rodless cylinders with dual-sided sealing

Surface Finish and Lubrication Optimization

The barrel surface finish critically affects boundary lubrication and hysteresis. We specify precision honing to achieve:

Surface roughness: Ra 0.2-0.4μm (vs. standard Ra 0.8-1.2μm)

Plateau honing4: Creates micro-reservoirs for lubricant retention

Directional finish: Honing marks aligned with motion direction

Combined with appropriate lubrication:

Synthetic lubricants (our standard at Bepto):

- ISO VG 32-68 viscosity range

- Excellent boundary lubrication properties

- Temperature-stable performance

- Compatible with seal materials

Application method:

- Factory pre-lubrication of all sliding surfaces

- Periodic re-lubrication ports (for long-stroke rodless cylinders)

- Automatic lubrication systems for critical applications

Mechanical Design Features

Beyond seals themselves, mechanical design reduces hysteresis effects:

Precision guide systems:

- Linear ball bearings or roller guides

- Separate load support from pneumatic force

- Reduces side loading on seals (major friction contributor)

Carriage preload adjustment:

- Allows optimization of seal compression

- Balances sealing reliability vs. friction

- Field-adjustable for wear compensation

Mounting rigidity:

- Stiff mounting reduces deflection-induced binding

- Proper alignment eliminates side loads

- Critical for long-stroke applications

I recently helped Michael, a machine builder in Wisconsin, solve a persistent positioning problem in a 2-meter stroke rodless cylinder application. His cylinders showed 2-3mm positioning variation due to deflection-induced seal binding. We redesigned the mounting system with intermediate support and switched to our Bepto precision rodless cylinders with optimized guides. His positioning error dropped to ±0.25mm across the full stroke—a 10x improvement. 🔧

Closed-Loop Control Integration

For ultimate precision, mechanical optimization must combine with intelligent control:

Position feedback:

- Linear encoders (5-10μm resolution)

- magnetostrictive sensors5 (50-100μm resolution)

- Allows compensation for hysteresis effects

Friction compensation algorithms:

- Model-based friction estimation

- Adaptive compensation for wear and temperature

- Can reduce positioning error by additional 40-60%

Pressure profiling:

- Velocity-dependent pressure adjustment

- Reduces overshoot and settling time

- Optimizes approach to final position

At Bepto, we provide application engineering support to help customers integrate our low-friction cylinders with their control systems. The combination of optimized mechanical design and intelligent control delivers positioning performance that approaches electric servo systems at a fraction of the cost.

Cost-Performance Trade-offs

Precision comes at a cost, and the key is matching technology to requirements:

Standard cylinder ($150-250):

- ±0.8-1.5mm repeatability

- Suitable for 70% of applications

- Lowest initial cost

Low-friction cylinder ($250-400):

- ±0.3-0.6mm repeatability

- Best cost-performance balance

- Our most popular Bepto precision option

Ultra-precision cylinder ($500-800):

- ±0.1-0.25mm repeatability

- PTFE seals, precision guides, feedback-ready

- For critical applications only

The decision should be based on total cost of ownership including scrap, rework, and quality costs. For a production line producing 10,000 parts daily where positioning errors cause 2% scrap at $5/part, the quality cost is $1,000/day. A $300 premium for precision cylinders pays back in hours, not months.

Conclusion

Dynamic seal hysteresis is the hidden enemy of precision positioning in pneumatic systems, creating friction-induced errors that no amount of control tuning can fully eliminate. By understanding hysteresis mechanisms and implementing optimized seal designs, appropriate materials, and integrated mechanical solutions, positioning accuracy can improve 5-10x compared to standard cylinders. At Bepto, our rodless cylinders incorporate decades of friction optimization research to deliver precision positioning performance that meets demanding industrial requirements while maintaining the cost advantages and simplicity of pneumatic actuation. 🌟

FAQs About Dynamic Seal Hysteresis

Q: Can I measure seal hysteresis in my existing cylinders to diagnose positioning problems?

Yes—perform a simple force-displacement test by slowly extending and retracting the cylinder while measuring force and position, plotting the results to visualize the hysteresis loop. The loop width indicates hysteresis magnitude. At Bepto, we recommend this diagnostic test before specifying replacement cylinders, as it quantifies whether hysteresis is actually your limiting factor or if other issues (pressure instability, mounting problems) are dominant.

Q: How does seal wear affect hysteresis over the cylinder’s lifetime?

Seal wear typically reduces hysteresis initially (first 100,000-200,000 cycles) as seals “break in” and contact pressure decreases, then hysteresis gradually increases as wear creates irregular contact patterns and surface damage. Well-designed seals like our Bepto precision profiles maintain stable hysteresis for 1-2 million cycles before significant degradation, while standard seals may show 50-100% hysteresis increase after 500,000 cycles.

Q: Is pneumatic positioning with low hysteresis comparable to electric servo systems?

For applications requiring ±0.1-0.3mm repeatability at moderate speeds (<500mm/s), optimized pneumatic cylinders with closed-loop control can match electric servo performance at 40-60% lower system cost. However, electric servos remain superior for applications requiring <±0.05mm accuracy, very high speeds (>1m/s), or complex motion profiles. The key is matching technology to actual requirements rather than over-specifying electric servos for applications where pneumatics would suffice.

Q: Can I retrofit low-friction seals into my existing cylinders to reduce hysteresis?

Seal replacement can help but is limited by existing barrel surface finish and groove geometry—low-friction seals require Ra 0.3-0.5μm barrel finish to function properly, while standard cylinders typically have Ra 0.8-1.2μm. Additionally, seal groove dimensions must match the optimized seal profile. In most cases, replacing the entire cylinder with a precision-designed unit like our Bepto low-friction rodless cylinders provides better performance and cost-effectiveness than attempting retrofits.

Q: How do I specify hysteresis requirements when ordering precision cylinders?

Specify bidirectional repeatability rather than just “accuracy”—request “±0.3mm bidirectional repeatability across full stroke” rather than vague terms like “precision” or “low-friction.” Also specify operating conditions (pressure, velocity, cycle rate, temperature range) as these affect hysteresis. At Bepto, we provide certified test data showing actual measured hysteresis force and positioning repeatability for our precision cylinders, ensuring you receive documented performance that meets your application requirements.

-

Learn about the underlying physics of the stick-slip phenomenon and how it contributes to friction-induced instability in mechanical systems. ↩

-

Explore the technical definition of static friction (stiction) and its impact on the breakaway force required for pneumatic actuation. ↩

-

Gain a deeper understanding of the Stribeck curve and how it defines the relationship between friction and lubrication regimes in sliding seals. ↩

-

Understand how the plateau honing process creates micro-reservoirs that optimize lubricant retention and reduce surface friction. ↩

-

Discover the working principles of magnetostrictive sensors and why they are preferred for high-resolution position feedback in industrial environments. ↩